Inorganic Polymers, Second Edition

... polymers provide between polymer science and ceramics. More and more chemistry is being used in the preparation of ceramics of carefully controlled structure, and inorganic polymers are increasingly important precursor materials in such approaches. The present book was prepared to provide an introdu ...

... polymers provide between polymer science and ceramics. More and more chemistry is being used in the preparation of ceramics of carefully controlled structure, and inorganic polymers are increasingly important precursor materials in such approaches. The present book was prepared to provide an introdu ...

Studies of Nanocrystalline SnO2 Doped with Titanium (Ti), Yttrium (Y

... increasing temperature in pure SnO2 and doped SnO2 were studied. In both pure and doped materials, RDFs suggest phase transition at higher temperature, where anatase SnO2 transforms to rutile SnO2. Rutile SnO2 was found to be more stable than anatase SnO2. The results showed that the dopants have di ...

... increasing temperature in pure SnO2 and doped SnO2 were studied. In both pure and doped materials, RDFs suggest phase transition at higher temperature, where anatase SnO2 transforms to rutile SnO2. Rutile SnO2 was found to be more stable than anatase SnO2. The results showed that the dopants have di ...

DUXSON, PETER Title - Minerva Access

... temperatures up to 1000˚C. The response of geopolymers to heating is characterised into four regions regardless of the extent of shrinkage or crystallisation. Several critical material performance relationships exist that are related to both the microstructure and chemical composition. The thesis pr ...

... temperatures up to 1000˚C. The response of geopolymers to heating is characterised into four regions regardless of the extent of shrinkage or crystallisation. Several critical material performance relationships exist that are related to both the microstructure and chemical composition. The thesis pr ...

10 - E-Prints Complutense

... 2.2.2. Dielectric losses: Conduction Mechanism. ..................................................................... 19 2.2.3. Magnetic losses: Induction mechanism .......................................................................... 22 2.2.4. Magnetic heating ................................. ...

... 2.2.2. Dielectric losses: Conduction Mechanism. ..................................................................... 19 2.2.3. Magnetic losses: Induction mechanism .......................................................................... 22 2.2.4. Magnetic heating ................................. ...

Solidification kinetics in undercooled pure iron and iron

... culture of mankind is culminated in our today’s high technology society. However, not before the first half of the 20th century scientists tried to develop a physical understanding how the material properties were related to the conditions of solidification. In the case of metals the major growth mo ...

... culture of mankind is culminated in our today’s high technology society. However, not before the first half of the 20th century scientists tried to develop a physical understanding how the material properties were related to the conditions of solidification. In the case of metals the major growth mo ...

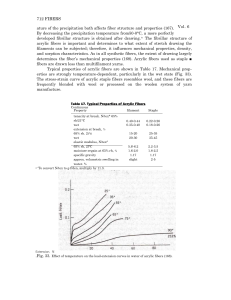

712 FIBERS Vol. 6 ature of the precipitation bath affects fiber

... Disperse dyes are relatively slow, but in the presence of certain dye assistants, satisfactory light shades can be produced. As a general class, acrylic fibers do not have well-developed crystalline structures, although there are strong dipolar interactions of the polymer chains through the nitrile ...

... Disperse dyes are relatively slow, but in the presence of certain dye assistants, satisfactory light shades can be produced. As a general class, acrylic fibers do not have well-developed crystalline structures, although there are strong dipolar interactions of the polymer chains through the nitrile ...

Author final version (postprint) - DTU Orbit

... applications for tomographic measurements on full-scale industrial combustion systems. The system was successfully applied on industrial scale for simultaneous fast exhaust gas temperature measurements in the three optical ports of the exhaust duct of the large Diesel engine. The results were compar ...

... applications for tomographic measurements on full-scale industrial combustion systems. The system was successfully applied on industrial scale for simultaneous fast exhaust gas temperature measurements in the three optical ports of the exhaust duct of the large Diesel engine. The results were compar ...

Full Article PDF - Advanced Materials Letters

... ZnO oxides in the hydroxide melts is described as the following (where M denotes Na or K). However, to simplify the chemical reactions here, we only include NaOH in the formula for simplicity; Zn(NO3)2.4H2O + NaOH → Zn(OH)2 + NaNO3 As Zn(OH)2 is chemically not stable and split to form ZnO and water ...

... ZnO oxides in the hydroxide melts is described as the following (where M denotes Na or K). However, to simplify the chemical reactions here, we only include NaOH in the formula for simplicity; Zn(NO3)2.4H2O + NaOH → Zn(OH)2 + NaNO3 As Zn(OH)2 is chemically not stable and split to form ZnO and water ...

Ab-initio calculations for structural properties of Zr–Nb alloys

... and additionally x = 87.5%, 93.75% and x = 96.875% for BCC alloys. In such a case, structures with niobium concentrations 3.125% and 96.875% are characterized by the largest number of atoms in the unit cell, 32. Hence, for the above mentioned values of the niobium concentration x in the alloy Zr– x ...

... and additionally x = 87.5%, 93.75% and x = 96.875% for BCC alloys. In such a case, structures with niobium concentrations 3.125% and 96.875% are characterized by the largest number of atoms in the unit cell, 32. Hence, for the above mentioned values of the niobium concentration x in the alloy Zr– x ...

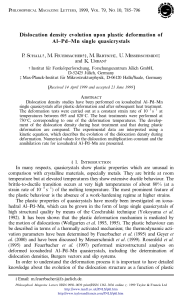

Dislocation density evolution upon plastic deformation of Al-Pd

... density during plastic deformation and subsequent heat treatment. The strain dependence of the dislocation density (® gure 1 (b)) shows a rapid increase at the onset of plastic deformation up to a maximum value, followed by a signi® cant decrease at higher strains. The latter behaviour distinctly di ...

... density during plastic deformation and subsequent heat treatment. The strain dependence of the dislocation density (® gure 1 (b)) shows a rapid increase at the onset of plastic deformation up to a maximum value, followed by a signi® cant decrease at higher strains. The latter behaviour distinctly di ...

Third phase formation in liquid/liquid extraction: a colloidal

... line with the pioneering work of Osseo Asare [9], the third phase can be understood by considering the organic phase as a complex fluid such as reverse micelles or a microemulsion [10]. Reverse micelles consist of a water core containing ionic species such as salt stabilized by an extractant layer d ...

... line with the pioneering work of Osseo Asare [9], the third phase can be understood by considering the organic phase as a complex fluid such as reverse micelles or a microemulsion [10]. Reverse micelles consist of a water core containing ionic species such as salt stabilized by an extractant layer d ...

Glass transition

The glass–liquid transition or glass transition for short is the reversible transition in amorphous materials (or in amorphous regions within semicrystalline materials) from a hard and relatively brittle state into a molten or rubber-like state. An amorphous solid that exhibits a glass transition is called a glass. Supercooling a viscous liquid into the glass state is called vitrification, from the Latin vitreum, ""glass"" via French vitrifier.Despite the massive change in the physical properties of a material through its glass transition, the transition is not itself a phase transition of any kind; rather it is a laboratory phenomenon extending over a range of temperature and defined by one of several conventions. Such conventions include a constant cooling rate (20 K/min) and a viscosity threshold of 1012 Pa·s, among others. Upon cooling or heating through this glass-transition range, the material also exhibits a smooth step in the thermal-expansion coefficient and in the specific heat, with the location of these effects again being dependent on the history of the material. However, the question of whether some phase transition underlies the glass transition is a matter of continuing research.The glass-transition temperature Tg is always lower than the melting temperature, Tm, of the crystalline state of the material, if one exists.