* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download MS PowerPoint - Catalysis Eprints database

Survey

Document related concepts

Transcript

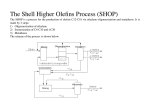

DIMERIZATION & OILGOMERIZATION Homogeneous Catalysis- Major Industrial Processes Processes/Products Production, MTA Terephthalic acid & Poly(Ethylene Terephthalate) 9 Acetic acid & acetyl chemicals 7 Aldehydes and alcohols- Hydroformylation 6 Adiponitrile- Hydrocyanation 1 Detergent-range alkenes- SHOP- Oligomerization 1 Alpha Olefins (C4- C20)- Dimerization & 4 Oligomerization Total fine chemicals manufacture <1 Olefins Polymerization (60% uses Ziegler-Natta) 60 Oligomerization & Dimerization – Key homogeneous processes Dimerization & Oligomerization Processes Dimerization of ethylene to Butene-1- Co-monomer in LLDPE- IFP & SABIC processes Dimerization of propylene- Methyl pentenes & HexenesGasoline additives- DIMERSOL- IFP Sumitomo & BP processes Dimerization of Butadiene- 1,5 Cyclo-octadieneCyclooctene- (ROP)- Vestenamer-Hulls process Trimerization of Butadiene-Cyclododecatriene- (ROP)Vestamid-Hulls process Butadiene+ Ethylene co-polymerization-EPDM rubberDuPont-Process Oligomerization of ethylene to Linear Alpha Olefins- LAO - Chevron-Phillips,(Gulf Oil)-GULFTENE, Ineos (Ethyl), Idemitsu, Conaco, Shell (SHOP), SABIC ( -SABLIN) Basis for the production of wide range of useful olefins & monomers Alpha Olefins-Applications C4 to C6 Co-monomers in polyethylene (4-12%) C8 to C10 C10 to C12 Plasticizer alcohols Synthetic lubricants C12 to C16 Detergents - Linear Alkyl Benzene (LAB) Alpha Olefin Sulphonates (LAO) C16 to C18 Lube oils, Surfactants C20 to C30+ Oil field Chemicals, Wax replacements Alpha Olefins via Ziegler Process 100 C, 10MPa 300 C, 1MPa Gulf Oil (1966) / Chevron (1983) Process • One step process with simultaneous chain growth & elimination • At 200 C & 25 Mpa ethylene pressure, with heptane as solvent • 0.4 wt% AlET3 w.r.t ethylene • Ethyl’s process is an improved version of Gulf’s Processes for Processes → Products↓ - Olefins - Comparison of product quality Wax Cracking Chevron Ethyl SHOP -Olefins 83-89 91-97 63-98 96-98 Branched olefins 3-12 2-8 2-29 1-3 Paraffins 1-2 1.4 0.1-0.8 0.1 Dienes 3-6 - - - Mono olefins 92-95 99 >99 99.9 Shell Higher Olefins Process (SHOP) Involves four processes 1. Oligomerization of ethylene to C4-C20+ α- olefins 80 to 120 °C and 70 to 140 bar (7 to 14 MPa) with a nickel phsophine complex (C6H5)2P(CH2)2COONi- Homogeneous 2. Isomerization of α-olefins to internal olefins- Heterogeneous 3. Metathesis of C20+olefins with C4-C8 olefins- Heterogeneous 4. Isomerization, hydroformylation & hydrogenation to αalcohols- Homogeneous Shell’s SHOP Process-Stepwise conversions Step. 1- Oligomerization H2C=CH2 -----------→ H (CH2-CH2)n-CH=CH2 n= 1 to 19 Ni complex Step.2- Fractionation of alpha-olefins C10-C14 - Olefins C4-C10 - Olefins C16-C40 - Olefins Step.3 – Hydroformylation of C10-C14 Olefins C10-C14 Olefins ------------→C11-C15 alcohols H2+CO CH3(CH2)7-CH=CH2-------------→CH3(CH2)7-CH2- CH2 –CHO Co(Co)6 ↓ H2 CH3(CH2)7-CH2- CH2 –CH2- OH Shell’s SHOP Process-Stepwise Conversions Step.4 – Isomerization Catalyst Na/K on Al2O3 or Mgo C4-C10 - Olefins ------------→ C4-C10 Internal olefins C16 –C40 - Olefins ------------→ C16 –C40 Internal olefins CH3-CH2-CH=CH2 ------------→ CH3-CH=CH-CH3 CH3 (CH2)17 -CH=CH2-------------→ CH3-(CH2)8-CH=CH-(CH2)8-CH3 Step.5- Metathesis of C4-C10and C16-C40 internal olefins Catalyst Mo/W/Re on Al2O3 CH3-CH=CH-CH3 + CH3-(CH2)8-CH=CH-(CH2)8-CH3 (i-C4) ↓ (iC20) 2 CH3-CH=CH –(CH2)8-CH3 Step.6 – Fractionation of internal olefins C10-C14 Internal Olefins C4-C10 Internal Olefins C16-C40 Internal Olefins Separation of C10-C14 olefins & Hydroformylation to alcohols Shell’s SHOP Process- Stepwise conversions Step.7 – Hydroformylation of C10-C14 Olefins C10-C14 Olefins ------------→C11-C15 alcohols H2+CO CH3(CH2)7-CH=CH2-------------→CH3(CH2)7-CH2- CH2 –CHO Co(Co)6 ↓ H2 CH3(CH2)7-CH2- CH2 –CH2- OH Step.8 – Repeat of steps 5,6 & 7 to exhaustion Shell’s SHOP Process- Block flow diagram Flow scheme of Shell’s SHOP Process Ethylene Oligomerization- Ni Complex catalyst Oligomerization-Addition of ethylene Dimerization of Propylene & Butadiene, Trimerization of Butadiene & Co-polymerization of Butadiene & ethylene to yield EPDM rubber Conversions with butadiene Olefin metathesis-Process steps Step.1 Formation of metal alkylidene complexes Step.2 Formation of metallocyclobutanes Step.3 Opening of metallocyclobutane to form products • Majority of metathesis reactions involve heterogeneous catalysis, Mo/W/Re supported on alumina • Homogeneous systems are also known Olefin Metathesis- Mechanism Alkene Metathesis-General cycle Different types of Olefin metathesis reactions