* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Proceedings - Edge - Rochester Institute of Technology

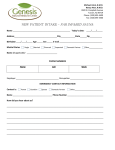

Survey

Document related concepts

Thermal comfort wikipedia , lookup

Space Shuttle thermal protection system wikipedia , lookup

Insulated glazing wikipedia , lookup

Thermoregulation wikipedia , lookup

Passive solar building design wikipedia , lookup

Underfloor heating wikipedia , lookup

Dynamic insulation wikipedia , lookup

Heat equation wikipedia , lookup

Heat exchanger wikipedia , lookup

Building insulation materials wikipedia , lookup

Solar water heating wikipedia , lookup

R-value (insulation) wikipedia , lookup

Intercooler wikipedia , lookup

Copper in heat exchangers wikipedia , lookup

Thermal conduction wikipedia , lookup

Cogeneration wikipedia , lookup

Transcript

Multidisciplinary Senior Design Conference Kate Gleason College of Engineering Rochester Institute of Technology Rochester, New York 14623 Project Number: 12481 GREEN SAUNA John Holleran Mechanical Engineering Tim Kapuscinski Electrical Engineering Dylan Williams Electrical Engineering ABSTRACT – USE STYLE “ABSTRACT CLAUSE TITLE” Saunas are not only a way to relax and sweat but are also known in some countries as a social gathering. However, most are expensive and not very eco-friendly. Our goal was to build a cheap sauna out of materials that were either biodegradable or recyclable, while also being light enough to be somewhat portable. We chose a urethane foam and packaging peanuts as our structure as a way to get rid of unrecyclable packaging material. On the electrical side of things, we implemented a system that can handle solar panels to charge a battery, providing about an hour of use after 5 hours of charging, as well as a solar collector to add heat. The heating system is heating tape wrapped around a pole, along with the inside of the sauna lined with Mylar to reflect the radiant heat. In case of cloudy weather, the heating source will have a plug. DESIGN PROCESS Looking at other saunas, we realized that they were all rectangular. While this shape is simple, we wanted a way to maximize space and minimize volume, as well as look sleek and stack well. We decided on a hexagon because it was close to a circle without adding too many sides. By making it a hexagon, we were also able to fit more than a traditional sauna of similar sizes (five, as opposed to 3). The height was determined on a person being six feet six inches able to fit through a door four feet in height. The apex of the sauna is eighty inches, but users will be sitting in the sauna. Several Green technologies were chosen to be key features of the final sauna. The main theme of the project was to be green and environmentally friendly which, in the world of saunas is nearly unheard of and almost goes against the whole idea of a sauna. Since a sauna is designed to provide a lot of heat for the user, by default this translates directly into a high energy usage. Taking in energy from the surrounding environment was a necessary feature to drastically reduce the energy required from the grid. Four key elements in our project that attempt to supplement the total energy usage are solar photovoltaic panels for electrical power, solar thermal collectors for heat, a corrugate air-to-air heat exchanger air filtration system, and an insulated structure made from panels of recycled packing peanuts. After these design decision were made, the individual systems were designed and integrated into the total sauna system. Copyright © 2012 Rochester Institute of Technology Proceedings of the Multidisciplinary Senior Design Conference Page 2 AIRFLOW According to ASHRAE standards (ANSI/ASHRAE Standard 62-2001 table 6.1), fifteen cubic feet per minute (cfm) of air needs to be cycled through the sauna. In order to do so, a 135 cfm boat fan will blow air through an air-to-air heat exchanger made out of recycled corrugated cardboard, roughly a cubic foot in volume. The heat exchanger will retain heat and humidity, requiring less energy coming from the power source. Also, new air will be blown through the electronic package to also help the sauna gain more heat. HEAT SOURCES The heat for the sauna comes from 2 sources: heat tape and a solar thermal collection panel. The heat tape is powered by either the solar photovoltaic cell or a normal 120 VAC plug which will be determined by the microcontroller. The heat tape itself can reach temperatures near 450 degrees Fahrenheit but very concentrated to the surface it is in contact with. It will be placed on a surface very good for heat conduction which will cause the IR heat to radiate out. Ideally this heat will cause people to feel a heat of around 140 degrees. Two thermometers will be used to measure the latent heat and radiated heat using an orange globe thermometer. These will be used to determine if the heat values in the sauna are safe, and also as a way to show the differences between the two types of heat in testing and demonstration. The heat will be infrared so power will only be used to heat the skin of the users, reducing the power necessary for heating the individuals and heat loss through the structure will be at a minimum. The inside of the sauna will be lined with Mylar in order to reflect the heat to the backs of the users as well as Project P12481 Proceedings of the Multi-Disciplinary Senior Design Conference Page 3 making sure as little heat escapes as possible. The solar collector will be piped into the sauna using natural airflow caused by the convection. On a seventy-degree day, the collectors reached a temperature of 105 degrees, which corresponds, to 450 BTUs per 15 square foot panel. CONTROLLER A TI Launchpad was used to control the whole system. This includes several devices and control paths. To ensure that the user gets environmental feedback in the form of temperatures, the two previously mentioned forms of temperature measurement are used to properly assess the sauna effect. Two thermistors are interfaced with the micro controllers analog to digital converters (ADC) to determine these temperatures. A thermistor is essentially a resistor that varies with temperature. By combing these in a circuit that creates a voltage division, a voltage value can be easily read with the Launchpad ADC to convert to Temperature in Fahrenheit. A serial output mode on the Launchpad yielded a straightforward 2x16 character back lit LCD interface. After the program determines the temperatures it will immediately display these for the user on the LCD. The user can then determine whether they would like to keep on heating up the sauna, or turn off the heat to either enjoy or leave alone. This is done by using a simply switch that sends the Launchpad either a ‘0’ or ‘1’ by connecting the pin to a high voltage or ground. When the Launchpad sees a change, it will trigger a relay circuit that allows the high current for the radiant heating cord to pass and provide heat. A relay is a simple electricalmechanical switch. By driving a current through an inductor in the relay, a physical switch is toggled. The advantage of using this device over a traditional electronic switch in the form of a transistor is that the relay can pass much higher currents. This simple, low cost control circuitry ensures that the user has control and feedback over the sauna system ensuring optimal comfort. PROCESS (OR METHODOLOGY) – USE STYLE “TEXT HEADING 1” First off, our process for creating the structure involved 6 frames in a mold. The frames were angled at a 30degree angle so each meeting point creates a 60-degree angle, making a full hexagon. We placed the frame, connected by fiberglass inserts, into our mold and filled the mold with packaging peanuts or foam board. Then, we mixed the two part foam and poured it onto the foam peanuts. Before it began to rise, we covered it with a board and put wait on it to let it cure. We repeated this process for all 6 panels. In order to put the panels together, we place them side-by-side with a gap. Fabric will be draped around the gap with a zipper in the middle in order to zip the gaps together. Around the top is a ratchet strap set to make sure the whole structure stays together. A fully functional door made out of polycarbonate plastic molded into the peanuts creates a nice seal and also allows sunlight in. Attached to the sauna will be two ducts leading in and out of the sauna from the heat exchanger to circulate air. The fan powering the heat exchanger will also pull warm air from the electrical box, keeping the components cool. RESULTS AND DISCUSSION The final prototype of this iteration consists of a hexagonal, lightweight, insulated structure made from recycled packing peanuts and a urethane foam. An air to air heat exchanger made from a corrugate type system pumps fresh air into the sauna while the air pumping out transfers its heat to the incoming air. This ventilation system was interfaced using standard ducting and a 135 CFM boat fan to produce at least 15 CFM per person in the sauna. The fresh air from outside is first pulled through a box containing the electrical and power systems. This allows for the air to be partially heated by the dissipating components. This power box contains an input for 120VAC grid voltage, an input for a solar photovoltaic panel, an input for a deep discharge DC battery, two inputs for two thermistor temperature measuring devices, an output for LED lights, and an output for the AC heating cord. Also inside this box is the control circuitry consisting of the Launchpad. Several linear voltage regulators were used to supply the micro controller with a steady 3.3V and the LCD with a steady 5V. The two thermistors connect to ADC pins to determine temperature. One thermistor measures air temperature while the other is inside a hollow copper sphere painted a shade of orange to reflect the feeling of radiant temperature absorption comparable to a human being. A simple switch was used to turn on/off total system power and a simple switch to control whether or not heat cord was outputting heat. A 12V photovoltaic panel sits on a top section of the sauna and connects to a solar charger to charge the 12V DC battery. Two solar thermal panels sit on adjacent sides of the sauna to be aimed at the sun and are connected via two holes at the top and bottom. This ensures the convection of heat into the sauna. A pole made from a good conductor of heat is used at the center of the sauna for the heat cord to be wrapped around. The heat cord will not only emit radiant heat, but will heat the center pole which will also emit radiant heat. LED lights are placed in the sauna for nighttime usage and are controlled using a dimmer switch. All of these features make up the current Green Sauna system. Copyright © 2008 Rochester Institute of Technology Proceedings of the Multidisciplinary Senior Design Conference Page 4 CONCLUSIONS AND RECOMMENDATIONS Overall, the project was a success given the circumstances. A three person team building a 5 person sauna was not adequate to complete the project in time due to time constraints of team members, as well as a lack of space to tackle such a large project. Successes that came out of the project are that a possible new technology was discovered in the form of a way to recycle packing peanuts and form panels for insulation that could have applications beyond a sauna structure. The sauna walls came out rigid, strong, and structurally sound and due to the fact that they were constructed from recycled packing peanuts is a big success. Given that a fully functional prototype was constructed, this left us satisfied with our efforts. Although the prototype was full and functional, it was still very rough. Many features had to be downgraded or eliminated in order to ensure something was finished in the end. By reassessing specs before building, better plans could have been made. Preliminary tests showed several design flaws and room for improvement. Due to faulty geometry, the structure did not fit together as expected. Supplemental designs are being considered to correct for this error. Also, a large part of poor fitting can be attributed to warped and flawed wood used in the frames. Future panels would most likely be constructed with some other form of frame. Finally, there were some accuracy issues with temperature measurement due to a poor choice of thermistor. The thermistors used have the greatest level of accuracy at temperatures lower than 70 degrees F. Since the sauna is designed to operate at temperatures over 100 degrees F, the measurements had a lower resolution and subsequently a lower accuracy. Future improvements to the sauna would be a more advanced power monitor system that could track how much energy you take in from the environment and how much you use off of the grid. A more advanced user interface would be considered such as a touch screen display for control and environmental monitoring. More accurate and precise walls would greatly benefit the insulation and installation of the unit. ACKNOWLEDGMENTS – USE STYLE “ACKNOWLEDGMENTS CLAUSE TITLE” We would like to take this time to recognize Dave Vincenzi (ID) and Rich Auburn (ID Wood Shop) for assisting us with wood cutting, Josh Stephenson (EEE) and Adam Sarafan (MET) for making our solar collectors, Colin Bradley of Xpedx for donating packaging peanuts, Professor Kausch (Pack. Sci.) for donating mylar and cardboard, Professor Mondragon (EE) for helping with the programming portion, and last but not least, Professor Carl Lungdren for helping us out along the way and donating some of his personal materials to us. Project P12481