* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download High-voltage vacuum Contactors

Resilient control systems wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Ground (electricity) wikipedia , lookup

Power engineering wikipedia , lookup

Three-phase electric power wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Power inverter wikipedia , lookup

Spark-gap transmitter wikipedia , lookup

Mercury-arc valve wikipedia , lookup

Electrical ballast wikipedia , lookup

Stepper motor wikipedia , lookup

History of electric power transmission wikipedia , lookup

Current source wikipedia , lookup

Voltage regulator wikipedia , lookup

Galvanometer wikipedia , lookup

Power MOSFET wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Stray voltage wikipedia , lookup

Transformer types wikipedia , lookup

Circuit breaker wikipedia , lookup

Power electronics wikipedia , lookup

Voltage optimisation wikipedia , lookup

Capacitor discharge ignition wikipedia , lookup

Earthing system wikipedia , lookup

Protective relay wikipedia , lookup

Opto-isolator wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Electrical substation wikipedia , lookup

Resonant inductive coupling wikipedia , lookup

Mains electricity wikipedia , lookup

Electrical wiring in the United Kingdom wikipedia , lookup

Buck converter wikipedia , lookup

Alternating current wikipedia , lookup

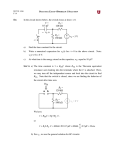

Safety Cautions Read the entire “Instruction Manual” carefully for important information about safety, handling, installation, operation, maintenance, and parts replacements. This equipment is designed and built in accordance with applicable safety standard in effect on the date of manufacture. Unauthorized modifications will void warranty and can result in severe injury, death and property damage. Do not make any modifications to the equipment. Only qualified persons are to install, operate or service this equipment according to all applicable codes and established safety practices. Use only genuine Toshiba replacement parts and accessories. Improper components could cause the equipment malfunction. Do not install this equipment in areas where unusual service conditions exist. Using this equipment in other than usual service conditions can result in equipment failure. Do not exceed the ratings specified on the equipment nameplate or system accessories. Underrated equipment can fail during operation causing fire, explosion, severe injury, death, and property damage. CV-6GAL/6HAL 7.2kV-200/400A-6.3kA TRANSMISSION DISTRIBUTION & INDUSTRIAL SERVICES COMPANY 1-1, SHIBAURA 1-CHOME, MINATO-KU, TOKYO 105-8001, JAPAN PHONE +81-3-3457-4898 FAX +81-3-5444-9169 http://www3.toshiba.co.jp/sic/english/swgr/products.htm The data given in this catalog are subject to change without notice. KSP-E2412 2008-12 (1.5) AD 4 Printed in Japan Excellent Breaking Performance Since the higher interrupting capacity and short-time withstand capability, Toshiba Vacuum Contactors are appropriate to fuse combination for large capacity load, and to high-speed breaking. Since the introduction of the first Vacuum Interrupter in 1962, Toshiba has been continuously improving and developing Vacuum Technology. Over 3 millions Vacuum interrupters have been produced for various types of vacuum apparatus such as contactors, circuit breakers and switches which are now widely used as result of their outstanding performance. Toshiba has become a leading Japanese manufacturer that has attained a record exceeding 230 thousands Low and High voltage Vacuum Contactors produced. Consistent with its dedication to the most advanced vacuum technology, Toshiba offers new series of High-voltage vacuum contactors. By adopting an electronics controlled circuit and being designed compactly to ensure reliability, handling ease and safety, the new series of High-voltage Vacuum Contactors are suitable for Motor starters, Transformer feeders and Capacitor switching applications. Compact and Lightweight Compact and slim design contactors can be applied to either two-tier motor starters or slim starters per IEC 60470 (2000). The Contactors CV-6GA(L) and CV-6HA(L) have the same outline and mounting dimensions, as well as dual voltage ratings (3.6/7.2kV). No Surge Protection Required Special main contact materials minimize chopping current. No surge suppressor/arrester is required except for special applications. Low Power Consumption The control device adopts an electronic circuit, the control voltage either AC or DC can be easily changed by switches in the circuit board without changing the coil and/or other parts. Since the economizing resistors are eliminated, the power consumption in holding condition has been reduced. Conformity to Industrial Standard Conforming to latest international standards such as IEC, BS, AS and JEM, being certified by class NK and TUV, Toshiba Vacuum Contactors can be used widely all over the world. 3 Class NK certificate (Marine application) 4 1 2 5 TIMER 52 CC OSCILLATION 6 POWER SWITCHING Fig. 1 Configuration of drive-unit TUV certificate Ratings Standard 7.2/3.6kV 200A 6.3kA 400A 6.3kA 720A 8.0kA CV-10HA(L) 15/12kV-400A-4/5kA CV-10HB(L) 12kV-400A-5kA CV-6KA1 7.2kV-720A-8kA 12kV 15/12kV 400A 400A 5.0kA 4.0/5.0kA Ratings (Rear side of CV-10HA) Special 7.2/3.6kV Main Terminals 12kV 15/12kV 1 400A 400A 400A 6.3kA 5.0kA 4.0/5.0kA Type Operating mechanism CV-6GA Non-Latched Type General Application CV-6GAL Latched Type General CV-6HA Non-Latched Type General CV-6HAL Latched Type General CV-6KA1 Non-Latched Type General CV-6KAL1 Latched Type General CV-10HB Non-Latched Type Capacitor CV-10HBL Latched Type Capacitor CV-10HA Non-Latched Type Motor/Transformer CV-10HAL Latched Type Motor/Transformer Type Operating mechanism Application CV-6HA-2 Non-Latched Type General CV-6HAL-2 Latched Type General CV-10HB-1 Non-Latched Type Capacitor CV-10HBL-1 Latched Type Capacitor CV-10HA-1 Non-Latched Type Motor/Transformer CV-10HAL-1 Latched Type Motor/Transformer Standard IEC, JEM, Class NK IEC IEC, NEMA Standard IEC, JEM IEC IEC, NEMA 2 3.6kV/7.2kV High-voltage Vacuum Contactors 3.6kV/7.2kV High-voltage Vacuum Contactors CV Type Standard Upper front terminal Form Operating Mechanism Rated Voltage (Ur) Rated Operational Current (Ie) Thermal Current (Ith) Rated Frequency Rated Short-time Withstand Current (Ik) Rated peak Withstand Current (Ip) Short-circuit Making and Breaking Current (Duty) Making Current (100times) AC4 Breaking Current (25times) AC4 Withstand Overload Current 6 times of Ie - 30s 15 times of Ie - 1s Coordination with Current-limiting Fuses Cut-off Current (Peak) Rated Insulation Level Power Frequency Withstand Voltage Impulse Withstand voltage Switching Frequency Mechanical Life Electrical Life (AC3) Closing Rated Control Voltage Tripping Allowable Control Voltage Fluctuation Closing Operating Current (at 100V) Holding/Tripping Endurance 6GA - Non-Latched Application Condition Maximum Load Weight 6HAL 6GAL 6HAL-2 Latched 3.6/7.2kV 400A 200A 400A 200A 450A 300A 450A 300A 50/60Hz 6300A - 1s 6300A - 2s 6300A - 1s 6300A - 2s 15.8kA 6300A "O" - 3min. - "CO" - 3min. - "CO" 4000A 4000A 2000A 2000A 3200A 3200A 1600A 1600A 2400A-30s 2400A-30s 1200A-30s 1200A-30s 4000A-12s 4000A-12s 4000A-4s 4000A-4s 6300A-2s 6300A-2s 6300A-1s 6300A-1s Prospective Short-circuit Current 40kA 55kA 85kA 55kA 85kA 22kV-1min. *1 60kV 1200 operating cycles/hr 300 operating cycles/hr 2.5 million operations 0.25 million operations 0.25 million operations 0.25 million operations 100-110, 115-120, 200-220, 230-240VAC / 100-110, 200-220VDC 24, 32, 48, 100-110, 200-220VDC 85% to 110% of the rated control voltage 4.5A (Peak) 4.0A (Peak) 0.1A (Average) 65 - 80ms 20 - 30ms Closing Time Opening Time Ratings of Auxiliary Contact 6HA 6HA-2 Contact arrangement Operational voltage Thermal Current AC Capacity DC Capacity Installation Altitude Ambient air temperature Relative humidity Vibration Shock Motor (kW) Transformer (kVA) Capacitor (kvar) 3NO-3NC 2NO-2NC Max. 480V, Min. 48V 10A 700VA (PF. 0.35) 60W (L/R 150ms) Floor Mount Vertical Installation 1000m or lower O -5 to 40 C 45 to 85% Max. 20Hz 1G Max. 30G 1500/3000 750/1500 1500/3000 750/1500 2000/4000 1000/2000 2000/4000 1000/2000 2000/2000 1000/2000 2000/2000 1000/2000 20.0kg 19.5kg 19.5kg 19.0kg Standard *2 IEC60470 (2000) JEM1167 (1990) Type Form Operating Mechanism Rated Voltage (Ur) Rated Operational Current (Ie) Thermal Current (Ith) Rated Frequency Rated Short-time Withstand Current (Ik) Rated peak Withstand Current (Ip) Short-circuit Making and Breaking Current (Duty) Making Current (100times) AC4 Breaking Current (25times) AC4 Withstand Overload Current 6 times of Ie - 30s 15 times of Ie - 1s Coordination with Current-limiting Fuses Cut-off Current (Peak) Rated Insulation Level Power Frequency Withstand Voltage Impulse Withstand voltage Switching Frequency Mechanical Life Electrical Life (AC3) Closing Rated Control Voltage Tripping Allowable Control Voltage Fluctuation Closing Operating Current (at 100V) Holding/Tripping Endurance Closing Time Opening Time Ratings of Auxiliary Contact Application Condition Maximum Load Contact arrangement Operational voltage Thermal Current AC Capacity DC Capacity Installation Altitude Ambient air temperature Relative humidity Vibration Shock Motor Transformer Capacitor Weight Standard CV 6KA1 Non-Latched 6KAL1 Latched 3.6/7.2kV 720A 800A 720A 800A 50/60Hz 8000A - 1s 20kA 8000A "O" - 3min. - "CO" - 3min. - "CO" 7200A 5760A 7200A 5760A 4320A-30s 4320A-30s 10800A-1s 10800A-1s Prospective Short-circuit Current 40kA 85kA 22kV - 1 min. *1 60kV 600 operating cycles/hr 300 operating cycles/hr 1.0 million operations 0.2 million operations 0.2 million operations 0.2 million operations 100-240VAC / 100-220VDC 100-110, 200-220VDC 85% to 110% of the rated control voltage 7.5A (Peak) 4.0A (Peak) 0.19A (Average) 80 - 100ms 55 - 65ms 3NO-3NC 2NO-2NC Max. 480V, Min. 48V 10A 700VA (PF. 0.35) 60W (L/R 150ms) Floor Mount Vertical Installation 1000m or lower O -5 to 40 C 45 to 85% Max. 20Hz 1G Max. 30G 2500/5000kW 3500/7000kVA 2000/2000kvar 28kg 27kg IEC60470 (2000) JEM1167 (1990) *1 : Special withstand voltage (32kV-1min.) will be available by request. *1 : Special withstand voltage (32kV-1min.) will be available by request. *2 : CE marking can be available by request. 3 4 Supplied Withstand Overload Current 6 times of Ie - 30s 15 times of Ie - 1s 4000A 3200A 4000A 3200A 2400A-30s 2400A-30s 8000A-1s 8000A-1s *1 : Special withstand voltage (42kV-1min.) will be available by request. 5 41kg 40kg IEC60470 (2000) 41kg Remarks Wipe gauge For checking contact wear Trip rod For latched type only Control wire With plug (1.25mm2 X 1m) Wipe gauge The wipe gauge can be used for checking contact wear of vacuum interrupters. Refer to the instruction manual for using this gauge. Wipe gauge t=0.5 CV-6GA/6HA t=1.0 CV-6KA1/CV-10 120 Trip rod The trip rod may be used for manual tripping for latched contactor and combination unit, however this operation shall be maintenance purpose or emergency case only. Prospective Short-circuit Current 50kA 36kA Power Frequency Withstand Voltage Rated 28kV - 1 min. *1 Insulation Level Impulse Withstand voltage 75kV Switching Frequency 300 op./hr 120 op./hr 120 op./hr 300 op./hr 0.25 mill. 0.25 mill. 0.25 mill. 0.25 mill. Mechanical Life Endurance 0.10 mill. 0.10 mill. 0.10 mill. 0.10 mill. Electrical Life (AC3) Closing 100-240VAC / 100-220VDC Rated Control Voltage Tripping 100-110, 200220VDC Allowable Control Voltage Fluctuation 85% to 110% of the rated control voltage Closing 6.0A (Peak) Operating Current (at 100V) Holding/Tripping 0.13A (Av.) 4.0A (Peak) 0.13A (Av.) 4.0A (Peak) 120-145ms 120-145ms 120-145ms 120-145ms Closing Time 80-90ms 30-40ms 80-90ms 30-40ms Opening Time 4NO-2NC 2NO-1NC 4NO-2NC 2NO-1NC Contact arrangement Operational voltage Max. 480V, Min. 48V Ratings of Auxiliary Contact Thermal Current 10A AC Capacity 700VA (PF. 0.35) DC Capacity 60W (L/R 150ms) Installation Floor Mount Vertical Installation Altitude 1000m or lower Ambient air temperature -5 to 40OC Application Condition Relative humidity 45 to 85% Vibration Max. 20Hz 1G Shock Max. 30G Motor 3500kW Transformer 4500kVA Maximum Load Capacitor 5000kvar 40kg CV-10HA/10HB Non-Latched Latched Non-Latched Latched Non-Latched Latched Trip rod Coordination with Current-limiting Fuses Cut-off Current (Peak) Weight Standard CV-6KA1 Name of parts 28 Operating Mechanism Rated Voltage (Ur) Rated Operational Current (Ie) Thermal Current (Ith) Rated Frequency Rated Short-time Withstand Current (Ik) Rated peak Withstand Current (Ip) Short-circuit Making and Breaking Current (Duty) Making Current (100 times) AC4 Breaking Current (25 times) AC4 CV-6GA/6HA 10HAL 10HAL-1 Latched 10HB 10HBL 10HB-1 10HBL-1 Non-Latched Latched 12kV 12/15kV 400A 400A 450A 450A 50/60Hz 5000A - 1s 5000A - 1s 12.5kA 12.5kA 5000/4000A 5000A "O"-3min.-"CO"-3min.-"CO" "O"-3min.-"CO"-3min.-"CO" 10HA 10HA-1 Non-Latched 60 CONNECTOR WIRE Control wire Control wire The control wire with plug is provides on CV-10 series contactor, however the additional wire will be available on request. 55 Standard Vertical terminals 63 From Not supplied CV Type DIA 7 12kV/15kV High-voltage Vacuum Contactors 14 23 1000 Fig. 2 Standard accessories Supplied Not supplied CV-6GA/6HA Name of parts CV-6KA1 CV-10HA/10HB LC9 Capacitor trip device Remarks NonNonNonLatched Latched Latched Latched Latched Latched LC10 CIT-10Q For Latched type 100/110VAC for 100-110V coil 200/220VAC for 200-220V coil 100/200VAC for 100-110V coil CR Surge suppressor NV60K304T1, NV95K304T1 (See Page 13) Mechanical interlock (See Fig. 9) Capacitor trip device The capacitor trip device will be used for latched contactor when DC power source is not available. The device charges from AC power, and supplies DC power to the trip coil at trip command. The alarm contact is provided on CIT-10Q. Surge suppressor The three phase type NV60K304T1 for 3.6/7.2kV and NVK95K304T1 for 12/15kV are available. Mechanical interlock The mechanical interlock shall be used in the reversing starter to prevent mechanically from closing the forward and reverse contactors simultaneously. The following vertical pitch interlocks are available for contactors. Vertical pitch 450 mm and 550mm for CV-6GA(L)/CV-6HA(L) Vertical pitch 600mm for CV-6KA(L)1 6 OUTLINE DIMENSIONS 30 368 13 69 115 30 115 69 Non-Latched type High-Voltage Vacuum Contactors RECOMMENDED PARTITION DISTANCE 31 OPERATING CIRCUITS P or R E 202 2 The typical operating circuit is shown in Fig. 5 15 30 indicating type CV-6GA/6HA contactor. 6 the "NO" auxiliary contacts of vacuum contactor, this may cause the welding of main contacts INTERRUPTERS MAIN CIRCUIT TERMINALS 12 DIA-6 HOLES 124 10 when COUNTER (OPTION) 217 LATCH MECHANISM (FOR LATCHED TYPE) 166 134 11 DIA - 4 HOLES 2E-RY 69 115 115 69 Latched type High-Voltage Vacuum Contactors REMOTE SWITCH P E contactor. ON E 60 VMC 3 1 11 30 13 12 25 24 23 22 5 DU 21 26 D 52CC 52CC 52TC 6 GL 2 RL 7 N VMC : Vacuum contactor 52CC : Closing coil 52TC : Trip coil DU : Drive unit 4 : Control relay 21) of vacuum contactor in trip circuit, and "Late Fig. 6 Latched type operating circuit (Shunt trip) Opening NC" auxiliary contacts (16-26) of vacuum 30 14 16 Make sure to use the "NO" auxiliary contacts (11- FRONT COVER 15 4 capacitor trip device (CTD) for tripping. MAIN CIRCUIT TERMINALS OFF 2E-RY E 4 4 source is not available, employ the AC closing and 15 contactor for control relay circuit. 6 MAIN CIRCUIT TERMINALS 12 DIA-3 HOLES 124 INTERRUPTERS E COS START INTERLOCK recommended for control circuit. If the DC power 202 13 2 31 : Vacuum contactor : Closing coil : Drive unit : Control relay Fig. 5 Non-Latched type operating circuit A stable DC power source such as battery is 13 GL RL VMC 52CC DU 4 The electrical trip free circuit must be furnished in 30 24 23 22 21 6 N or T control circuit. (outside of contactor) 368 52CC 2 and Fig. 7 indicating type CV-6GAL/6HAL Fig. 3 Types CV-6GA(L)/CV-6HA(L) 30 26 25 5 DU 4 The typical operating circuits are shown in Fig. 6 DETAIL OF MOUNTING HOLES (TOP VIEW) RECOMMENDED PARTITION DISTANCE 14 13 12 11 (refer to the marked 2 in figure) 300-+ 1 (FRONT) MOUNTING HOLES 16 15 4 52CC 100-110VDC 200-220VDC CONTROL TERMINAL 10 195 219 21 1 STOP INTERLOCK pushed against coil, resulting in prolonged opening time. (REAR) 345-+ 1 166 179 10 60 is 3 discharging circuit will be formed by rectifiers MAIN CIRCUIT TERMINALS 195-+ 1 128 DIA 15 180 87654321 EARTHING TERMINAL (M8 BOLT) 300 373 button VMC 4 Should the coil be switched on AC side, a 30 AUXILIARY SWITCH 13 18 (ON) Make sure to switch the closing coil on DC side. 371 6 400 TRIP LEVER (FOR LATCHED TYPE) TRIPPING HOLE (DIA 9) start *2 ON COS START INTERLOCK incompletely. (refer to the marked 1 in figure) INDICATOR OFF ON the REMOTE SWITCH E 4 100-110VAC/DC 200-220VAC/DC operating relay (4) self-holding circuit. Do not use 30 E *1 Make sure to use the "NO" contacts of quick FRONT COVER OFF E M10 SCREW 10 REMOTE SWITCH 30 INDICATOR 371 TRIPPING HOLE (DIA 9) 166 179 10 LATCH MECHANISM (FOR LATCHED TYPE) 10 60 21 MOUNTING HOLES Fig. 4 Types CV-6HA(L)-2 195 215 10 195-+ 1 AUXILIARY SWITCH 300 373 CONTROL TERMINAL E (REAR) 345-+ 1 217 128 DIA-15 13 18 EARTHING TERMINAL (M8 BOLT) TRIP LEVER (FOR LATCHED TYPE) 87654321 180 OFF ON 166 134 11 DIA-4 HOLES ON E COS START INTERLOCK 100/110VAC 200/220VAC 6 400 R OFF 2E-RY VMC 4 3 11 15 14 13 12 CTD 4 1 5 16 DU 26 (FRONT) E P U N V 300-+ 1 DETAIL OF MOUNTING HOLES (TOP VIEW) E 52CC D 52CC 21 52TC 6 4 2 7 25 24 GL 23 22 RL T VMC : Vacuum contactor 52CC: Closing coil 52TC: Trip coil DU : Drive unit 4 : Control relay CTD : Capacitor trip device Fig. 7 Latched type operating circuit (Capacitor trip) OPERATING CIRCUITS OUTLINE DIMENSIONS Non-Latched type High-Voltage Vacuum Contactors RECOMMENDED PARTITION DISTANCE 25 390 80 115 115 80 239 18 5 205 20 P or R E The typical operating circuit is shown in Fig. 10 25 19 25 E indicating type CV-6KA1 contactor. operating relay (4) self-holding circuit. Do not use 30 INTERRUPTERS 10 the "NO" auxiliary contacts of vacuum contactor, 15 E ON VMC A1 4 16 15 14 13 12 11 COS START INTERLOCK T1 STOP INTERLOCK DU 52CC this may cause the welding of main contacts MAIN TERMINALS when DIA 13 incompletely. (refer to the marked 1 in figure) 10 120 DIA 13 4 E *1 Make sure to use the "NO" contacts of quick 15 100-110VAC/DC 200-220VAC/DC 2 FRONT COVER OFF REMOTE SWITCH the start (ON) button is 2E-RY pushed N or T VMC : 52CC : DU : 4 : 433 468 30 TRIP LEVER (FOR LATCHED TYPE) Vacuum contactor Closing coil Drive unit Control relay 273 Fig. 10 Non-Latched type operating circuit DIA 15 MOUNTING HOLES 11 DIA-4 HOLES 122 CONTROL TERMINAL FOR CLOSING 10 48 20 29 154 EARTHING TERMINAL (M8 BOLT) 368 388 Latched type High-Voltage Vacuum Contactors MOUNTING HOLES MOUNTING HOLES REMOTE SWITCH 25 208 226 P E ON E COS The typical operating circuits are shown in Fig. 10 and Fig. 11 specifying type CV-6KAL1 contactor. LATCH MECHANISM (FOR LATCHED TYPE) The electrical trip free circuit must be furnished in A1 ARM OFF ON D 52CC 52CC T2 A2 8O 25 24 23 22 GL T3 RL N VMC : Vacuum contactor 52CC: Closing coil 52TC: Trip coil DU : Drive unit 4 : Control relay 21) of vacuum contactor in trip circuit, and "NC" SHAFT (VMC) 21 52TC 4 Fig. 11 Latched type operating circuit (Shunt trip) auxiliary contacts (16-26) of vacuum contactor for VMC : OFF 13 12 DU 26 Make sure to use the "NO" auxiliary contacts (11- COUPLING 15 14 16 capacitor trip device (CTD) for tripping. ELLIPSE 2E-RY VMC 11 T1 recommended for control circuit. If the DC power source is not available, employ the AC closing and OFF T4 A stable DC power source such as battery is CV-6KA1 CV-6KAL1 E START INTERLOCK control circuit. (outside of contactor) Fig. 8 Types CV-6KA1/CV-6KAL1 E 4 100-110VDC 200-220VDC CONTROL TERMINAL FOR TRIPPING AUXILIARY SWITCH 105 TRIPPING HOLE (DIA 9) 3 24 160 190 OFF ON GL RL T2 A2 4 26 25 24 23 22 21 52CC control relay circuit. ADJUTING NUTS (M8) REMOTE SWITCH COUPLING ROD R 25 MOUNTING HOLES 11 DIA-4 HOLES E E 4 8O 468 ON OFF SHAFT (VMC) 100-110VAC 200-220VAC COS COUPLING E A1 OFF 2E-RY 29 38 368 435 10 15 14 13 12 DU 26 D 52CC T2 CTD P U N V T1 16 A2 10 VMC 11 4 128 154 266 T4 START INTERLOCK M8 BOLTS FOR FIXING INTERLOCK UNIT DETAIL OF INTERLOCKING MECHANISM Fig. 9 Mechanical Interlock on CV-6KA(L)1 9 ON E ARM 160 P VMC : OFF PITCH BETWEEN CONTACTORS ADJUTING NUTS (M8) 52CC 21 52TC T3 25 24 GL 23 22 RL T VMC : 52CC: 52TC: DU : 4 : CTD : Vacuum contactor Closing coil Trip coil Drive unit Control relay Capacitor trip device Fig. 12 Latched type operating circuit (Capacitor trip) 10 OUTLINE DIMENSIONS OPERATING CIRCUITS Non-Latched type High-Voltage Vacuum Contactors RECOMMENDED PARTITION DISTANCE P or R E The typical operating circuit is shown in Fig. 15 E 110 475 8 165 137 65 165 37 15 8 165 30 6 INTERRUPTERS 165 100-110VAC/DC 200-220VAC/DC indicating type CV-10HA/10HB contactor. 65 Make sure to use the "NO" contacts of quick operating relay (4) self-holding circuit. Do not use the "NO" auxiliary contacts of vacuum contactor, LIFTING HOLES (20 DIA -2 HOLES) OFF REMOTE SWITCH E E 206 when the start (ON) button is 4 7 5 3 1 12 10 8 6 4 2 11 COS 9 1 START INTERLOCK 5 STOP INTERLOCK 52CC 52CC DU 6 2 2E-RY pushed incompletely. (refer to the marked 1 in figure) VMC AUS 4 T11 T15 T16 T17 T18 T19 T20 N or T 6 15 MAIN CIRCUIT TERMINALS 13 DIA- 6 HOLES T5 T6 T7 T8 T9 T10 T1 ON *1 this may cause the welding of main contacts INSULATION BARRIER 4 565 VMC 52CC DU 4 474 METAL COVER 320 Fig. 15 Non-Latched type operating circuit 63 COUNTER (OPTION) CONTROL CONNECTOR 170 200 INDICATOR TRIPPING HOLES (DIA 9) MOUNTING HOLES (14 DIA-4 HOLES) 13 500 REMOTE SWITCH 24 146 23 P Latched type High-Voltage Vacuum Contactors 193 13 235 526 ON E E COS contactor. 165 165 8 165 17 15 8 140 137 6 165 30 91 T8 T3 9 7 5 3 1 10 8 6 4 2 VMC 52CC 52CC 52TC 6 T15 4 2 4 T11 T16 T17 T18 T13 N VMC : Vacuum contactor 52CC : Closing coil 52TC : Trip coil DU : Drive unit 4 : Control relay source is not available, employ the AC closing and capacitor trip device (CTD) for tripping. Make sure to use the "NO" auxiliary contacts (1-2 INTERRUPTERS D DU control circuit. (outside of contactor) 75 65 1 12 recommended for control circuit. If the DC power 475 T7 OFF 2E-RY AUS 5 A stable DC power source such as battery is 65 T6 E T5 11 The electrical trip free circuit must be furnished in RECOMMENDED PARTITION DISTANCE T1 START INTERLOCK 100-110VDC 200-220VDC and Fig. 17 specifying type CV-10HAL/10HBL Fig. 13 Types CV-10HA(L)/CV-10HB(L) E 4 The typical operating circuits are shown in Fig. 16 115 : Vacuum contactor : Closing coil : Drive unit : Control relay Fig. 16 Latched type operating circuit (Shunt trip) and 3-4) of vacuum contactor in trip circuit LIFTING HOLES (20 DIA-2 HOLES) 245 (connected in contactor), and "NC" auxiliary INSULATION BARRIER 6 MAIN CIRCUIT TERMINALS 13 DIA-6 HOLES contacts (11-12) of vacuum contactor for control REMOTE SWITCH relay circuit. R 15 606 E ON E 30 100-110VAC 200-220VAC 346 COUNTER (OPTION) CONTROL CONNECTOR 63 170 200 INDICATOR 500 13 1 146 D DU T8 5 T3 3 OFF 2E-RY VMC 1 CTD 52CC 6 4 2 P U N V 52CC 52TC 6 4 2 T11 23 10 8 5 T15 24 T7 AUS 9 7 E T5 11 4 13 T6 START INTERLOCK 12 TRIPPING HOLES (DIA 9) E T1 COS 474 METAL COVER 4 T16 T17 T18 T13 T 526 193 MOUNTING HOLES (14 DIA-4 HOLES) 215 Fig. 14 Types CV-10HA(L)-1/CV-10HB(L)-1 11 VMC : Vacuum contactor 52CC: Closing coil 52TC: Trip coil DU : Drive unit 4 : Control relay CTD : Capacitor trip device Fig. 17 Latched type operating circuit (Capacitor trip) 12 CAPACITOR APPLICATION OPERATING COIL EXCITATION The current limiting fuses shall be combined for capacitor switching application. Non-Latched (Continuous Excitation) The series reactor shall be connected, especially back-to-back application. Mainly applied to frequent switching operation such as motor. Service life of capacitor switching The switching, opening and closing, of capacitor produces severe condition for contactor, such as Latched (Instantaneous Excitation) Mainly applied to non-frequent switching operation and/or to the important load which high frequency inrush current and interpole recovery voltage higher than twice of normal voltage. require to be contact closed even by power loss. The criteria of maximum number of capacitor switching are shown in the figure below. The vacuum interrupters should be replaced when the number of switching operations reached to point shown in figure. PROTECTION COORDINATION The protection coordination with upper/lower stream relay shall be evaluated by considering total system and load characteristics. 100 The single-phase protection shall be performed which may be occurred by power fuses. APPLICATION GUIDE TO SURGE No surge protection is required except for special application, however the insulation coordination shall be evaluated by following table. Load Protection Notice The surge suppressor shall be installed for machine rated at 55kW or below, and/or be subject to inching operation. Rotating Machine Not required The surge suppressor shall be installed between starting contactor and autotransformer for machine started by autotransformer. Switching Life (Thousand Op.) (Apply 2E-relay or fuse blown detection which is provided on combination unit as standard.) 50 40 30 20 10 20 The suppressor shall be installed for machine which has inferior insulation. Dry-type Transformer Not required The surge arrester shall be installed for transformer rated at 30 50 100 200 300 400 Switc hing Curre nt (A) Fig. 18 Capacitor Switching Life (with 6% reactor) 150kVA or below and exciting inrush is interrupted. The installation of suppressor and insulation coordination shall Oil-immersed Transformer Not required be evaluated when the low surge level apparatus are connected on secondary circuit of transformer. Capacitor Not required Refer to the clause for capacitor application. The surge suppressor is composed of capacitor and series resistor, and is one of the most excellent protection mediums. The device features suppression as well as a decrease of surge generation. Particularly being free from limitation on the number of operating times, this device is suitable for protecting motors and transformer required performing frequent operations. The surge arrester has no effect of suppressing the surge generation, this suppresses overvoltage to within a fixed level. CONTROL TRANSFORMER The contactor can be operated with following burden of control transformer. Type Form (Contactor) 13 Control Transformer CV-6GA(L), 6HA(L) 400VA or more CV-6KA(L)1 600VA or more CV-10HA(L), 10HB(L) 500VA or more VT 100VA 10P10 Ordering Information Non-Latched Type Vacuum Contactor 1. Type-Form CV2. Quantity Set(s) 3. Ratings Voltage(Ur) kV Current (Ie) A Short-circuit Making & Breaking Current kA 4. Operating voltage VDC or AC 5. Options, Accessories, Spare Parts 6. Special Operating Condition Latched Type Vacuum Contactor 1. Type-Form CV2. Quantity Set(s) 3. Ratings Voltage(Ur) kV Current (Ie) A Short-circuit Making & Breaking Current kA 4. Operating voltage Closing VDC or AC Tripping VDC 5. Options, Accessories, Spare Parts 6. Special Operating Condition 14