* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Mesas: Their Role in the Formation of Widely Spaced Step Arrays

Surface tension wikipedia , lookup

Tunable metamaterial wikipedia , lookup

Glass transition wikipedia , lookup

Low-energy electron diffraction wikipedia , lookup

Photoconductive atomic force microscopy wikipedia , lookup

Molecular nanotechnology wikipedia , lookup

History of nanotechnology wikipedia , lookup

Atomic force microscopy wikipedia , lookup

Societal impact of nanotechnology wikipedia , lookup

Nanogenerator wikipedia , lookup

Sessile drop technique wikipedia , lookup

Self-assembled monolayer wikipedia , lookup

Strengthening mechanisms of materials wikipedia , lookup

Microelectromechanical systems wikipedia , lookup

Semiconductor wikipedia , lookup

Nanotechnology wikipedia , lookup

Synthetic setae wikipedia , lookup

Colloidal crystal wikipedia , lookup

Sol–gel process wikipedia , lookup

Impact of nanotechnology wikipedia , lookup

Ultrahydrophobicity wikipedia , lookup

Nanomaterials wikipedia , lookup

Energy applications of nanotechnology wikipedia , lookup

Nanochemistry wikipedia , lookup

Industrial applications of nanotechnology wikipedia , lookup

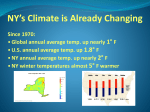

Materials Spontaneous Formation and Breakdown of Ridges on Si(111) Mesas: Their Role in the Formation of Widely Spaced Step Arrays CNF Project # 317-87 Abstract: Mesa structures fabricated on Si(111) surfaces have been found experimentally to develop step arrays with large spacing of the order of a micron or more after annealing at temperatures where sublimation becomes important. Ridges around the edges initially develop during annealing and form barriers to step motion. When the ridges eventually break down, an array of steps of the same sign with a few wide terraces are produced. Summary: Arrays of steps with controlled spacing in order of microns may have applications as templates for nanowires or organic thin films. Fabrication of such step arrays on Si(111) have been investigated by using the following method: Si(111) was patterned by standard optical lithographic methods using silicon oxide as an etch mask. Mesa structures with different azimuthal orientations and size were etched into the silicon by reactive ion etching. The etch depth was around 2 µm for all of our samples. 15 mm x 5 mm samples were cut from the wafer using a diamond tip scriber. The samples were then dipped in HF for 3 minutes to remove any residual oxide and to hydrogen-terminate the surface before loading into the vacuum chamber. The samples were heated by direct current in a UHV system (base pressure 10-10 Torr) while the temperature was monitored with an optical pyrometer. Some samples were subjected to flashing above 1200°C to quickly remove the native oxide layer before annealing while others were annealed without flashing. The annealing temperature ranged from 925°C to 1150°C. After annealing, the samples were taken out of the vacuum chamber and imaged in air by atomic force microscopy. Image 1 shows an example of the typical height profile of a mesa after annealing. Ridges have formed along most of the edges of the mesas. The portion of the edge without a ridge act as a step source for the widely separated step arrays that develop on the mesa tops. The step arrays formed through this Cornell NanoScale Facility, Member: National Nanotechnology Infrastructure Network Principal Investigator(s): Jack Blakely process showed similar step spacing on other mesas that were of the same size and orientation on the same sample. From a series of mesas patterned at different azimuthal orientations on the sample, we also find that the length of the mesa edge without a ridge increases dramatically as the mesa edge becomes nearly parallel to the miscut axis as shown in Image 2. Neither the crystallographic direction of the mesa edges nor the direction of the DC heating current (and hence electromigration effects) had any influence on the location or amount of ridge breakdown. The formation of the step arrays involves two separate stages: (1) ridge formation and its subsequent breakdown, and (2) the motion of steps across the mesa surface. Below the crystal roughening temperature, ridge formation can take place by the modification of the shape of the steps near the mesa edge as illustrated in Image 3. Ridge formation is a transient phenomena which will slow down as the sharp corners and edges of the fabricated mesa becomes more rounded due to the migration of atoms. As annealing progresses, the ridges will subsequently break down. The height of the ridge depends on the number of steps at the mesa edge, which explains the more extensive ridge breakdown for the mesa edges that are oriented parallel to the miscut axis. The effect of the ridges is to create a crater on top of the mesa. The steps density inside the crater is lowered during annealing through a step clearing process that has also been investigated by our group [1]. When a ridge breaks down and the steps move into the mesa top that has a low density of steps, the distance between the steps is large enough so that the step dynamics is dominated by the sublimation of adatoms between the steps. In this case, widely spaced steps in the order of microns can persist on the mesa tops, even as steps move in from a mesa edge and sweep across the mesa top during annealing. References: [1] D.H. Lee, J.M. Blakely, Surf. Sci. 445 (2000) 32. page 132 Spontaneous Formation and Breakdown of Ridges on Si(111) Mesas: Their Role in the Formation of Widely Spaced Step Arrays CNF Project # 317-87 User(s): Kee-Chul Chang Principal Investigator(s): Jack Blakely Affiliation(s): Materials Science and Engineering, Cornell University Primary Funding: Cornell Center for Materials Research (CCMR) Principal Investigator(s): Jack Blakely • Fabricated mesas on silicon(111). • Annealed the patterned silicon under ultrahigh vacuum. • Observed the resulting pattern of steps with AFM. • The process resulted in an array of widely spaced steps. Image 1: Height profile of a mesa on Si(111) that has been annealed at 1000°C for 1 hour followed by flashing at 1220°C for 20 seconds. Ridges have formed along most of the edges of the mesas. The portion of the edge without a ridge acts as a step source for the widely separated step arrays that develop on the mesa tops. Contact Information: [email protected] [email protected] Image 3: Chemical potential gradients set up by high curvature at the mesa edges results in mass flow from the mesa edge to a step on the mesa as illustrated on the top picture. The existence of inner steps is critical for this process as the nucleation of a new island on the mesa involves a high energy barrier. Reshaping of the inner steps results in Cornell NanoScale Facility Materials, page 133 Image 2: Deflection AFM image of step arrays formed on top of a rectangular mesa on Si(111) after flashing at 1250°C followed by annealing at 1100°C for 15 minutes. National Nanotechnology Infrastructure Network Materials Leakage Current through Thin Silicon Oxide Grown on Atomically Flat Silicon Surfaces CNF Project # 317-87 Abstract: Our research project involves building and characterizing MOS capacitors starting with Si (111) surfaces that are almost atomically flat (with no atomic steps). Atomically flat surfaces can be obtained by high-temperature annealing in UHV of specially patterned silicon samples according to a procedure developed previously [1]. Thin silicon oxide layers were then grown by dry oxidation on three types of surfaces: (a) atomically flat surfaces, (b) normal (stepped) surfaces cleaned in UHV by the same high-temperature annealing, and (c) normal wafer surfaces which underwent just an RCA chemical cleaning before oxidation. Atomic force microscopy (AFM) was performed to reveal the topography of the surfaces. Aluminum pads were deposited on these oxidized surfaces using photolithography techniques, obtaining arrays of MOS capacitors with dimensions of 18 x 18 µm. The leakage current through the oxide was measured for all three cases. Summary: The leakage current was measured for these capacitors, tracing I-V characteristics and testing against the Fowler-Nordheim (FN) theory. The slope of the FN plot is related to the effective thickness of the oxide. The rougher stepped surface was expected to show a higher tunneling current according to the model developed by Majkusiak and Strojwas [2]. Initial results obtained in our group showed that, for an oxide thickness of about 5 nm, the ratio of the slope of the FN plots for the capacitors on areas outside the craters to the slope for the capacitors on step-free surfaces is about 0.9 [3]. Our more recent investigations also indicated that the slope of the FN plot is about 5% higher for capacitors built on step-free surfaces than on stepped surfaces for 6 nm oxide and about 10% higher for 5 nm oxide. There is no measurable difference if the oxide is thicker than 8 nm. Cornell NanoScale Facility, Member: National Nanotechnology Infrastructure Network Principal Investigator(s): Jack M. Blakely While it was expected that this difference should increase for thinner oxide, our results for 3.5 and 4 nm oxide thickness showed only a ~ 5% higher slope for the capacitors built on step-free surfaces. A possible explanation for this result is that the thinner oxide requires a lower growth temperature, which in turn is known to create a rougher Si/SiO2 interface. Nevertheless, for a given voltage, the tunneling current is significantly lower for the capacitors built on step-free regions than for those on the UHV treated stepped surface. A much bigger leakage current was measured for the capacitors built on the unpatterned wafer, which did not undergo a UHV high temperature cleaning. In that case, the slope of the FN plot is several times smaller than for the sample cleaned in the UHV chamber by high temperature annealing. Also, the overall tunneling current is much higher in the case of the normal wafer surface. We are currently investigating in detail this very important observation. References: [1] D. Lee and J. Blakely, “Formation and stability of large step-free areas on Si(001) and Si(111)”, Surface Science 445, 32 (2000). [2] B. Majkusiak and A. Strojwas, “Influence of oxide thickness non-uniformities on the tunnel current-voltage and capacitance-voltage characteristics of the metal-oxide-semiconductor system”, J. Appl. Phys. 74, 5638 (1993). [3] A. C. Oliver and J. M. Blakely, “A comparison of tunneling through thin oxide layers on step-free and normal Si surfaces”, Mat. Res. Soc. Symp. Proc. 747, V 4.6.1 (2003). page 134 Leakage Current through Thin Silicon Oxide Grown on Atomically Flat Silicon Surfaces CNF Project # 317-87 • Principal Investigator(s): Jack M. Blakely Step-free surfaces obtained by heating patterned samples in ultra-high vacuum chamber. • Affiliation(s): Materials Science and Engineering, Cornell University Thin silicon oxide layer grown by dry furnace oxidation. • MOS capacitors built both on normal wafer and on UHV cleaned, step-free and stepped regions. Primary Funding: National Science Foundation • Electrical characterization of these MOS capacitors. User(s): Valerian Ignatescu Contact Information: [email protected] [email protected] Principal Investigator(s): Jack M. Blakely Figure 1: AFM scan over a large area (60x60 µm), showing a crater & the surrounding, stepped region; the steps have been removed from the crater bottom. http://people.ccmr.cornell.edu/ ~blakely/ Figure 2: Optical image showing the aluminum pads deposited after oxidation on step-free surfaces (inside the craters) and on stepped surfaces (outside the patterned area); the smaller pads in-between craters represents areas with slightly reduced step density. Cornell NanoScale Facility Materials, page 135 Figure 3: Average leakage current for five capacitors built respectively on (A) step-free surfaces, (B) stepped surfaces and (C) on normal (not cleaned in UHV) wafer surface; the oxide thickness is 3.5 nm. National Nanotechnology Infrastructure Network Materials Thin Film Nucleation and Growth using Energetic Neutral Species CNF Project # 459-92 Introduction: The deposition and growth of organic materials for applications in electronics and photonics differs fundamentally from that of more conventional inorganic materials such as metals, semiconductors and oxides. A key difference involves the presence of strong covalent and ionic bonding in the latter class of materials, whereas organic materials are often bound by rather weak dispersion (van der Waals) forces. In addition, many organic materials are often known to crystallize in different phases, separated in total energy by amounts on the order of a few kT. As a consequence, considerable promise exists in the use of energy tunable molecular beams for the deposition of organic thin films. In this project, we have used supersonic molecular beams as sources for film deposition, in particular, for the deposition of thin films of pentacene, an organic semiconductor. Summary: Pentacene is a promising candidate for applications in organic thin-film electronics owing to the ability to form highly ordered thin films near room temperature with excellent electrical transport properties [1-2]. Pentacene, which possesses a very low vapor pressure, presents a number of experimental challenges that must be overcome in order to generate energy tunable beams. First, we designed an in-vacuum evaporator heatable to 200-300°C to provide enough flux for supersonic molecular beams. Next, using time-offlight quadrupole mass spectrometry, we characterized supersonic molecular beams of pentacene generated using carrier gases of N2, He and H2. With these carrier gases, we were able to obtain kinetic energies over the range of Ei = 1.4-10.6 eV whereas incident molecular fluxes were on the order of 1015 molecules-cm-2s-1 [3]. Then we carried out nucleation and thin film deposition experiments with these energetic sources and the samples were characterized by atomic force microscopy (AFM) and ellipsometry. Cornell NanoScale Facility, Member: National Nanotechnology Infrastructure Network Principal Investigator(s): James R. Engstrom We find that beam energy affects a number of phenomena, namely nucleation in the monolayer regime, and both the kinetics of thin film deposition and the microstructure in the multilayer regime. Closer examination of the data indicates that the deposition rate in the monolayer regime is determined by the trapping probability of pentacene [3], which decreases with increasing energy. However, in this same regime the trapping probability is found to decrease with more glancing angles of incidence, a result inconsistent with socalled normal energy scaling. Analysis of the data indicates that both parallel and perpendicular energy of incident pentacene molecules are critical to the process of adsorption [3]. In the multilayer regime, trapping probability also decreases with increasing incident energy, but does so at a rate less than that observed in the submonolayer regime. In addition, grain size of multilayer pentacene films is found to increase with increasing incident energy at normal incidence. These results demonstrate that the morphological evolution of organic thin films can be modified substantially at high incident kinetic energies. We have also fabricated organic thin film transistors (OTFTs) with these pentacene films with gold top contacts on bare thermal SiO2 and hexamethyldisilizane (HMDS) coated SiO2 substrates to understand the relationship between performance characteristics of organic thin film transistors (OTFTs), film microstructure and film-dielectric interface properties. We find that with increasing incident energy of pentacene molecules, the grains get larger and hence the field effect mobility obtained for the corresponding OTFTs increases. In addition, the devices with HMDS primed SiO2 showed improved performance characteristics with respect to bare thermal SiO2, owing to reduced trapping at the semiconductor-dielectric interface. References: [1] C.D. Dimitrakopoulos & P.R.L. Malenfant, Adv. Mater. (Weinheim,Ger.) 14, 99 (2002) [2] S.R. Forrest, Chem. Rev. (Washington, D.C.) 97, 1793 (1997). [3] A.S. Killampalli, T.W. Schroeder & J.R. Engstrom, Appl. Phys. Lett. in press (2005). page 136 Thin Film Nucleation and Growth using Energetic Neutral Species CNF Project # 459-92 Principal Investigator(s): James R. Engstrom User(s): Aravind S. Killampalli Jared L. Mack Principal Investigator(s): James R. Engstrom Affiliation(s): Chemical and Biomolecular Engineering, Cornell University • Pentacene thin films have been deposited using energetic supersonic molecular beams. • Incident energy of pentacene molecules strongly influences nucleation, film deposition rate and thin film microstructure. • Organic thin film transistors fabricated from these pentacene films show promising performance characteristics. Primary Funding: CCMR Contact Information: [email protected] [email protected] Figure 1: Atomic force micrographs of pentacene on SiO2 as a function of exposure to the supersonic beam (Ei = 6.7 eV, qi = 0˚). In each case the field of view is 20 µm x 20 µm. A line scan (across the 75 s image) yields the height of pentacene islands to be 1.59 nm. Pentacene grows layer by layer for the first two layers on SiO2. Cornell NanoScale Facility Materials, page 137 Figure 2: Coverage-exposure relationships, deduced from AFM, for the adsorption of pentacene on SiO2 at the four incident kinetic energies indicated and normal incidence. The solid lines represent linear least-squares fits to the data. Deposition rate decreases with increasing energy characteristic of trapping mediated physisorption of pentacene on SiO2. National Nanotechnology Infrastructure Network Materials Low Heat Capacity Substrates for Calorimetry Measurements CNF Project # 522-94 Abstract: The goal of our group is to develop new thermal analysis characterization techniques and devices for nanometer scale thin films of metals, polymers and nanoliter volumes of proteins [1-8]. Our technique makes use of MEMS fabrication [7] techniques using Si-N membranes. A variety of sample configurations can be used including vacuum-deposited, spin-cast, or deposited via solution such as samples of self-assembled monolayers of alkanethiols (SAMS). In this report we show work on two topics: (1) heat capacity of the melting/ order-disorder transitions in 2D and 3D C16 alkanethiols SAMs [8], and (2) size-dependence melting point depression and possible superheating of bismuth nanoparticles [9]. Summary: Our technique is used to characterize the thermal properties of twodimensional (2D) self-assembled monolayers (SAMs) of C-16 alkanethiols on a gold surface. The amount of SAMs is typically in the 10 picomole range over an area of 0.025 cm-cm. The order-disorder transition characteristics of C16 2D SAMs grown on polycrystalline Au surfaces are easily observed via nanocalorimetry in their as-deposited state without desorption for scan temperatures below 100°C. Melting for the 2D SAMs occurs over a broad temperature range (100°C) with a melting temperature of about 70°C. The thiol can be thermally desorbed from the surface by scanning the sample to temperatures above 100°C (Figure 1). The scanning nanocalorimeter is also used to investigate the melting of Bi nanoparticles. The particles were formed by evaporating Bi onto a silicon nitride substrate. The particles self-assemble into truncated spherical particles. Below 5 nm average film thickness, the mean particle sizes increased linearly with deposition thickness, but increased rapidly for films 10 nm thick. As expected, small particles were found to exhibit size-dependent melting temperatures less than the bulk melting temperature (e.g. 67 K lower for a 3 nm radius particle). The measured melting temperatures for particles under ~7 nm in radius, however, were ~50 K above the value predicted by the Cornell NanoScale Facility, Member: National Nanotechnology Infrastructure Network Principal Investigator(s): Leslie H. Allen homogeneous melting model (Figure 2). We discuss this discrepancy in terms of a possible size-dependent crystal structure change and the superheating of the solid phase. Results from a two-step deposition, which created a bimodal particle size distribution are shown in Figure 3. A 10-nm Bi deposition was made in order to form large particles, then an additional 0.8 nm deposited to form small ones. (a) A TEM micrograph showing a few very large particles combined with many smaller ones. (b) Heat capacity data from the 10-nm and the 10 nm + 0.8-nm films. The smaller particles have a lower Tm which can be seen in the small melting peak at ~225°C thus demonstrating two different melting temperatures for the same material. References: [1] MY Efremov, F Schiettekatte, M Zhang, EA Olson, AT Kwan, RS Berry & LH Allen, “Discrete Periodic Melting Points in Nanostructure” Phys. Rev. Lett. 85, 3560 (2000). [2] M. Zhang, M.Y.Efremov, F. Schiettekatte, E.A.Olson, A.T.Kwan, L.S.Lai, J. E. Greene & L. H. Allen “Melting Point Depression of Nanostructures using Heat Capacity Measurements: Nanocalorimetry” Phys. Rev. B., 62, 10548 (2000). [3] M. Yu. Efremov, E. A. Olson, M. Zhang, S. L. Lai, F. Schiettekatte, Z. S. Zhang, and L. H. Allen, “Thin-Film Differential Scanning Nanocalorimetry: Heat Capacity Analysis” Thermochimica Acta, 412, 13 (2004). [4] M. Y. Efremov, E. A. Olson, M. Zhang, Z. Zhang & L. H. Allen. “Glass transition in ultrathin polymer films: calorimetric study”, Phys. Rev. Lett., 91, 85703 (2003). [5] M. Y. Efremov, E. A. Olson, M. Zhang, Z. Zhang, F. Schiettekatte, and L. H. Allen, “UltraSensitive Thin-Film Differential Scanning Calorimeter”, Rev. Sci. Inst., 75, 179 (2004). [6] M. Y. Efremov, E. A. Olson, M. Zhang, Z. Zhang & L. H. Allen. “Glass transition in ultra-thin polymer films: calorimetric study: Annealing Study”, Macromolecule, 37, 4607 (2004), see also Macromolecules, 35, 1481 (2002). [7] E. A. Olson, M. Yu. Efremov, M. Zhang, Z. S. Zhang, and L. H. Allen “The Design and Operation of a MEMS Differential Scanning Nanocalorimeter”, IEEE J. Microelectromech Sys. (JMEMS) 13, 355 (2003). [8] Z. S. Zhang, O.Wilson, M. Efremov, E. Olson, M. Zhang, P. Braun, C. Ober, & L. H. Allen, “Heat Capacity Measurements of 2D Self-Assembled Monolayers on Polycrystalline Gold”, Appl. Phys. Lett., 84, 5198 (2004). [9] E. A. Olson, M. Yu. Efremov, M. Zhang, Z. Zhang, and L. H. Allen “Size-dependent melting of Bi nanoparticles” J. of Appl. Phys. v97, p034304 (2005). page 138 Low Heat Capacity Substrates for Calorimetry Measurements CNF Project # 522-94 Principal Investigator(s): Leslie H. Allen User(s): Mike Efremov Eric Olson Ming Zhang Zishu (Sue) Zhang Liang Hu Figure 1, top left: A series of heat capacity Cp(T) curves of multiple scans with two different maximum scanning temperatures. The 200˚C shows the gradual desorption of 2D SAMs. There is a 30% loss of mass and a 40% decrease in the heat during this series. For samples scanned to 330˚C most of the remaining alkanethiol desorbs in the first few pulses during these high temperature scans [Appl. Phys. Lett., 84, 5198 (2004)]. Figure 2, below left: Melting temperatures as functions of particle sizes, using eight films 0.3 nm to 10 nm thick. The horizontal dotted-line is the bulk Tm for Bi—271˚C. The dashed line shows the expected Tm(r) behavior calculated from values using the homogeneous melting model and the standard accepted surface energies The upper dashed-line is a linear fit to the our experimental values for Tm(r) for smaller particles. The difference between the dashed lines represents superheating of the bismuth or a difference in crystal structure. Principal Investigator(s): Leslie H. Allen Affiliation(s): Material Science, University of Illinois at Urbana-Champaign Primary Funding: NSF Materials Research Dr. L. Hess (0108694); American Chemical Society-Petroleum Research Fund (37027-AC7); NSF Materials Research Dr. L. Hess (0304149) Dr. William Nes Figure 1 Figure 2 Figure 3, below right: C p measurements of a bimodal particle size distribution (a) A TEM micrograph showing a few very large particles combined with many smaller ones. (b) Heat capacity Cp data demonstrating two different melting temperatures for the same material. Contact Information: [email protected] http://allen.mse.uiuc.edu/index.htm Figure 3 Cornell NanoScale Facility Materials, page 139 National Nanotechnology Infrastructure Network Materials Investigation of the Effect of Biaxial Strain on the Diffusivity of B in Si CNF Project # 1007-02 Abstract: The purpose of this project is to measure the effect of biaxial stress on the in-plane diffusivity of B in Si. For non-hydrostatic stresses, the diffusivity is affected by the product of the stress tensor and the activation strain tensor [1]. For a cubic system, this three-by-three tensor can be reduced through symmetry considerations to only three independent parameters. Our measurement of the effect of biaxial stress on the in-plane diffusivity of B in Si will contribute to the complete determination of this tensor. This measurement will be performed by examining the lateral spread of B-doped stripes in a strained Si film which will be patterned through standard lithographic techniques at the Cornell NanoScale Facility (CNF). Summary: Externally applied stress influences the diffusivity through the scalar activation volume in the case of hydrostatic pressure and the activation strain tensor in the case of non-hydrostatic stresses [1]. This activation strain is the sum of a formation (Vf) and migration volume(Vm), which are the volume changes necessary for the formation of a mobile point defect and the additional deformation when that defect is at the saddle point in its migration path. For a cubic system, this three-by-three activation strain tensor can be reduced through symmetry considerations to only three independent parameters. If the entire tensor were known, we would be able to predict the effect of any arbitrary stress state on the diffusivity in any arbitrary direction. Determination of three independent parameters requires three independent measurements, two of which have been performed to date [2]. The samples we eventually plan to use to perform this experiment consist of biaxially strained Si layers which have been grown on top of relaxed SiGe buffer layers. We plan to create a series of B-doped stripes in these strained Si layers, and we will then anneal these samples and observe the lateral spread of Cornell NanoScale Facility, Member: National Nanotechnology Infrastructure Network Principal Investigator: Michael Aziz the B lines using Scanning Capacitance Microscopy (SCM). We are using the CNF to actually create these samples. There are several steps of the sample fabrication which require the use of the resources at the CNF, and which have been performed in the past year The first step was to use a mask to lithographically pattern some wafers. We coated plain Si wafers with 98 nm of PECVD oxide, after which they were spun with resist and exposed with the Autostep. We then etched these films, creating a physical mask for the B implantation. The B implantation was performed elsewhere, but the wafers were brought back into the CNF and a second layer of patterning was performed. This second set of lines was an outline of the major features of the sample, and these lines were etched through the oxide and into the Si using the Unaxis deep-Si etcher. The oxide was then removed with wet chemistry. The last processing step was laserannealing, performed elsewhere. We used Scanning Capacitance Microscopy to measure the lateral boron profile and fitted the data to extract a diffusion length. On a set of samples made from plain Si wafers the measured diffusion length was found to agree with the predicted value from literature [2] to within a factor of about 3. This sample fabrication has been an iterative process. There have been several generations of samples over the past three years, involving both plain Si wafers and strained Si films. Each generation has required two trips to the CNF. We are about to begin the process and create what should be the final set of samples with strained films. References: [1] Aziz, APL 70, 2810 (1997). [2] Zhao, APL 74, 31 (1999). page 140 Investigation of the Effect of Biaxial Strain on the Diffusivity of B in Si CNF Project # 1007-02 Principal Investigator: Michael Aziz User(s): Jennifer Sage Principal Investigator(s): Michael Aziz Affiliation(s): Division of Engineering & Applied Sciences, Harvard University Primary Funding: NSF Goal: Measure the effect of biaxial strain on the in-plane component of B diffusivity in Si. Figure 1: Mask design. Numbers represent stripe width, stripe spacing and stripe length in microns. Figure 2: Cross section of final sample. B stripes in thin, strained Si film grown epitaxially on Si1-xGex. Later: laser-melt, furnace anneal. Contact Information: [email protected] [email protected] Figure 3, above: Scanning Capacitance Microscopy (SCM) image of a boron-doped stripe. Areas of lighter contrast have higher doping. Figure 4, right: Plot of predicted diffusion length, based on known anneal time and temp and lit value of D vs. the measured diffusion length from SCM data. They agree to within a factor of 3. Cornell NanoScale Facility Materials, page 141 National Nanotechnology Infrastructure Network Materials Effects of Surface Properties on the Fracture Strength of Materials at Nanoscale CNF Project # 1154-03 Abstract: In our work, we are investigating the effects of surface properties on the fracture of nano-scale materials. For this purpose, single crystal silicon beams with chemically modified surface step structures were fabricated and the fracture strength statistics were determined by loading them with a carefully calibrated AFM cantilever. The obtained mean strengths of 10.79 GPa and 12.93 GPa for different surface properties indicate that higher fracture strength values, which are closer to the theoretical limit, are possible by surface modification. Summary: Fracture strength of bulk materials is much smaller than the theoretical cleavage strength, which only considers the separation of perfect crystal planes. Existing bulk or surface flaws (small cracks or geometric singularities such as surface steps) act as stress concentrators and decrease the fracture strength of the material. The flaw density decreases with decreasing size. Hence, at smaller length scales experimental values approach theoretical ones [1]. To investigate the surface effects, we fabricated doubly clamped beams from (111) single crystal silicon wafers. In order to isolate effects of surface properties, the samples were designed to have a tapered region avoiding corner stress singularities. The beams were 5 µm long and 1 µm wide. They were released by potassium hydroxide (KOH) and tetramethyl ammonium hydroxide (TMAH) etching. After release, their thicknesses were determined by resonance frequency measurements in high vacuum and their surface properties were characterized by an AFM scan. Surface step characteristics depend on the etchant type as well as other parameters like concentration, temperature, stirring, etc. For instance, TMAH released beams have smaller step height and step density then the KOH etched ones. Cornell NanoScale Facility, Member: National Nanotechnology Infrastructure Network Principal Investigator(s): Alan T. Zehnder Samples released with different etchants were tested with AFM in force mode. Before the experiment, the geometric properties of the AFM cantilever were obtained by SEM analysis and resonance frequency measurements, and the stiffness was determined by a static Finite Element Model. The experiment consisted of loading the samples with the AFM cantilever until they fractured. The deflection signal from the photo detector, the cantilever stiffness, and the piezo motion were used to obtain the force deflection curve and therefore the stress value at fracture. In order to analyze the effects of an individual step, the theoretical behavior of the stress near a geometric singularity [2] is compared to Finite Element Simulations. Since there is a statistical variation in size, number and orientation of the steps for fixed etching parameters, the fracture strength values were analyzed statistically using Weibull Probability distribution. The Weibull analysis indicated that the KOH and TMAH released beams were 10.79 GPa and 12.93 GPa respectively. Their Weibull Modulus, m (less scatter in data for higher values of m), however, were 15.14 and 11.81 respectively. It should be noted that both strength values are much larger than the strength of millimeter sized samples (0.5 GPa [1]) and close to the approximate theoretical strength (~E/10). Modifying the surface steps further, we are expecting to reach the theoretical strength value. References: [1] T. Namazu, Y. Isono, T. Tanaka, “Evaluation of Size Effect on Mechanical Properties of Single Crystal Silicon by Nanoscale Bending Test Using AFM”, Journal of Microelectromechanical Systems, Vol. 9, pp. 450-459 (2000). [2] W. Suwito, M. L. Dunn, and S. J. Cunningham, “Fracture initiation at sharp notches in single crystal silicon”, J. Appl. Phys., 83, p. 3574 (1998). page 142 Effects of Surface Properties on the Fracture Strength of Materials at Nanoscale CNF Project # 1154-03 User(s): Tuncay Alan Principal Investigator(s): Alan T. Zehnder Affiliation(s): Theoretical and Applied Mechanics, Cornell University Primary Funding: Cornell Center for Materials Research (CCMR), a Materials Science and Engineering Center of the National Science Foundation (DMR-0079992). Principal Investigator(s): Alan T. Zehnder • 5 µm long single crystal silicon beams fabricated. • Fracture tests performed with AFM. • Surface steps act as stress concentrators, decreasing the fracture strength. • Higher strength values were obtained by chemical surface modification. Figure 1: AFM image of the KOH released beam. Contact Information: [email protected] [email protected] Figure 3: Probability of failure of KOH and TMAH released beams. Cornell NanoScale Facility Materials, page 143 Figure 2: Local stress behavior near the corner of a step during fracture. Inset: A fractured test beam. National Nanotechnology Infrastructure Network Materials Ordering on Corrugated Glass Surfaces CNF Project # 1163-03 Abstract: Corrugations were formed on glass surfaces by off-normal ion beam erosion. Small amounts of gold were deposited onto the corrugated glass surfaces. The changes in the positions of the deposited gold nanoclusers as a function of annealing conditions were investigated by atomic force microscopy (AFM). The glass substrates were also used to form cells in which to test the influence of the corrugations on the alignment of nematic liquid crystals (LC’s). Experimental Details: Pieces of a commercial boroaluminosilicate glass (Corning Code 1737) were washed with acetone and isopropyl alcohol and blown with dry nitrogen. The pieces then were placed in a Veeco Ion Mill with an incoming ion angle of 45° where they were bombarded at 450 V and 80 mA for 20 minutes. The resulting corrugations had a wavelength of approximately 50 nm, and amplitude of 1.5 nm. The corrugated samples were then placed in the CVC 4500 evaporator where gold coverages with thicknesses ranging from 5 to 15Å were thermally deposited onto the corrugated glass surface at normal incidence. Samples were placed in an Rapid Thermal Anneal (RTA) oven for various times ranging from 10-60 seconds at 450°C. AFM characterization was performed after each annealing period. Before depositing a liquid crystal onto the substrate, the glass was soaked in acetone for approximately 15 minutes to remove any organic residues, rinsed with methanol and dried. Then a plasma cleaner, running for ten minutes, was used to clean the sample. Two types of liquid crystal cell were fabricated: a parallel cell (corrugations parallel to each other) and a twisted-nematic cell (corrugations perpendicular to each other). The cell is made by sandwiching liquid crystals between two Cornell NanoScale Facility, Member: National Nanotechnology Infrastructure Network Principal Investigator(s): Christopher Umbach sputtered glass substrates. The two pieces of sputtered glass are separated by a uniform gap approximately 8 µm. Using a pipette, a small drop of liquid crystal (Merck E7) is deposited onto the sputtered glass and pressed down by the second piece of sputtered glass. The alignment of LC’s relative to the corrugation directions is determined by the intensity of the polarized light transmitted through the cell in a cross-polarizer geometry. Results: At coverages of 3 nm of gold, the corrugation morphology is significantly obscured by the gold overlayer. At coverages of 1 nm and less, the corrugations can be distinguished from the gold nanoparticles that are present on the surface. With annealing, the nanoparticles coarsen in size; because of the limitations of AFM in imaging the troughs of the corrugations, it is not possible to determine if the gold exhibits any preference for the trough or crests of the corrugation. In the case of the liquid crystal cells, the parallel cell showed alignment that was more uniform than that achieved with unsputtered glass and close to the quality that can be achieved with the conventional rubbed polymer alignment layer. The twisted nematic cell showed macroscopic regions of the alignment that typically occurs in a conventional twisted nematic cell, but this alignment was not achieved over the entire cell. Summary: Corrugated glass substrates can be used as substrates for thin-film or liquid crystal devices. The corrugations strongly influence the alignment of the liquid crystals, while the ordering of gold particles is not detectible with atomic force microscopy. page 144 Ordering on Corrugated Glass Surfaces CNF Project # 1163-03 Principal Investigator(s): Christopher Umbach • Bombard glass with 500 eV ions at 45° offnormal incidence. • Bombardment produces surface corrugations with 50 nm wavelength and 1.5 nm amplitude. Affiliation(s): 1. Electrical Engineering & Phyiscs, Lehigh University; 2. Materials Science & Engineering, Cornell University • Deposit 1 nm gold and anneal at 450˚C. • Align liquid crystals (LC’s) in a sandwich of corrugated glass substrates. Primary Funding: CNF REU program (Saboktakin), Cornell LIFE program (Huang) Figure 1, top: User(s): Marjan Saboktakin1 Chunghung Michael Huang2 Principal Investigator(s): Christopher Umbach2 Contact Information: [email protected] [email protected] [email protected] Atomic force microscopy of gold on corrugations. Gold nanoparticles replicate corrugations before annealing. After annealing, gold nanoparticles coarsen and corrugations are obscured. Figure 1: 1 nm of gold deposited on corrugated glass. Figure 2, bottom: Polarized light microscopy of LC’s. Bright transmission at 45˚ shows LC’s are aligned with corrugations. Figure 2: Transmission of polarized light through cross-polarizers corrugated glass. Cornell NanoScale Facility Materials, page 145 National Nanotechnology Infrastructure Network Materials Self-Assembly of Non-Spherical Colloids CNF Project # 1177-03 Abstract: Fabrication of three-dimensional (3D) structures with micron-scale features presents a continuing challenge. Photonic crystals are one example of such 3D structures which are of interest to the scientific community. While multilayer and 3D lithography are potential routes to these structures, we attempt to construct with micron scale building blocks which self-assemble in solution. Or in other words, we seek to develop a chemistry of non-spherical colloids. Summary: Previously we demonstrated the ability to create colloidal particles using contact photolithography. A layer of OmniCoat sacrificial layer was spin-coated on a wafer before spin-coating a layer of SU-8-2002. Both of these products are available through MicroChem. After exposure and development of the SU8, the OmniCoat layer is dissolved using MicroChem’s PG Remover which releases the particles into solution. This year we have optimized the process by using the GCA5x Autostep instead of the EV620 contact aligner. By using the Autostep, we have achieved greater reproducibility with higher resolution of features. We have achieved yields of over one billion particles per four inch wafer using the Autostep. Also, we are able to generate a variety of shapes. For releasing these high density arrangements of particles, we have found that sonication of the wafer with isopropanol is useful. Cornell NanoScale Facility, Member: National Nanotechnology Infrastructure Network Principal Investigator(s): Abraham Stroock After releasing the particles into isopropanol, we wash them in isopropanol by repeated pelleting with centrifugation to remove any residual amounts of processing chemicals. Pellets of SU-8 colloids can then be redispersed into isopropanol or aqueous surfactant solutions via sonication. It is important to note that neither pelleting nor sonication damages the colloids. The SU-8 particles have been successfully stabilized in aqueous solutions of Sodium Dodeclysulfate (SDS). Currently we are exploring depletion interactions as a means for selfassembly of our particles. In an effort to precisely control concentrations in small volumes, we fabricate microfluidic devices in polydimethlysiloxane (PDMS) by casting in molds fabricated from SU-8 100 via contact lithography in CNF. Our initial results are promising and we plan to pursue the fabrication of similarly shaped particles in different materials such as silicon, silicon oxide, or other materials for which CNF has processing capabilities. References: [1] J.D. Joannopoulos, R.D. Meade, J.N. Winn, Photonic Crystals: Molding the Flow of Light (Princeton University Press, Princton, 1995). [2] S. Asakura, F. Oosawa, On interaction between two bodies immersed in a solution of macromolecules, Journal of Chemical Physics, 22, 1255 (1954). page 146 Self-Assembly of Non-Spherical Colloids CNF Project # 1177-03 User(s): Stephane Badaire1 Cecile Cottin-Bizonne1 Joseph Woody1 Allen Yang2 Principal Investigator(s): Abraham Stroock Goals: 1) Investigate the role of shape in defining the interaction between colloidal particles and 2) develop a set of tools with which to self assemble structures on the 100 nanometer to 100 micron scale. Principal Investigator(s): Abraham Stroock1 Affiliation(s): 1. Chemical and Biomolecular Engineering, Cornell University; 2. Chemical Engineering, Carnegie Mellon University Primary Funding: Cornell Center for Materials Research, Cornell University Contact Information: [email protected] [email protected] [email protected] [email protected] Figure 1: Lithographic process for the fabrication of colloids. Colloids patterned on a wafer patterned with the Autostep 200 are released to form a colloidal dispersion. Cornell NanoScale Facility Materials, page 147 Figure 2: Scanning electron micrograph of cylindrical particles fabricated in negative photoresist, released, stabilized, and redeposited. Particles of aspect ratio 0.2, 0.5, and 1.2 are shown. National Nanotechnology Infrastructure Network Materials Mimicry of Biological Adhesion Through Fabrication of Fibrillar Surfaces CNF Project # 1225-04 Introduction: Geckos and other lizards as well as many species of insects utilize fibrillar contact surfaces to enhance their ability to adhere to a wide variety of natural surfaces. The arrays of tiny setae found on the contact surfaces of these organisms are typically between 0.5 and 5 µm in diameter and range in length from 5 to nearly 100 µm. Previous researchers have determined that the mechanism of adhesion for the fibrillar structures found in nature is noncovalent (predominantly van der Waals) interactions [1]. In theoretical work, we have shown that a fibrillar surface in contact with a substrate can possess both larger adhesion force and larger fracture energy than a corresponding flat interface of the same materials [2]. In addition, fibrillar surfaces are locally more compliant at the interface than flat ones due to the ability of fibrils to bend [3]. We have shown in other theoretical work that this allows a fibrillar surface to adhere better to rough surfaces than a flat surface [4]. Seeking to confirm these theoretical ideas with quantitative experimental data and to understand the functioning of the natural surfaces more fully, we built several model fibrillar arrays that mimic the biological exemplars. Summary: Our first attempt was at macroscopic length scales, using manual fabrication methods. We constructed fibrils approximately 1 mm in diameter from the rubbery polymer poly(vinyl butyral) and showed via tensile pull off tests that the fibrillar samples have about an order of magnitude larger adhesion energy than flat control samples [5]. The caveat with these samples is that uniform adhesive contact is difficult to achieve, and heat treatment at the interface was required to attain it. However, at smaller length scales, surface forces become stronger relative to the elastic restoring forces of the fibrillar structures. Hence, at small length scales, it should be possible to bring a fibrillar surface into intimate adhesive contact simply by placing it in proximity to the desired adherend. Cornell NanoScale Facility, Member: National Nanotechnology Infrastructure Network Principal Investigator(s): Anand Jagota Because of this, and because our theory predicts even larger adhesion strength as the diameter of the fibril is reduced, we set about to build microscopic fibrillar arrays. Using tools at CNF, we carried out two separate processes to produce arrays of fibrils with diameter between 1 and 15 µm and length between 5 and 100 µm. The first process used standard photolithography and deep reactive ion etching to produce holes in Si with the desired cross-sections and depths. This Si master surface was then used to mold poly(dimethylsiloxane) (PDMS), which was cured and removed from the master to give fibrils of the same shape and size as the holes in the Si surface. In the second process, photolithography and a wet chemical etch were used to pattern an array of circles on an Al layer atop a cured polyimide (PI) film. A reactive ion etch was then used to remove PI except where masked by the Al circles. The result was circular PI fibrils with approximately 1 µm diameter and lengths between 5 and 10 µm, depending on the etch time. In preliminary results for the adhesion of microscopic samples, we found in a tensile test that the pull off force of the fibrillar PDMS samples was about 80% that of the flat control [2]. Although the adhesion force is slightly smaller, one must note that the area of contact is about 20 times as large for the flat sample. Future work will involve maximizing the contact area for microscopic fibrillar samples, as well as adding more complex geometry to the ends of the fibrils, to increase compliance and increase the contact area and adhesion. References: [1] [2] [3] [4] [5] Autumn, K. et al. Proc. Natl. Acad. Sci. USA 99, 12252-12256 (2002). Hui, C.-Y. et al. J. Roy. Soc., Interface 1, 35-48 (2004). Glassmaker, N. J., et al. J. Roy. Soc., Interface 1, 23-33 (2004). Hui, C.-Y., et al. J. Adhesion 81, in press (2005). Glassmaker, N. J., et al. Acta Biomaterialia 1, in press (2005). page 148 Mimicry of Biological Adhesion Through Fabrication of Fibrillar Surfaces CNF Project # 1225-04 User(s): Nicholas J. Glassmaker Ajita Rajan Principal Investigator(s): Anand Jagota Affiliation(s): Chemical Engineering, Lehigh University Primary Funding: Lehigh University Start-Up Funds Contact Information: [email protected] [email protected] [email protected] Principal Investigator(s): Anand Jagota • Natural fibrillar surfaces provide improved adhesion in animals (Figure 1). • Theory shows fibrillar surfaces are stronger than flat surfaces. • Large aspect ratio fibrils more compliant than flat surfaces, allowing better contact with rough surfaces. • Synthetic fibrillar surfaces fabricated by molding (Figure 2) or direct reactive ion etching (Figure 3). Figure 1: Fibrillar surface, lizard (Anolis carolinensis). Figure 2: Silicon master for molding fibrils. Cornell NanoScale Facility Materials, page 149 Figure 3: Polyimide fibrillar array (1 µm diameter). National Nanotechnology Infrastructure Network Materials Electronic Charge Trap States Dynamics and Effect on Imprint Behavior in P(VDF-TrFE) Ferroelectric Thin Films CNF Project # 1253-04 Abstract: We investigate the effect of imprint, a time-dependent tendency for ferroelectric materials to resist polarization reversal, on ferroelectric Poly(vinylidene fluoride-trifluoroethylene) (P(VDF-TrFE)) thin films. Based on experimental measurements of the time and temperature dependence of imprint, we have developed a model that links imprint to electronic charge trap states in the bulk or near the metal/polymer interfaces. A fast-ramp thermally stimulated current (TSC) measurement technique has been developed to monitor trap state dynamics within the seconds time-frame. Thin films of P(VDF-TrFE) with Ti electrodes were fabricated on oxidized Si substrates. Following controlled polarization and imprint initialization, charging of trap states was monitored through temperature cycling at fixed heating and cooling rates. The post-TSC final polarization state was also determined. Thermally induced trap filling has been directly correlated with post-cycling imprint conditions. Future experiments will focus on correlating trap densities, energetics and kinetics with polymer and electrode compositions. Summary: P(VDF-TrFE) is a potential material for use as a storage medium for threedimensional, stacked non-volatile memory [1]. Imprint, a time-dependent tendency for ferroelectric materials to resist polarization reversal, often limits such memory applications. In inorganic ferroelectrics, imprint is related to the contact materials and microstructure. In contrast, for P(VDF-TrFE), imprint is hypothesized to result from internal electric fields formed by charges at trap sites distributed throughout the film, as well as at interfaces between the polymer and electrodes. The origin, dynamics, and control of these traps remain a key research challenge to fully understand this material. This research focuses on understanding and quantifying the origin of the trap states in the polymer. To characterize the density and dynamics of these Cornell NanoScale Facility, Member: National Nanotechnology Infrastructure Network Principal Investigator(s): Michael O. Thompson traps, we have extended the thermally stimulated discharge current technique, typically used to study dipole relaxation in electrets [2], by almost two orders of magnitude in time. The fast-ramp thermally stimulated current (TSC) measurement is suitable for monitoring the trap state dynamics within the seconds time-frame. Thin films of P(VDF-TrFE) with Ti electrodes were fabricated on oxidized Si substrates. Trap states were thermally filled/emptied through temperature cycling between 20-100°C with heating and cooling rates of 1-5°C/s, and observed as a function of poling conditions and imprint times. In addition to charge accumulated during thermal cycling, the final polarization state was also determined. Imprint-induced filling of trap states has been verified from the TSC in the 1-10000 second time-frame [3]. Similarly, thermally induced trap filling has been directly correlated with post-cycling imprint conditions. In addition, results show a significant asymmetry with field orientation (top versus bottom electrodes), suggesting that the trap density and characteristics are directly related to processing conditions and materials. Future experiments will focus on correlating trap energetics and kinetics with polymer and electrode composition in order to determine relationships between polymer/metal interactions and trap behavior. References: [1] O. Auciello, J.F. Scott, and R. Ramesh. “The Physics of Ferroelectric Memories”, Physics Today, 51 (7), (1998), 22. [2] E.R. Neagu, J.S. Hornsby, D.K. Das-Gupta. “Polarization and Space Charge Analysis in Thermally Poled PVDF”, J. Phys. D (Appl. Phys), 35 (11), (2002), 1229. [3] C. Lew, M.O. Thompson, “Quantifying the Role of Electronic Charge Trap States on Imprint Behavior in Ferroelectric Poly(vinylidene fluoride-trifluoroethylene) (P(VDFTrFE)) Thin Films”, MRS Proc. 830, (2005), D2.4. page 150 Electronic Charge Trap States Dynamics and Effect on Imprint Behavior in P(VDF-TrFE) Ferroelectric Thin Films CNF Project # 1253-04 Principal Investigator(s): Michael O. Thompson • P(VDF-TrFE) ferroelectric polymer for nonvolatile memory. • Affiliation(s): Materials Science and Engineering, Cornell University Correlate imprint behavior with model of electronic charge trap states in polymer and polymer-metal interfaces. • Primary Funding: Intel, Thin Film Electronics, and others Developed fast-ramp thermally stimulated current (TSC) technique to study trap dynamics and energetics. • Proved and quantified trap states filling in 1-10000s imprint time-frame. User(s): Connie Lew Principal Investigator(s): Michael O. Thompson Contact Information: [email protected] [email protected] Figure 2 Figure 3 Figure 1 Figure 1, above: Measurement: (a) poling, (b) imprint, (c) TSC. Figure 2, opposite top: TSC filling trap states during first heat cycle. Figure 3, opposite bottom: TSC with increasing imprint time, showing trap filling during imprint. Cornell NanoScale Facility Materials, page 151 National Nanotechnology Infrastructure Network