* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download 67066d5ef22c412

Survey

Document related concepts

Transcript

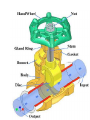

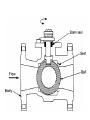

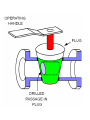

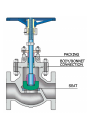

Main Target Definition Function Main parts Classifications Actuator Selection Problems Definition A valve is mechanical device that controls the flow of fluid and pressure within a system Function 1-stopping and starting fluid flow 2-varying the amount of fluid flow 3-controlling the direction of fluid flow 4-regulating down stream system or process pressure 5-relieving component or piping over pressure Main parts 1-body 2-bonnet 3-disk 4-seat 5-stem 6-actuator 7-packing Introduction to the Type of valves Each type of valve has been designed to meet specific needs. Some valves are capable of throttling flow; other type can only stop flow. Other work well in corrosive system and other handle high pressure fluid. Each type has certain inherent advantages and disadvantages. Classification of valves Valves may be classified in a number of ways according to control 1-pressure control valve as relief valve 2-direction control valve as check valve 3-flow control valve as throttling valve according to construction 1-gate valve 3-plug valve 5-pinch valve 7-globe valve 2-ball valve 4-reducing valve 6-diaphram valve 8-miscellaneouc valves Common type of valves 1- Manual valve 2- Check valve 3- Relief valve Valve actuator 1-Mannual actuator 2-Electric actuator 3-Hydraulic actuator 4-Pneumatic actuator Valve Selection 1- According to the type of fluid to be controlled and its condition 2- According to the required condition required Common Valve Problem 1-cavitation 2-high velocity 3-water hammer Manual valves : A manual valve: is considered to be a valve that is operated by plant personnel directly, by the use of either a hand wheel/wrench or an on/off actuator in the case of shutdown valves. Function of Manual valves Manual valves: serve three major functions in fluid-handling systems: 1_Stopping and starting flow 2_controlling flow rate, 3_ diverting flow. Manual valves type Manual valves involve these types: 1_ Gate valves 2_Globe valves 3_ Plug valves 4_Piston valves 5_ Ball valves 6_ Diaphragm valve 7_ Butterfly valves 1_gate valve 1_ A gate valve is a linear motion valve 2_ used to start or stop fluid flow however, it does not regulate or throttle flow. 3_ The name gate is derived from the appearance of the disk in the flow stream Design and application of the gate valve . Gate valves are primarily designed to serve as isolation valves . In service, these valves generally are either fully open or fully closed . When fully open, the fluid flows through the valve in a straight line with very little resistance . Gate valves should not be used in the regulation or throttling of flow because accurate control is not possible and disk will damage . Designed for full-area flow to minimize the pressure drop and allow the passage of a pipe-cleaning pig. Construction of a Gate Valve 1-The body: is generally connected to the piping by means of flanged, screwed, or welded connections.. 2-The bonnet: containing the moving parts, is joined to the body, generally with bolts, to permit cleaning and maintenance 3-The valve trim : consists of the stem, the gate, the wedge, or disc, and the seat rings. TYPES OF GATE VALVE 1-Solid Wedge gate valve . The solid wedge gate valve is the most commonly used disk because of its simplicity and strength. . A valve with this type of wedge may be installed in any position and it is suitable for almost all fluids. It is practical for turbulent Solid Wedge gate valve 2-Flexible Wedge gate valve . The flexible wedge gate valve is a one piece disk with a cut around the perimeter to improve the ability to match error or change in the angle between the seats.. . Gate valves used in steam systems have flexible wedges The reason for using a flexible gate is to prevent binding of the gate within the valve when the valve is in the closed position. Flexible Wedge gate valve 3-Split wedge gate valves . Split wedge gate valves: are of the ball and socket Design . This type of wedge is suitable for handling no condensing gases and liquids at normal temperatures, particularly corrosive liquids. Split valves wedge gate SOLID WEDGE SPLIT WEDGE FLEXIBLE WEDGE Other classification of gate valve 1_The parallel-gate valve Use a flat disk gate as the closure element that fits between two parallel seats 2_The knife-gate valve . Has a sharp edge on bottom of the gate to prevent entrained of solids as well as to separate slurries 3_The through-conduit gate valve . Has a rectangular closure element with a circular opening equal to the full-area flow passage Advantages of Gate Valves : 1_It can be applied to both liquid and gas services 2_They have good shut off characteristics 3_ The pressure loss through the valve is minimal 4_ the gate valve is relatively inexpensive Disadvantage of gate valve 1_Gate valves are not quick opening or closing valves. 2_Gate valves require large space envelope for installation operation, and maintenance 3_High-flow velocity in partially opened valves may cause erosion of the discs and seating surfaces. Ball valves . Ball valve is a valve with a spherical disk . Is a quarter-turn valve suitable for clean gas, compressed air, and liquid service. They also can be used for slurry service. . The body of ball valves may be made of metal, plastic or metal with a ceramic center. . Ball valves can be used for service temperatures ranging from ( 270 to 360 ᴼC) HANDLE Ball valves BALL FLOW PASSAGE Construction of a Ball Valve Major components of the ball valve are: 1- Body 2-Spherical plug 3-Seat Ball valves are made in three general patterns: 1-venturi port 2- full port 3-reduced port Construction of a Ball Valve Ball valve may be: 1- unidirectional 2- bidirectional 3- multidirectional Depending on: 1- the number of valve ports 2- the number of valve seats. Construction of a Ball Valve Ball valves are referred to as : 2-way 3-way 4-way 5-way multiport valves. Advantages of Ball Valves 1. Provides bubble-tight services 2. Quick to open and close. 3. Smaller in size than a gate valve. 4. Lighter in weight than a gate valve. 5. Multiport design offers versatility not available with gate or globe valves. 6. Several designs of ball valves offer flexibility of selection 7. Can be used in clean and slurry applications. 8. High-quality ball valves provide reliable service in high-pressure and high-temperature applications. 9. Force required to actuate the valve is smaller than that required for a gate or a globe valve. Disadvantages of Ball Valves: 1. They are not suitable for sustained throttling applications 2. In slurry or other applications, the suspended particles can settle and become trapped in body C- Plug valves . Plug valves are called cocks, generally are used for the same full-flow service as gate valves, . where quick shutoff is required. . They are used for steam, water, oil, gas, and chemical liquid service. . They are available for pressure service from vacuum to 10000 psi (69000 k Pa) and temperatures from 50 to 1500 F (46 to 816 C). Construction of a Plug Valve Advantages of Plug Valves The following summarizes the advantages of plug valves: 1. Simple design with few parts. 2. Quick to open or close. 3. Can be serviced in place. 4. Offers minimal resistance to flow. 5. Provides reliable leak tight service. 6. Multiple port design helps reduce number of valves needed and permits change in flow direction. Disadvantages of Plug Valves The disadvantages include: 1. Requires greater force to actuate, due to high friction. 2. Reduced port, due to tapered plug. 3. Typically, plug valves may cost more than ball valves. Typical Applications of Plug Valves 1. Air, gaseous, and vapor services 2. Natural gas piping systems 3. Coal slurries, mineral ores, mud, and sewage applications 4. Oil piping systems 5. Vacuum to high-pressure applications Diaphragm Valves A diaphragm valve is a linear motion valve that is used to start, regulate, and stop fluid flow. The name is derived from its flexible disk, which mates with a seat located in the open area at the top of the valve body to form a seal. Construction of a Diaphragm Valve There are three cases for diaphragm valve 1-open 2-throttling 3- closed STEM BONNET COMPRESSOR DIAPHRAGM FLOW VALVE BODY FULLY OPEN THROTTLED FULLY CLOSED Advantages of Diaphragm Valves 1. Can be used as on-off and throttling service valves. 2 Offer good chemical resistance due to variety of linings available.. 3. Stem leakage is eliminated. 4. Provides bubble-tight service Disadvantages of Diaphragm Valves 1.The weir may prevent full drainage of piping 2. Working temperatures. and pressures are limited by the diaphragm material. 3.The diaphragm may also limit the hydrostatic pressure. 4. Diaphragm valves are available in limited sizes. Typical Applications of Diaphragm Valves 1. Clean or dirty water and air service applications . 2. Demineralized water systems . 3. Corrosive applications . 4. Vacuum service . 6. Food processing, pharmaceutical, and brewing systems . Globe valves • A globe valve is a type of valve used for regulating flow in a pipeline, • consisting of a movable disk-type element and a stationary ring seat in a generally spherical body. • globe valves may be used for isolation and throttling services . The essential principle of globe valve operation • is the perpendicular movement of the disk away from the seat. • This causes the annular space between the disk and seat ring to gradually close as the valve is closed. • This characteristic gives the globe valve good throttling ability, which permits its use in regulating flow. globe valve involve these types: 1. Tee Pattern globe valves have the lowest coefficient of flow and higher pressure drop They are used in severe throttling services, Tee pattern globe valves may also be used in applications where pressure drop is not a concern and throttling is required 2. Wye Pattern globe valves offer the least resistance to flow They can be cracked open for long periods without severe erosion They are extensively used for throttling during seasonal or startup operations They can be rod through to remove debris when used in drain lines that are normally closed. Refer to Fig 3.Angle Pattern globe valves turns the flow direction by 90 degrees without the Use of an elbow and one extra weld They have a slightly lower coefficient of flow Than wye pattern globe valves They are used in applications that have periods of Pulsating flow Advantages of a Globe Valve 1 .Good shutoff capability 2 .Moderate to good throttling capability 3 .Shorter stroke compared to a gate valve. 4 .Available in tee, wye, and angle patterns, each offering unique capabilities. 5 .With disc not attached to the stem, valve can be used as a stop-check valve Disadvantages of a Globe Valve 1 .Higher pressure drop compared to a gate valve. 2 .Requires greater force or a larger actuator to seat the valve with pressure under the seat. 3 .Throttling flow under the seat and shutoff flow over the seat. Applications of Globe Valves 1. Cooling water systems 2 .Fuel oil system 3 .High-point vents and low-point drains when leak tightness 4 .Feed water, chemical feed, condenser air extraction, and extraction drain systems. 5 .Turbine seals and drains. 6 .Turbine lube oil system and others. Butterfly valves • called quarter turn valves • Butterfly valves are used to control and regulate or throttle the flow. • They are characterized by fast operation and low-pressure drop They require only a quarter turn from closed to full-open position. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is open, the disc is rotated a quarter turn so that it allows unrestricted passage. The position of the disc is effected from outside the valve. OPERATOR BODY SEAT DISK Advantages of Butterfly Valves 1. The compact design requires considerably less space, compared to gate, globe, or other valves. 2. Light in weight. 3. Quick acting; as a quarter-turn valve, it requires less time to open or close. 4. They have low-pressure drop and high pressure recovery. 5. It is available in large sizes 6. Provide bubble-tight service. Disadvantages of a Butterfly Valve 1.Throttling service is limited to low differential pressure. 2.Cavitations and choked flow are two potential concerns. 3.The disc movement is unguided and affected by flow turbulence Applications of Butterfly Valves 1. Cooling water, air, gases, and other similar applications, such as fire protection, circulating water, et cetera 2. Corrosive services requiring lined valves 3. High-pressure and high-temperature steam services 4. Vacuum service PISTON VALVES In these valves, the seat seal is achieved between the lateral faces of the piston and the seat bore. When the valve is being opened, flow cannot start until the piston has been completely withdrawn from the seat bore. piston valves permit good flow control. If sensitive flow adjustment is required, the piston may be fitted with a needle shaped extension. Piston valves are also used for stopping and starting flow when flow resistance due to the tortuous flow passage is accepted. Like globe valves, piston valves permit good flow control. If sensitive flow adjustment is required, the piston may be fitted with a needle shaped extension. Piston valves are also used for stopping and starting flow when flow resistance due to the tortuous flow passage is accepted. NAME: Abdallah Omar El-sayed CITY :Helwan Governorate: Cairo E-mail:[email protected] Ph.No:01017828720 Is a mechanical device, a valve, which normally allows fluid (liquid or gas) to flow through it in only one direction. Frank P. Cotter developed a "simple self sealing check valve, adapted to be connected in the pipe connections without requiring special fittings and which may be readily opened for inspection or repair" 1907. Nikola Tesla invented a deceptively simple oneway valve for fluids in 1916 . Construction of a Check Valve A basic check valve consists of a valve body, bonnet or cover, and a disc which is attached to a hinge and swings away from the valve seat to allow fluid to flow in the forward direction, as in a swing- or tilting-disc check valve, and returns to valve seat when upstream flow is stopped. Thus, reverse flow is prevented. In folding disc check valves, the disc consists of two halves attached in the middle. The two halves fold backward when upstream flow is initiated. Activated by a spring, the two halves quickly close the flow path when upstream flow ceases. In the case of lift-check valves, the disc is in the form of a piston which is moved out of the flow path by upstream flow and returns to the valve seat by gravity to stop back flow. Ball-check valves have a disc in the form of a ball. The Function of Check Valves The prime function of a check valve is to protect mechanical equipment in a piping system by preventing reversal of flow by the fluid. This is particularly important in the case of pumps and compressors, where back flow could damage the internals of the equipment and cause an unnecessary shutdown of the system and in severe cases the complete plant. Check valves are automatic valves that open with forward flow and close against reverse flow. This mode of flow regulation is required to prevent return flow, to maintain prime after the pump has stopped, to enable reciprocating pumps and compressors to function Check valve The main parts of check valve There are a number of reasons for using check valves, which include: 1)Protection of any item of equipment that can be affected by reverse flow, such as flow meters, strainers and control valves. 2)To check the pressure surges associated with hydraulic forces, for example, water hammer. These hydraulic forces can cause a wave of pressure to run up and down pipe work until the energy is dissipated 3)Prevention of flooding. 4)Prevention of reverse flow on system shutdown. 5)Prevention of flow under gravity. 6)Relief of vacuum conditions. 7)may also be required in lines feeding a secondary system in which the pressure can rise above that of the primary system. Types of Check Valves There are several types of check valves having varying body configurations. The following are some commonly used types of check valves: 1-Swing Check Valve Is check valve in which the disc, the movable part to block the flow, swings on a hinge or trunnion, either onto the seat to block reverse flow or off the seat to allow forward flow. The seat opening cross-section may be perpendicular to the centerline between the two ports or at an angle. Although swing check valves can come in various sizes, large check valves are often swing check valves. They are recommended for lines having low velocity flow and should not be used on lines with pulsating flow Types of swing check valves 1-the flapper valve 2-the clapper valve DISK NUT ANGLE PLUG CAP HINGE PIN ARM DISK Swing check valve Swing check valve 2-Lift check valves Are particularly adapted for high-pressure service where velocity of flow is high Large steam jackets are located to eliminate sticking because of differential expansion. is commonly used in piping systems in which globe valves are being used as a flow control valve. They have similar seating arrangements valves are suitable for installation in horizontal or vertical lines with upward flow. They are recommended for use with steam, air, gas, water, and on vapor lines with high flow velocities. These valves are available in three body patterns: horizontal, angle, and vertical. The disk or ball is forced onto the seat of the valve by both the backflow and gravity. The piston type lift check valves have a tendency to stick in the open position when service fluid has sediment trapped above the piston. CAP PLUG DISK OUTLET INLET SEAT BODY Lift check valve 3-Tilting Disc Check Valve The tilting disk check valve is similar to the swing check valve. Like the swing check, the tilting disk type keeps fluid resistance and turbulence low because of its straight-through design. check valves can be installed in horizontal lines and vertical lines having upward flow. The tilting-disc check valve is designed to overcome some of the weaknesses inherent in conventional swing check valves . • A combination of design features enables the valve to open fully and remain steady at lower flow velocities and to close quickly upon cessation of forward flow. • It performs well in pulsating, turbulent, and highvelocity flows. These attributes prolong the valve’s lift and reduce flow-induced dynamic loads on the piping system. • As flow decreases, the disk starts closing available with a soft seal ring, metal seat seal, or a metal-to-metal seal. The latter is recommended for high temperature operation. The soft seal rings are replaceable, but the valve must be removed from the line to make the replacement. Tilting Disc Check Valve Tilting Disc Check Valve 4-A ball check valve A ball check valve is a check valve in which the closing member, the movable part to block the flow, is a spherical ball. In some (but not all) ball check valves, the ball is spring-loaded to help keep it shut. For those designs without a spring, reverse flow is required to move the ball toward the seat and create a seal. They are commonly used in liquid or gel High pressure (HP) pumps and similar applications commonly use small inlet and outlet ball check valves with both balls and seats made of artificial ruby, for both hardness and chemical resistance. After prolonged use, such check valves can eventually wear out or the seat can develop a crack, requiring replacement Ball check valves should not be confused with ball valves, which is a different type of valve in which a ball acts as a controllable rotor to stop or direct flow. An application in sucker rod pump in Subsurface Pumping Unit 1)The standing valve 2)The travelling valve A ball check valve Start of upstroke Start of down stroke Plunger falls through fluid Fluid Lifted toward surface Tubing Plunger Traveling valve Barrel Standing valve Seating nipple Tubing Plunger Moving Up Plunger moving down Traveling valve open Barrel Standing valve closed Seating nipple Ball & seat Cage 5-Stop Check Valve A stop check valve can either be used as a unidirectional check valve or as an isolation (stop) valve like a gate or globe valve. These valves are available in tee-pattern, wyepattern, angle-pattern, and inclined pattern. HANDWHEEL BONNET PLUG SEAT Stop Check Valve 6-Diaphragm Check Valves The check valve consists of a perforated coneshaped basket that supports a matching diaphragm. Flow passing through the cone lifts the diaphragm off its seat and lets the fluid pass. When forward flow ceases, the diaphragm regains its original shape and closure is fast. One application worth mentioning is in purge-gas lines, which feed into lines, handling slurry or gluey substances. Under these conditions, diaphragm valves tend to operate with great reliability, while other valves hang up very quickly. Because the diaphragm is elastically strained in the open position, and travel of the lip from the fully open to the closed position is short, the diaphragm check valve closes extremely fast. This valve is well-suited for applications in which the flow varies within wide limits. However, the pressure differential for which the valve may be used is limited to 10 bar (145 lb/in2), and the operating temperature is limited to about 74°C (158°F). The inside of the sleeve is soft and capable of embedding trapped solids. Diaphragm check valve Diaphragm check valve SELECTION OF CHECK VALVES 1)closing speed 2) the closing characteristic of the valve 3) size SELECTION OF CHECK VALVES Most check valves are selected qualitatively by comparing the required closing speed with the closing characteristic of the valve. This selection method leads to good results in the majority of applications. However , sizing is also a critical component of valve selection If the application is critical, a reputable manufacturer should be consulted. Check Valves for incompressible Fluids These are selected primarily for their ability to close without introducing an unacceptably high surge pressure due to the sudden shutoff of reverse flow. Selecting these for a low pressure drop across the valve is normally only a secondary consideration Check Valves for Compressible Fluids Check valves for compressible fluids may be selected on a basis similar to that described for incompressible fluids. However, valve flutter can be a problem for high lift check valves in gas service, and the addition of a dashpot may be required. Where rapidly fluctuating gas flow is encountered, compressor-type check valves a good choice. Application Considerations 1)The force of gravity . 2) The flow velocity of the fluid. 3) The valve should be sized . 4) a check valve should not be located immediately downstream of a source of turbulence. 5) the fluid pressure The force of gravity plays an important role in the functioning of a check valve and, therefore, the location and orientation of the check valve must always be given consideration. Lift and ball check valves must always be placed so that the direction of lift is vertical. Swing checks must be located to ensure that the disc will always be closed freely and positively by gravity. The flow velocity of the fluid through the valve has a significant effect on the life of the check valve. The valve should be sized such that the fluid velocity under normal conditions is sufficient to keep the disc fully open and pressed against the stop. This minimizes disc fluttering, which is the primary cause of valve failure. A swing check valve may be used in the vertical run of a pipe only when flow is upward. the fluid pressure must be adequate to overcome the disc weight and swing it to the fully open position. When the flow is suspected to be pulsating and low, use of a swing check valve is not recommended. Due to the continuous flapping of the swing disc against the seat, valves suffer considerable damage, and at times the swing discs can come loose. The user must evaluate specific application features to determine the right valve for the application. Advantages of Check Valves They are self-actuated and require no external means to actuate the valve either to open or close. They are fast acting. Generally speaking check valves have no requirement for operators, and so the valve is operated automatically by flow reversal; however, in very special circumstances this unidirectional facility has to be overridden. Disadvantages of Check Valves The following are some of the disadvantages that are attributed to check valves: 1) Since all moving parts are enclosed, it is difficult to determine whether the valve is open or closed. Furthermore, the condition of internal parts cannot be assessed. 2)Each type of check valve has limitations on its installation configurations. 3)Valve disc can stick in open position PRESSURE RELIEF VALVES • Pressure relief device: • A device designed to open in response to excessive internal normal or subnormal fluid pressure, and sized to prevent the fluid pressure from exceeding a specified normal or subnormal limit. • The device may be either of the type that closes after the pressure excursion has receded or of the non-reclosing type. • Pressure relief valve: • A pressure relief device that recloses automatically after the pressure excursion has receded. TYPES OF PRESSURE RELIEF VALVES 1.Direct-loaded pressure relief valve 2.Pilot-operated pressure relief valve 1.Direct-loaded pressure relief valve A pressure relief valve in which the fluid pressure acting on the disc in the opening direction is opposed by a direct mechanicalloading device such as a weight or a spring. 2.Pilot-operated pressure relief valve A pressure relief valve consisting of a main valve that is the actual pressure relieving device, and a self actuated pilot that controls the opening and closing of the main valve by either pressurizing or depressurizing the dome of the main valve. Pilot-operated pressure relief valve with direct-acting pilot Type of Direct-loaded pressure relief valve A . Safety valve: A direct-loaded pressure relief valve that is intended mainly for gas, vapor, or boiler and steam applications and characterized by pop-opening action. B. Safety relief valve: A direct-loaded pressure relief valve that may be used either in gas or vapor service or in liquid service. The valve will open in gas or vapor service with a pop action, and in liquid service in proportion to the rise in overpressure though not necessarily linearly. Type of Safety relief valve 1 .Conventional safety relief valve: A pressure relief valve in which the loading device is enclosed in a pressure-tight bonnet that is vented to the valve outlet. 2.Balanced safety relief valve: A pressure relief valve that incorporates a means for minimizing the effect of back pressure on the performance characteristic. Bellows BBalanced Safely Relief Valve, Bonnet Vented. (Courtesy of Sempell A.G.) Bellows Relief Valve 3.Supplementary loaded pressure relief valve: • A direct-loaded pressure relief valve with an externally powered auxiliary loading device that is designed to inhibit valve simmer by introducing a supplementary seating load during normal operation of the pressure system. • Depending on the Code of Practice, the supplementary-loading force augmenting the spring force may be restricted or unrestricted. The load is automatically removed at a pressure not greater than the set pressure of the valve. 4.Assisted pressure relief valve: • A direct-loaded pressure relief valve with an externally powered auxiliary assist device that is designed to inhibit valve chatter by introducing a supplementary lifting force when the valve is called upon to open. • When the safe operating pressure is restored, the assist device is deactivated and the valve closes normally. • If the power to the assist device should fail, there is no interference with the normal operation of the valve. Assisted pressure relief valve 5.Liquid Relief Valves : Normally, liquid relief valves differ from conventional safety relief valves only in a slight modification of the geometry around the disc to achieve a specific performance in liquid service. Safety Relief Valve with Open Bonnet. [Courtesy of Crosby Valve & Gage Company, Wrentham, MA.) 6.Vacuum Relief Valves 2.Type of Pilot-operated pressure relief valve 1.Pilot-operated pressure relief valve with direct-acting pilot: A pilot-operated pressure relief valve in which the pilot represents a pressure actuated three ported valve that controls the operation of the main valve. 2.Pilot-operated pressure relief valve with indirect-acting pilot: A pilot-operated pressure relief valve in which the pilot represents a spring loaded pressure relief valve that controls the operation of the main valve by the fluid being discharged System Characteristics 1.Operating pressure: The maximum pressure that is expected during normal operating conditions. 2.Operating pressure differential: The pressure differential between operating pressure and set pressure expressed as a percentage of the set pressure or in pressure units. 3.Maximum allowable working pressure: The maximum pressure at which the pressure system is permitted to operate under service conditions in compliance with the applicable construction code for the pressure system. This pressure is also the maximum pressure setting of the pressure-relief devices that protect the pressure system. 4.Accumulation: The pressure increase in the pressure system over the maximum allowable working pressure, expressed in pressure units or percent of the maximum allowable working pressure. 5.Maximum allowable accumulation: The maximum allowable pressure increase in the fluid pressure over the maximum allowable working pressure as established by applicable codes for operating and fire contingencies, expressed in pressure units or percent of the maximum allowable working pressure. 6.Overpressure: The pressure increase over the set pressure of the relieving device, expressed as a percentage of the set pressure or in pressure units. Introduction Some type of actuator is necessary to allow for the positioning of a valve. Actuators vary from simple manual hand wheels to relatively complex electrical and hydraulic manipulators Choosing the type of actuator Valve actuators are selected based upon a number of factors including torque necessary to operate the valve and the need for automatic actuation. Types of Actuators The following are some of the commonly used valve actuators: •Mechanical Actuators •Pneumatic Actuators •Hydraulic Actuators •Electric Motors Mechanical Actuators Is Manual, Fixed, and Hammer Actuators Manual actuators are capable of Fixed Handwheel placing the valve in any position but do not permit automatic operation. the hammer handwheel moves freely through a portion of its turn and then hits against a lug on a secondary wheel. The secondary wheel is attached to the valve stem. With this arrangement, the valve can be pounded shut for tight closure or pounded open if it is stuck shut. Manual Gear Head If additional mechanical advantage is necessary for a manually-operated valve, the valve bonnet is fitted with Manually-operated gear heads as illustrated in Figure Pneumatic actuators Pneumatic actuators utilize the motive force provided by a compressed gas such as air, nitrogen , or other inert gas. Pneumatic actuators are the most common type of actuator because of 1-cheap and readily available power source less expensive ,which is compressed air 2- less complex in design and so are easier to maintain. 3- Pneumatic actuators can be used on valves of most sizes. Types of Pneumatic Actuators There are three basic types of pneumatic actuators, given below 1- Diaphragm air actuator. 2- Piston type air actuator. 3- Vane type actuator. Electric actuators An electric motor provides the actuating energy to place the valve in the desired position. Modern electric motor powered actuators allow local, remote, and hand operation and they are available for a variety of types of valves and sizes. Hydraulic Actuators Hydraulic actuators are capable of delivering very high torques, and with it the fast stroking speed necessary to operate larger valves Hydraulic actuators utilize pressurized liquids, usually oils but sometimes water, or the process liquid is used to provide the motive force for actuating the valve. Actuator specification sheet To ensure that the actuator meets all the process requirements and to avoid any confusion, it is essential that an Engineering Specification Sheet be created for each valve that will be operated by an actuator. This sheet must contain technical information about the actuator and the valve body that it will be attached to. This will avoid any confusion within the design group and it will also allow procurement to confidently place requisitions with potential suppliers. Sizing actuators for control valves When an actuator for a control valve is sized it is essential that the worst possible case is considered when the valve is open/closed or in the throttling mode. Spare parts and maintaining Actuated valves When actuators are selected it is usually for the duration of the plant life, which is usually 20 to 25 years. It is therefore necessary to consider ordering spare parts when the actuator is purchased. 1. Type of fluid to be controlled 2. Temperature of fluid 3. Viscosity of fluid 4. Specific gravity of fluid 5. Flow capacity required 6. Inlet pressure at valve 7. Outlet pressure 8. Pressure drop during normal flowing 9.Maximum permissible noise 10.Degrees of existence of flashing 11.Inlet and outlet pipeline size