* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

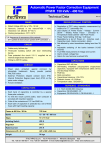

Download Catalogue PFC Parts and Trays

Spark-gap transmitter wikipedia , lookup

Electrification wikipedia , lookup

Power over Ethernet wikipedia , lookup

Audio power wikipedia , lookup

Current source wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Electrical ballast wikipedia , lookup

Electric power system wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Power inverter wikipedia , lookup

Power factor wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Electrical substation wikipedia , lookup

Voltage regulator wikipedia , lookup

Three-phase electric power wikipedia , lookup

Power engineering wikipedia , lookup

History of electric power transmission wikipedia , lookup

Power MOSFET wikipedia , lookup

Stray voltage wikipedia , lookup

Opto-isolator wikipedia , lookup

Surge protector wikipedia , lookup

Power electronics wikipedia , lookup

Buck converter wikipedia , lookup

Niobium capacitor wikipedia , lookup

Voltage optimisation wikipedia , lookup

Switched-mode power supply wikipedia , lookup