* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download display

Buck converter wikipedia , lookup

Wireless power transfer wikipedia , lookup

Electrification wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Electric motor wikipedia , lookup

Stray voltage wikipedia , lookup

History of electric power transmission wikipedia , lookup

Voltage optimisation wikipedia , lookup

Power engineering wikipedia , lookup

Induction motor wikipedia , lookup

Stepper motor wikipedia , lookup

Resonant inductive coupling wikipedia , lookup

Mains electricity wikipedia , lookup

Dynamometer wikipedia , lookup

Magnetic core wikipedia , lookup

Galvanometer wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Alternating current wikipedia , lookup

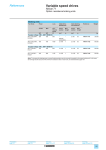

Variable-frequency drive wikipedia , lookup

Subsystem: Safety Project: 7201 - 10 kg Motor Module Objective: Concept development of the braking system of the motor module. Written By: Mark Kaupa The first step in developing the concepts was to brainstorm some ideas. One main method was to look at existing braking systems and see if they were be applicable to our motor module. The next step was to research to find any other applicable concepts. The concepts next were divided into subcategories. Mechanical: 1. Drum Braking 2. Disc Braking Electrical: 1. Dynamic Braking 2. Regenerative Braking 3. Motor Shorting Electromechanical: 1. Magnetic Particle Braking 2. Power off Braking 3. Flange Mounting Spring Braking For the purpose of this subsystem we are not going to discuss the electrical concepts developed. They we integrated in the motor subsystem concept development. They are definitely concepts that are applicable to the project but, they are assumed to be applied and that this subsystem is a “fail-safe” system to the electrical braking that will be applied to the project. The electrical concepts we be reevaluated at the concept selection process. Mechanical: Drum Braking This system is ideal due to the emergency brake lever. This is an added safety measure to the braking system. However, this application will need to be discussed with mechanical subsystem to ensure that this safety concept can be used. The piston is engaged and the discs are applied to the rotating system. The method of braking is a friction and wedging method. Mechanical: Disc Braking This application is more applicable than the drum braking system. Any wheel system will be able to utilize this braking system. A rotor is attached to the shaft and a caliper would have to be mounted inside the yoke. There are both hydraulic and mechanical disc brakes. The ability to lock in the brake (parking brake) is possible. However, the size of the wheels will be an issue. If they are not large enough it might not be possible buy a rotor and caliper to fit the motor module. Issues with Mechanical Braking Systems: The main issues the integration of these mechanical braking systems into an electrical system. In addition, the size of the wheel application is needed to be determined to be able to apply these systems. The mechanical braking system can also replace the electrical braking system as well. Both applications can be applied and have “fail-safe” application applied to it. However, with any friction system heat is developed. And this can lead to failure of some mechanical systems. Therefore, maintenance is also an issue if the application becomes very demanding of the braking system continuous maintenance will be needed on the mechanical braking system. Electromechanical: Electromagnetic Braking These brakes use a single plate friction surface to engage the input and output members of the brake. This style of brake is used in applications ranging from copy machines to conveyor drives. They are the most common type of electromechanical brakes. Other applications for these brakes could include packaging machinery, printing machinery, food processing machinery and factory automation. Electromechanical brakes operate via an electric actuation, but transmit torque mechanically. When voltage/current is applied, the coil is energized creating a magnetic field. This turns the coil into an electromagnet that develops magnetic lines of flux. The magnetic flux attracts the armature to the face of the brake. The armature and hub are normally mounted on the shaft (customer supplied) that is rotating. Since the brake coil is mounted solidly, the brake armature, hub and shaft come to a stop in a short amount of time. When current/voltage is removed from the brake, the armature is free to turn with the shaft. In most designs, springs hold the armature away from the brake surface when power is released, creating a small air gap. Slippage should occur only during deceleration. When the brake is engaged, there should be no slippage once the brake comes to a full stop. This is a variation of the mechanical disc and drum that was previously discussed. Electromechanical: Power off Braking Power off brakes stop or hold a load when electrical power is either accidentally lost or intentionally disconnected. In the past, some companies have referred to these as "fail safe" brakes. These brakes are typically used on or near an electric motor. Typical applications include robotics, holding brakes for Z axis ball screws and holding brakes for servo motors. Many custom designs are available and can be made for use with different motor applications. When no current/voltage is applied to the brake, a series of springs push against the pressure plate, squeezing the friction disk between the inner pressure plate and the outer cover plate. This frictional clamping force is transferred to the hub, which is mounted to a shaft (customer supplied). The power off brake is considered engaged when no power is applied to it. It is typically required to hold or stop a load in the event of a loss of power, when power is not available to run a machine. When the brake is required to release, voltage/current is applied to the coil creating a magnetic field. This magnetic field pulls in the pressure plate pulling against the springs, creating an air gap between the pressure plate and the friction disk, allowing it to turn freely with the shaft. Electromechanical: Multiple Disks Electromagnetic Braking Multiple disk brakes are used to deliver extremely high torque in minimal dimensional requirements. These brakes can be used either wet or dry, which makes them ideal to run in multiple speed gear box applications. Machine tool applications top the list where these brakes are used. Electromechanical brakes operate via an electric actuation, but transmit torque mechanically. When voltage/current is applied to the coil, it creates a magnetic field. This turns the coil into an electromagnet, which develops magnetic lines of flux. The magnetic flux attracts the armature to the face of the brake. As it does so, it squeezes the inner and outer friction disks together. The armature and hub are normally mounted on the shaft (customer supplied) that is rotating. Since the brake coil is mounted solidly, the brake armature, hub and shaft come to a stop in a short amount of time. When current/voltage is removed from the brake, the armature is free to turn with the shaft. Springs hold the armature away from the brake surface when power is released, creating a minimal drag. Slippage should occur only during deceleration. When the brake is engaged, there should be no slippage once the brake comes to a full stop. Electromechanical: Magnetic Particle Braking Magnetic particle/current brakes are unique in their design from other electromechanical brakes because of the wide operating torque range available. Like an electromechanical brake, torque to voltage is almost linear; however, in a magnetic particle brake, torque can be controlled very accurately (within the operating rpm range of the unit). This makes these units ideally suited for tension control applications, such as wire winding, foil and film tension control and tape tension control. Because of their fast response, they can also be used in high cycle applications, such as magnetic card readers, sorting machines and labeling equipment. Magnetic particles (very similar to iron filings) are located in the powder cavity. Without any voltage/current, they sit in the cavity; however, when voltage/current is applied to the coil, the magnetic flux that is created, tries to bind the particles together, almost like a magnetic particle slush. As the voltage/current is increased, the binding of the particles becomes stronger. The brake rotor passes through these bound particles. The output of the housing is rigidly attached to some portion of the machine. As the particles start to bind together, a resistant force is created on the rotor, slowing, and eventually stopping the output shaft. When current voltage is removed from the brake, the input is free to turn with the shaft. Since magnetic particle powder is in the cavity, all magnetic particle units have some type of minimum drag associated with them. Conclusion: There are many electrical braking systems to apply the mechanical braking systems that were discussed. However, the mechanical braking system cannot be ruled out. The next issue to be applied is which application will be best for our motor module system.