* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Flatpack 1500

Standby power wikipedia , lookup

Stray voltage wikipedia , lookup

Wireless power transfer wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Power factor wikipedia , lookup

Three-phase electric power wikipedia , lookup

Power over Ethernet wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Electrical substation wikipedia , lookup

Power inverter wikipedia , lookup

Mercury-arc valve wikipedia , lookup

Electrification wikipedia , lookup

Voltage optimisation wikipedia , lookup

Electric power system wikipedia , lookup

Audio power wikipedia , lookup

Control system wikipedia , lookup

Buck converter wikipedia , lookup

History of electric power transmission wikipedia , lookup

Amtrak's 25 Hz traction power system wikipedia , lookup

Opto-isolator wikipedia , lookup

Alternating current wikipedia , lookup

Power engineering wikipedia , lookup

Power supply wikipedia , lookup

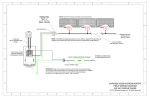

FLATPACK Rev.5 September 2002 Updated versions may be available Flatpack 1500 The rectifier module in the new Eltek Medium Range Systems Power Density SMPS 1000 SI SMPS 1000 SI Flatpack 1500 1000W, convection cooled vs. Flatpack 1500 1400W, fan cooled Power density Power density 230 VAC: 0.26 W/cm3 4.23 W/inch3 W x D x H=66.8 x 220 x 264 (mm) 2.63 x 8.66 x 10.39 (inches) 230 VAC: 0.648 W/cm3 10.58 W/inch3 120 VAC: 0.278 W/cm3 4.53 W/inch3 W x D x H=214 x 243 x 41.5 (mm) 8.43 x 9.57 x 1.64 (inches) Flatpack 1500 Key parameters: Maximum output power 1400 W Global input range: 85 – 300 VAC Automatic disconnect at input voltages > 300 VAC Wide temperature range: -40°C to +70°C (-40°F to +158°F) Compact and flexible (1U high/2 rectifiers in 19” width) Vertical or Horizontal mounting Hot swap (output diode) Fan cooled Cost efficient Automatic de-rating of output power at low input voltage and/or high ambient temperatures Easy and quick mounting and removal Flatpack 1500 Input Voltage vs. Output Power 1600 Output Power (W) 1400 1200 1000 185 800 600 150 400 200 85 312 0 0 50 100 150 200 Input Voltage (VAC) 250 300 350 Power Derate with Respect to Temperature (230VAC Input) Maximum Available Power (Watts) 1600 1400 1200 1000 800 600 400 200 0 60 65 70 75 80 85 Ambient Temperature (degC) Comment: Measured on a stand-alone rectifier module 90 95 100 Flatpack 1500 (48V) MODULE DATA Input voltage: 0-85 VAC no output 85-150 VAC 500 W at 48 VDC 150-185 VAC 1100 W at 48 VDC 185-300 VAC 1400 W at 48-59 VDC > 275 VAC - reduced power factor > 300 VAC - disconnection from mains and automatic reconnect Power Factor: > 0.99 Efficiency: > 90% Output power: 1400 W from 48V to 59V (230 VAC input) (de-rated in lower input range) Output current: 29 Amps at 48V Ripple/noise: < 100mVp-p < 0.96mV psophometric noise Hold-up time: > 10ms Ambient temp: -40°C to 70°C (-40°F to +158°F) (Power limiting may occur > 40°C (104°F)) Dimensions: 214 x 243 x 41.5mm (8.8” x 9.8” x 1.64”) (WxDxH) Approvals: IEC/EN 60950, UL 1950 IEC/EN 60215, BS3192 FCC 68, GR-1089-CORE Flatpack 1500 (48V) LED bargraph 10 green LED’s indicate output current from 0 Amps to 29 Amps Alarm LED Power LED Internal rectifier failure Rectifier On No fault 2 fans Flatpack 2U Power System 19” horizontal mounting 1U high building blocks: 44.45mm (1.75”) Allows optimal utilisation of rack height The 1U Power Shelf accommodates 2 Flatpack rectifiers The 1U DC-distribution and monitoring unit is mounted on top Flatpack 1U System Components for 19” rack mounting ”Flatpack MCU” Monitoring & Control Unit (1U) ”Flatpack DCD 125A” 125A DC Distribution (1U) 2 ”Flatpack 1500” rectifiers in a 1U high power shelf 19” horizontal mounting The capacity is increased by adding more power shelves 19” horizontal mounting Two rectifiers mounted in a 1U Power Shelf 19” horizontal mounting 1U Power Shelf rear view RJ45 connectors for internal system communication Mains input terminals DC output terminals 19” horizontal mounting with 3U distribution The distribution on top will vary in size, depending on maximum current and the number of circuit breakers/fuses required 19” horizontal mounting with 3U distribution Mains input Load MCB’s Battery MCB’s Sample Flatpack Distribution Option Common positive bar DC output on top of MCB’s. Max 25 mm2 Alarm outputs max 2.5 mm2 19” horizontal mounting with 3U distribution Mains input Load MCB’s Battery Fuses 19” horizontal mounting with 3U distribution Front Side Top Rear 19” horizontal mounting with 3U distribution Mains input Load MCB’s Load Fuses Battery Fuses Sample Flatpack in Cabinet Application Intermediate PRS Solution A comprehensive amount of PRS 700 system solutions have been made to fulfill many different customer and regional requirements. Compared with today's system solutions the Flatpack 1500 has the following improvements: Improved operating temperature range (some old system designs may experience power de-ration at temperatures < 40°C (104°F)) Improved power density (convection cooled rectifiers require a lot of open space above and underneath to achieve a good airflow) Wider input voltage range (De-rated output power at input voltages below 205 VAC and no high voltage disconnect) New important features are added when replacing the SMPS 1000 with the Flatpack 1500 rectifier. A large range of existing system designs with various distribution solutions can be used. Intermediate PRS Solution Implement Flatpack 1500 rectifiers into existing Power Rack Systems 7 kW 16.8 kW AL 175 NT Flatpack 1500 Intermediate PRS Solution Highly competitive systems can be made by replacing SMPS 1000 with Flatpack 1500 in standard PRS 700 Advantages Current system solutions are made highly competitive Short development time and short time to market More than twice the power density of a standard PRS 700 Utilizes existing distribution, monitoring and cabinet solutions Wider operating temperature range Wider input voltage range with high voltage disconnect Functionality which is not included Digital inputs for monitoring of external equipment Individual control of two contactors Single/several rectifier alarms Future Flatpack Systems New cabinet designs based on the Flatpack 1500 rectifier, various rack mountable distribution units and the Flatpack MCU will be made. The main improvements will be: Increased flexibility (the systems can be designed with a building block approach) Improved monitoring & control features using the Flatpack MCU Reduced cost as more parts of the system can be manufactured in high volumes Increased power density (the system designs will be even more compact, since the height of the monitoring unit including interface PCB is only 1U as opposed to today's 5U) The rectifiers can be mounted vertically to achieve even higher power density in ETSI cabinets (15.4 kW in only 5U height) Future Flatpack Systems A common MPSU solution Future Flatpack Systems Future Flatpack Systems Outdoor Cabinets Flatpack Solutions 19” horizontal mounting Different distribution units for different needs 1U Power Shelf Power Tower Highlights Flatpack MCU Front panel LCD and keypad for on-site service RS-232 for PC connection or remote monitoring & control via modem / SNMP Up to 11 configurable alarm relay outputs for traditional remote monitoring 4 configurable digital inputs for monitoring of other equipment on site Battery monitoring and testing (manual & automatic) Temperature Compensated Charging for increased battery lifetime Hot Plug-In Password protected operator access levels Alarm/event log with time and date Windows based software for easy access and configuration (WinPower Silver) Remote Monitoring & Control Options for remote monitoring & control Potential free relays (6 or 11 form C contacts) Modem with call-back functionality SNMP direct connection to TCP/IP network connection using micro-wave WinPower Silver through TCP/IP Web browser (future option)

![World History and Geography: 1500 A.D. (C.E.) to the Present [WHII]](http://s1.studyres.com/store/data/000846344_1-9832429773e24a8a14d9dd47b3db1434-150x150.png)