* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Anisotropy of Elastic Behavior

Negative-index metamaterial wikipedia , lookup

Multiferroics wikipedia , lookup

Piezoelectricity wikipedia , lookup

Microelectromechanical systems wikipedia , lookup

Ferromagnetism wikipedia , lookup

Fracture mechanics wikipedia , lookup

Jahn–Teller effect wikipedia , lookup

History of metamaterials wikipedia , lookup

Density of states wikipedia , lookup

Cauchy stress tensor wikipedia , lookup

Tensor operator wikipedia , lookup

Fatigue (material) wikipedia , lookup

Acoustic metamaterial wikipedia , lookup

Pseudo Jahn–Teller effect wikipedia , lookup

Strengthening mechanisms of materials wikipedia , lookup

Viscoplasticity wikipedia , lookup

Deformation (mechanics) wikipedia , lookup

Sol–gel process wikipedia , lookup

Paleostress inversion wikipedia , lookup

Seismic anisotropy wikipedia , lookup

Spinodal decomposition wikipedia , lookup

Colloidal crystal wikipedia , lookup

Crystal structure wikipedia , lookup

Elastic Properties and Anisotropy of

Elastic Behavior

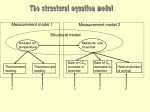

Figure 7-1 Anisotropic materials: (a) rolled material,

(b) wood, (c) glass-fiber cloth in an epoxy matrix, and

(d) a crystal with cubic unit cell.

• Real materials are never perfectly isotropic. In some

cases (e.g. composite materials) the differences in

properties for different directions are so large that one

can not assume isotropic behavior - Anisotropic.

• There is need to discuss Hooke’s Law for anisotropic

cases in general. This can then be reduced to isotropic

cases - material property (e.g., elastic constant) is the

same in all directions.

• In the general 3-D case, there are six components of

stress and a corresponding six components of strain.

• In highly anisotropic materials, any one component of

stress can cause strain in all six components.

• For the generalized case, Hooke’s law may be expressed

as:

i Cij j

(7-1)

i Sij j

(7-2)

where,

C Stiffness (or Elastic cons tan t )

S Compliance

• Both Sijkl and Cijkl are fourth-rank tensor quantities.

• Expansion of either Eqs. 7-1 or 7-2 will produce nine

(9) equations, each with nine (9) terms, leading to 81

constants in all.

• It is important to note that both ij and ij are symmetric

tensors.

• Symmetric tensor

Means that the off-diagonal

components are equal. For example, in case of stress:

13 31 , 12 21

23 32

We can therefore write:

11 12 13 11 12 13

21 22 23 12 22 23

31 32 33 13 23 33

(7-3)

Similarly, the strain tensor can be written as:

11 12 13 11 12 13

21 22 23 12 22 23

31 32 33 13 23 33

(7-4)

• Symmetry effect leads to a significant simplification of

the stress-strain relationship of Eqs. 7-1 and 7-2.

We can write:

ij Sijkl kl or ij Sijlk lk

and since

Sijkl kl Sijlk lk ; kl lk ; and Sijkl Sijlk

We can also write:

ij Sijkl kl ji S jikl kl

Sijkl S jikl

• The direct consequence of the symmetry in the

stress and strain tensors is that only 36

components of the compliance tensor are

independent and distinct terms.

• Similarly, only 36 components of the stiffness

tensor are independent and distinct terms.

Additional simplification of the stress-strain relationship

can be realized through simplifying the matrix notation

for stresses and strains.

We can replace the indices as follows:

11 1

23 4

22 2

13 5

33 3

12 6

11 12 13

22 23

33

Notation I

1

=

5

2 4

3

6

Notation II

• The foregoing transformation is easy to remember: In

other to obtain notation II, one must proceed first along

the diagonal (1 2 3 ) and then back ( 4 5 6 ).

• Notation II method makes life very easy when

correlating the stresses and strains for general case, in

which the elastic properties of a material are dependent

on its orientations.

We now have the stress and strain, in general form, as

1

6

5

6

2

4

1

5

4 and 6

2

3

5

2

6

2

2

4

2

5

2

4

2

3

It should be noted that

and 3 33, but

22

2 ,11 1 ,

4 2 23 23

5 213 13

6 212 12

(7-5)

In matrix format, the stress-strain relation showing the

36 (6 x 6) independent components of stiffness can be

represented as:

1 C11

2 C21

C

3 31

4 C41

C

5 51

6 C61

C12

C13

C14

C15

C22

C23 C24

C25

C32

C33

C34

C35

C42

C43 C44

C45

C52

C53

C54

C55

C62

C63

C64

C65

C16 1

C26 2

C36 3

C46 4

C56 5

C66 6

Or in short notation, we can write:

i Cij j and i Sij j

(7-6)

Further reductions in the number of independent

constants are possible by employing other symmetry

considerations to Eq. 7-6.

• Symmetry in Stiffness and Compliance matrices

requires that:

Cij C ji and Sij S ji

Of the 36 constants, there are six constants where i = j,

leaving 30 constants where i j.

But only one-half of these are independent constants

since Cij = Cji

Therefore, for the general anisotropic linear elastic solid

there are: 30

2

6 21

independent elastic constant.

• The 21 independent elastic constants can be reduced still

further by considering the symmetry conditions found in

different crystal structures.

• In Isotropic case, the elastic constants are reduced from

21 to 2.

• Different crystal systems can be characterized exclusively

by their symmetries. Table 7-1 presents the different

symmetry operations defining the seven crystal systems.

• The seven crystalline systems can be perfectly described

by their axes of rotation. For example, a threefold rotation

is a rotation of 120o (3 x 120o = 360o); after 120o the

crystal system comes to a position identical to the initial

one.

Table 7.1 Minimum Number of Symmetry Operations in

Various Systems

______________________________________________

System

Rotation

______________________________________________

Triclinic

None (or center of symmetry)

Monoclinic

1 twofold rotation

Orthorhombic

2 perpendicular twofold rotation

Tetragonal

1 fourfold rotation around [001]

Rhombohedral

1 threefold rotation around [111]

Hexagonal

1sixfold rotation around [0001]

Cubic

4 threefold rotations around <111>

abc

90

o

abc

90

o

abc

90

o

The hexagonal system exhibits a sixfold rotation around the

[0001] - c axis; after 60 degrees, the structure superimposes

upon itself.

In terms of a matrix, we have the following:

Orthorhombic

Tetragonal

11 12 13 0 0 0 11 12 13 0 0 16

. 22 23 0 0 0 . 11 13 0 0 16

. 33 0 0 0 .

. 33 0 0

0

.

,

.

.

. 44 0 0

.

.

. 44 0

0

.

.

. 55 0 .

.

.

. 44 0

.

.

.

.

. 66 .

.

.

.

.

66

.

(7.7a)

Hexagonal

11 12 13 0 0

. 11 13 0 0

. 33 0 0

.

.

.

. 44 0

.

.

. 44

.

0

0

0

0

x

(7.7b)

where

x 2( s11 s12 ),

or

1

x (C11 C12 )

2

• Laminated composites made by the consolidation of

prepregged sheets, with individual piles having

different fiber orientations, have orthotropic symmetry

with nine independent elastic constant.

• This is analogous to orthorhombic symmetry, and

possess symmetry about three orthogonal (oriented 90o

to each other) planes. The elastic constants along the

axes of these three planes are different.

Cubic

11 12 12 0 0 0

. 11 12 0 0 0

. 11 0 0 0

.

. 44 0 0

.

.

. 44 0

.

.

.

. 44

(7.7c)

The number of independent elastic constants in a cubic system

is three (3).

For isotropic materials ( most polycrystalline aggregates can

be treated as such) there are two (2) independent constants, b/c :

C44

C11 C12

2

(7.8)

The stiffness matrix of an isotropic system is:

C11 C12 C12

. C

C12

11

. C11

.

.

.

.

.

.

.

.

.

.

0

0

0

0

0

C11 C12

2

0

0

.

C11 C12

2

.

.

0

0

0

0

C11 C12

2

0

(7.9)

For cubic systems, Equation (7-8) does not apply, and we

define an anisotropy ratio (also called the Zener anisotropy

ratio, in honor of the scientist who introduced it):

2C44

A

C11 C12

(7.10)

• Several metals have high “A” anisotropy ratio.

• Aluminum and tungsten, have values of A very close

to 1. Single crystals of tungsten are almost isotropic.

Elastic compliances - for the isotropic case:

0

0

0

S11 S12 S12

. S

S

0

0

0

11

12

. S11

0

0

0

.

.

.

. 2( S11 S12 )

0

0

.

.

.

2( S11 S12 )

0

.

.

.

.

.

.

2

(

S

S

)

11

12

(7.11)

Similarly, the 81 components of elastic compliance for the

cubic system have been reduced to three (3) independent

ones while for the isotropic case, only two (2) independent

elastic constants are needed.

The elastic constants for an isotropic material are given

by:

Young’s modulus

1

E

S11

(7.12)

Rigidity or Shear modulus

1

1

G

2( S11 S12 )

S4

(7.13)

Compressibility (B) and bulk modulus (K):

1

11 22 33

B

K 1 ( )

11

12

13

3

(7.14)

Poisson’s ratio

S12

v

S11

(7.15)

1

1

u C44 (C11 C12 )

G

2

S44

(7.16)

C12

(7.17)

Lame’s constants:

• The equation to determine the compliance of isotropic

materials can be written as (by using Eqs. 7-2 and 7-11):

1 S11

2 S12

S

3 12

4 0

0

5

6 0

S12

S12

0

0

0

S11

S12

0

0

0

S12

S11

0

0

0

0

0

2S11 S12

0

0

0

0

0

2S11 S12

0

0

0

0

0

2S11

1

2

3

4

5

S12 6

(7.18)

The relationship of Eq. 7-18 can be expanded and equated to

Eq. 6-9 to give:

1

1 S11 1 S12 2 S12 3 1 2 3

E

1

2 S12 1 S11 2 S12 3 2 1 3

E

1

3 S12 1 S12 2 S11 3 3 1 2

E

(7.19)

Also,

4 2S11

5 2S11

6 2S11

1

S12 4 4 ,

G

1

S12 5 5 ,

G

1

S12 6 6 ,

G

(7.19)

• Expressing the strains as function of stresses, we have

1 C111 C12 2 C12 3 2 1 2 3 ,

2 C121 C11 2 C12 3 1 2 2 3 ,

3 C121 C12 2 C11 3 1 2 2 3 ,

1

4 C11 C12 4 4

2

1

5 C11 C12 5 5

2

1

6 C11 C12 6 6

2

(7.20)

Note : G

• A great number of materials can be treated as isotropic,

although they are not microscopically so.

• Individual grains exhibit the crystalline anisotropy and

symmetry, but when they form a poly-crystalline aggregate

and are randomly oriented, the material is microscopically

isotropic.

• If the grains forming the poly-crystalline aggregate have

preferred orientation, the material is microscopically

anisotropic.

• Often, material is not completely isotropic; if the

elastic modulus E is different along three perpendicular

directions, the material is Orthotropic; composites are a

typical case.

In a cubic material, the elastic moduli can be determined

along any orientation, from the elastic constants, by the

application of the following equations:

1

1

S11 2( S11 S12 S44 )(li21l 2j 2 l 2j 2lk23 li21lk23

Eijk

2

(7.21a)

1

1

S44 4( S11 S12 S44 )(li21l 2j 2 l 2j 2lk23 li21lk23

Gijk

2

(7.21b)

Eijk and Gijk are the Young’s and shear modulus, respectively, in

the [ijk] direction; li1 , l j 2 , lk 3 are the direction cosines of the

direction [ijk]

Table 7-2 Stiffness and compliance constants for cubic crystals

___________________________________________________

Metal

C11

C12

S11

S44

C44

S12

___________________________________________________

Aluminum

10.82

6.13

2.85

1.57

-0.57

3.15

Copper

16.84 12.14

7.54

1.49

-0.62

1.33

Iron

23.70 14.10 11.60 0.80

-0.28 0.86

Tungsten

50.10 19.80 15.14 0.26

-0.07

0.66

___________________________________________________

Stiffness constants in units of 10-10 Pa.

Compliance in units of 10-11 Pa

Using the direction cosines l, m, n (as described in the text book)

the equation for determining the Elastic Moduli along any direction

is given by:

1

1

S11 2[(S11 S12 ) S44 ](l 2 m 2 m 2 n 2 l 2 n 2 )

E

2

(7.22)

Typical values of elastic constants for cubic metals are given in

Table 7.2.

All the relations described in Eqs. 7-12 to 7-20 for obtaining Elastic

constants are applicable. This include:

1

S11

E

v

S12

E

1

S44

G

Example

A hydrostatic compressive stress applied to a material

with cubic symmetry results in a dilation of -10-5. The

three independent elastic constants of the material are

C11 = 50 GPa, C12 = 40 GPa and C44 = 32 GPa. Write an

expression for the generalized Hooke’s law for the

material, and compute the applied hydrostatic stress.

SOLUTION

Dilation is the sum of the principal strain components:

= 1 + 2 + 3 = -10-5

Cubic symmetry implies that 1 = 2 = 3 = -3.33 x10-5

and

4 = 5 = 6 = 0

From Hooke’s law,

i = Cijj

1 C111 C12 2 C12 3

and

the applied hydrostatic stress is:

p = 1 = (50 + 40 + 40)(-3.33) 103 Pa

= -130 x 3.33 x 103 = -433 kPa

Example: Determine the modulus of elasticity for tungsten and iron

in the <111> and <100> directions. What conclusions can be drawn

about their elastic anisotropy? From Table 7.1

____________________________

Fe:

W:

S12 S44

S11

________________

0.80 -0.28 0.86

0.26 -0.07 0.66

SOLUTION

The direction cosines for the chief directions in a cubic lattice are:

_______________________________________

Directions

li1

l j2

lk 3

_______________________________________

<100>

1

0

0

<110>

0

1/ 2

1/ 2

1/ 3

<111>

1/ 3

1/ 3

For iron:

1

1 1 1

0.80 2{(0.80 0.28) 0.86 / 2}

E111

9 9 9

1

1

1

0.80 2(1.08 0.43) 0.80 1.30

E111

3

3

0.80 0.43

1

E111

2.70 x1011 Pa

0.37

1

0.80 1.30(0) 0.80

E100

E100 1.25x1011 Pa

For tungsten:

1

0.66 1

0.26 2(0.26 0.07)

E111

2 3

1

1

0.26 20.33 0.33 0.26

E111

3

1

E111

3.85x1011 Pa 385GPa

0.26

1

0.66

0.26 2(0.26 0.07)

0 0.26

E100

2

E100

1

3.85x1011 Pa

0.26

Therefore, we see that tungsten is elastically isotropic while iron

is elastically anisotropic.