* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download LED and ILED

Smart glass wikipedia , lookup

Image intensifier wikipedia , lookup

Upconverting nanoparticles wikipedia , lookup

Atmospheric optics wikipedia , lookup

Gaseous detection device wikipedia , lookup

Astronomical spectroscopy wikipedia , lookup

Ultrafast laser spectroscopy wikipedia , lookup

Anti-reflective coating wikipedia , lookup

Magnetic circular dichroism wikipedia , lookup

Retroreflector wikipedia , lookup

Thomas Young (scientist) wikipedia , lookup

Infrared photography wikipedia , lookup

Photomultiplier wikipedia , lookup

Ultraviolet–visible spectroscopy wikipedia , lookup

Night vision device wikipedia , lookup

James R. Biard wikipedia , lookup

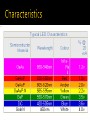

Characteristics, Structures, and Applications Description of LED and Infrared LED Schematic Symbol Structure Function and Characteristics Application and Operation Actual Component Figure LED is a semiconductor chip that generates light when current is applied to it, which is very different from any other technology currently used in lighting. There are also different types of LED emitters that have different characteristics that affect their applicability in lighting. An infrared light-emitting diode (IRLED) is a type of electronic device that emits infrared light not visible to the naked eye. An infraredLED operates like a regular LED, but may use different materials to produce infrared light. LED is visible than Infrared LED Infrared LEDs have a lower forward voltage, and a higher rated current compared to visible LEDs. This is due to differences in the material properties of the junction. A typical drive current for an infrared LED can be as high as 50 milliamps, so dropping in a visible LED as a replacement for an infrared LED could be a problem with some circuit designs. run very low current levels, in the tens of Milliamps commonly LEDs” Low cost referred as “indicator applications (push buttons, switches), clocks, tail lights on cars and trucks, reader boards and low wattage accent lighting applications approximately 50% of their initial light output within a few thousand hours and cannot generate or maintain enough light for use in general lighting applications always of surface mount form factor (meaning a chip or multiple chips on a die) running hundreds of milliamps per chip and generate a much more useful amount of light far more expensive than their low powered LED cousin but for “general lighting applications” they will perform best main concern with high powered LEDs is negligible heat die lead frame which houses the die encapsulation epoxy which protectively surrounds the die, and also disperses the light anvil post The die is bonded with conductive epoxy into a recess in one half of the lead frame, called the anvil due to its shape. The recess in the anvil is shaped to throw the light radiation forward. The die's top contact is wire-bonded to the other lead frame terminal, the post. LEDs are p-n junction devices constructed of gallium arsenide (GaAs), gallium arsenide phosphide (GaAsP), or gallium phosphide (GaP). Silicon and germanium are not suitable because those junctions produce heat and no appreciable IR or visible light. The junction in an LED is forward biased and when electrons cross the junction from the n- to the p-type material, the electron-hole recombination process produces some photons in the IR or visible in a process called electroluminescence. An exposed semiconductor surface can then emit light. LED is a semiconductor chip doped, with impurities to create a p-n junction. The current flows from the p-side, or anode, to the nside, or cathode, but not in the reverse direction. Charge carriers electrons and holes that flow into the junction from electrodes with different voltages (3 to 3.9VDC). When an electron meets a hole, it falls into a lower energy level, and releases energy in the form of a photon (Photon=light). The wavelength of the light emitted, and therefore its color, depends on the band gap energy of the materials forming the p-n junction. AV instruments such as Audio, TV, VCR, CD, DVD, MD etc. Home appliances such as Air conditioner, Fan etc. The other equipments with wireless remote control. CATV set top boxes. Multi-media Equipment. Sensors and light barrier systems for long distances indication lights computer components watches medical devices tanning equipment The simplest way to operate an LED is to apply a voltage source across it with a resistor in series. The LED emits constant-intensity light as long as the operating voltage (VB) remains constant (although the intensity decreases with increasing ambient temperature). You can vary the light intensity as required by changing the resistor value. Note that the voltage drop across an LED increases with forward current. Assuming that a single green LED with 10mA forward current should have a constant operating voltage of 5V, the series resistor RV equals (5V VF,10mA)/10mA = 300Ω.