Class 7

... relatively soft and easy to deform into different shapes. It will retain this shape until the temperature exceeds the phase transition temperature, at which point the material reverts to its parent structure known as Austenite. ...

... relatively soft and easy to deform into different shapes. It will retain this shape until the temperature exceeds the phase transition temperature, at which point the material reverts to its parent structure known as Austenite. ...

6 The scaling of silicon on insulator

... channel of these devices is around the saturation electron velocity in the bulk silicon (~107cm2/V-s). This is an indication that the simulation, which does not include velocity overshoot effects, underestimates device performance. Further reasons to expect higher performance in the simulated device ...

... channel of these devices is around the saturation electron velocity in the bulk silicon (~107cm2/V-s). This is an indication that the simulation, which does not include velocity overshoot effects, underestimates device performance. Further reasons to expect higher performance in the simulated device ...

Embedded Capacitance Fabrication Process Guide

... fabricator’s inner layer processing capability. Standard processing speeds, materials and chemistry can be used for wet chemical clean, dry film lamination, UV expose and Develop, Etch and Strip (DES). The material does not have metal tie layers or other adhesion promoters that require special proce ...

... fabricator’s inner layer processing capability. Standard processing speeds, materials and chemistry can be used for wet chemical clean, dry film lamination, UV expose and Develop, Etch and Strip (DES). The material does not have metal tie layers or other adhesion promoters that require special proce ...

Thin film high value resistor

... standard deviation by 50%. A very tight sheet resistance spec window was achieved for all NiCr process flows of difference technologies. A novel approach for uniformity fine tuning by wafer position adjustment was also introduced in this paper and within-wafer uniformity can reach <1% using this app ...

... standard deviation by 50%. A very tight sheet resistance spec window was achieved for all NiCr process flows of difference technologies. A novel approach for uniformity fine tuning by wafer position adjustment was also introduced in this paper and within-wafer uniformity can reach <1% using this app ...

Effects of silicon on seed setting rate of rice intersubspecific hybrids

... treatment for the 2 intersubspecies hybrids. The in vitro germination rate of pollen after silicon processing was 75.15 ± 1.28% and 76.23 ± 1.34% (Figure 4B), in treatment and non-treatment group, respectively, whereas the in vitro germination rate without silicon processing was 46.7 ± 1.5% and 48.1 ...

... treatment for the 2 intersubspecies hybrids. The in vitro germination rate of pollen after silicon processing was 75.15 ± 1.28% and 76.23 ± 1.34% (Figure 4B), in treatment and non-treatment group, respectively, whereas the in vitro germination rate without silicon processing was 46.7 ± 1.5% and 48.1 ...

AMM&NS programme

... In this work, sidewall profile and roughness of silicon waveguides (made up of via/trench) fabricated by Reactive Ion Etching (RIE) process using the P5000 etcher of the Applied Materials was investigated. The critical roles of the SF6 and HeO2 gas flow rate (the chemical etching component), as wel ...

... In this work, sidewall profile and roughness of silicon waveguides (made up of via/trench) fabricated by Reactive Ion Etching (RIE) process using the P5000 etcher of the Applied Materials was investigated. The critical roles of the SF6 and HeO2 gas flow rate (the chemical etching component), as wel ...

Silicon Detectors

... (SNR). A good detector should have a large SNR. However this leads to two contradictory requirements:! # Large signal " low ionisation energy " small band gap! # Low noise " very few intrinsic charge carriers " large band gap! An optimal material should have Eg ≈ 6 eV. ! In this case the conduct ...

... (SNR). A good detector should have a large SNR. However this leads to two contradictory requirements:! # Large signal " low ionisation energy " small band gap! # Low noise " very few intrinsic charge carriers " large band gap! An optimal material should have Eg ≈ 6 eV. ! In this case the conduct ...

Principle of ductile regime machining

... one approach to prolong tool life is to apply ultrasonic vibration to the diamond cutting tool with vibration during cutting, the lubricant can easily penetrate the cutting zone. Also, the shatter contact time between the cutting tool and work material improves the tool life. In addition to incr ...

... one approach to prolong tool life is to apply ultrasonic vibration to the diamond cutting tool with vibration during cutting, the lubricant can easily penetrate the cutting zone. Also, the shatter contact time between the cutting tool and work material improves the tool life. In addition to incr ...

- Universiti Teknikal Malaysia Melaka Repository

... MOSFET such as double gate MOSFET, vertical MOSFET, silicon on insulator and many more. ...

... MOSFET such as double gate MOSFET, vertical MOSFET, silicon on insulator and many more. ...

Animating Matter: Creating Organic

... As HCI researchers we always look for new ways to enrich human computer interactions. Engelbart and Sutherland pioneered the field with a human-centered approach to technology that emphasizes the human experience. Buxton, Fitzmaurice and Ishii [2] presented the vision of physical-digital interaction ...

... As HCI researchers we always look for new ways to enrich human computer interactions. Engelbart and Sutherland pioneered the field with a human-centered approach to technology that emphasizes the human experience. Buxton, Fitzmaurice and Ishii [2] presented the vision of physical-digital interaction ...

ABCStar for ATLAS Strips

... • After the first ABC ASICs (named ABC130) were designed and fabricated on the IBM 130nm technology, the ATLAS trigger rate requirement was increased to 1 MHz. • The ABC130/HCC readout architecture could not support this 1 MHz rate and, therefore, a design change was required. • The fundamental chan ...

... • After the first ABC ASICs (named ABC130) were designed and fabricated on the IBM 130nm technology, the ATLAS trigger rate requirement was increased to 1 MHz. • The ABC130/HCC readout architecture could not support this 1 MHz rate and, therefore, a design change was required. • The fundamental chan ...

ppt - UCSB HEP

... Was implemented to stop digitisation early. Found to make chip go into a high current state. Now SRC & FIB protect against this ...

... Was implemented to stop digitisation early. Found to make chip go into a high current state. Now SRC & FIB protect against this ...

Integrated circuits in military equipment

... manufacturers are exploring their use for high-volume logic applications. The choice of modular circuits or discrete components in new computer design is difficult, and the decision cannot be made by comparing one component approach with another because the alternative circuits seldom have the same ...

... manufacturers are exploring their use for high-volume logic applications. The choice of modular circuits or discrete components in new computer design is difficult, and the decision cannot be made by comparing one component approach with another because the alternative circuits seldom have the same ...

Ink-jet printed nanoparticle microelectromechanical

... ICROFABRICATION of electronic and mechanical structure at the submillimeter scale is typically a time-consuming and expensive process. Lithographic techniques for silicon micromachining, used to fabricate integrated circuits and MEMS, typically take several weeks to go from drawings to completed chi ...

... ICROFABRICATION of electronic and mechanical structure at the submillimeter scale is typically a time-consuming and expensive process. Lithographic techniques for silicon micromachining, used to fabricate integrated circuits and MEMS, typically take several weeks to go from drawings to completed chi ...

SiT5001 - SiTime

... • Revised initial tolerance, stability over temperature and first/10 year aging values in the electrical characteristics table • Revised frequency stability option ...

... • Revised initial tolerance, stability over temperature and first/10 year aging values in the electrical characteristics table • Revised frequency stability option ...

Supplementary Information for

... cylindrical arc of radius 432/pi. The SRR was then patterned Simulation unit cell. in the plane of the bent cantilever, ensuring that it, too, will have the correct angle. As a result of this method, it should be noted that the angle = 0 simulations were actually angle = .01 degrees. Since the physi ...

... cylindrical arc of radius 432/pi. The SRR was then patterned Simulation unit cell. in the plane of the bent cantilever, ensuring that it, too, will have the correct angle. As a result of this method, it should be noted that the angle = 0 simulations were actually angle = .01 degrees. Since the physi ...

Market Survey Request 1. SCOPE The deposition system specified

... In addition to what is mentioned about the scope of the system, there are some features of the system that we consider will be of importance for realizing high quality coatings for our process now and in the near future process developments. It is required that the substrate table is electrically is ...

... In addition to what is mentioned about the scope of the system, there are some features of the system that we consider will be of importance for realizing high quality coatings for our process now and in the near future process developments. It is required that the substrate table is electrically is ...

Concept and Proposal Augmenting the Design Flow with

... At some level of k1, the context of the circuit and the device must be considered carefully ...

... At some level of k1, the context of the circuit and the device must be considered carefully ...

EE 2 Fall 2007

... electrons. When one of these impurity atoms is substituted for silicon in the crystal lattice, four of the five electrons complete the four covalent bonds and the fifth electron is not participating in the covalent bond and is weakly bound to the site of the impurity atom. It takes very small amount ...

... electrons. When one of these impurity atoms is substituted for silicon in the crystal lattice, four of the five electrons complete the four covalent bonds and the fifth electron is not participating in the covalent bond and is weakly bound to the site of the impurity atom. It takes very small amount ...

L12a_4345_Sp02

... Since substrate modulation can inject substantial noise into high-impedance circuitry consider placing wells under resistors and capacitors to isolate them from substrate noise coupling. ...

... Since substrate modulation can inject substantial noise into high-impedance circuitry consider placing wells under resistors and capacitors to isolate them from substrate noise coupling. ...

Section 2 – Kulite Sensing Technology

... insulating layer of silicon dioxide between. This technology is referred to as either “silicon on silicon” ,”silicon on insulator” or “dielectrically isolated silicon strain gauges”. This single development resulted in the extension of the maximum operating temperature capability from 150°C up to 54 ...

... insulating layer of silicon dioxide between. This technology is referred to as either “silicon on silicon” ,”silicon on insulator” or “dielectrically isolated silicon strain gauges”. This single development resulted in the extension of the maximum operating temperature capability from 150°C up to 54 ...

Lecture 2

... • When doped into Si, 4 electrons used to form the covalence bond with Si. • 1 extra electron is left in the outermost shell and will occupy a new energy level called Donor Energy. • Energy required to elevate donor electron is less than that for electron involved in covalence bonding. • With small ...

... • When doped into Si, 4 electrons used to form the covalence bond with Si. • 1 extra electron is left in the outermost shell and will occupy a new energy level called Donor Energy. • Energy required to elevate donor electron is less than that for electron involved in covalence bonding. • With small ...

Atom-size gaps and contacts between electrodes

... demand methods to fabricate various nanostructured materials and devices.1–3 This letter describes a self-terminated electrochemical method to fabricate atomic-scale contacts and gaps between two metallic electrodes. The conductance of the contacts varies in a stepwise fashion with a tendency to qua ...

... demand methods to fabricate various nanostructured materials and devices.1–3 This letter describes a self-terminated electrochemical method to fabricate atomic-scale contacts and gaps between two metallic electrodes. The conductance of the contacts varies in a stepwise fashion with a tendency to qua ...

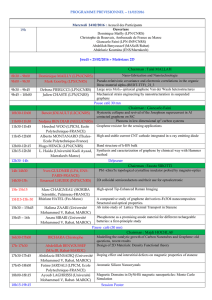

Nano-TN 2016 Program

... Photoelectron spectroscopic studies of ultra-thin CuPc layers on Si(111)√3 × √3 R30°Ag surface 2D-TEM investigations of CNTs synthetized within vertical-PAA templates for devices applications Raman study of zigzag configuration of C70 inside single wall carbon nanotube Déjeuner ...

... Photoelectron spectroscopic studies of ultra-thin CuPc layers on Si(111)√3 × √3 R30°Ag surface 2D-TEM investigations of CNTs synthetized within vertical-PAA templates for devices applications Raman study of zigzag configuration of C70 inside single wall carbon nanotube Déjeuner ...

Comprehensive investigation of sequential plasma activated Si/Si

... using oxygen (O2 ) reactive ion etching (RIE) plasma followed by nitrogen (N2 ) microwave (MW) radicals. This treatment is called surface activation, which removes contaminants (i.e. hydrocarbon and metal ions from tweezers), native oxides (i.e. SiO2 in the case of silicon (Si)), and particles from ...

... using oxygen (O2 ) reactive ion etching (RIE) plasma followed by nitrogen (N2 ) microwave (MW) radicals. This treatment is called surface activation, which removes contaminants (i.e. hydrocarbon and metal ions from tweezers), native oxides (i.e. SiO2 in the case of silicon (Si)), and particles from ...

Microelectromechanical systems

Microelectromechanical systems (MEMS) (also written as micro-electro-mechanical, MicroElectroMechanical or microelectronic and microelectromechanical systems and the related micromechatronics) is the technology of very small devices; it merges at the nano-scale into nanoelectromechanical systems (NEMS) and nanotechnology. MEMS are also referred to as micromachines (in Japan), or micro systems technology – MST (in Europe).MEMS are separate and distinct from the hypothetical vision of molecular nanotechnology or molecular electronics. MEMS are made up of components between 1 to 100 micrometres in size (i.e. 0.001 to 0.1 mm), and MEMS devices generally range in size from 20 micrometres to a millimetre (i.e. 0.02 to 1.0 mm). They usually consist of a central unit that processes data (the microprocessor) and several components that interact with the surroundings such as microsensors. At these size scales, the standard constructs of classical physics are not always useful. Because of the large surface area to volume ratio of MEMS, surface effects such as electrostatics and wetting dominate over volume effects such as inertia or thermal mass.The potential of very small machines was appreciated before the technology existed that could make them (see, for example, Richard Feynman's famous 1959 lecture There's Plenty of Room at the Bottom). MEMS became practical once they could be fabricated using modified semiconductor device fabrication technologies, normally used to make electronics. These include molding and plating, wet etching (KOH, TMAH) and dry etching (RIE and DRIE), electro discharge machining (EDM), and other technologies capable of manufacturing small devices. An early example of a MEMS device is the resonistor – an electromechanical monolithic resonator.