4-single-crystal wafers to solar cells

... attached to both the n-type and the p-type region ,the metal to be deposited is heated in a vacuum to a high enough temp to cause it to melt and vaporize, it will then condense on any cooler parts of the vacuum system in direct line of sight, including the solar cells, the back contact is normally d ...

... attached to both the n-type and the p-type region ,the metal to be deposited is heated in a vacuum to a high enough temp to cause it to melt and vaporize, it will then condense on any cooler parts of the vacuum system in direct line of sight, including the solar cells, the back contact is normally d ...

Si-Con™ 4X Low Concentration PV

... A solution to this problem was found by developing technologies which enable the solar radiation to be concentrated onto a smaller geometric area of Silicon. Using concentrator technology requires a significantly smaller area of costly Silicon while still producing the desired level of power. The Si ...

... A solution to this problem was found by developing technologies which enable the solar radiation to be concentrated onto a smaller geometric area of Silicon. Using concentrator technology requires a significantly smaller area of costly Silicon while still producing the desired level of power. The Si ...

NON METALS- SILICON

... electric furnace to about 3073K, silicon carbide is formed. Si + C → SiC ...

... electric furnace to about 3073K, silicon carbide is formed. Si + C → SiC ...

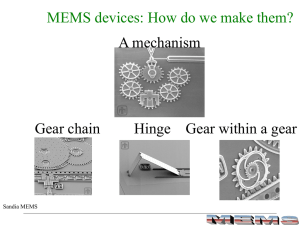

Assembly Method for Three-Dimensional MEMS Saves Chip Space

... This technology is an efficient process for assembling large arrays of three-dimensional, hinged micro structures for micro electromechanical systems (MEMS) applications. Using a single electromagnet for actuation, this new method saves chip space as well as actuates large arrays of devices in paral ...

... This technology is an efficient process for assembling large arrays of three-dimensional, hinged micro structures for micro electromechanical systems (MEMS) applications. Using a single electromagnet for actuation, this new method saves chip space as well as actuates large arrays of devices in paral ...

Fabrication of PN-Junction Diode by IC- Fabrication process

... The fabrication of I.C depends on material, process and design principals which form a highly developed semiconductor technology. Production of integrated circuit is a multistep sequential process like chemical cleaning, oxidation, etching, diffusion, photolithography etc. NMOS, CMOS, bipolar and in ...

... The fabrication of I.C depends on material, process and design principals which form a highly developed semiconductor technology. Production of integrated circuit is a multistep sequential process like chemical cleaning, oxidation, etching, diffusion, photolithography etc. NMOS, CMOS, bipolar and in ...

Tutorial 5. Fundamentals of the MOSFET

... Design the semiconductor doping concentration to yield a specified threshold voltage. Consider an aluminium-silicon dioxide-silicon MOS structure (ms -0.35 V). The silicon is n type, the oxide thickness is tox = 650x10-8 cm, and the trapped charge density is Q’ss = 1010 electronic charges per cm. ...

... Design the semiconductor doping concentration to yield a specified threshold voltage. Consider an aluminium-silicon dioxide-silicon MOS structure (ms -0.35 V). The silicon is n type, the oxide thickness is tox = 650x10-8 cm, and the trapped charge density is Q’ss = 1010 electronic charges per cm. ...

Semiconductor device fabrication

... the wafer. Available technologies consist of physical vapor deposition (PVD), chemical vapor deposition (CVD), electrochemical deposition (ECD), molecular beam epitaxy (MBE) and more recently, atomic layer deposition (ALD) among others. Removal processes are any that remove material from the wafer e ...

... the wafer. Available technologies consist of physical vapor deposition (PVD), chemical vapor deposition (CVD), electrochemical deposition (ECD), molecular beam epitaxy (MBE) and more recently, atomic layer deposition (ALD) among others. Removal processes are any that remove material from the wafer e ...

Kelvin Bridge

... 1. Wet Chemical Etching: Wet etching is accomplished by partial submersion of the wafer in an acid bath having some definite concentration. Etching solutions are housed in a temperature-controlled baths. ...

... 1. Wet Chemical Etching: Wet etching is accomplished by partial submersion of the wafer in an acid bath having some definite concentration. Etching solutions are housed in a temperature-controlled baths. ...

Class 3 updated Sep 30 2011

... (deposition takes place without the need for chemical reaction) spin coating, evaporation, sputtering, ion implantation. – Chemical Deposition (deposition results from a chemical reaction) LPCVD, APCVD, PECVD, epitaxy, Lithography Removal – Wet isotropic etching – Wet anisotropic etching – Plasma et ...

... (deposition takes place without the need for chemical reaction) spin coating, evaporation, sputtering, ion implantation. – Chemical Deposition (deposition results from a chemical reaction) LPCVD, APCVD, PECVD, epitaxy, Lithography Removal – Wet isotropic etching – Wet anisotropic etching – Plasma et ...

Semiconductor Manufacturing Process

... Etching is the process where unwanted areas of films are removed by either dissolving them in a wet chemical solution (Wet Etching) or by reacting them with gases in a plasma to form volatile products (Dry Etching). Resist protects areas which are to remain. In some cases a hard mask, usually patter ...

... Etching is the process where unwanted areas of films are removed by either dissolving them in a wet chemical solution (Wet Etching) or by reacting them with gases in a plasma to form volatile products (Dry Etching). Resist protects areas which are to remain. In some cases a hard mask, usually patter ...

Bulk and Surface Micromachining

... away. Typically, a sacrificial layer of silicon dioxide layer is formed by a combination of thermal and chemical vapor deposition processes. Phosphosilicate glass (PSG) is also often used as a sacrificial layer because of its high etch rate in hydrofluoric acid. After the polysilicon structural laye ...

... away. Typically, a sacrificial layer of silicon dioxide layer is formed by a combination of thermal and chemical vapor deposition processes. Phosphosilicate glass (PSG) is also often used as a sacrificial layer because of its high etch rate in hydrofluoric acid. After the polysilicon structural laye ...

substrates

... molecules (mostly isotropic process). In RIE,under the influence of RF power the gas molecules break into ions which are accelerated towards, and react at, the surface of the material being etched. The balance of chemical and physical etching can give sidewalls that have vertical shapes. ...

... molecules (mostly isotropic process). In RIE,under the influence of RF power the gas molecules break into ions which are accelerated towards, and react at, the surface of the material being etched. The balance of chemical and physical etching can give sidewalls that have vertical shapes. ...

Prezentacja programu PowerPoint

... molecules (mostly isotropic process). In RIE,under the influence of RF power the gas molecules break into ions which are accelerated towards, and react at, the surface of the material being etched. The balance of chemical and physical etching can give sidewalls that have vertical shapes. ...

... molecules (mostly isotropic process). In RIE,under the influence of RF power the gas molecules break into ions which are accelerated towards, and react at, the surface of the material being etched. The balance of chemical and physical etching can give sidewalls that have vertical shapes. ...

Chapter 29 MEMS

... Evaporation, Metal is heated in a vacuum to its vaporization point. Upon evaporation the metal forms in thin layers on the substrate surface. Sputtering, bombarding a target with high energy ions in a vacuum. As ions impinge on the target, atoms are knocked off and deposited on the wafers. ...

... Evaporation, Metal is heated in a vacuum to its vaporization point. Upon evaporation the metal forms in thin layers on the substrate surface. Sputtering, bombarding a target with high energy ions in a vacuum. As ions impinge on the target, atoms are knocked off and deposited on the wafers. ...

Device Fabrication

... capacitors; all told, including power supply and an air cooling system, it weighed over thirty tons and consumed 200 kilowatts of electrical power. ...

... capacitors; all told, including power supply and an air cooling system, it weighed over thirty tons and consumed 200 kilowatts of electrical power. ...

MEMS Processing

... Basic MEMS materials Silicon and its derivatives, mostly • Micro-electronics heritage Si is a good semiconductor, properties can be tuned Si oxide is very robust Si nitride is a good electrical insulator ...

... Basic MEMS materials Silicon and its derivatives, mostly • Micro-electronics heritage Si is a good semiconductor, properties can be tuned Si oxide is very robust Si nitride is a good electrical insulator ...

MEMS Micro Electro Mechanical Systems.doc

... • Silicon nitride is common in the semiconductor industry for the passivation ...

... • Silicon nitride is common in the semiconductor industry for the passivation ...

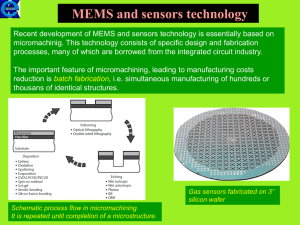

Microelectromechanical systems

Microelectromechanical systems (MEMS) (also written as micro-electro-mechanical, MicroElectroMechanical or microelectronic and microelectromechanical systems and the related micromechatronics) is the technology of very small devices; it merges at the nano-scale into nanoelectromechanical systems (NEMS) and nanotechnology. MEMS are also referred to as micromachines (in Japan), or micro systems technology – MST (in Europe).MEMS are separate and distinct from the hypothetical vision of molecular nanotechnology or molecular electronics. MEMS are made up of components between 1 to 100 micrometres in size (i.e. 0.001 to 0.1 mm), and MEMS devices generally range in size from 20 micrometres to a millimetre (i.e. 0.02 to 1.0 mm). They usually consist of a central unit that processes data (the microprocessor) and several components that interact with the surroundings such as microsensors. At these size scales, the standard constructs of classical physics are not always useful. Because of the large surface area to volume ratio of MEMS, surface effects such as electrostatics and wetting dominate over volume effects such as inertia or thermal mass.The potential of very small machines was appreciated before the technology existed that could make them (see, for example, Richard Feynman's famous 1959 lecture There's Plenty of Room at the Bottom). MEMS became practical once they could be fabricated using modified semiconductor device fabrication technologies, normally used to make electronics. These include molding and plating, wet etching (KOH, TMAH) and dry etching (RIE and DRIE), electro discharge machining (EDM), and other technologies capable of manufacturing small devices. An early example of a MEMS device is the resonistor – an electromechanical monolithic resonator.