* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Welding Accessories

Survey

Document related concepts

Transcript

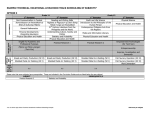

033-54 Welding 2012_033-054 Welding1a 08.qxd 3/19/13 12:32 PM Page 13 Welding Accessories Welding Accessories SyncrowaVe 200 Squarewave output with AC balance control features adjustable penetration and cleaning action while increasing arc stability on various aluminum alloys, and helps eliminate tungsten spitting and arc rectification. NEW! Dual digital meters with alpha-numeric displays allow for quick and easy viewing and preset values for voltage, amperage and other key variables. Allows for greater accuracy and repeatability in the welding procedure. NEW! Runner has low cylinder rack to eliminate the need for lifting when changing gas cylinders. NEW! 115 V auxiliary power receptacle is conveniently located on the front panel, allowing for operation of a Coolmate ™ torch coolant system or other small tools. NEW!Syncro Start ™ allows the operator to choose from three different starting conditions to optimize the application (Soft/Standard/Hot). Arc hour/cycle counter records actual welding time and number of arc starts. DIG control allows the arc characteristics to be changed for specific applications and electrodes. Lower the DIG setting for smooth running electrodes like E7018 and increase the DIG setting for stiffer, more penetrating electrodes like E6010. NEW! Built-in pulse control enhances weld bead and puddle control for improved appearance and quality —reduce burn through, coordinate the addition of filler material, and reduce the warping effects of distortion by reducing the average heat input. NEW! Cable management system uses dual cable hangers and foot control storage conveniently attach to the power source side panels to allow all weld cables and the remote foot control to be neatly stored, preventing torch, cable or remote damage. NEW! Auto-Postflow protects the weld end zone and electrode by optimizing postflow time based on welding amperage —for adequate shielding every time without waste and no need for adjustment. Adaptive Hot Start™ for Stick arc starts automatically increases the output amperage at the start of a weld should the start require it. Prevents the electrode from sticking and creating an inclusion. Fan-On-Demand™ improves power efficiency and reduces noise and maintenance by lessening the amount of airborne contaminants pulled through the machine. NEW! Weldcraft® WP1712SFDI50 TIG torch. 150 A, air-cooled torch features super flex (SF) braided nylon power cable for maximum flexibility. SyncrowaVe 250 dX and 350 lX 250 dX The balance control is adjustable to provide additional oxide removal (more cleaning) or less cleaning based on the condition of the material being welded. Syncro Start ™ allows the choice of Soft, Standard or Hot TIG starts based on the application, lead lengths and tungsten size. Dual inline high-frequency points provide intense high frequency for arc starting and stabilization. Internal machine components are protected from HF interference with additional grounding and filtering for extended product life. Digital welding meters display both amperage and voltage for viewing of the actual and preset values for greater accuracy and repeatability in your welding procedure. Last procedure recall simplifies changing your Syncrowave back and forth from aluminum TIG to stainless TIG to stick welding. One switch makes all the control panel changes. Standard Machine Syncrowave Complete Package includes: Syncrowave® Coolmate™, 3X cooler, No. 37 running gear, TIG torch kit with accessories, Foot pedal, NEW! Four gallons of coolant. Pulsed TIG control lowers the heat input into the part and reduces warping and distortion (optional on 250 DX models). TIGRunner ™ system packages with Coolmate™ 3X cooler. A 3-gallon cooling system equipped with a visual flow indicator ensures that the coolant is flowing. An external coolant filter stops foreign objects from entering the water cooled torch cable for better flow and longer life. Extended cooling capacity ensures maximum productivity. 3-year cooler warranty. Stick welding features such as Adaptive Hot Start ™ provide good arc strikes without sticking. Once welding, the DIG control makes dynamic adjustments to the welder to ensure smooth E7018 and deep penetration E6010. Tilted operator interface and built-in consumable drawer provide added convenience to your welding experience. Arc timer/cycle counter records actual welding time and number of arc starts. Great for estimating job costs. Squarewave technology developed and patented by Miller Electric in 1976. Squarewave technology was developed to improve your weld quality and make TIG welding easier. Miller Squarewave technology provides arc stability when welding aluminum, prevents arc rectification and eliminates tungsten erosion. Welding aluminum? Oxides that form on aluminum melt at temperatures over 3700° F. The aluminum material that is located under this layer of oxide melts at 1200° F. The Syncrowave’s AC Squarewave welding current automatically removes the layer of oxide which is necessary for producing high quality welds. Do you have power fluctuations? The Syncrowave compensates for power fluctuation without changing your welding parameters. Line voltage compensation works on fluctuating power ±10%. NEW! Easy Load Dual Cylinder Rack minimizes cylinder lifting. 350 lX www.fmmafco.com WORLD-WIDE 1.513.367.2151 CINCINNATI, OH – BIRMINGHAM, AL – CARSON CITY, NV – CHARLOTTE, NC 45 © 2013 - ALL RIGHTS RESERVED