* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Conditions for Running the DTC

Opto-isolator wikipedia , lookup

Flexible electronics wikipedia , lookup

Electrical ballast wikipedia , lookup

Control theory wikipedia , lookup

Distributed control system wikipedia , lookup

Electrical substation wikipedia , lookup

Regenerative circuit wikipedia , lookup

Control system wikipedia , lookup

Circuit breaker wikipedia , lookup

Fault tolerance wikipedia , lookup

Resilient control systems wikipedia , lookup

Resonant inductive coupling wikipedia , lookup

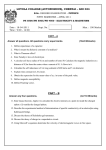

DTC Descriptors DTC P0201: Injector 1 Control Circuit DTC P0202: Injector 2 Control Circuit DTC P0203: Injector 3 Control Circuit DTC P0204: Injector 4 Control Circuit DTC P0205: Injector 5 Control Circuit DTC P0206: Injector 6 Control Circuit DTC P0207: Injector 7 Control Circuit DTC P0208: Injector 8 Control Circuit Diagnostic Fault Information Circuit Short to Ground Open/High Resistance Short to Voltage Signal Performance Ignition 1 Voltage - Odd Coil P0201, P0203, P0205, P0201, P0203, P0205, P0207, --Fuse P0207, P0300 P0300 Ignition 1 Voltage - Even Coil P0202, P0204, P0206, P0202, P0204, P0206, P0208, --Fuse P0208, P0300 P0300 Fuel Injector 1 Control P0201 P0201 P0201 -Fuel Injector 2 Control P0202 P0202 P0202 -Fuel Injector 3 Control P0203 P0203 P0203 -Fuel Injector 4 Control P0204 P0204 P0204 -Fuel Injector 5 Control P0205 P0205 P0205 -Fuel Injector 6 Control P0206 P0206 P0206 -Fuel Injector 7 Control P0207 P0207 P0207 -Fuel Injector 8 Control P0208 P0208 P0208 -Circuit/System Description The control module enables the appropriate fuel injector pulse for each cylinder. Ignition voltage is supplied to the fuel injectors. The control module controls each fuel injector by grounding the control circuit via a solid state device called a driver. The control module monitors the status of each driver. If the control module detects an incorrect voltage for the commanded state of the driver, a fuel injector control circuit DTC sets. Conditions for Running the DTC • The engine is running. • The ignition voltage is more than 11 volts. • DTC P0201-P0208 runs continuously when the above conditions are met. Conditions for Setting the DTC • The control module detects an incorrect voltage on the fuel injector control circuit. • The above condition is met for 1 second. Action Taken When the DTC Sets DTCs P0201, P0202, P0203, P0204, P0205, P0206, P0207, and P0208 are Type B DTCs. Conditions for Clearing the MIL/DTC DTCs P0201, P0202, P0203, P0204, P0205, P0206, P0207, and P0208 are Type B DTCs. Diagnostic Aids Performing the Fuel Injector Diagnosis may help isolate an intermittent condition. Refer to Fuel Injector Diagnosis. DTC Type Reference Powertrain Diagnostic Trouble Code (DTC) Type Definitions Special Tools J 43244 Relay Puller Pliers Circuit/System Testing 1. Ignition OFF, disconnect the affected fuel injector harness connector at the fuel injector. 2. Ignition ON, verify that a test lamp illuminates between the ignition 1 voltage circuit terminal A and ground. ⇒If the test lamp does not illuminate, test the ignition 1 voltage circuit for a short to ground or an open/high resistance. If the circuit tests normal and the ignition 1 voltage circuit fuse is open, test or replace the fuel injector. 3. Connect the J 34730-405 between the control circuit terminal B and the ignition 1 voltage circuit terminal A. 4. Pulse the fuel injector with a scan tool. The test lamp should flash ON and OFF when commanded. ⇒If the test lamp is always ON, test the control circuit for a short to ground. If the circuit tests normal, replace the engine control module (ECM). ⇒If the test lamp is always OFF, test the control circuit for a short to voltage or an open/high resistance. If the circuit tests normal, replace the ECM. 5. If all circuits test normal, test or replace the fuel injector. Component Testing Important: The engine coolant temperature (ECT) sensor must be between 10-32°C (50-90°F) for an accurate measurement. Measure for 11-14 ohms of resistance between the terminals of the fuel injector. ⇒If the resistance is not within the specified range, replace the fuel injector. DTC Descriptors DTC P0351: Ignition Coil 1 Control Circuit DTC P0352: Ignition Coil 2 Control Circuit DTC P0353: Ignition Coil 3 Control Circuit DTC P0354: Ignition Coil 4 Control Circuit DTC P0355: Ignition Coil 5 Control Circuit DTC P0356: Ignition Coil 6 Control Circuit DTC P0357: Ignition Coil 7 Control Circuit DTC P0358: Ignition Coil 8 Control Circuit Diagnostic Fault Information Short to Open/High Short to Signal Circuit Ground Resistance Voltage Performance Ignition Coil 1 Control Circuit P0300, P0351 P0300, P0351 P0300, P0351 -Ignition Coil 2 Control Circuit P0300, P0352 P0300, P0352 P0300, P0352 -Ignition Coil 3 Control Circuit P0300, P0353 P0300, P0353 P0300, P0353 -Ignition Coil 4 Control Circuit P0300, P0354 P0300, P0354 P0300, P0354 -Ignition Coil 5 Control Circuit P0300, P0355 P0300, P0355 P0300, P0355 -Ignition Coil 6 Control Circuit P0300, P0356 P0300, P0356 P0300, P0356 -Ignition Coil 7 Control Circuit P0300, P0357 P0300, P0357 P0300, P0357 -Ignition Coil 8 Control Circuit P0300, P0358 P0300, P0358 P0300, P0358 -Circuit/System Description The ignition system on this engine uses an individual coil/module for each cylinder. The engine control module (ECM) controls the spark event for each cylinder through the eight individual ignition control (IC) circuits. When the ECM commands the IC circuit ON, electrical current will flow through the primary winding of the ignition coil, creating a magnetic field. When a spark event is requested, the ECM will command the IC circuit OFF, interrupting current flow through the primary winding. The magnetic field created by the primary winding will collapse across the secondary coil windings, producing a high voltage across the spark plug electrodes. The ECM uses information from the crankshaft position (CKP) sensor, and the camshaft position (CMP) sensor for sequencing and timing of the spark events. Each ignition module/coil assembly has the following electrical circuits attached. • An ignition 1 voltage circuit • A ground circuit • An IC circuit • A low reference circuit If the ECM detects that the IC circuit has an incorrect voltage level, DTC P0351-P0358 will set. Conditions for Running the DTC • The ignition is ON. • DTC P0351-P0358 runs continuously when the above condition is met. Conditions for Setting the DT The ECM detects one of the following failures on the IC circuit: • An open • A short to ground • A short to voltage Action Taken When the DTC Sets DTCs P0351-P0358 are Type B DTCs. Conditions for Clearing the DTC DTCs P0351-P0358 are Type B DTCs. Diagnostic Aids • This test procedure requires that the vehicle battery has passed a load test and is completely charged. Refer to Battery Inspection/Test. • A high resistance condition on any IC circuit can cause an engine misfire without setting DTC P0351-P0358. Circuit/System Verification 1. Engine running, monitor the following ignition control (IC) circuit status parameters, with a scan tool. • Cylinder 1-8 Ckt. Short Gnd Test Status • Cylinder 1-8 Ckt. Open Test Status • Cylinder 1-8 Ckt. Short to Volts Test Status • Each parameter should display OK. Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data. Circuit/System Testing Important: Perform the Circuit/System Verification first. 1. Turn OFF the ignition. 2. Disconnect the ECM C2 harness connector. Important: A high resistance on any IC circuit can cause a misfire condition, before DTCs P0351P0358 set. 3. Disconnect the affected ignition/coil module harness connector. 4. Test the affected IC circuit for the fault condition identified in Circuit/System Verification. ⇒ If a condition is detected, repair the circuit as required. 5. Connect the ECM C2 harness connector. 6. Exchange the affected ignition coil/module, with the ignition coil/module of a cylinder that is not affected. 7. Start and run the engine. With a scan tool, monitor the IC circuit parameters. ⇒If the circuit status fault identified in Circuit/System Verification transfers with the ignition coil/module, replace the ignition coil/module assembly. ⇒If the circuit status fault identified in Circuit/System Verification does not transfer with the ignition coil/module, replace the ECM. Repair Instructions • Ignition Coil Replacement • Engine Control Module Replacement • Engine Control Module Programming and Setup Repair Verification Important: An IC circuit fault condition will result in an engine misfire, and under certain driving conditions could possibly overheat the 3-way catalytic converter. 1. Install any components or connectors that have been removed or replaced during diagnosis. 2. Perform any adjustment, programming, or setup procedures that are required when a component or module is removed or replaced. 3. Start and run the engine. With a scan tool, monitor the IC circuit status parameters. All IC circuit status parameters should display OK. ⇒If another DTC is present, refer to Diagnostic Trouble Code (DTC) List - Vehicle and perform the appropriate diagnostic. 4. To verify that the performance of the catalytic converter has not been affected by the condition that set this DTC, perform the Repair Verification for DTC P0420 or P0430. Refer to DTC P0420 or P0430. 2. Action Taken When the DTC Sets - Type B • The control module illuminates the MIL on the second consecutive ignition cycle that the diagnostic runs and fails. • The control module records the operating conditions at the time the diagnostic fails. The first time the diagnostic fails, the control module stores this information in the Failure Records. If the diagnostic reports a failure on the second consecutive ignition cycle, the control module records the operating conditions at the time of the failure. The control module writes the operating conditions to the Freeze Frame and updates the Failure Records. • The following applies to misfire DTCs: - If the control module detects a low level or an emission level misfire condition during 2 consecutive trips, the control module illuminates the MIL. - If the control module detects a high level or catalyst damaging misfire, the control module flashes the MIL at a rate of once per second. - If the control module detects a misfire during 2 non-consecutive trips, the stored conditions are compared with the current conditions. The control module illuminates the MIL when the following conditions occur: • The engine load is within 20 percent of the previous test that failed. • The engine speed is within 375 RPM of the previous test that failed. • The engine coolant temperature is in the same range of the previous test that failed. • The following applies to fuel trim DTCs: - If the control module detects a fuel trim condition during 2 consecutive trips, the control module illuminates the MIL. - If the control module detects a fuel trim condition during 2 non-consecutive trips, the stored conditions are compared with the current conditions. The control module illuminates the MIL when the following conditions occur: • The engine load is within 20 percent of the previous test that failed. • The engine speed is within 375 RPM of the previous test that failed. • The engine coolant temperature is in the same range of the previous test that failed. Conditions for Clearing the MIL/DTC - Type A or Type B • The control module turns OFF the MIL after 4 consecutive ignition cycles that the diagnostic runs and does not fail. • A current DTC, Last Test Failed, clears when the diagnostic runs and passes. • A history DTC clears after 40 consecutive warm-up cycles, if no failures are reported by this or any other emission related diagnostic. • Clear the MIL and the DTC with a scan tool.