* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Starter - Linn-Benton Community College Homepage

Fault tolerance wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Brushless DC electric motor wikipedia , lookup

Electric battery wikipedia , lookup

Electric motor wikipedia , lookup

Stepper motor wikipedia , lookup

Electric machine wikipedia , lookup

Automatic test equipment wikipedia , lookup

Rechargeable battery wikipedia , lookup

Induction motor wikipedia , lookup

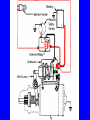

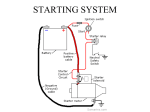

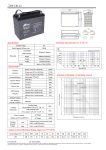

Starting Systems State a major safety precaution when removing or working around a starting motor Don’t make your starter an Arc Welder! Always unhook the battery ground Before removing the starter motor Starting Systems Identify the following components Armature Commutator Brushes Pole Shoe Field Coil Starter Armatures The Armature is a rotating electromagnet Commutator bars allow current in and out of the armature Brushes Brushes ride transfer on commutator electrons from bars the stationary field coils to the spinning armature InsulatedBrushes Brushes Grounded Field Coils are Stationary Pole Shoes concentrate the Electromagnets stationary magnetic field Starting Systems Identify the following components Starter housing or frame Bushings Starter Drive Pinion Over-running clutch Starter Diagnosis Worn outthe bushings... Allow armature to drag on the pole shoes This will slow the starter and INCREASE amp draw Worn or Dry Armature shaft will INCREASE amp flow Burned commutator bars restrict the amp flow Worn out brushes DECREASE amp flow There will be more questions... ...On the test…. …than I am covering here. Read your book… and complete Starter Labs Test the Starting System Check Cranking RPM Check Cranking Volts Check Cranking Amps Low Cranking RPM A slow turning starter will pull extra amps Could be caused by tight engine (New Engines) Can be caused by advanced timing Low Cranking RPM Low cranking RPM…. …With low cranking Amps… Bad Starter Worn brushes, Bad commutator bars, open in field or armature Cranking Volts Power is required to turn motor P=IxE Low volts will cause high amps Low Cranking Volts Cranking volts at battery should be over 10V Load test battery if low cranking volts Excessive amp draw can cause low cranking volts in a good battery High Cranking Amps Check voltage drop across STARTER MOTOR If Battery cranking volt is 1/2 volt more than Starter volt drop diagnose battery cables and connections If cranking volts are within 1 volt of battery… Insure engine turns freely Insure ignition does not cause slow turning engine Replace Starter Motor (assuming there are excessive amps) Before you install the rebuilt starter Bench test the replacement It may save you a starter R & R Starting Systems Understand the operation of the two starting circuits #1 Starter Control Circuit #2 Starter Motor Circuit Starter Solenoid Understand the function of the Pull In solenoid windings…. …and the hold in solenoid windings Starter Solenoids Predict the effect of an open circuit in the solenoid pull in windings…. ….and the solenoid hold in windings Notice pitted contact ring 24 Volt Series/Parallel Switch Understand how 12 volt batteries can be used to run a 24 Volt starting system Series/Parallel Switch Diagnose a defective series parallel switch using a volt meter Starter Control Identify variations in starter control circuits Test the Starting System The Bottom Line Test cranking RPM Test Cranking Volts Test Cranking Amps