* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Press Release

Ground (electricity) wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Electric machine wikipedia , lookup

Buck converter wikipedia , lookup

Transformer wikipedia , lookup

Voltage optimisation wikipedia , lookup

Spark-gap transmitter wikipedia , lookup

Electric power system wikipedia , lookup

Wireless power transfer wikipedia , lookup

Transformer types wikipedia , lookup

Power inverter wikipedia , lookup

Power engineering wikipedia , lookup

Electrification wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Power electronics wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Rectiverter wikipedia , lookup

Three-phase electric power wikipedia , lookup

Mains electricity wikipedia , lookup

Alternating current wikipedia , lookup

Mercury-arc valve wikipedia , lookup

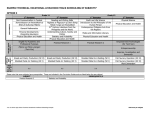

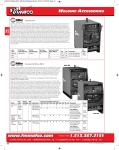

Press Release Constantly manual Stable arc with MMA welding An ideal characteristic leads to perfect welding results. With MMA welding, welders can achieve such results with the help of resonant intelligence. Even in adverse conditions, the machine technology patented for Fronius always ensures a perfect and constant arc. Moreover, it provides the welder with a considerable power reserve. This prevents the arc from breaking for example. Because the “technically controlled inner life” of a welding system with resonant intelligence is very complex, this technology was previously only available for single-phase TransPocket 1500. Now Fronius developers have it solved, and have equipped two three-phase systems with this technology and its benefits: the new TransPocket 2500 and 3500. With conventional MMA welding machines, fluctuations in the mains voltage and mains cables of different lengths have a negative effect on the output power. The same applies to changes in the arc length. Fluctuations in the current then lead to changes in the arc, and in turn to poor quality welding results. Such undesirable side effects are not an issue with resonant intelligence, even with cable lengths of 100 m. So that sticking is avoided if there is a short circuit, the control briefly raises the current. If the electrode threatens to sink into the weld pool, the increased current prevents the weld pool from solidifying. This practically prevents the rod electrode from "sticking". With all TransPockets, “just-in-time” control of the power source generates a gently burning arc. The welder can therefore also process cellulose electrodes up to 5 mm in diameter in vertical-down seam position. This is barely possible with most conventional welding machines. The prerequisite for resonant intelligence is the resonance inverter developed by Fronius. It generates an interaction between welding transformer and capacitor. In addition to the capacitors, the transformer also takes on the role of energy buffer. Resonant here denotes a particular condition: Transformer and capacitors are matched in such a way that they reboot each other. The cleverly devised combination of resonance and buffer function creates power reserves that are on hand if required by the arc. The welding current range of the three-phase TransPocket 2500 reaches 250 A and that of the TransPocket 3500 to 350 A. Extra functions such as SoftStart, HotStart and Anti Stick complete the positive weld properties and make for added convenience when working. Equally worth mentioning is the extremely robust housing with integral handle. The machines’ low weights (12.5 kg and 18 kg) mean they are ideal for portable use. Number of characters approx. : 2.690 With a workforce of 1600,Fronius achieved a turnover of approx. 200 million euro in 2005. The family-owned company ranks as an international leader in arc welding technology in all sectors of metalworking. Fronius offers its customers manual to fully automated welding systems for high-quality, cost-effective processes. Users are supported by 10 subsidiaries and 82 sales and service partners worldwide. In addition to welding technology, the company’s other divisions are solar electronics and battery charging systems Photos: 1: The single-phase and three-phase TransPocket welding systems provide high power reserves for rod electrode and TIG welding work, even for portable use. 2: The resonance inverter generates an ideal characteristic with a high voltage reserve for optimised weld properties under all conditions. This press release and pictures can be downloaded from http://www.fronius.com/press. Please send an author's copy to the international contact person: Fronius International GmbH, Marketing & Communications, Ms. MMag. Matejka Marketa, Günter-Fronius-Straße 1, A-4600 Wels-Thalheim, Tel. +43(0)7242/241 2590, Fax: +43(0)7242/241 2670, E-Mail: [email protected]