* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Live Power Line Inspection Robot

Stray voltage wikipedia , lookup

Public address system wikipedia , lookup

Alternating current wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Mains electricity wikipedia , lookup

Electrical engineering wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Distributed control system wikipedia , lookup

Electric machine wikipedia , lookup

Rotary encoder wikipedia , lookup

Resilient control systems wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Geophysical MASINT wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Power electronics wikipedia , lookup

Analog-to-digital converter wikipedia , lookup

Electronic engineering wikipedia , lookup

Buck converter wikipedia , lookup

Control theory wikipedia , lookup

MECHATRONICS

U5MEA22

Prepared by

Mr. S Riyaz Ahammed & Mr. Hushein

Assistant Professor, Mechanical Department

VelTech Dr.RR & Dr.SR Technical University

Unit 1

Mechatronics: Mechatronics basically refers to mechanical electrical

systems and is centered on mechanics, electronics,

computing and control which, combined, make

possible the generation of simpler, more economical,

reliable and versatile systems.

•The term "mechatronics" was first assigned by

Mr.Tetsuro Mori, a senior engineer of the Japanese

company Yaskawa, in 1969.

• Mechatronics is the combination of mechanical,

electronic, computer,control engineering's and system

engineering to design and manufacture useful products.

Key Elements

Measurement system

Control Systems

Control Systems are mainly of Two Types

• Open Loop Control Systems

• Closed Loop control Systems

•An open-loop controller, also called a non-feedback

controller.

• Basic difference between two types of systems is

closed loop systems have feed back which makes them

to be good precise control systems or automated

systems.

•PID controller, a commonly used closed-loop controller

Water Level Controller

• Controlled variable- water level in tank

• Reference value- initial setting of float, lever

position

• Comparison element- Lever

• Error signal- Difference between the actual

and initial settings of lever

position

• Control unit- Pivoted lever

• Correction unit- Flap opening or closing water

supply

• Process- water level in the tank

Shaft speed control systems

Description

• Potentiometer is used to set the voltage to be

supplied to the power amplifier.

• Differential amplifier is used to amplify and

compare the feed back value and reference

value.

• Amplified error signal is fed to the motor to

adjust the speed of rotating shaft.

• Tachometer is used to measure the speed of

rotating shaft and speed is fed to amplifier.

Washing Machine control

• Example of an event based sequential control

system is washing machine. Each event of

washing machine may consist of number of

sub events or steps. For example pre wash

cycle, rinse cycle, main cycle, spinning cycle.

• Following figures represent the various events

of washing machine system.

•During Pre wash cycle operation, the inlet valve is

opened when the machine is switched ON and the

valve is closed when the required level of water is filled

in the drum.

Main wash cycle is then started by micro processor by

operating the inlet valve to allow the water in to the

drum.

Water level sensor senses the water level in the drum

and it closes the inlet valve after reaching certain level,

Micro processor switches ON the heating coil in the

drum.

AUTOMATIC CAMERA

• Basic elements of control systems used in

automatic camera are body, lenses and flash.

• Depending up on mode selected, the required

combination of aperture and shutter speed

and focus are automatically taken care by the

camera.

• A typical camera system comprises drives and

sensors, interfaces for lenses, flash and the

user.

• Micro processor systems for lenses, user and

flash are incorporated for controlling various

operations. Micro processor takes input from

range sensor and sends output to lens.

• Position is fed back to micro processor and it

modifies the same.

• Light sensor gives input to micro processor,

When photographer selects shutter controller,

shutter opens up for photograph to be taken.

Engine Management System

• System consists of sensors for supplying, after

suitable signal conditioning, the input signals

to micro controller, and its providing output

signals via drivers to actuate actuators.

• Engine speed sensor is an inductive sensor

and consists of a coil for which inductance

changes as the teeth of the sensor wheel pass

it and so gives oscillating output.

• Temperature sensor is usually a thermistor.

• Mass air flow sensor may be a hot wire sensor,

as air passes over heated wire it will be

cooled, the amount of cooling will depend on

the mass rate of flow.

• Oxygen sensor is generally closed end tube

made of zirconium oxide with porous

platinum electrodes on inner and outer

surfaces.

• Following figure represents an engine

management system

Unit 2

MICROPROCESOR

IN

MECHATRONICS

MICROPROCESSOR

• A microprocessor incorporates the functions

of a computer's central processing unit (CPU)

on a single integrated circuit (IC),or at most a

few integrated circuits. Microprocessor is a

multipurpose, programmable device that

accepts digital data as input, processes it

according to instructions stored in its memory,

and provides results as output

8085 ARCHITECTURE

INPUT AND OUTPUT PERIPHERAL

CIRCUITS

• A peripheral is a device that is connected to a

host computer, but not part of it. It expands the host's

capabilities but does not form part of the

core computer architecture. It is often, but not always,

partially or completely dependent on the host.

• There are three different types of peripherals:

• Input, used to interact with, or send data to the

computer (mouse, keyboards, etc.)

• Output, which provides output to the user from the

computer (monitors, printers, etc.)

• Storage, which stores data processed by the computer

(hard drives, flash drives, etc.)

COMMUNICATIONS-INPUT,OUTPUT

AND MEMORY WITH TIMING

DIAGRAM

• Input/output (I/O) scheduling is the method

that computer operating systems use to

decide which order block I/O operations will

be submitted to storage volumes. I/O

Scheduling is sometimes called 'disk

scheduling'.

PURPOSE

• I/O schedulers can have many purposes depending on

the goal of the I/O scheduler. Some common ones are:

• To minimize time wasted by hard disk seeks

• To prioritize a certain processes' I/O requests

• To give a share of the disk bandwidth to each running

process

• To guarantee that certain requests will be issued before

a particular deadline

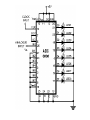

A/D CONVERTER

• An analog-to-digital

converter (abbreviated ADC, A/D or A to D) is

a device that converts a continuous physical

quantity (usually voltage) to a digital number

that represents the quantity's amplitude.

• The conversion involves quantization of the

input, so it necessarily introduces a small

amount of error. Instead of doing a single

conversion, an ADC often performs the

conversions ("samples" the input) periodically.

The result is a sequence of digital values that

have converted a continuous-time and

continuous-amplitude analog signal to

a discrete-time and discrete-amplitude digital

signal.

• An ADC may also provide an isolated measurement such as

an electronic device that converts an input

analog voltage or current to a digital number proportional

to the magnitude of the voltage or current. However, some

non-electronic or only partially electronic devices, such

as rotary encoders, can also be considered ADCs. The digital

output may use different coding schemes. Typically the

digital output will be a two's complement binary number

that is proportional to the input, but there are other

possibilities. An encoder, for example, might output a Gray

code.

• The inverse operation is performed by a digital-to-analog

converter (DAC).

ELECTRICAL SYMBOL

• The key parameters to test a SAR ADC are

following:

• DC Offset Error

• DC Gain Error

• Signal to Noise Ratio (SNR)

• Total Harmonic Distortion (THD)

• Integral Non Linearity (INL)

• Differential Non Linearity (DNL)

• Spurious Free Dynamic Range

• Power Dissipation

D/A CONVERTER

• a digital-to-analog converter (DAC or D-to-A)

is a device that converts a digital (usually

binary) code to an analog

signal (current, voltage, or electric charge).

An analog-to-digital converter (ADC) performs

the reverse operation. Signals are easily stored

and transmitted in digital form, but a DAC is

needed for the signal to be recognized by

human senses or other non-digital systems.

• A common use of digital-to-analog converters

is generation of audio signals from digital

information in music players. Digital video

signals are converted to analog

in televisions and mobile phones to display

colors and shades. Digital-to-analog

conversion can degrade a signal, so conversion

details are normally chosen so that the errors

are negligible.

• Due to cost and the need for

matched components, DACs are almost

exclusively manufactured on integrated

circuits (ICs). There are many

DACarchitectures which have different

advantages and disadvantages. The suitability

of a particular DAC for an application is

determined by a variety of measurements

including speed and resolution.

RECENT DEVELOPMENTS IN MICROPROCESSORS AND

CONTROLLERS

•

The recent development In microprocessor technology makes

Implementation of advanced control strategies feasible at the

generating level. A self-tuning (ST) proportional-plus-lntegral-plusderivative (PID) digital automatic voltage regulator (DAVR) for a large

synchronous machine is proposed and the influence of this regulator

on the generator dynamic and transient stability is investigated. The

algorithm for this regulator combines a least-square estimator with a

digital PID control algorithm. The parameters of the PID control

algorithm are computed and updated according to the estimated

model. The dynamic performance of the machine when equipped

with a digital PID governor is also presented. A comparison of the

computer results as obtained from the simulation study are

compared with the available experimental results.

Unit 3

ELECTRICAL DRIVES

AND

CONTROLLERS

Electromagnetic principles

• "When a conductor is exposed to a changing magnetic field, an

electric current will flow in the conductor."

• This principle is the basis for the generation of electricity. In a

typical large-scale operating electrical generator, an armature coil (a

coil of wire of many turns) is wrapped around a soft iron armature

and forced to spin in a powerful electromagnetic field. The spinning

is achieved by forcing high-pressure steam (in a thermal generator),

fast-flowing water (in a hydro generator), or wind (in a wind

generator) across a turbine (similar to a propeller blade) attached to

the end of the armature. As the armature spins, an electric current

is induced (forced) to flow in the armature coil where it is extracted

and sent to the electricity grid that supplies electricity across a

broad area (the province of Ontario and beyond, for example). It is

the direction of flow of this induced current that is addressed by

Lenz's law.

SOLENOIDS

• In physics, the term refers specifically to a

long, thin loop of wire, often wrapped around

a metallic core, which produces a

uniform magnetic field in a volume of space

(where some experiment might be carried

out) when an electric current is passed

through it. Solenoids are important because

they can create controlled magnetic fields and

can be used as electromagnets.

• In engineering, the term may also refer to a

variety of transducer devices that

convert energy into linear motion. The term is

also often used to refer to asolenoid valve, which

is an integrated device containing an

electromechanical solenoid which actuates either

a pneumatic or hydraulic valve, or a solenoid

switch, which is a specific type of relay that

internally uses an electromechanical solenoid to

operate an electrical switch; for example,

an automobile starter solenoid, or a linear

solenoid, which is an electromechanical solenoid.

SOLENOID

RELAYS

• A relay is an electrically operated switch. Many relays

use an electromagnet to operate a switching

mechanism mechanically, but other operating

principles are also used. Relays are used where it is

necessary to control a circuit by a low-power signal

(with complete electrical isolation between control and

controlled circuits), or where several circuits must be

controlled by one signal. The first relays were used in

long distance telegraph circuits, repeating the signal

coming in from one circuit and re-transmitting it to

another. Relays were used extensively in telephone

exchanges and early computers to perform logical

operations.

ELECTROMECHANICAL RELAY

• A type of relay that can handle the high power

required to directly control an electric motor

or other loads is called a contactor. Solid-state

relays control power circuits with no moving

parts, instead using a semiconductor device to

perform switching. Relays with calibrated

operating characteristics and sometimes

multiple operating coils are used to protect

electrical circuits from overload or faults; in

modern electric power systems these

functions are performed by digital instruments

still called "protective relays".

STEPPER MOTORS

• A stepper motor (or step motor) is a brushless

DC electric motor that divides a full rotation

into a number of equal steps. The motor's

position can then be commanded to move

and hold at one of these steps without any

feedback sensor (an open-loop controller), as

long as the motor is carefully sized to the

application.

TYPES OF STEPPER MOTORS

• There are four main types of stepper motors:[1]

• Permanent magnet stepper (can be subdivided

into 'tin-can' and 'hybrid', tin-can being a cheaper

product, and hybrid with higher quality bearings,

smaller step angle, higher power density)

• Hybrid synchronous stepper

• Variable reluctance stepper

• Lavet type stepping motor

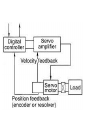

SERVO MOTORS

• A servomotor is a rotary actuator that allows for precise

control of angular position, velocity and acceleration. It

consists of a suitable motor coupled to a sensor for position

feedback. It also requires a relatively sophisticated

controller, often a dedicated module designed specifically

for use with servomotors.

• Servomotors are not a different class of motor, on the basis

of fundamental operating principle, but

uses servomechanism to achieve closed loop control with a

generic open loop motor.

• Servomotors are used in applications such

as robotics, CNC machinery or automated manufacturing.

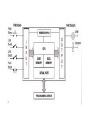

PROGRAMMABLE LOGIC CONTROLLER

• A Programmable Logic

Controller, PLC or Programmable Controller is

a digital computer used

for automation of electromechanical processes,

such as control of machinery on factory assembly

lines, amusement rides, or light fixtures. The

abbreviation "PLC" and the term "Programmable

Logic Controller" are registered trademarks of

the Allen-Bradley Company (Rockwell

Automation).

• PLCs are used in many industries and machines.

Unlike general-purpose computers, the PLC is

designed for multiple inputs and output

arrangements, extended temperature ranges,

immunity to electrical noise, and resistance to

vibration and impact. Programs to control

machine operation are typically stored in batterybacked-up or non-volatile memory. A PLC is an

example of a hard real time system since output

results must be produced in response to input

conditions within a limited time, otherwise

unintended operation will result.

MEMORY- INPUT , OUTPUT MODULES

• In computer architecture, the combination of

the CPU and main memory (i.e. memory that the CPU

can read and write to directly, with

individual instructions) is considered the brain of a

computer, and from that point of view any transfer of

information from or to that combination, for example

to or from a disk drive, is considered I/O. The CPU and

its supporting circuitry providememory-mapped

I/O that is used in low-level computer programming,

such as the implementation of device drivers. An I/O

algorithm is one designed to exploit locality and

perform efficiently when data reside on secondary

storage, such as a disk drive.

TIMERS- INTERNAL RELAYS

• A timer is a clock that controls the sequence

of an event while counting in fixed intervals of

time

• A timer is a specialised type of clock for

measuring time intervals

Counters – shift registers

• In digital circuits a shift register is a cascade of

flip-flops , sharing the same clock, in which

the output of each flip flop is connected to the

data input of next flip flop in the chain

resulting in the circuit that shifts by one

position the bit array stored in it,shifting in the

data present at its input and shifting out the

last bit in the array, at each transition of clock

input.

Counter- timing

PLC- USING LADDER DIAGRAM

A ladder diagram represents a program in

“LADDER LOGIC”

A ladder logic is a method of drawing electrical

logic schematics.

PLC WITH LADDER LOGIC

PLC - APPLICATIONS

Unit 4

Limit Switch

• A limit switch is an electromechanical device

that consists of an actuator mechanically

linked to a set of contacts.

• When an object comes into contact with the

actuator, the device operates the contacts to

make or break an electrical connection.

• It can determine the presence or absence of

an object. It was first used to define the limit

of travel of an object; hence the name "Limit

Switch."

Basic Components

• Actuator: The portion of the switch that comes in

contact with the object being sensed.

• Head: It houses the mechanism that translates

actuator movement into contact movement.

When the actuator is moved as intended, the

mechanism operates the switch contacts.

• Contact Block: It houses the electrical contact

elements of the switch. It typically contains either

two or four contact pairs.

Basic Components (contd.)

• Terminal Block: The terminal block contains the

screw terminations. This is where the electrical

(wire) connection between the switch and the

rest of the control circuit is made.

• Switch Body: The switch body houses the contact

block in a plug-in switch. It and terminal block in

the nonplug-in switch.

• Base: The base houses the terminal block in a

plug-in switch. Nonplug-in switches do not have a

separate base.

Type-1 Nonplug-in Housing

• They are box

shaped with a

separate cover.

• Seals between the

head, body, and

cover are

maintained by an

O-ring and a flat

gasket.

Type-2 Plug-in Housing

• Developed to ease

replacement of the switch

if needed.

• Plug-in housing splits in

half to allow access to the

terminal block for wiring.

• A set of stabs in the

switch body “plugs” into

sockets in the base to

make electrical

connections between the

contact block and the

terminal block.

Encoders

• What is an encoder?

An encoder is a sensor for converting rotary motion or position

to a series of electronic pulses

• Advantages

Simplicity of construction (low cost)

High sensitivity (depending upon the supply voltage)

•

Disadvantages

It includes the familiar drawbacks related to contacting

and communicating devices like friction, wear, brush

bounce due to vibration, signal glitches and metal

oxidation due to electrical arcing.

The types of encoders

• Absolute encoders

• Absolute encoders have a unique code that can be

detected for each angular position

• Absolute encoders are much more complex and expensive

than incremental encoders

The types of encoders

• Incremental encoders

• Pulses from LEDS are counted to provide rotary position

• Two detectors are used to determine direction (quadrature)

• Index pulse used to denote start point

• Otherwise pulses are not unique

Temperature Sensor

• Temperature sensors appear in building, chemical

process plants, engines, appliances, computers, and

many other devices that require temperature

monitoring

• Many physical phenomena depend on temperature,

so we can often measure temperature indirectly by

measuring pressure, volume, electrical resistance,

and strain

Temperature Sensor

• Bimetallic Strip

L L 0[1 (T - T0)]

Metal A

δ

• Application

– Thermostat (makes or

breaks electrical

connection with

deflection)

Metal B

Temperature Sensor

• Resistance temperature

device.

R R 0[1 (T - T0)]

R R0 e

1 1

T T0

Position Sensors

Position Sensors is a device that provides the position

measurement of a component. A position sensor can

be:

1.Linear

2.Angular

3.Multi-axis

Some of the well-known position sensors are:

Linear Variable Differential Transformer (LVDT)

Hall Effect Sensor

Proximity Sensor

LDVT-Configuration

• An alternating current is driven

through the primary, causing a

voltage to be induced in each

secondary proportional to its

mutual inductance with the

primary. The frequency is usually

in the range 1 to 10 kHz.

Hall Effect Sensor

•

•

•

The Hall effect was discovered by Edwin Hall in

1879; “electron” was not experimentally

discovered; had to wait until quantum mechanics

came

Development of semiconductor compounds

in 1950's led to first useful Hall effect magnetic

instrument

In the 1960's, first combinations of Hall elements

and integrated amplifiers

–

–

Resulted to classic digital output Hall switch

In 1965, first low-cost solid state sensor

Theory of the “Hall Effect”

Hall effect principle, no

magnetic field

Hall effect principle,

magnetic field present

Potential Difference

(voltage) across output:

V=I*B

Basic Hall Effect Sensor

• Hall element is the basic

magnetic field sensor

• Differential Amplifier

amplifies the potential difference

(Hall voltage)

• Regulator holds current value

so that the output of the sensor

only reflects the intensity of the

magnetic field

• Types

1. Unipolar

2.Latching

3.Bipolar

Proximity Sensor

• A proximity sensor is a sensor able to detect

the presence of nearby objects without any

physical contact.

• These sensors use mutual inductance

between a known inductor and a conductive

material

• Commonly referred to as “eddy current”

probes

• Mutual inductance is a function of the

distance between the inductor and the

material

How “Eddy Currents” Work

• An inductive coil is placed near a

conductive surface

• An AC voltage (typically around

2Mhz) is applied to the coil

• Mutual inductance begins to

occur

• The coil generates a magnetic

field

• Circular or “Eddy Currents” begin

to flow in the conductive material

• These currents resemble an eddy

in a stream of water

How “Eddy Currents” Work

• The Eddy Currents

generate their own

magnetic field

• These fields have

interaction with the coil

through mutual

inductance

• This leads to a

measurable result

What can be measured?

• Electrical conductivity and magnetic

permeability of the target material

• The amount of material cutting through the

coils of the magnetic field

• The condition of the material(whether it

contains cracks or defects

• Lift-Off

Pressure Sensor

•

Two Main Types of Pressure Sensors

Capacitive Sensors

– Work based on measurement of

capacitance from two parallel plates.

– C = εA/d , A = area of plates d =

distance between.

– This implies that the response of a

capacitive sensor is inherently nonlinear. Worsened by diaphragm

deflection.

– Must use external processor to

compensate for non-linearity

Pressure Sensor

Piezoresistive Sensors

•

•

•

•

Work based on the piezoresistive

properties of silicon and other

materials.

Piezoresistivity is a response to stress.

Some piezoresistive materials are Si,

Ge, metals.

In semiconductors, piezoresistivity is

caused by 2 factors: geometry

deformation and resistivity changes.

Pressure Sensing

• Pressure is sensed by mechanical

elements such as plates, shells, and tubes

that are designed and constructed to

deflect when pressure is applied.

• This is the basic mechanism converting displacement

pressure to physical movement.

• Next, this movement must be transduced

to obtain an electrical or other output.

• Finally, signal conditioning may be

electric

needed, depending on the type of sensor

and the application. Figure 8 illustrates

the three functional blocks.

Pressure

Sensing

Element

Transduction

element

Signal

Conditioner

V or I output

Sensing Elements

• The main types of sensing

elements are Bourdon

tubes, diaphragms,

capsules, and bellows

• All except diaphragms

provide a fairly large

displacement that is useful

in mechanical gauges and

for electrical sensors that

require a significant

movement

Potentiometric Pressure Sensors

• Potentiometric pressure sensors

use a Bourdon tube, capsule, or

bellows to drive a wiper arm on a

resistive element.

• For reliable operation the wiper

must bear on the element with

some force, which leads to

repeatability and hysteresis

errors.

• These devices are very low cost,

however, and are used in lowperformance applications such as

dashboard oil pressure gauges

Inductive Pressure Sensors

• Several configurations based on

varying inductance or inductive

coupling are used in pressure

sensors. They all require AC

excitation of the coil(s) and, if a DC

output is desired, subsequent

demodulation and filtering. The

LVDT types have a fairly low

frequency response due to the

necessity of driving the moving core

of the differential transformer

• The LVDT uses the moving core to

vary the inductive coupling

between the transformer primary

and secondary.

Capacitive Pressure Sensors.

• Capacitive pressure sensors typically use a thin diaphragm as

one plate of a capacitor.

• Applied pressure causes the diaphragm to deflect and the

capacitance to change.

• This change may or may not be linear and is typically on the

order of several picofarads out of a total capacitance of 50100 pF.

• The change in capacitance may be used to control the

frequency of an oscillator or to vary the coupling of an AC

signal through a network.

• The electronics for signal conditioning should be located close

to the sensing element to prevent errors due to stray

capacitance.

INTRODUCTION OF TRANSDUCERS

• A transducer is a device that convert one form of energy

to other form. It converts the measurand to a usable

electrical signal.

• In other word it is a device that is capable of converting

the physical quantity into a proportional electrical

quantity such as voltage or current.

Pressure

Voltage

BLOCK DIAGRAM OF TRANSDUCERS

• Transducer contains two parts that are closely related to

each other i.e. the sensing element and transduction

element.

• The sensing element is called as the sensor. It is device

producing measurable response to change in physical

conditions.

• The transduction element convert the sensor output to

suitable electrical form.

CHARACTERISTICS OF TRANSDUCERS

1.

2.

3.

4.

5.

6.

7.

8.

Ruggedness

Linearity

Repeatability

Accuracy

High stability and reliability

Speed of response

Sensitivity

Small size

TRANSDUCERS SELECTION FACTORS

1.

2.

3.

4.

5.

6.

Operating Principle: The transducer are many times selected

on the basis of operating principle used by them. The operating

principle used may be resistive, inductive, capacitive ,

optoelectronic, piezo electric etc.

Sensitivity: The transducer must be sensitive enough to

produce detectable output.

Operating Range: The transducer should maintain the range

requirement and have a good resolution over the entire range.

Accuracy: High accuracy is assured.

Cross sensitivity: It has to be taken into account when

measuring mechanical quantities. There are situation where the

actual quantity is being measured is in one plane and the

transducer is subjected to variation in another plan.

Errors: The transducer should maintain the expected inputoutput relationship as described by the transfer function so as

to avoid errors.

Contd.

7.

Transient and frequency response : The transducer should meet

the desired time domain specification like peak overshoot, rise

time, setting time and small dynamic error.

8. Loading Effects: The transducer should have a high input

impedance and low output impedance to avoid loading effects.

9. Environmental Compatibility: It should be assured that the

transducer selected to work under specified environmental

conditions maintains its input- output relationship and does not

break down.

10. Insensitivity to unwanted signals: The transducer should be

minimally sensitive to unwanted signals and highly sensitive to

desired signals.

CLASSIFICATION OF TRANSDUCERS

The transducers can be classified as:

I.

II.

III.

IV.

V.

Active and passive transducers.

Analog and digital transducers.

On the basis of transduction principle used.

Primary and secondary transducer

Transducers and inverse transducers.

Unit 5

Stages in designing Mechatronics

Systems

Traditional and Mechatronics

Design

• system is partitioned into individual

homogenous subsystems according to the

disciplines,

• homogenous subsystems are designed by

specialists from a design team,

• each homogenous subsystem is designed

by traditional way,

• each product function is from the most

part realized by only one homogenous

subsystem,

• ¾ interactions are minimized, emphasis is

mainly laid on common interfaces of the

subsystems.

• more functions,

• higher efficiency and

reliability,

• lower demands on energy,

• minimal size and weight,

• lower cost.

Engine Management Systems

1.Throttle position

sensor

2.EGO sensor

3.MAP Sensor

4.Temperature

sensor

5.Speed/Timing

Sensor

6.EGR diagnostic

switch

7.EGR valve position sensor

Sensors and actuators in EMS

Pick and Place Robot

• The robot has three axis about which motion can occur.

• The following movements are required for this robot.

1. clockwise and anticlockwise rotation of the robot unit on its base.

2. Linear movement of the arm horizontally i.e., extension or

contraction of arm.

3. Up and down movement of the arm and

4. Open and close movement of the gripper.

• The foresaid movements can be obtained by pneumatic cylinder

which is operated by solenoid valves with limit switches.

• Limits switches are used to indicate when a motion is completed.

• The clockwise rotation of the robot unit on its base can be obtained

from a piston and cylinder arrangement during pistons forward

movement

• v Similarly counter clockwise rotation can be obtained during

backward

• movement of the piston in cylinder.

Control circuit diagram of the pick

and place robot

Automatic car parking system

• Consider an automatic car park system with barriers operated by coin

inserts.

• The system uses a PLC for its operation.

• There are two barriers used namely in barrier and out barrier. In barrier is

used to open when the correct money is inserted while out barrier open

when the car is detected in front of it.

• It shows a schematic arrangement of an automatic car park barrier. It

consists of a barrier which is pivoted at one end, two Solenoid valves A and

B and a piston cylinder arrangement

• A connecting rod connects piston and barrier as shown in fig below

Solenoid valves are used to control the movement of the piston.

• Solenoid A is used to move the piston upward inturn barrier whereas

solenoid B is used to move the piston downward.

• Limit switches are used to

detect the foremost position

of the barrier. When current

flows through solenoid A, the,

piston in the cylinder moves

upward and causes the barrier

to rotate about its pivot and

raises to let a car through

THANK YOU