* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

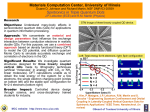

Download Fabrication and characterization of single luminescing quantum dots

X-ray photoelectron spectroscopy wikipedia , lookup

Coherent states wikipedia , lookup

Density matrix wikipedia , lookup

Quantum entanglement wikipedia , lookup

Quantum dot cellular automaton wikipedia , lookup

Quantum fiction wikipedia , lookup

Double-slit experiment wikipedia , lookup

Orchestrated objective reduction wikipedia , lookup

Symmetry in quantum mechanics wikipedia , lookup

Bohr–Einstein debates wikipedia , lookup

Many-worlds interpretation wikipedia , lookup

Bell's theorem wikipedia , lookup

Delayed choice quantum eraser wikipedia , lookup

Hydrogen atom wikipedia , lookup

Quantum electrodynamics wikipedia , lookup

Wave–particle duality wikipedia , lookup

Quantum computing wikipedia , lookup

Theoretical and experimental justification for the Schrödinger equation wikipedia , lookup

Quantum teleportation wikipedia , lookup

Interpretations of quantum mechanics wikipedia , lookup

Particle in a box wikipedia , lookup

EPR paradox wikipedia , lookup

History of quantum field theory wikipedia , lookup

Quantum machine learning wikipedia , lookup

Quantum group wikipedia , lookup

Canonical quantization wikipedia , lookup

Quantum state wikipedia , lookup

Hidden variable theory wikipedia , lookup

X-ray fluorescence wikipedia , lookup