* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download BD9870FPS

Mercury-arc valve wikipedia , lookup

Stepper motor wikipedia , lookup

Power engineering wikipedia , lookup

Spark-gap transmitter wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Three-phase electric power wikipedia , lookup

Electrical ballast wikipedia , lookup

Power inverter wikipedia , lookup

History of electric power transmission wikipedia , lookup

Electrical substation wikipedia , lookup

Integrating ADC wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Current source wikipedia , lookup

Stray voltage wikipedia , lookup

Power MOSFET wikipedia , lookup

Surge protector wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Schmitt trigger wikipedia , lookup

Distribution management system wikipedia , lookup

Power electronics wikipedia , lookup

Voltage regulator wikipedia , lookup

Alternating current wikipedia , lookup

Voltage optimisation wikipedia , lookup

Current mirror wikipedia , lookup

Mains electricity wikipedia , lookup

Switched-mode power supply wikipedia , lookup

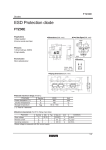

Single-chip Type with Built-in FET Switching Regulator Series Simple Step-down Switching Regulator with Built-in Power MOSFET No.09027EAT26 BD9870FPS ● Description The BD9870FPS single-channel step-down switching regulator incorporates a Pch MOSFET capable of PWM operation at 900kHz, enabling use of a smaller coil, as well as circuitry that eliminates the need for external compensation – only a diode, coil, and ceramic capacitor are required – reducing board size significantly. ●Features 1) Maximum switching current: 1.5A 2) 2. Built-in Pch FET ensures high efficiency 3) Output voltage adjustable via external resistors 4) High switching frequency: 900kHz (fixed) 5) Soft start time: 5ms (fixed) 6) Overcurrent and thermal shutdown protection circuits built in 7) ON/OFF control via STBY pin 8) Ceramic output capacitor compatibility 9) Small surface mount TO252S-5 package ●Applications TVs, printers, DVD players, projectors, gaming devices, PCs, car audio/navigation systems, ETCs, communication equipment, AV products, office equipment, industrial devices, and more. ●Absolute Maximum Ratings(Ta=25℃) Parameter Symbol Ratings Unit Vcc 36 V STBY-GND VSTBY 36 V OUT-GND VOUT 36 V INV-GND VINV 5 V Supply Voltage(VCC-GND) (*1) Maximum Switching Current Iout 1.5 Power Dissipation Pd 800(*2) mW A Operating Temperature Topr -40 to +85 ℃ Storage Temperature Tstg -55 to +150 ℃ (*1) Do not exceed Pd, ASO, and Tjmax=150℃ (*2) Derated at 6.4mW/°C over Ta=25℃ ●Operating Conditions(Ta=-40 to +85℃) Parameter Input Voltage Output Voltage www.rohm.com © 2009 ROHM Co., Ltd. All rights reserved. Limit Symbol Unit MIN MAX VCC 8.0 35.0 V Vo 1.0 0.8×(VCC-Io×Ron) V 1/11 2009.05 - Rev.A Technical Note BD9870FPS ●Electrical Characteristics(Unless otherwise noted, Ta=25℃,Vcc=12V,Vo=5V,STBY=3V) Limit Parameter Symbol Unit MIN TYP MAX Output ON Resistance Ron - 1.0 Ω 1.5 η 80 88 - % fosc 810 900 990 kHz Load Regulation ΔVOLOAD - 5 40 mV Line Regulation Efficiency Switching Frequency ΔVOLINE - 5 25 mV Over Current ProtectionLimit Iocp 1.6 - - A INV Pin Threshold Voltage VINV 0.99 1.00 1.01 V INV Pin Input Current IINV - 1 2 μA ON VSTBYON 2.0 - 36 V OFF VSTBYOFF -0.3 - 0.3 V Istby 5 15 30 μA STBY Pin Threshold Voltage STBYPin Input Current Conditions Io=0.5A Vcc=20V, Io=0.5 to 1.5A Vcc=10 to 30V, Io=1.0A VINV=1.0V STBY=3V Circuit Current Icc - 5 12 mA INV=2V Stand-by Current Ist - 0 5 μA STBY=0V Soft Start Time Tss 1 4 10 ms * This product is not designed to be resistant to radiation. ●Block Diagram VCC 1 VREF PWM COMP DRIVER OSC STBY 5 STBY CTL LOGIC OUT 2 OCP TSD INV Error AMP 4 SS FIN GND Fig.1 www.rohm.com © 2009 ROHM Co., Ltd. All rights reserved. 2/11 2009.05 - Rev.A Technical Note BD9870FPS ●Package Dimensions TO252S-5(Unit:mm) Fig.2 ●Pin Description Pin No. Pin Name Function 1 VCC Input Power Supply Pin 2 OUT Internal Pch FET Drain Pin 3 OUT Internal Pch FET Drain Pin FIN GND Ground 4 INV Output Voltage Feedback Pin 5 STBY ※ ON/OFF Control Pin ※Normally OPEN www.rohm.com © 2009 ROHM Co., Ltd. All rights reserved. 3/11 2009.05 - Rev.A Technical Note BD9870FPS ●Block Function Explanations ・ VREF Generates the regulated voltage from Vcc input, compensated for temperature. ・ OSC Generates the triangular wave oscillation frequency (900kHz) using an internal resistors and capacitor. Used for PWM comparator input. ・ Error AMP This block, via the INV pin, detects the resistor-divided output voltage, compares this with the reference voltage, then amplifies and outputs the difference. ・ PWM COMP Outputs PWM signals to the Driver block, which converts the error amp output voltage to PWM form. ・ DRIVER This push-pull FET driver powers the internal Pch MOSFET, which accepts direct PWM input. ・ STBY Controls ON/OFF operation via the STBY pin. The output is ON when STBY is High. ・ Thermal Shutdown (TSD) This circuit protects the IC against thermal runaway and damage due to excessive heat. A thermal sensor detects the junction temperature and switches the output OFF once the temperature exceeds a threshold value (175°C). Hysteresis is built in (15°C) in order to prevent malfunctions due to temperature fluctuations. ・ Over Current Protection (OCP) The OCP circuit detects the voltage difference between Vcc and OUT by measuring the current through the internal Pch MOSFET and switches the output OFF once the voltage reaches the threshold value. The OCP block is a self-recovery type (not latch). ・ Soft Start (SS) This block conducts soft start operations. When STBY is High and the IC starts up the internal capacitor begins charging. The soft start time is fixed at 5ms. ●Notes for PCB layout C3 R1:4kΩ R2:1kΩ 4 STBY INV 5 L1 OUT 2 1 VCC 5.0V C2 GND FIN D1 C1 Fig.3 • Place capacitors between Vcc and Ground, and the Schottky diode as close as possible to the IC to reduce noise and maximize efficiency. • Connect resistors between INV and Ground, and the output capacitor filter at the same Ground potential in order to stabilize the output voltage. (If the patterning is longer or thin, it’s possible to cause ringing or waveform crack.) www.rohm.com © 2009 ROHM Co., Ltd. All rights reserved. 4/11 2009.05 - Rev.A Technical Note BD9870FPS ●Application component selection and settings Inductor L1 A large inductor series impedance will result in deterioration of efficiency. OCP operation greater than 1.6A may cause inductor overheating, possibly leading to overload or output short. Note that the current rating for the coil should be higher than IOUT(MAX)+⊿IL. Iout(MAX): maximum load current If you flow more than maximum current rating, coil will become overload, and cause magnetic saturation, and those account for efficiency deterioration. Select from enough current rating of coil which doesn’t over peak current. VOUT (VCC-VOUT) ⊿IL. = × × 1 fosc VCC L1 L1:inductor value, VCC:maximum input voltage, VOUT:output voltage, ⊿IL:coil ripple current value, fosc:oscillation frequency If you make a point of efficiency, we will recommend C10-H5R(mitsumi).The efficiency will improve about 1-2%. Schottky Diode D1 A Schottky diode with extremely low forward voltage should be used. Selection should be based on the following guidelines regarding maximum forward current, reverse voltage, and power dissipation: ・The maximum current rating is higher than the combined maximum load current and coil ripple current (⊿IL). ・The reverse voltage rating is higher than the VIN value. ・Power dissipation for the selected diode must be within the rated level. The power dissipation of the diode is expressed by the following formula: Pdi=Iout(MAX)×Vf×(1-VOUT/VCC) Iout(MAX): maximum load current, Vf: forward voltage, VOUT: output voltage, VCC: input voltage Output Capacitor C1 A suitable output capacitor should satisfy the following formula for ESR: ESR≦⊿VL/⊿IL ⊿VL : permissible ripple voltage, ⊿IL : coil ripple current Another factor that must be considered is the permissible ripple current. Select a capacitor with sufficient margin, governed by the following formula: IRMS =⊿IL/2√3 IRMS: effective value of ripple current to the output capacitor, ⊿IL : coil ripple current Use ceramic capacitor over B characteristic of temperature. Except that, it is possible to cause abnormal movement of IC. It’s depends on ambient temperature or output voltage setting Also it is possible to use Al electronic capacitor, but use it by enough confirmation. Input Capacitor C2 The input capacitor is the source of current flow to the coil via the built-in Pch FET when the FET is ON. When selecting the input capacitor sufficient margin must be provided to accommodate capacitor voltage and permissible ripple current. The expression below defines the effective value of the ripple current to the input capacitor. It should be used in determining the suitability of the capacitor in providing sufficient margin for the permissible ripple current. IRMS=IOUT×√ (1-VOUT / VCC)×VOUT / VCC IRMS : effective value of the ripple current to the input capacitor IOUT : output load current, VOUT: output voltage, VCC: input voltage Capacitor C3 This capacitor is utilized to stabilize the frequency characteristics, but is seldom used. However, if the phase margin is insufficient and oscillation is likely, connecting this capacitor may improve frequency stability. Resistor R1,R2 These resistors determine the output voltage: VOUT=1.0V×(1 + R1/R2) Select resistors less than 10kΩ. www.rohm.com © 2009 ROHM Co., Ltd. All rights reserved. 5/11 2009.05 - Rev.A Technical Note BD9870FPS <Recommended Components (Example)> Inductor L1=10μH :C6-K3LA (MITSUMI) Schottky Diode D1 :RB050LA-30(ROHM)… use when VCC is less than 30V D2 :RB050LA-40(ROHM)… use when VCC is greater than 30V Capacitor C1=10μF(25V) :ceramic cap GRM31CB31E106KA75L(murata) C2=4.7μF(50V) :ceramic cap GRM32EB31H475KA87L(murata) C3=OPEN <Recommended Components example 2>…when the Duty ratio of output/input voltage is less than 10% Inductor L1=10μH :C6-K3LA (MITSUMI) Schottky Diode D1 :RB050LA-30(ROHM)… use when VCC is less than 30V D2 :RB050LA-40(ROHM)… use when VCC is more than 30V Capacitor C1=100μF(25V):Al electric capacitor UHD1E101MED(nichicon) C2=4.7μF(50V) :ceramic cap GRM32EB31H475KA87L(murata) C3=OPEN ●Test Circuit Vcc OUT GND INV STB 1 2 FIN 4 5 SW2 + Icc SW4 SW5 A IINV A A ISTB 1kΩ Vcc 2kΩ VINV + f VST SW6 V Vo Io Fig.4 www.rohm.com © 2009 ROHM Co., Ltd. All rights reserved. 6/11 2009.05 - Rev.A Technical Note BD9870FPS ●Typical Performance Characteristics(Unless otherwise noted, Ta=25℃,Vcc=12V,Vo=5V,STBY=3V) 10 5.0 Io=0m A STBY=0V 4.5 8 Stand-by Current[uA] Circuit Current[mA] 9 7 6 5 4 3 2 1 0 4.0 3.5 3.0 2.5 VCC=8V VCC=12V VCC=24V 2.0 1.5 1.0 0.5 0.0 0 10 20 30 40 -40 Input Voltage[V] 10 35 60 85 Fig.6 Stand-by Current vs. Ambient temperature 1100 1100 Oscillator Frequency[kHz] Oscillator Frequency[kHz] -15 Ambient Temperature[℃ ] Fig.5 Circuit Current vs. Supply Voltage:no load 1050 1000 950 900 850 800 750 700 1050 1000 950 900 850 800 750 700 0 10 20 30 40 -40 Input Voltage[V] -15 10 35 60 85 Am bient Tem perature[ ℃ ] Fig.7 Oscillator Frequency vs. Supply Voltage Fig.8 Oscillator Frequency vs. Supply Voltage 7 1.05 1.04 6 1.03 Output Voltage[V] Threshold Voltage[V] VCC=35V 1.02 1.01 1.00 0.99 0.98 0.97 5 4 3 2 1 0.96 0 0.95 5 10 15 20 25 30 35 0.0 40 Fig.9 ErrorAmp Threshold Voltage vs. Supply Voltage www.rohm.com 2.0 3.0 STBY Input Voltage[V] Input Voltage[V] © 2009 ROHM Co., Ltd. All rights reserved. 1.0 Fig.10 Output Voltage vs. STBY Pin Voltage 7/11 2009.05 - Rev.A Technical Note BD9870FPS 100 90 VCC=8V 2.5 2.0 Effeciency[%] Drain-Source Voltage[V] 3.0 VCC=12V 1.5 1.0 VCC=35V 0.5 VCC=8V 80 70 60 VCC=12V VCC=24V 50 40 30 20 10 0 0.0 0.0 0.5 1.0 1.5 0 2.0 Output Current[A] 1500 2000 Fig.12 Efficiency vs. Load Current 7 5.05 5.04 Ro=50Ω Output Voltage[V] 6 Output Voltage[V] 1000 Load Current[mA] Fig.11 Driver Drain-Source Voltage vs. Output Current 5 4 3 2 1 VCC=35V 5.03 VCC=12V 5.02 5.01 5.00 VCC=8V 4.99 4.98 4.97 4.96 0 4.95 0 Output Voltage[V] 500 10 20 30 0 40 500 1000 Input Voltage[V] Load Current[mA] Fig.13 Output Voltage vs. Supply Voltage Fig.14 Output Voltage vs. Load Current 6.0 5.5 5.0 4.5 4.0 3.5 1500 STBY 0→ 3V 1V/div 3.0 2.5 2.0 1.5 1.0 0.5 0.0 Vo 2V/div 0.0 0.5 1.0 1.5 2.0 2.5 Ta=25℃ Ro=5Ω L:C10-H5R(MITSUMI) 3.0 Load Current[A] Fig.15 Over Current Protection Characteristics www.rohm.com © 2009 ROHM Co., Ltd. All rights reserved. Fig.16 Output Start-up Characteristics 8/11 2009.05 - Rev.A Technical Note BD9870FPS ●I/O Equivalent Circuit Pin 1 (Vcc, GND) Pin 2 (OUT) Pin 4 (INV) Pin 5 (STBY) VCC VCC VCC STBY VCC INV OUT GND ●Operation Notes 1. Absolute Maximum Ratings Exceeding the absolute maximum ratings (i.e. supply voltage, temperature) may cause damage to the device and make it impossible to determine the failure mode (short/open). Therefore, when conditions exceeding the maximum ratings are anticipated, consideration should be given to preventive countermeasures (e.g. fuses). 2. Application circuit Although we can recommend the application circuits contained herein with a relatively high degree of confidence, we ask that you verify all characteristics and specifications of the circuit as well as performance under actual conditions. Please note that we cannot be held responsible for problems that may arise due to patent infringements or noncompliance with any and all applicable laws and regulations. 3. Operating conditions Proper operation is guaranteed under the recommended conditions/specifications. 4. GND voltage Ensure that the GND fin is connected and is at the lowest potential under any operating conditions, including transients. 5. Input supply voltage Ensure that the Vcc pin is connected to the supply voltage. 6. Thermal design Thermal designs should allow for sufficient margin for power dissipation under actual use. 7. Soldering During mounting ensure that the OUT, Vcc, and GND pins are not shorted with one another. Carefully note IC orientation. 8. Operation in strong electromagnetic field Operation in a strong electromagnetic field may cause malfunction. 9. Operation The IC will turn ON when the voltage at the STBY pin is greater than 2.0V and will switch OFF if under 0.3V. Therefore, do not input voltages between 0.3V and 2.0V. Malfunctions and/or physical damage may occur.. www.rohm.com © 2009 ROHM Co., Ltd. All rights reserved. 9/11 2009.05 - Rev.A Technical Note BD9870FPS 10.This IC is a monolithic IC which (as below) has P+ substrate and between the various pin. A P-N junction is formed from this P layer of each pin. For example the relation between each potential is as follows.(When GND > PinB and GND > PinA, the P-N junction operates as a parasitic diode.) Parasitic diodes can occur inevitably in the structure of the IC. The operation of parasitic diodes can result in mutual interference among circuits as well as operationfaults and physical damage. Accordingly, you must not use methods by which parasitic diodesoperate, such as applying a voltage that is lower than the GND(P substrate)voltage toan input pin. B (PinB) ~ ~ C Transistor (NPN) ~ ~ Resistance (PinA) E GND N P+ P+ P N P+ P N N N N N P substrate Parasitic diode P substrate GND GND Parasitic diode (PinB) ~ ~ (PinA) P+ C B ~ ~ Parasitic diode GND E GND Parasitic diode Simplified structure of a Bipolar IC Other adjacent components ●Power Dissipation (W) 5 ①No heat sink ②2 layer PCB (Copper laminate area 15 mm×15mm) ③2 layer PCB (Copper laminate area 70 mm×70mm) POWER DISSIPATION [Pd] 4 ③3.50W 3 ②1.85W 2 ①0.80W 1 0 0 25 50 75 85 100 125 AMBIENT TEMPERATURE [Ta] 150 (℃) *When mounted on a 70mmx70mmx1.6mm board www.rohm.com © 2009 ROHM Co., Ltd. All rights reserved. 10/11 2009.05 - Rev.A Technical Note BD9870FPS ●Ordering part number B D 9 8 7 0 F Part No. Part No. P S Package FPS = TO252S-5 - E 2 Packaging and forming specification E2: Embossed tape and reel (TO252S-5) TO252S-5 +0.2 5.1−0.1 1.5±0.2 <Tape and Reel information> 1.2±0.1 0.27±0.1 6.5±0.2 C0.5 Tape Embossed carrier tape Quantity 2000pcs Direction of feed E2 The direction is the 1pin of product is at the lower left when you hold ( reel on the left hand and you pull out the tape on the right hand ) 0.8 3 9.5±0.3 1.0±0.2 2.5±0.15 5.5±0.2 FIN 0.71 1 2 4 5 4 +6 –4 0.27±0.1 0.35±0.1 S 1.27 0.27±0.1 0.08 S 0.08 0.6±0.2 M 1pin (Unit : mm) www.rohm.com © 2009 ROHM Co., Ltd. All rights reserved. Reel 11/11 Direction of feed ∗ Order quantity needs to be multiple of the minimum quantity. 2009.05 - Rev.A Datasheet Notice Precaution on using ROHM Products 1. Our Products are designed and manufactured for application in ordinary electronic equipments (such as AV equipment, OA equipment, telecommunication equipment, home electronic appliances, amusement equipment, etc.). If you (Note 1) , transport intend to use our Products in devices requiring extremely high reliability (such as medical equipment equipment, traffic equipment, aircraft/spacecraft, nuclear power controllers, fuel controllers, car equipment including car accessories, safety devices, etc.) and whose malfunction or failure may cause loss of human life, bodily injury or serious damage to property (“Specific Applications”), please consult with the ROHM sales representative in advance. Unless otherwise agreed in writing by ROHM in advance, ROHM shall not be in any way responsible or liable for any damages, expenses or losses incurred by you or third parties arising from the use of any ROHM’s Products for Specific Applications. (Note1) Medical Equipment Classification of the Specific Applications JAPAN USA EU CHINA CLASSⅢ CLASSⅡb CLASSⅢ CLASSⅢ CLASSⅣ CLASSⅢ 2. ROHM designs and manufactures its Products subject to strict quality control system. However, semiconductor products can fail or malfunction at a certain rate. Please be sure to implement, at your own responsibilities, adequate safety measures including but not limited to fail-safe design against the physical injury, damage to any property, which a failure or malfunction of our Products may cause. The following are examples of safety measures: [a] Installation of protection circuits or other protective devices to improve system safety [b] Installation of redundant circuits to reduce the impact of single or multiple circuit failure 3. Our Products are designed and manufactured for use under standard conditions and not under any special or extraordinary environments or conditions, as exemplified below. Accordingly, ROHM shall not be in any way responsible or liable for any damages, expenses or losses arising from the use of any ROHM’s Products under any special or extraordinary environments or conditions. If you intend to use our Products under any special or extraordinary environments or conditions (as exemplified below), your independent verification and confirmation of product performance, reliability, etc, prior to use, must be necessary: [a] Use of our Products in any types of liquid, including water, oils, chemicals, and organic solvents [b] Use of our Products outdoors or in places where the Products are exposed to direct sunlight or dust [c] Use of our Products in places where the Products are exposed to sea wind or corrosive gases, including Cl2, H2S, NH3, SO2, and NO2 [d] Use of our Products in places where the Products are exposed to static electricity or electromagnetic waves [e] Use of our Products in proximity to heat-producing components, plastic cords, or other flammable items [f] Sealing or coating our Products with resin or other coating materials [g] Use of our Products without cleaning residue of flux (even if you use no-clean type fluxes, cleaning residue of flux is recommended); or Washing our Products by using water or water-soluble cleaning agents for cleaning residue after soldering [h] Use of the Products in places subject to dew condensation 4. The Products are not subject to radiation-proof design. 5. Please verify and confirm characteristics of the final or mounted products in using the Products. 6. In particular, if a transient load (a large amount of load applied in a short period of time, such as pulse. is applied, confirmation of performance characteristics after on-board mounting is strongly recommended. Avoid applying power exceeding normal rated power; exceeding the power rating under steady-state loading condition may negatively affect product performance and reliability. 7. De-rate Power Dissipation (Pd) depending on Ambient temperature (Ta). When used in sealed area, confirm the actual ambient temperature. 8. Confirm that operation temperature is within the specified range described in the product specification. 9. ROHM shall not be in any way responsible or liable for failure induced under deviant condition from what is defined in this document. Precaution for Mounting / Circuit board design 1. When a highly active halogenous (chlorine, bromine, etc.) flux is used, the residue of flux may negatively affect product performance and reliability. 2. In principle, the reflow soldering method must be used; if flow soldering method is preferred, please consult with the ROHM representative in advance. For details, please refer to ROHM Mounting specification Notice - GE © 2014 ROHM Co., Ltd. All rights reserved. Rev.002 Datasheet Precautions Regarding Application Examples and External Circuits 1. If change is made to the constant of an external circuit, please allow a sufficient margin considering variations of the characteristics of the Products and external components, including transient characteristics, as well as static characteristics. 2. You agree that application notes, reference designs, and associated data and information contained in this document are presented only as guidance for Products use. Therefore, in case you use such information, you are solely responsible for it and you must exercise your own independent verification and judgment in the use of such information contained in this document. ROHM shall not be in any way responsible or liable for any damages, expenses or losses incurred by you or third parties arising from the use of such information. Precaution for Electrostatic This Product is electrostatic sensitive product, which may be damaged due to electrostatic discharge. Please take proper caution in your manufacturing process and storage so that voltage exceeding the Products maximum rating will not be applied to Products. Please take special care under dry condition (e.g. Grounding of human body / equipment / solder iron, isolation from charged objects, setting of Ionizer, friction prevention and temperature / humidity control). Precaution for Storage / Transportation 1. Product performance and soldered connections may deteriorate if the Products are stored in the places where: [a] the Products are exposed to sea winds or corrosive gases, including Cl2, H2S, NH3, SO2, and NO2 [b] the temperature or humidity exceeds those recommended by ROHM [c] the Products are exposed to direct sunshine or condensation [d] the Products are exposed to high Electrostatic 2. Even under ROHM recommended storage condition, solderability of products out of recommended storage time period may be degraded. It is strongly recommended to confirm solderability before using Products of which storage time is exceeding the recommended storage time period. 3. Store / transport cartons in the correct direction, which is indicated on a carton with a symbol. Otherwise bent leads may occur due to excessive stress applied when dropping of a carton. 4. Use Products within the specified time after opening a humidity barrier bag. Baking is required before using Products of which storage time is exceeding the recommended storage time period. Precaution for Product Label QR code printed on ROHM Products label is for ROHM’s internal use only. Precaution for Disposition When disposing Products please dispose them properly using an authorized industry waste company. Precaution for Foreign Exchange and Foreign Trade act Since our Products might fall under controlled goods prescribed by the applicable foreign exchange and foreign trade act, please consult with ROHM representative in case of export. Precaution Regarding Intellectual Property Rights 1. All information and data including but not limited to application example contained in this document is for reference only. ROHM does not warrant that foregoing information or data will not infringe any intellectual property rights or any other rights of any third party regarding such information or data. ROHM shall not be in any way responsible or liable for infringement of any intellectual property rights or other damages arising from use of such information or data.: 2. No license, expressly or implied, is granted hereby under any intellectual property rights or other rights of ROHM or any third parties with respect to the information contained in this document. Other Precaution 1. This document may not be reprinted or reproduced, in whole or in part, without prior written consent of ROHM. 2. The Products may not be disassembled, converted, modified, reproduced or otherwise changed without prior written consent of ROHM. 3. In no event shall you use in any way whatsoever the Products and the related technical information contained in the Products or this document for any military purposes, including but not limited to, the development of mass-destruction weapons. 4. The proper names of companies or products described in this document are trademarks or registered trademarks of ROHM, its affiliated companies or third parties. Notice - GE © 2014 ROHM Co., Ltd. All rights reserved. Rev.002 Datasheet General Precaution 1. Before you use our Pro ducts, you are requested to care fully read this document and fully understand its contents. ROHM shall n ot be in an y way responsible or liabl e for fa ilure, malfunction or acci dent arising from the use of a ny ROHM’s Products against warning, caution or note contained in this document. 2. All information contained in this docume nt is current as of the issuing date and subj ect to change without any prior notice. Before purchasing or using ROHM’s Products, please confirm the la test information with a ROHM sale s representative. 3. The information contained in this doc ument is provi ded on an “as is” basis and ROHM does not warrant that all information contained in this document is accurate an d/or error-free. ROHM shall not be in an y way responsible or liable for an y damages, expenses or losses incurred b y you or third parties resulting from inaccur acy or errors of or concerning such information. Notice – WE © 2014 ROHM Co., Ltd. All rights reserved. Rev.001