* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

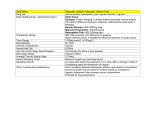

Download Guidelines on the quality, safety, and efficacy of biotherapeutic

Drug interaction wikipedia , lookup

Pharmacogenomics wikipedia , lookup

Drug design wikipedia , lookup

Prescription costs wikipedia , lookup

Pharmacokinetics wikipedia , lookup

Clinical trial wikipedia , lookup

Neuropharmacology wikipedia , lookup

Pharmaceutical industry wikipedia , lookup

Neuropsychopharmacology wikipedia , lookup

Drug discovery wikipedia , lookup

Pharmacognosy wikipedia , lookup