Materials_for_Automo..

... it is applied. The method of preparing the metal should reduce the activity of the metal surface, so that underfilm corrosion is prevented at the interface between paint and metal. • Phosphate coatings promote good paint adhesion, • increase the resistance of the films to humidity and water soaking, ...

... it is applied. The method of preparing the metal should reduce the activity of the metal surface, so that underfilm corrosion is prevented at the interface between paint and metal. • Phosphate coatings promote good paint adhesion, • increase the resistance of the films to humidity and water soaking, ...

Pseudoelasticity and thermoelasticity of nickel

... needed on some recent investigations as to whether the formation of SIM, as a modification of the lattice, could interfere or modify the temperature range of the phase transformation. Some recent investigations have actually found that SIM generates a shift of the preset TTR of the alloy toward high ...

... needed on some recent investigations as to whether the formation of SIM, as a modification of the lattice, could interfere or modify the temperature range of the phase transformation. Some recent investigations have actually found that SIM generates a shift of the preset TTR of the alloy toward high ...

Guide to Ultrasonic Plastics Assembly

... Ultrasonic plastics assembly is the joining or reforming of thermoplastics through the use of heat generated from high frequency mechanical motion. It is accomplished by converting electrical energy into high frequency mechanical motion (vibrations) that creates frictional heat at the joint area. Th ...

... Ultrasonic plastics assembly is the joining or reforming of thermoplastics through the use of heat generated from high frequency mechanical motion. It is accomplished by converting electrical energy into high frequency mechanical motion (vibrations) that creates frictional heat at the joint area. Th ...

Magnastat - Soldering iron

... The metal cap that is firmly secured to the back of the soldering tip is the temperature sensor of this system; the Magnastat. It is ferromagnetic, i.e. it attracts iron as does a magnet. The number on the cap is the code for the control temperature, when the iron is heated. When this control temper ...

... The metal cap that is firmly secured to the back of the soldering tip is the temperature sensor of this system; the Magnastat. It is ferromagnetic, i.e. it attracts iron as does a magnet. The number on the cap is the code for the control temperature, when the iron is heated. When this control temper ...

thermal cutting and flame straightening

... Excessive hardening of the cut surface affects the bendability of the plate in the hot-rolled condition. Excessive hardening in flame cutting can be avoided by sufficient preheating (150 – 200°C). In hardened boron steels, an area softer than the base metal, approximately 2 mm in depth, is formed be ...

... Excessive hardening of the cut surface affects the bendability of the plate in the hot-rolled condition. Excessive hardening in flame cutting can be avoided by sufficient preheating (150 – 200°C). In hardened boron steels, an area softer than the base metal, approximately 2 mm in depth, is formed be ...

Lecture 4 EMF and Galvanic Series - Bimetallic Couples

... Consider a uniformly zinc coated steel surface exposed to a corrosive environment. Even if portions of zinc coating are abraded away, the base steel will still be protected! (Due to favourable area effect). See Fig 4.2. ...

... Consider a uniformly zinc coated steel surface exposed to a corrosive environment. Even if portions of zinc coating are abraded away, the base steel will still be protected! (Due to favourable area effect). See Fig 4.2. ...

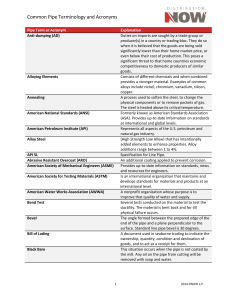

Common Pipe Terminology and Acronyms

... Normally associated with a limited number of chemical elements. Minimum or maximum limits are established in most ASTM and API Specifications. Countervailing duties on imports are sought when the supplying country’s production and/or exports are directly or indirectly subsidized to the extent that t ...

... Normally associated with a limited number of chemical elements. Minimum or maximum limits are established in most ASTM and API Specifications. Countervailing duties on imports are sought when the supplying country’s production and/or exports are directly or indirectly subsidized to the extent that t ...

G020258-00

... • Like metals easy to shape and braze: allow advanced engineering and mechanical geometries. • Naturally produced in thin films or ribbons. • Not fragile (no water problem) • Allow loads of 4, 5 or even 6 GPa!!! • (Best steel limit at 1.8 Gpa, typical fused silica 0.7 GPa) ...

... • Like metals easy to shape and braze: allow advanced engineering and mechanical geometries. • Naturally produced in thin films or ribbons. • Not fragile (no water problem) • Allow loads of 4, 5 or even 6 GPa!!! • (Best steel limit at 1.8 Gpa, typical fused silica 0.7 GPa) ...

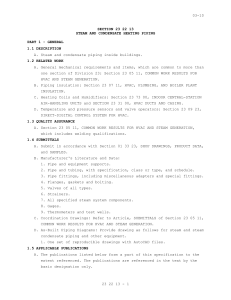

Section 23 22 13 - STEAM AND CONDENSATE

... B. Screwed: Threads shall conform to ASME B1.20; joint compound shall be applied to male threads only and joints made up so no more than three threads show. Coat exposed threads on steel pipe with joint compound, or red lead paint for corrosion protection. C. 125 Pound Cast Iron Flange (Plain Face): ...

... B. Screwed: Threads shall conform to ASME B1.20; joint compound shall be applied to male threads only and joints made up so no more than three threads show. Coat exposed threads on steel pipe with joint compound, or red lead paint for corrosion protection. C. 125 Pound Cast Iron Flange (Plain Face): ...

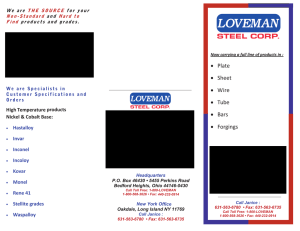

• Plate • Sheet • Wire • Tube • Bars • Forgings

... A- 28 6 alloy is a heat and corrosion resistant austenitic ironbase material which can be age hardened to a high strength level. The alloy is also used for low temperature applications requiring a ductile, non-magnetic high strength material at temperatures ranging from above room temperature down t ...

... A- 28 6 alloy is a heat and corrosion resistant austenitic ironbase material which can be age hardened to a high strength level. The alloy is also used for low temperature applications requiring a ductile, non-magnetic high strength material at temperatures ranging from above room temperature down t ...

TIG-160P 200P.cdr

... faster freezing weld puddle for uphill welding on curved surfaces such as process piping. The TIG pulse also helps moderate filler metal deposition for consistent bead appearance. • High-frequency TIG starting: Makes it easy to establish an arc under a variety of conditions. Enhances quality by minim ...

... faster freezing weld puddle for uphill welding on curved surfaces such as process piping. The TIG pulse also helps moderate filler metal deposition for consistent bead appearance. • High-frequency TIG starting: Makes it easy to establish an arc under a variety of conditions. Enhances quality by minim ...

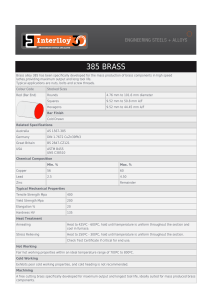

Products 2 - City Special Metals

... high vacuum For industrial applications, oxygen-free copper is valued more for its chemical purity than its electrical conductivity. OF/OFE grade copper is used in plasma deposition (sputtering) processes, including the manufacture of semiconductors and superconductor components, as well as in high ...

... high vacuum For industrial applications, oxygen-free copper is valued more for its chemical purity than its electrical conductivity. OF/OFE grade copper is used in plasma deposition (sputtering) processes, including the manufacture of semiconductors and superconductor components, as well as in high ...

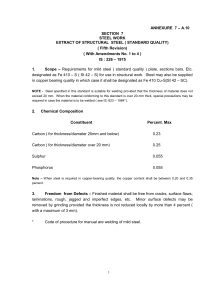

annexure 7 – a.10

... designated as Fe 410 – S ( St 42 – S) for use in structural work. Steel may also be supplied in copper bearing quality in which case it shall be designated as Fe 410 Cu-S(St 42 – SC). NOTE - Steel specified in this standard is suitable for welding provided that the thickness of material does not exc ...

... designated as Fe 410 – S ( St 42 – S) for use in structural work. Steel may also be supplied in copper bearing quality in which case it shall be designated as Fe 410 Cu-S(St 42 – SC). NOTE - Steel specified in this standard is suitable for welding provided that the thickness of material does not exc ...

NIM Transportation, L

... Dick Robinson. NIM Transportation is a wholly owned subsidiary of Norfolk Iron and Metal. NIM Transportation was formed in February of 2004 to service our customers without relying on a third party carrier. Norfolk Iron and Metals main business is the sale of new carbon steel products. We also offer ...

... Dick Robinson. NIM Transportation is a wholly owned subsidiary of Norfolk Iron and Metal. NIM Transportation was formed in February of 2004 to service our customers without relying on a third party carrier. Norfolk Iron and Metals main business is the sale of new carbon steel products. We also offer ...

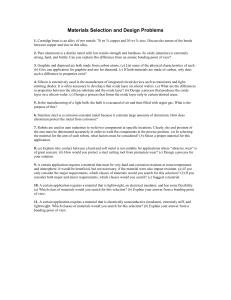

Chapter 2 Materials Selection and Design Problems

... 1. Cartridge brass is an alloy of two metals: 70 wt % copper and 30 wt % zinc. Discuss the nature of the bonds between copper and zinc in this alloy. 2. Pure aluminum is a ductile metal with low tensile strength and hardness. Its oxide (alumina) is extremely strong, hard, and brittle. Can you explai ...

... 1. Cartridge brass is an alloy of two metals: 70 wt % copper and 30 wt % zinc. Discuss the nature of the bonds between copper and zinc in this alloy. 2. Pure aluminum is a ductile metal with low tensile strength and hardness. Its oxide (alumina) is extremely strong, hard, and brittle. Can you explai ...

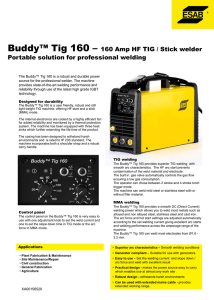

Buddy™ Tig 160

... alloyed and non alloyed steel, stainless steel and cast iron. The arc force and hot start settings are adjusted automatically according to the set welding current giving excellent arc starts and welding performance across the amperage range of the ...

... alloyed and non alloyed steel, stainless steel and cast iron. The arc force and hot start settings are adjusted automatically according to the set welding current giving excellent arc starts and welding performance across the amperage range of the ...

quote - AgriSETA

... Plan daily work and organise physical environment in compliance with the relevant regulations of the Occupational Health and Safety Act (Act No 85, 1993) Apply safe work practices in all aspects of work including welding and gas cutting equipment. Use hand tools when executing general fitting work: ...

... Plan daily work and organise physical environment in compliance with the relevant regulations of the Occupational Health and Safety Act (Act No 85, 1993) Apply safe work practices in all aspects of work including welding and gas cutting equipment. Use hand tools when executing general fitting work: ...

products

... The silk screening process is performed by tools and equipment, specially designed in house. Ultrasonic Welding The ultrasonic welding is performed with tools which are specially designed for the product. ...

... The silk screening process is performed by tools and equipment, specially designed in house. Ultrasonic Welding The ultrasonic welding is performed with tools which are specially designed for the product. ...

BWE XTasy 400

... which is associated with parameters to be adjusted func onally, the operator only need to adjust the wire feeder rate when working condi on changes. BWE XTasy 400/500 comes complete with: ...

... which is associated with parameters to be adjusted func onally, the operator only need to adjust the wire feeder rate when working condi on changes. BWE XTasy 400/500 comes complete with: ...

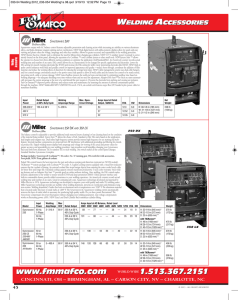

Welding Accessories

... welding time and number of arc starts. DIG control allows the arc characteristics to be changed for specific applications and electrodes. Lower the DIG setting for smooth running electrodes like E7018 and increase the DIG setting for stiffer, more penetrating electrodes like E6010. NEW! Built-in pul ...

... welding time and number of arc starts. DIG control allows the arc characteristics to be changed for specific applications and electrodes. Lower the DIG setting for smooth running electrodes like E7018 and increase the DIG setting for stiffer, more penetrating electrodes like E6010. NEW! Built-in pul ...

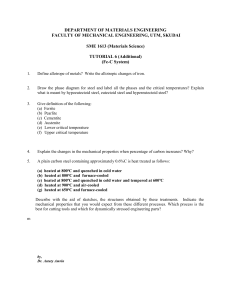

Tut-06_SME1613

... Explain the changes in the mechanical properties when percentage of carbon increases? Why? ...

... Explain the changes in the mechanical properties when percentage of carbon increases? Why? ...

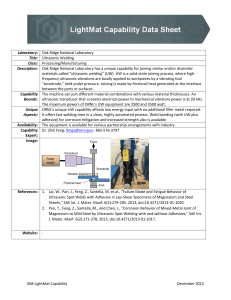

068_ORNL

... materials called “ultrasonic welding” (UW). UW is a solid-state joining process, where highfrequency ultrasonic vibrations are locally applied to workpieces by a vibrating tool “sonotrode,” held under pressure. Joining is made by frictional heat generated at the interface between the parts or surfac ...

... materials called “ultrasonic welding” (UW). UW is a solid-state joining process, where highfrequency ultrasonic vibrations are locally applied to workpieces by a vibrating tool “sonotrode,” held under pressure. Joining is made by frictional heat generated at the interface between the parts or surfac ...