* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download IDEM Operator Certification Information Part I

Portable water purification wikipedia , lookup

Water tariff wikipedia , lookup

Anaerobic lagoon wikipedia , lookup

Membrane bioreactor wikipedia , lookup

Water purification wikipedia , lookup

Anaerobic digestion wikipedia , lookup

Water pollution wikipedia , lookup

Ultraviolet germicidal irradiation wikipedia , lookup

Sewage sludge wikipedia , lookup

Biochemical oxygen demand wikipedia , lookup

Constructed wetland wikipedia , lookup

Sewage treatment wikipedia , lookup

Sewage sludge treatment wikipedia , lookup

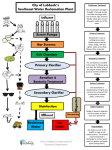

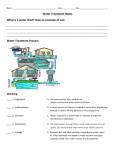

Wastewater Operator Certification Information Terms CWA – Clean Water Act passed in 1972 NPDES – National Pollutant Discharge Elimination System – permit good for 5 years (must reapply 180 day prior to expiration date) PE – Population Equivalency – how plants are designed – design for 20 years future growth PE, capita = (Flow, MGD)(BOD, mg/L)(8.34lb/gal) 0.17 lbs/BOD/capita/day * An operator should be present during construction to become familiar with the plant, including the equipment, machinery and the operation of it. Provides you with the opportunity to relate your plant to the drawings. Overview Collection Systems Rain Water I & I Wastewater Flow Preliminary Treatment Secondary Treatment Solids Handling Tertiary Treatment Laboratory Safety Rain Water Inflow and Infiltration (I&I) Enters collection system through cracks and holes in pipes, open cleanouts, cross connections, manholes, #1 cause – leaking pipe joints Can cause hydraulic overload at WPCF, decreased capacity due to sand and grit accumulation, lift station pump failures and overflows, increased operating costs Accounts for 30% of wastewater flow Liftstations Must maintain a velocity of 2ft per second to stop solids from settling and H2S from forming, when unable to reach that velocity build a lift station – lift flow to a higher elevation where it can again flow by gravity Has forced ventilation to prevent toxic gas fume build-up Most common is air-lift pump Wastewater Contents Domestic waste is 99.9% water Contains pathogenic (disease causing) bacteria, viruses, cysts that can cause Typhoid, Cholera, Dysentery, Polio and Hepatitis Floatable – floats to surface (scum & grease) Settleable – settles to bottom Suspended – won’t float or settle (same weight as water) Dissolved – such as food dye Colloidal – finely dissolved that remains in suspension causing turbidity (cloudiness) due to its size and electrical charge Raw Wastewater Solids Composition Wastewater is 99.9% water Dissolved solids makes up the highest percent of solids Dissolved and Suspended Solids make up Total Solids Preliminary Treatment To remove material that can damage or plug up equipment – grit, rags, plastics, sticks, etc. Flow Equalization / Surge Basins Bars Screens / Bar Racks Moving or Rotating Screens Shredding / Grinding Grit Chambers / Channels Odor Control Pumps (not considered treatment, but located in head works of plant) Pumps Impeller vane damage Cavitation The formation of partial vacuums in a liquid by a swiftly moving solid body (as a propeller) or by high-intensity sound waves The pitting and wearing away of solid surfaces (as of metal or concrete) as a result of the collapse of these vacuums in surrounding liquid Sedimentation and Floatation Sedimentation and Floatation happens in both Primary and Secondary (or final) clarifiers Purpose – to remove settleable and floatable solids from raw ww – Organic solids have high oxygen demand (BOD) Primary Clarifiers follows grit removal – Velocity 1.0 to 2.0 feet per minute Secondary Clarifier follows any biological treatment Primary VS Secondary Sludge Primary is denser (heavier) Primary is darker in color (dark chocolate) Effluent (liquid on top) is gray in color Secondary is lighter is color (milk chocolate) Secondary is mainly microorganisms (lighter) Effluent is clear Rotating Biological Contactor (RBC) Mechanical or air operated drive units rotate the media through wastewater Biomass is attached to the moving media (attached growth) 40% of the media is immersed in ww Covered RBCs Sequencing Batch Reactors (SBR) Treatment is carried out in a single tank through sequencing stages Handles periodic flows or batch dumps with ease Especially well suited for industries – Automatic control through Programmable Logic Control (PLC) – Stable due to high sludge age and long retention time – Less costly to build – no need for sludge handling – can be sent directly to drying beds or composting process BOD/N/P The ratio of biochemical oxygen demand to nitrogen to phosphorus should be 100/5/1. If the organic loading rate increases the appropriate N & P need to be added at a point where the incoming wastewater is highly mixed to provide nutrients needed by the microbes. The pounds of N & P required per day will be about 10% of the organic solids (dry weight) produced every day. The P required will be one-fifth of the N requirement. The amount of P & N added daily are equal to the difference between the quantity required and the quantity in the waste. Aqueous ammonia or anhydrous ammonia may be added to provide the nitrogen. Phosphate fertilizers or phosphoric acid from a waste acid facility may be used to provide P. Conventional Activated Sludge Detention time – 4 to 8 hours (6 hrs) Sludge Age – 3.5 to 7 days MLSS – 1,000 to 3,000 mg/L DO – 2 to 4 mg/L or ppm – High (>5.0) shear floc, waste energy – Low (<0.5) lead to bulking, poor effluent Mixing – Distributes oxygen evenly – Brings food in contact with microorganisms – Prevents septic conditions on bottom of tank Nitrification Cycle Heterotrophic Bacteria – Carbonaceous Stage Get energy from the oxidation of organic materials Common bacteria in wastewater This bacteria is responsible for denitrification Form floc – fast growing Autotrophic Bacteria – Nitrogenous Stage Get energy from inorganic materials or from the sunlight (some are algae) Are the nitrifiers Sulfide oxidizing organisms Do not form floc – slow growing Sludge Floc Floc under electron microscope Good floc Notice the large Floc looks like a lace thing running doily, almost no clear through this – that water between the floc is a filament. The particles, not way for small rice shaped this to settle. Acts more objects are the floc like a parachute. forming bacteria (heterotrophic). Young – weak lacy You can clearly make Floc is almost see through, out each floc particle very fragile looking. Sharp andinsee pretty clear edges comparison to the liquid outside of the floc. Good Floc. Filaments are There is very little starting to reach outside filament outside of the the floc particles. floc and the floc is “roundish” in shape. Old – dark and falling apart Ponds Primary Pond or Lagoon Secondary or Two Stage Pond This is how it works Tertiary or Three Stage Pond Feed the Primary Heat and Mix theisNo Sludge transferred Heating or Mixing – allow Digester with Primary Primary orDigester – solids (pumped) fromto the settle and liquids Secondary (WAS) called Sludge primary because Primary Digester (supernatant) to the to float to the it is the first digester –top Secondary Digester – some gas production creates gas Chemical Stabilization Lime – Addition of lime adds to the overall quantity of solids that must be disposed – High costs Chlorine – pH will drop <3.5 (acidic) – Lime may be added before dewatering Sludge Incineration Use dewatered sludge Converts dewatered sludge by combustion to carbon dioxide and water vapor Reduce volume up to 90% Most common is MHF (multiple hearth furnace) Temperature 1,300 – 1,700°F Only use the chlorine wrench when opening or closing cylinders – open 100%, close then reopen ¼ turn only Trunions – used to Fusible plug – center is turn ton cylinders so lead – will melt at 158 the valves are to 165ºF to release straight vertically gas instead of liquid or when opening explosion Train cargo cars (Class C) Ton (2,000 lb) cyliners (Class B) Biological Treatment Luxury Uptake of Phosphorous – modification of activated sludge Definitions – Aerobic (oxic): free DO is present – Anoxic: oxygen is deficient or present as combined oxygen in Nitrate (NO3) and Sulfate (SO4) Anaerobic: No oxygen Safety Top three injuries in wastewater in order: – Back – Leg – Hand Lockout/Tagout – Everyone who is working on that piece of equipment must sign/date/add lock Lab Miscellaneous Meniscus (commonly found in pipettes) – read at the bottom of the curve or the top of the curve You can preserve a metals sample for 6 months BOD solution water make-up – phosphate buffer, magnesium sulfate, calcium chloride, ferric chloride A bottle containing only dilution water is called a blank Pretreatment Total toxic organics (TTO) refers to the sum of the masses or concentrations of certain toxic organic pollutants found in the regulated discharge at a concentration greater than 0.01 mg/L Inspection – minimum of once per year or as needed Sampling – Significant Industrial User (SIU) at least annually and self monitored semi-annually