* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Chemistry of beer

Proteolysis wikipedia , lookup

Fatty acid synthesis wikipedia , lookup

Oxidative phosphorylation wikipedia , lookup

Genetic code wikipedia , lookup

Butyric acid wikipedia , lookup

Nicotinamide adenine dinucleotide wikipedia , lookup

Adenosine triphosphate wikipedia , lookup

Amino acid synthesis wikipedia , lookup

Biosynthesis wikipedia , lookup

Citric acid cycle wikipedia , lookup

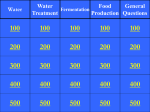

How Chemistry Affects Beer Taste Matt Kade Chem 290 5/15/08 Some beer history Evidence that beer has been made since 6000 B.C. Reinheitsgebot (German purity law) of 1487 Barley, hops and water ONLY Pasteur discovers yeast (1857) Beer Styles • Alcohol content • Residual sugars • Hop bitterness • Adjuncts used • Other products of fermentation Overview of Process Malting Barley is incubated to open hull, start conversion of starches Heated to 60°C to dry malt, stop process, Dry to less than 4% water content Kilning 75°C Czech Pilsener 110°C Pale Ale Amber Malt vs. Brown Malt Maillard Reaction Discovered by Louis Camille Maillard in 1913 Essential in cooked food (e.g. seared meat, bakery products, roasted coffee) Reactions between ‘reducing sugar’ and amino acid Produces thousands of potential flavor and color compounds Maillard Reaction N-glucosylamine (Amadori complex) • Five main reducing sugars * 20 amino acids = 100 possible Amadori products Maillard Products Biscuit-like Cooked rice Sharp toasted, burnt Sweet corn Mashing Break down carbohydrates into fermentable sugars Break down proteins into usable amino acids Choose temperature range where different enzymes are highly active for various processes Amylases (α and β) can only break down 1,4 linkages Maltose: 1,4 linkage Isomaltose: 1,6 linkage Laminaribiose: 1,3 linkage Mashing schedule T e m p e r a t u r e o C 80 α amylase 70 β amylase 60 proteases 50 peptidases Beta Glucanase 40 30 20 10 0 0 20 40 60 Time / minutes 80 100 The Boil Sanitizes wort Remove volatile products (e.g. dimethyl sulfide) Additional Maillard reactions occur Hop chemistry Hops Balance residual sweetness Provide aroma Preservative properties Major components: Alpha acids (Sesqui)terpenes Hetero-atom containing hydrocarbons α- acids humulene linalool Alpha Acid Isomerization humulone isohumulone Hop addition schedule For a typical one hour boil: Add hops at start Add hops with <5 minutes left Sometimes add hops after boil during fermentation humulene myrcene farnesene caryophyllene Aroma-providing hydrocarbons are volatile! Fermentation Uses single strand of yeast Follows Emden-Meyerhoff-Parnas pathway (glycolysis) ending in ethanol Must Avoid bacterial / wild yeast infection Requires steady temperature Yeast Discovered by Louis Pasteur Saccharomyces cerevisiae (ale) Saccharomyces carsbergenis (lager) Typically ‘pitch’ 15-20 million yeast cells per mL of wort EMP Pathway ATP ADP Hexokinase Phosphoglucose isomerase ATP Phosphofructokinase + Fructose bisphosphate aldolase ADP Glycolysis Glyceraldehyde phosphate dehydrogenase NAD+ NADH Triosephosphate isomerase NAD+ NADH Phosphoglycerate kinase ADP ADP ATP ATP H2O H2O Enolase Phosphoglycerate mutase Formation of Ethanol ADP ATP CO2 NADH Pyruvate kinase • Typical concentrations of ethanol formed: 40 to 60 g/L NAD+ Strickland Reaction • Amino acid pool determines fusel alcohols present in fermenting beer Fusel Alcohols in Beer Name Structure Range (mg/L) Threshold Flavor (mg/L) Propanol 10 - 40 600 - 800 Alcohol, rough Butanol 5 - 60 160 - 200 Alcohol, rough Isobutanol 10 - 60 180 - 200 Alcohol, rough 3-methylbutanol 100 - 110 40 - 130 Alcohol, banana Isoamyl alcohol 100 - 110 40 - 130 Alcohol, banana 2-phenylethanol 100 - 200 10 - 80 Roses, bitter, chem 4-ethylphenol 100 - 200 10 - 80 Roses, bitter, chem Important Ketones in Beer Name Structure Threshold (mg/L) Taste Diacetyl 0.1-0.5 Buttery α-acetolactic acid _ Sour Acetoin 1.0 Fruity, musty 2,3-pentanedione 1.0 Honey α-acetoxyhydroxy butyric acid 1.0 Rubber Esters in Beer Name Structure Range (mg/L) Threshold Flavor (mg/L) Ethyl acetate 15-20 (up to 40 in English ales) 33 Fruity with solvent undertone Isoamyl acetate 1.5 – 2.5 (up to 6 in Belg/English) 3 Bananas Ethyl hexanoate Widely varying 123 Apples Budweiser vs. Coors How do professional tasters distinguish between: : apple : pineapple Bottling Cask or bottle conditioned (natural) Force carbonate Allow to age in bottle Ageing • Goaty and cheesy flavors • Ageing can induce haze formation from proteins or tannins: • Silica gels • Sols Poly(vinylpyrrolidone) Skunky Beer Flavor Wheel Conclusions A good beer requires: Quality malt Good choice of kilned or roasted malt Effective use of hops or other adjuncts Healthy fermentation Right amount of other products (esters, etc.) Effective storage References Fix, George. Principles of Brewing Science, 1999. Janson, Lee W., Brew Chem 101, 1996. Palmer, John, How to Brew, 2006. http://www.wikipedia.com Lehninger, et al, Principles of Biochemistry, 2006 Heath, B, Flavor Chemistry and technology, 1988. Ingledew, W.M., J. Am. Soc. Brew. Chem., 37, 1979 Peacock, V.E. et al, J. Agric. Food Chem, 29, 1981 Papazian, Charlie, Microbrewed Adventures, 2005 Mosher, Randy, Radical Brewing, 2004 Acknowledgements Dan Burke, Eric Pressly, Katie Feldman, Nalini Gupta, Neil Treat, Jasmine Hunt James Pavlovich Louis Pasteur Louis Maillard Charlie Papazian (founder of American Homebrewers Association and the Great American Beer Festival)