* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download ucn5804b

Commutator (electric) wikipedia , lookup

Power engineering wikipedia , lookup

Control system wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Three-phase electric power wikipedia , lookup

Electrical substation wikipedia , lookup

Stray voltage wikipedia , lookup

Electrification wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

History of electric power transmission wikipedia , lookup

Power inverter wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Current source wikipedia , lookup

Electric machine wikipedia , lookup

Voltage regulator wikipedia , lookup

Mains electricity wikipedia , lookup

Power MOSFET wikipedia , lookup

Two-port network wikipedia , lookup

Schmitt trigger wikipedia , lookup

Voltage optimisation wikipedia , lookup

Power electronics wikipedia , lookup

Alternating current wikipedia , lookup

Electric motor wikipedia , lookup

Buck converter wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Brushless DC electric motor wikipedia , lookup

Opto-isolator wikipedia , lookup

Induction motor wikipedia , lookup

Current mirror wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Stepper Motor Musings

November 15, 2001 – Page 1

Introduction

I wanted to put down my latest thoughts on the stepper motor information that I’ve

gathered up. Obviously there is a bunch of stuff attached, but I think it should help move

us forward.

General Stepper Motor Info

There is a tutorial available on the we called, “Control of Stepping Motors, a tutorial”

which is available athttp://www.cs.uiowa.edu/~jones/step/index.html. It seems to deal

with the physics of the device in great detail. Also there’s a good reference at Wirz

(http://www.wirz.com/stepper/index.html) that has a good discussion about positioning.

I’ve attached some other relevant info as follows:

Attachment 1 – A description of 5, 6 and 8 lead stepper motors

Attachment 2 – StampWorks Project 26

Attachment 3 – 5804 Schematic

Attachment 4 - Basic Stamp I Stepper Controller

Attachment 5 – UNL2003 info

What We Have

So far we’ve received:

==============================================================

?? The Little Step-U and a 5-lead 12 Volt / 75 Ohm Unipolar Stepper Motor and a

ULN2803A Darlington Array.

Motor specs are at: http://dropball.cs.emporia.edu/stepper/index.html.

The full Little Step-U doc is at: http://dropball.cs.emporia.edu/stepper/5804.pdf.

The schematic for using this guy is:

Stepper Motor Musings

November 15, 2001 – Page 2

With details of the implementation and the Step-U at:

http://dropball.cs.emporia.edu/stepper/LittleStep.PDF.

I’ve order the addit ional components shown in the schematic from DigiKey and they

should arrive next week.

?? A generic stepper motor control using the basic stamp II. Schematic included as

Attachment 2.

Stepper Motor Musings

November 15, 2001 – Page 3

I’ve order the additional components shown in the schematic from DigiKey and they

should arrive next week.

==============================================================

?? From Alltronics (http://www.alltronics.com/stepper_motors.htm) I’ve received:

UNIPOLAR STEPPER MOTOR DRIVER IC UCN5804

NEMA size 23 (2.25" sq. x 2.25" L). 0.25" shaft both ends (front 0.375"L, rear 0.625"L).

Unipolar, six wires. 1.7 Volts, 3.4 Amps, 1.8°/step. Coil resistance 0.7 Ohm. Japan Servo

Co. #KP6M2-020 or equivalent.

SIX-WIRE UNIPOLAR STEPPER MOTOR 5VDC, 15°/step, 2" dia. x 1" thick. brass

gear. Nippon Pulse #PF55-48C5.

The schematic for using the 5804 is included as attachment 3.

I’ve order the additional components shown in the schematic from DigiKey and they

should arrive next week.

==============================================================

Basic Stamp I Circuit

Circuit is shown in Attachment 4. The circuit utilizes a ULN2003 Darlington array. Specs

for the ULN2003 are included in attachment 5,

I’ve order the additional components shown in the schematic from DigiKey and they

should arrive next week.

Attachment 1

Stepper Motor 5,6 and 8 Lead Descriptions

DIY KIT 109 STEPPER MOTOR DRIVER

Stepper motors can be used in a wide variety of hobby

applications: searchlights on small boats & cars, video

camera positioning, radio antenna control, controls

operating through waterproof housing, telescope control

where the azimuth, elevation & focus must be varied

independently, moving table positioning. In these

applications what is required is one or both of a

continuous stepping at varying speeds and a single

stepping, fine control to get the final position.

This kit is a stepper motor driver for 5, 6 & 8 lead

unipolar stepper motors. These are the most common

types today on the surplus market. The older four lead

bipolar stepper motors are not supported by this kit.

Visual indication that a pulse has gone to the stepper

motor is provided by 4 LED’s, one connected to each of

the four coils in the motor. (This may be very useful if

you cannot see the motor and want to be sure that it has

stepped.) The direction of stepping can be changed by a

switch. Three stepping modes are possible.

The kit uses an IC especially designed to drive 6 lead

unipolar stepper motors, the UCN5804B. As will be

shown the 5 and 8 lead steppers can be configured into a

6 lead pattern. The data sheet for this IC is included. The

various features of this IC are brought out to 5 SPDT

switches on the PCB. This kit was designed using Protel

for DOS.

ASSEMBLY

Check the components against the Component listing.

Make sure you identify C1, the 474 monoblok. It looks

just the same as C2 C4 & C6 which are 104 monobloks

with the same pitch. Note there are four links to go on the

board. One of the links goes under an IC socket. Make

sure the flat on the four LED’s corresponds to the bar

shown on the overlay. They all face right. It is generally

best to solder the lowest height components into the board

first. We have included a 6-pin header to make the

connection of the stepper motor to the PCB easier.

Motor Identification.

This is straight forward because the number of wires

coming out of the motor identifies it. Bipolar motors

have 4 leads coming out of them. One winding is on each

stator pole. These motors are not supported by this kit.

They were common in the late 1980’s and many kits using

discrete components were built to support them.

Unipolar motors may have 5 leads but generally have 6

or 8 wires. In all the motors we have seen, the wires for

the 6 & 8 types come out in two bundles of 3 or 4 wires

resp. Unipole steppers have two coils per stator pole. In

the 8 lead motors the 2 leads from the 2 coils from both

stators emerge from the motor. In the 6 lead motors the

two coils on each stator pole are joined (opposite sense)

together before they emerge from the motor. In the 5 lead

motors each of the two joined wires are themselves joined

before they leave the motor.

In the 6 wire version a multimeter (set it to 200ohm

resistance range) will show which is the centre lead within

each group of 3 leads. Typically the resistance between

the centre lead to the other two will be about 40 ohms

while the resistance between the outer two leads will be

twice that. Call the outer two leads in each of the two

bunches of wires A & B,

C & D. Solder them into

those positions on the

PCB. The centre lead in

each bunch is the power

lead & goes into the pad

marked +. Note that it

does not matter which

way around the A/B, C/D

leads go onto the pads.

5 wire version. Note that both + pads on the PCB are

connected together. In the 5 wire motor these centre leads

are connected internally.

So to power a 5 lead

stepper just connect the

common centre tap lead

from both phases to one of

the + pads. The A/B, C/D

leads are connected just as

in the 6 lead motors.

8 wire version. In each

bunch of 4 leads find the 2 pairs of wires connected to

each phase of the motor. Take one of each and join them

together. This is now the common lead to connect to the +

pad just as in the 6 lead case. The remaining leads are A

& B and C & D to the PCB..

Now there are 1, possibly

2, complications. First the

common connection must

join the coils in the

opposite sense. This refers

to the way in which they

are wound. This means

that the dot on one coil is

joined to the no-dot end

on the other coil in the

diagram. There is no way to tell the sense of the coils

unless you have the motor winding colour specification

which for surplus motors is generally missing. So you just

have to try it. Now if the wires are colour coded the same

in both bundles this is just a matter of two possibilities to

try. If the wires are not colour coded then there are four

possibilities. You will not damage the motor during this

testing if connections are wrong. The motor will either not

work or oscillate to and fro when the power is connected.

CIRCUIT DESCRIPTION

We have designed the kit so that the stepper motor can be

run continuously at a fast or low stepping rate then, when

it nears the desired position, it can be switched to

DIY KIT 109 STEPPER MOTOR DRIVER

PARTS LIST - K109

Resistors 1/4W, 5%:

180R brown grey brown ..... R1 ................................. 1

1K brown black red ............ R2 R3 ........................... 2

1M brown black green ........ R4 ................................. 1

1M potentiometer ............... POT .............................. 1

1000uF/35V electrolytic capacitor C3...................... 1

0.47uF 474 monoblok capacitor C1.......................... 1

0.1uF 104 monoblok capacitor C2 C4 C5 C6........... 4

UCN5804B ........................ IC2................................ 1

LM/NE555 nmos ................ IC1................................ 1

7805 voltage regulator ........ IC3................................ 1

2 pole terminal block .......... ...................................... 1

8 pin IC socket.................... ...................................... 1

16 pin IC socket.................. ...................................... 1

SPDT PCB-mounted switch ...................................... 5

6 pin header ........................ ...................................... 1

3mm red LED ..................... ...................................... 4

4 leg tact switch .................. ...................................... 1

K109 PCB .......................... ...................................... 1

single step mode and manually pulsed into final position.

Another switch controls the direction. A third switch can

turn the IC off and any power to the motor is removed.

Two other switches bring out halfstep and one phase

control modes supported by the IC.

A 555 IC is configured to deliver a continuous stream of

pulses to pin 11 of the 5804. The frequency is determined

by the values of the potentiometer and C1. Alternatively,

the single step switch allows individual pulses to be

delivered manually to the 5804 using a tact switch. A

switch debounce circuit is present using R4 & C5. LED’s

are included on the output of the 5804 to show which

phases of the motor are powered.

The Driver. The 5804 stepper driver is one of those

marvellous devices that replaces a handful of discrete

components. The driver will operate motors at up to 35V

and 1.25A. The step input is to pin 11 and direction goes

to pin 14. Pins 9 and 10 control one phase and half step

operation, respectively. Ref. 6 shows how to drive the IC

direct from a computer.

Motor Movement.

To make the motor step, power is applied to each coil in

turn. The 4 windings have to be energised in the right

sequence. Steppers have three different stepping methods:

wave, two phase & half-step. This is because there are

three basic patterns of energising the coils to make them

move. The last two are the most efficient. These patterns

are given in the data sheet on the 5804. No more than 2

coils are on at any one time.

In wave drive (or one phase operation) only one coil is

on at any time. In two phase drive two coils are always

on. In halfstep drive the number of coils energised cycles

between 1 & 2. We will not go into the details here since

they are given every year or so in the hobby electronics

magazines and in text books. Two of the best write-ups

starting from basics are references 2, 4 and 5 below. You

can see the pattern of coils being turned on/off by looking

at the LED’s as the motor steps.

As the motor is spinning, try varying the supply voltage.

This will make the motor run more roughly or smoothly.

Stepping motors are very sensitive to supply voltage

variations.

If you want the RUN stepping rate to be slower then

replace the 1M potentiometer by a 5M or even 10M pot.

What to do if it does not work

If there are more than 2 LED’s on then there is a short

circuit on the output of the 5804. Check that all the 4 links

are added to the board. Check the 555 IC is in the correct

way.

Ballast or Forcing Resistor

For two reasons a low value (typically 20 to 60 ohm), 5W

or 10W cement resistor is sometimes included in both the

+ lines between the 5804 and the stepper motor.

Lenz’s Law. Voltage driving gets into a time constant

problem (L/R) which limits speed & power. If R is

increased then the time constant is reduced. However, for

hobby applications it does not matter if the time constant

is 50msec or 10 msec.

Current Limiting. The resistor helps to limit current to

the motor. This is to help reduce overheating when it is

stopped (not stepping) but the power is still connected to

it to maintain its position.

External Diodes. These are mentioned in the data sheet

on the 5804 as possibly being necessary. However, for the

hobby stepper motors we are discussing here they are not

required.

Data Sheet. Download the data sheet for the UCN5804

from the Allegro website at:

www.allegromicro.com/control/pn1frame.htm

REFERENCES.

1. Control Stepper Motors with your PC, by Marque

Crozman. Silicon Chip, january, 1994, p80.

2. Stepper Motors and how they work, by Peter Phillips.

Electronics Australia, October & November, 1994.

3. A PC-Based Stepper-Motor Controller, by Larry

Antonuk. Popular Electronics, June 1992, p41.

4. Computer Controlled Stepper Motors, by Jim Spence.

ETI, august, 1994, p18.

5. Stepping Motor Driver/Interface, by Mark Stuart.

Everyday Electronics, january, 1992, p34.

6. Linear Motion Table, by John Iovine. Nut’s ‘n Volts,

august, 1995, p76.

------------------

DIY KIT 109 STEPPER MOTOR DRIVER

Attachment 2

StampWorks Project 26

Experiment #26: Stepper Motor Control

Experiment #26:

Stepper Motor Control

This experiment demonstrates the control of a small 12-volt unipolar stepper motor. Stepper motors

are used as precision positioning devices in robotics and industrial control applications.

New PBASIC elements/commands to know:

•

ABS

Building The Circuit

StampWorks Manual Version 1.1a • Page 125

Experiment #26: Stepper Motor Control

'

'

'

'

'

'

'

=========================================================================

File: STEPPER.BS2

Unipolar stepper motor control

{$STAMP BS2}

=========================================================================

PotCW

PotCCW

Coils

CON

CON

VAR

0

1

OutB

' clockwise pot input

' counter-clockwise pot input

' output to stepper coils

speed

x

sAddr

rcRt

rcLf

diff

VAR

VAR

VAR

VAR

VAR

VAR

Word

Byte

Byte

Word

Word

Word

'

'

'

'

'

'

delay between steps

loop counter

EE address of step data

rc reading - right

rc reading - left

difference between readings

' ------------------------------------------------------------------------'

__

'

ABAB

'

----Step1

DATA %1100

' A on

B on

A\ off B\ off

Step2

DATA %0110

' A off B on

A\ on

B\ off

Step3

DATA %0011

' A off B off A\ on

B\ on

Step4

DATA %1001

' A on

B off A\ off B\ on

' ------------------------------------------------------------------------Initialize:

DirB = %1111

speed = 5

' make stepper pins outputs

' set starting speed

' ------------------------------------------------------------------------Main:

FOR x = 1 TO 100

GOSUB StepFwd

NEXT

PAUSE 200

FOR x = 1 TO 100

GOSUB StepRev

Page 126 • StampWorks Manual Version 1.1a

' 1 rev forward

' 1 rev back

Experiment #26: Stepper Motor Control

NEXT

PAUSE 200

StepDemo:

HIGH PotCW

HIGH PotCCW

PAUSE 1

RCTIME PotCW,1,rcRt

RCTIME PotCCW,1,rcLf

' discharge caps

' read clockwise

' read counter-clockwise

rcRt = rcRt MAX 600

rcLf = rcLf MAX 600

' set speed limits

diff = ABS(rcRt - rcLf)

IF (diff < 25) THEN StepDemo

' get difference between readings

' allow deadband

IF (rcLf > rcRt) THEN StepCCW

StepCW:

speed = 60 - (rcRt / 10)

GOSUB StepFwd

GOTO StepDemo

' calculate speed

' do a step

StepCCW:

speed = 60 - (rcLf / 10)

GOSUB StepRev

GOTO StepDemo

' ------------------------------------------------------------------------StepFwd:

sAddr = sAddr + 1 // 4

READ (Step1 + sAddr),Coils

PAUSE speed

RETURN

StepRev:

sAddr = sAddr + 3 // 4

READ (Step1 + sAddr),Coils

PAUSE speed

RETURN

' point to next step

' output step data

' pause between steps

' point to previous step

StampWorks Manual Version 1.1a • Page 127

Experiment #26: Stepper Motor Control

Behind The Scenes

Stepper motors differ from standard DC motors in that they do not spin freely when power is applied.

For a stepper motor to rotate, the power source must be continuously pulsed in specific patterns.

The step sequence (pattern) determines the direction of the stepper’s rotation. The time between

sequence steps determines the rotational speed. Each step causes the stepper motor to rotate a fixed

angular increment. The stepper motor supplied with the StampWorks kit rotates 3.6 degrees per

step. This means that one full rotation (360 degrees) of the stepper requires 100 steps.

The step sequences for the motor are stored in DATA statements. The StepFwd subroutine will read

the next sequence from the table to be applied to the coils. The StepRev subroutine is identical

except that it will read the previous step. Note the trick with the modulus (//) operator used in

StepRev. By adding the maximum value of the sequence to the current value and then applying the

modulus operator, the sequence goes in reverse. Here’s the math:

0

3

2

1

+

+

+

+

3

3

3

3

//

//

//

//

4

4

4

4

=

=

=

=

3

2

1

0

This experiment reads both sides of the 10K potentiometer to determine its relative position. The

differential value between the two readings is kept positive by using the ABS function. The position is

used to determine the rotational direction and the strength of the position is used to determine the

rotational speed. Remember, the shorter the delay between steps, the faster the stepper will rotate.

A dead-band check is used to cause the motor to stop rotating when the RCTIME readings are nearly

equal.

Challenge

Rewrite the program to run the motor in 200 half steps. Here’s the step sequence:

Step1

Step2

Step3

Step4

Step5

Step6

Step7

Step8

=

=

=

=

=

=

=

=

%1000

%1100

%0100

%0110

%0010

%0011

%0001

%1001

Page 128 • StampWorks Manual Version 1.1a

Attachment 3

5804 Chip Schematic

5804

BiMOS II UNIPOLAR

STEPPER-MOTOR

TRANSLATOR/DRIVER

TYPICAL APPLICATION

L/R Stepper-Motor Drive

5V

28V

1

VDD

16

2

OE

15

14

3

4

DIRECTION

CONTROL

13

LOGIC

5

12

6

11

7

10

8

9

STEP INPUT

1

VDD

16

2

OE

15

14

3

OR

4

13

LOGIC

5

12

6

11

7

10

8

9

Dwg. EP-029A

Attachment 4

Basic Stamp I Stepper Controller

BASIC Stamp I Application Notes

6: A Serial Stepper Controller

Introduction. This application note demonstrates simple hardware

and software techniques for driving and controlling common four-coil

stepper motors.

Background. Stepper motors translate digital switching sequences

into motion. They are used in printers, automated machine tools, disk

drives, and a variety of other applications requiring precise motions

under computer control.

Unlike ordinary dc motors, which spin freely when power is applied,

steppers require that their power source be continuously pulsed in

specific patterns. These patterns, or step sequences, determine the

speed and direction of a stepper’s motion. For each pulse or step input,

the stepper motor rotates a fixed angular increment; typically 1.8 or 7.5

degrees.

The fixed stepping angle gives steppers their precision. As long as the

motor’s maximum limits of speed or torque are not exceeded, the

controlling program knows a stepper’s precise position at any given

time.

Steppers are driven by the interaction (attraction and repulsion) of

magnetic fields. The driving magnetic field “rotates” as strategically

placed coils are switched on and off. This pushes and pulls at permanent magnets arranged around the edge of a rotor that drives the output

TO PIN 11 1

(C) 1992 Parallax, Inc.

EEPROM

PIC16C56

PC

BASIC STAMP

+5V

Vin

0

1

2

3

4

5

6

7

BLK

16

IN 1

OUT 1

IN 2

OUT 2

IN 3

OUT 3

IN 4

OUT 4

IN 5

OUT 5

IN 6

OUT 6

IN 7

OUT 7

RED

BRN

ULN 2003

+5

+12

GRN

YEL

Stepper Motor

ORG

AIRPAX COLOR CODE:

RED & GREEN = COMMON

+5

TO PIN 10

1k

NC

1k

GND

1k

1k

TO PIN 1

22k

8

Serial Input

NC

9

GND

TEST

TO PIN 4

NC

Serial Output

Figure 1. Schematic for the serial stepper controller.

Parallax, Inc. • BASIC Stamp Programming Manual 1.9 • Page 99

1

BASIC Stamp I Application Notes

6: A Serial Stepper Controller

shaft. When the on-off pattern of the magnetic fields is in the proper

sequence, the stepper turns (when it’s not, the stepper sits and quivers).

The most common stepper is the four-coil unipolar variety. These are

called unipolar because they require only that their coils be driven on

and off. Bipolar steppers require that the polarity of power to the coils

be reversed.

The normal stepping sequence for four-coil unipolar steppers appears

in figure 2. There are other, special-purpose stepping sequences, such

as half-step and wave drive, and ways to drive steppers with multiphase analog waveforms, but this application concentrates on the

normal sequence. After all, it’s the sequence for which all of the

manufacturer’s specifications for torque, step angle, and speed apply.

Step Sequence

coil 1

coil 2

coil 3

coil 4

1

2

3

4

1

1

0

1

0

1

0

0

1

0

1

0

1

0

1

1

0

1

0

1

0

Figure 2. Normal stepping sequence.

If you run the stepping sequence in figure 2 forward, the stepper rotates

clockwise; run it backward, and the stepper rotates counterclockwise.

The motor’s speed depends on how fast the controller runs through the

step sequence. At any time the controller can stop in mid sequence. If it

leaves power to any pair of energized coils on, the motor is locked in

place by their magnetic fields. This points out another stepper motor

benefit: built-in brakes.

Many microprocessor stepper drivers use four output bits to generate

the stepping sequence. Each bit drives a power transistor that switches

on the appropriate stepper coil. The stepping sequence is stored in a

lookup table and read out to the bits as required.

This design takes a slightly different approach. First, it uses only two

output bits, exploiting the fact that the states of coils 1 and 4 are always

Page 100 • BASIC Stamp Programming Manual 1.9 • Parallax, Inc.

6: A Serial Stepper Controller

BASIC Stamp I Application Notes

the inverse of coils 2 and 3. Look at figure 2 again. Whenever coil 2 gets

a 1, coil 1 gets a 0, and the same holds for coils 3 and 4. In Stamp designs,

output bits are too precious to waste as simple inverters, so we give that

job to two sections of the ULN2003 inverter/driver.

The second difference between this and other stepper driver designs is

that it calculates the stepping sequence, rather than reading it out of a

table. While it’s very easy to create tables with the Stamp, the calculations required to create the two-bit sequence required are very simple.

And reversing the motor is easier, since it requires only a single

additional program step. See the listing.

How it works. The stepper controller accepts commands from a terminal or PC via a 2400-baud serial connection. When power is first applied

to the Stamp, it sends a prompt to be displayed on the terminal screen.

The user types a string representing the direction (+ for forward, – for

backward), number of steps, and step delay (in milliseconds), like this:

step>+500 20

As soon as the user presses enter, return, or any non-numerical character at the end of the line, the Stamp starts the motor running. When the

stepping sequence is over, the Stamp sends a new step> prompt to the

terminal. The sample command above would take about 10 seconds

(500 x 20 milliseconds). Commands entered before the prompt reappears are ignored.

YELLOW

BROWN

RED

GREEN

ORANGE

BLACK

Figure 3. Color code for Airpax steppers.

On the hardware side, the application accepts any stepper that draws

500 mA or less per coil. The schematic shows the color code for an

Airpax-brand stepper, but there is no standardization among different

Parallax, Inc. • BASIC Stamp Programming Manual 1.9 • Page 101

1

BASIC Stamp I Application Notes

6: A Serial Stepper Controller

brands. If you use another stepper, use figure 3 and an ohmmeter to

translate the color code. Connect the stepper and give it a try. If it

vibrates instead of turning, you have one or more coils connected

incorrectly. Patience and a little experimentation will prevail.

' Program STEP.BAS

' The Stamp accepts simply formatted commands and drives a four-coil stepper.

Commands

' are formatted as follows: +500 20<return> means rotate forward 500 steps with 20

' milliseconds between steps. To run the stepper backward, substitute - for +.

Symbol

Symbol

Symbol

Symbol

Symbol

Directn = b0

Steps = w1

i = w2

Delay = b6

Dir_cmd = b7

dirs = %01000011 : pins = %00000001 ' Initialize output.

b1 = %00000001 : Directn = "+"

goto Prompt

' Display prompt.

'

'

'

'

Accept a command string consisting of direction (+/-), a 16-bit number

of steps, and an 8-bit delay (milliseconds) between steps. If longer

step delays are required, just command 1 step at a time with long

delays between commands.

Cmd:

serin 7,N2400,Dir_cmd,#Steps,#Delay ' Get orders from terminal.

if Dir_cmd = Directn then Stepit

' Same direction? Begin.

b1 = b1^%00000011

' Else reverse (invert b1).

Stepit:

for i = 1 to Steps

' Number of steps.

pins = pins^b1

' XOR output with b1, then invert b1

b1 = b1^%00000011

' to calculate the stepping sequence.

pause Delay

' Wait commanded delay between

' steps.

next

Directn = Dir_cmd

' Direction = new direction.

Prompt: serout 6,N2400,(10,13,"step> ")

goto Cmd

' Show prompt, send return

' and linefeed to terminal.

Page 102 • BASIC Stamp Programming Manual 1.9 • Parallax, Inc.

Program listing: As with the other application notes, this program may be downloaded from our Internet ftp site at

ftp.parallaxinc.com. The ftp site may be

reached directly or through our web site

at http://www.parallaxinc.com.

Attachment 5

ULN2003 Specs

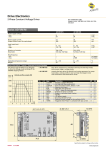

ULN2001A, ULN2002A, ULN2003A, ULN2004A,

ULQ2003A, ULQ2004A

DARLINGTON TRANSISTOR ARRAY

SLRS027A – DECEMBER 1976 – REVISED MAY 2001

HIGH-VOLTAGE HIGH-CURRENT DARLINGTON TRANSISTOR ARRAYS

D

D

D

D

D

D

500-mA Rated Collector Current

(Single Output)

High-Voltage Outputs . . . 50 V

Output Clamp Diodes

Inputs Compatible With Various Types of

Logic

Relay Driver Applications

Designed to Be Interchangeable With

Sprague ULN2001A Series

D OR N PACKAGE

(TOP VIEW)

1B

2B

3B

4B

5B

6B

7B

E

description

1

16

2

15

3

14

4

13

5

12

6

11

7

10

8

9

1C

2C

3C

4C

5C

6C

7C

COM

The ULN2001A, ULN2002A, ULN2003A, ULN2004A, ULQ2003A, and ULQ2004A are monolithic high-voltage,

high-current Darlington transistor arrays. Each consists of seven npn Darlington pairs that feature high-voltage

outputs with common-cathode clamp diodes for switching inductive loads. The collector-current rating of a

single Darlington pair is 500 mA. The Darlington pairs may be paralleled for higher current capability.

Applications include relay drivers, hammer drivers, lamp drivers, display drivers (LED and gas discharge), line

drivers, and logic buffers. For 100-V (otherwise interchangeable) versions, see the SN75465 through SN75469.

The ULN2001A is a general-purpose array and can be used with TTL and CMOS technologies. The ULN2002A

is specifically designed for use with 14- to 25-V PMOS devices. Each input of this device has a zener diode and

resistor in series to control the input current to a safe limit. The ULN2003A and ULQ2003A have a 2.7-kΩ series

base resistor for each Darlington pair for operation directly with TTL or 5-V CMOS devices. The ULN2004A and

ULQ2004A have a 10.5-kΩ series base resistor to allow operation directly from CMOS devices that use supply

voltages of 6 to 15 V. The required input current of the ULN/ULQ2004A is below that of the ULN/ULQ2003A,

and the required voltage is less than that required by the ULN2002A.

logic symbol†

logic diagram

9

CLAMP

1B

2B

3B

4B

5B

6B

7B

1

16

2

15

3

14

4

13

5

12

6

11

7

10

9

COM

1B

1C

2C

2B

3C

4C

3B

5C

6C

4B

7C

† This symbol is in accordance with ANSI/IEEE Std 91-1984

and IEC Publication 617-12.

5B

6B

7B

1

16

2

15

3

14

4

13

5

12

6

11

7

10

COM

1C

2C

3C

4C

5C

6C

7C

Copyright 2001, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 655303

• DALLAS, TEXAS 75265

1

ULN2001A, ULN2002A, ULN2003A, ULN2004A,

ULQ2003A, ULQ2004A

DARLINGTON TRANSISTOR ARRAY

SLRS027A – DECEMBER 1976 – REVISED MAY 2001

schematics (each Darlington pair)

COM

COM

7V

Output C

Output C

Input B

Input B

10.5 kΩ

7.2 kΩ

E

7.2 kΩ

3 kΩ

3 kΩ

E

ULN2002A

ULN2001A

COM

RB

Output C

Input B

ULN/ULQ2003A: RB = 2.7 kΩ

ULN/ULQ2004A: RB = 10.5 kΩ

7.2 kΩ

3 kΩ

E

ULN2003A, ULN2004A, ULQ2003A, ULQ2004A

All resistor values shown are nominal.

absolute maximum ratings at 25°C free-air temperature (unless otherwise noted)

Collector-emitter voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 V

Clamp diode reverse voltage (see Note 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 V

Input voltage, VI (see Note 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 V

Peak collector current (see Figures 14 and 15) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500 mA

Output clamp current, IOK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500 mA

Total emitter-terminal current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . – 2.5 A

Continuous total power dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Dissipation Rating Table

Operating free-air temperature range, TA, ULN200xA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . – 20°C to 85°C

ULQ2003A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . – 40°C to 85°C

ULQ2004A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . – 40°C to 70°C

Operating junction temperature range, TJ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . – 40°C to 105°C

Storage temperature range, Tstg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . – 65°C to 150°C

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260°C

NOTE 1: All voltage values are with respect to the emitter/substrate terminal E, unless otherwise noted.

DISSIPATION RATING TABLE

TA = 25°C

POWER RATING

DERATING FACTOR

ABOVE TA = 25°C

TA = 85°C

POWER RATING

D

950 mW

7.6 mW/°C

494 mW

N

1150 mW

9.2 mW/°C

598 mW

PACKAGE

2

POST OFFICE BOX 655303

• DALLAS, TEXAS 75265

ULN2001A, ULN2002A, ULN2003A, ULN2004A,

ULQ2003A, ULQ2004A

DARLINGTON TRANSISTOR ARRAY

SLRS027A – DECEMBER 1976 – REVISED MAY 2001

electrical characteristics, TA = 25°C (unless otherwise noted)

PARAMETER

VI(on)

VCE(sat)

( )

On-state input voltage

Collector-emitter

C

ll t

itt

saturation voltage

VF

Clamp forward voltage

ICEX

Collector cutoff current

TEST

FIGURE

6

5

8

TEST CONDITIONS

II

Input current

4

IR

Clamp reverse current

7

hFE

Static forward current

transfer ratio

5

Ci

Input capacitance

TYP

MAX

0.9

1.1

1.1

II = 350 µA,

II = 500 µA,

IC = 200 mA

IC = 350 mA

1

1.3

1

1.3

1.2

1.6

1.2

1.6

1.7

2

1.7

2

VCE = 50 V,,

TA = 70°C

3

MIN

0.9

2

Off state input current

Off-state

MAX

IC = 300 mA

IC = 100 mA

VCE = 50 V,,

TA = 70°C

II(off)

I( ff)

ULN2002A

TYP

VCE = 2 V,

II = 250 µA,

IF = 350 mA

VCE = 50 V,

1

ULN2001A

MIN

VI = 17 V

VR = 50 V,

13

II = 0

II = 0

VI = 6 V

IC = 500 µ

µA,

50

50

100

100

50

65

50

VR = 50 V

VI = 0,

f = 1 MHz

V

V

µA

µA

65

0.82

IC = 350 mA

V

500

TA = 70°C

VCE = 2 V,

UNIT

1.25

100

100

50

50

mA

µA

1000

15

25

15

25

pF

electrical characteristics, TA = 25°C (unless otherwise noted)

PARAMETER

TEST

FIGURE

TEST CONDITIONS

ULN2003A

MIN

TYP

IC = 125 mA

IC = 200 mA

VI(

I(on))

VCE(sat)

( )

ICEX

On state input voltage

On-state

Collector-emitter

C

ll t

itt

saturation voltage

Collector cutoff current

6

VCE = 2 V

MAX

IC = 250 mA

IC = 275 mA

2.7

IC = 300 mA

IC = 350 mA

3

6

7

1.1

5

1

1.3

1

1.3

II = 500 µA,

VCE = 50 V,

IC = 350 mA

II = 0

1.2

1.6

1.2

1.6

1

2

VCE = 50 V,,

TA = 70°C

II = 0

VI = 1 V

Off state input current

Off-state

3

VCE = 50 V,,

TA = 70°C

II

Input current

4

7

50

VI = 3.85 V

VI = 5 V

0.93

TA = 70°C

f = 1 MHz

POST OFFICE BOX 655303

50

100

100

• DALLAS, TEXAS 75265

2

65

VI = 12 V

VR = 50 V

VR = 50 V,

VI = 0,

50

V

µA

500

1.7

IC = 500 µ

µA,,

V

8

0.9

II(off)

I( ff)

UNIT

5

2.4

1.1

IF = 350 mA

Input capacitance

TYP

0.9

8

Ci

MIN

IC = 100 mA

IC = 200 mA

Clamp forward voltage

Clamp reverse current

MAX

II = 250 µA,

II = 350 µA,

VF

IR

ULN2004A

15

1.7

50

2

V

µA

65

1.35

0.35

0.5

1

1.45

50

50

100

100

25

15

25

mA

µA

pF

3

ULN2001A, ULN2002A, ULN2003A, ULN2004A,

ULQ2003A, ULQ2004A

DARLINGTON TRANSISTOR ARRAY

SLRS027A – DECEMBER 1976 – REVISED MAY 2001

electrical characteristics, TJ = –40°C to 105°C (unless otherwise noted)

TEST

FIGURE

PARAMETER

TEST CONDITIONS

ULQ2003A

MIN

TYP

ULQ2004A

MAX

IC = 125 mA

IC = 200 mA

VI(

I(on))

On state input voltage

On-state

VCE(sat)

( )

Collector-emitter

C

ll t

itt

saturation voltage

6

VCE = 2 V

2.9

IC = 300 mA

IC = 350 mA

3

6

7

1.1

5

1

1.4

1

1.3

II = 500 µA,

VCE = 50 V,

IC = 350 mA

II = 0

1.2

1.7

1.2

1.6

1

2

VCE = 50 V,,

TA = 70°C

II = 0

VI = 1 V

IF = 350 mA

II(off)

I( ff)

Off state input current

Off-state

3

VCE = 50 V,,

TA = 70°C

II

Input current

4

100

µA

500

1.7

IC = 500 µ

µA,,

30

0.93

TA = 70°C

f = 1 MHz

2.2

65

VI = 12 V

VR = 50 V

VR = 50 V,

VI = 0,

V

50

100

VI = 3.85 V

VI = 5 V

7

V

8

0.9

8

Input capacitance

IC = 250 mA

IC = 275 mA

1.2

Clamp forward voltage

UNIT

5

2.7

0.9

VF

Ci

MAX

IC = 100 mA

IC = 200 mA

Collector cutoff current

Clamp reverse current

TYP

II = 250 µA,

II = 350 µA,

ICEX

IR

MIN

15

1.7

50

2

V

µA

65

1.35

0.35

0.5

1

1.45

100

50

100

100

25

15

25

mA

µA

pF

switching characteristics, TA = 25°C

PARAMETER

TEST CONDITIONS

ULN2001A, ULN2002A,

ULN2003A, ULN2004A

MIN

tPLH

tPHL

Propagation delay time, low-to-high-level output

VOH

High-level output voltage after switching

Propagation delay time, high-to-low-level output

See Figure 9

VS = 50 V,

See Figure 10

IO ≈ 300 mA,

UNIT

TYP

MAX

0.25

1

µs

0.25

1

µs

VS – 20

mV

switching characteristics, TJ = –40°C to 105°C

PARAMETER

tPLH

tPHL

VOH

4

TEST CONDITIONS

Propagation delay time, low-to-high-level output

Propagation delay time, high-to-low-level output

High-level output voltage after switching

POST OFFICE BOX 655303

ULQ2003A, ULQ2004A

MIN

See Figure 9

VS = 50 V,

See Figure 10

IO ≈ 300 mA,

• DALLAS, TEXAS 75265

VS – 500

UNIT

TYP

MAX

1

10

µs

1

10

µs

mV

ULN2001A, ULN2002A, ULN2003A, ULN2004A,

ULQ2003A, ULQ2004A

DARLINGTON TRANSISTOR ARRAY

SLRS027A – DECEMBER 1976 – REVISED MAY 2001

PARAMETER MEASUREMENT INFORMATION

Open

Open

VCE

ICEX

VCE

ICEX

Open

VI

Figure 1. ICEX Test Circuit

Open

Figure 2. ICEX Test Circuit

VCE

Open

II(off)

IC

II(on)

Open

VI

Figure 3. II(off) Test Circuit

Figure 4. II Test Circuit

Open

Open

IC

hFE =

II

VCE

II

IC

VI(on)

VCE

IC

NOTE: II is fixed for measuring VCE(sat), variable for

measuring hFE.

Figure 5. hFE, VCE(sat) Test Circuit

Figure 6. VI(on) Test Circuit

VR

IR

VF

Open

IF

Open

Figure 7. IR Test Circuit

POST OFFICE BOX 655303

Figure 8. VF Test Circuit

• DALLAS, TEXAS 75265

5

ULN2001A, ULN2002A, ULN2003A, ULN2004A,

ULQ2003A, ULQ2004A

DARLINGTON TRANSISTOR ARRAY

SLRS027A – DECEMBER 1976 – REVISED MAY 2001

PARAMETER MEASUREMENT INFORMATION

50%

Input

50%

t PHL

t PLH

50%

Output

50%

VOLTAGE WAVEFORMS

Figure 9. Propagation Delay Time Waveforms

VS

Input

Open

Pulse

Generator

(see Note A)

2 mH

1N3064

ULN2001A only

2.7 kΩ

200 Ω

Output

ULN2002A

ULN/ULQ2003A

ULN/ULQ2004A

CL = 15 pF

(see Note B)

TEST CIRCUIT

≤ 5 ns

≤ 10 ns

90%

1.5 V

Input

10%

VIH

(see Note C)

90%

1.5 V

10%

40 µs

0V

VOH

Output

VOL

VOLTAGE WAVEFORMS

NOTES: A. The pulse generator has the following characteristics: PRR = 12.5 kHz, ZO = 50 Ω.

B. CL includes probe and jig capacitance.

C. For testing the ULN2001A, the ULN2003A, and the ULQ2003A, VIH = 3 V; for the ULN2002A, VIH = 13 V;

for the ULN2004A and the ULQ2004A, VIH = 8 V.

Figure 10. Latch-Up Test Circuit and Voltage Waveforms

6

POST OFFICE BOX 655303

• DALLAS, TEXAS 75265

ULN2001A, ULN2002A, ULN2003A, ULN2004A,

ULQ2003A, ULQ2004A

DARLINGTON TRANSISTOR ARRAY

SLRS027A – DECEMBER 1976 – REVISED MAY 2001

TYPICAL CHARACTERISTICS

COLLECTOR-EMITTER

SATURATION VOLTAGE

vs

TOTAL COLLECTOR CURRENT

(TWO DARLINGTONS PARALLELED)

COLLECTOR-EMITTER

SATURATION VOLTAGE

vs

COLLECTOR CURRENT

(ONE DARLINGTON)

VCE(sat)

VCE(sat) – Collector-Emitter Saturation Voltage – V

TA = 25°C

2

II = 250 µA

II = 350 µA

II = 500 µA

1.5

1

0.5

0

0

100

200

300

400

500

600

700

800

2.5

TA = 25°C

II = 250 µA

2

II = 350 µA

1.5

II = 500 µA

1

0.5

0

0

100

200

300

400

500

600

700

800

IC(tot) – Total Collector Current – mA

IC – Collector Current – mA

Figure 11

Figure 12

COLLECTOR CURRENT

vs

INPUT CURRENT

500

RL = 10 Ω

TA = 25°C

450

IIC

C – Collector Current – mA

VCE(sat)

VCE(sat) – Collector-Emitter Saturation Voltage – V

2.5

400

VS = 10 V

350

VS = 8 V

300

250

200

150

100

50

0

0

25

50

75

100

125

150

175

200

II – Input Current – µA

Figure 13

POST OFFICE BOX 655303

• DALLAS, TEXAS 75265

7

ULN2001A, ULN2002A, ULN2003A, ULN2004A,

ULQ2003A, ULQ2004A

DARLINGTON TRANSISTOR ARRAY

SLRS027A – DECEMBER 1976 – REVISED MAY 2001

THERMAL INFORMATION

N PACKAGE

MAXIMUM COLLECTOR CURRENT

vs

DUTY CYCLE

D PACKAGE

MAXIMUM COLLECTOR CURRENT

vs

DUTY CYCLE

600

IIC

C – Maximum Collector Current – mA

IIC

C – Maximum Collector Current – mA

600

500

N=1

N=4

400

N=3

300

N=2

N=6

N=7

N=5

200

100

TA = 70°C

N = Number of Outputs

Conducting Simultaneously

500

400

N=4

300

N=5

N=6

N=7

200

100

TA = 85°C

N = Number of Outputs

Conducting Simultaneously

0

0

0

10

20

30

40

50

60

70

80

90 100

0

10

20

30

40

50

60

70

Duty Cycle – %

Duty Cycle – %

Figure 14

8

N=1

N=3

N=2

Figure 15

POST OFFICE BOX 655303

• DALLAS, TEXAS 75265

80

90 100

ULN2001A, ULN2002A, ULN2003A, ULN2004A,

ULQ2003A, ULQ2004A

DARLINGTON TRANSISTOR ARRAY

SLRS027A – DECEMBER 1976 – REVISED MAY 2001

APPLICATION INFORMATION

ULN2002A

VSS

P-MOS

Output

V

ULN2003A

ULQ2003A

VCC

V

1

16

1

16

2

15

2

15

3

14

3

14

4

13

4

13

5

12

5

12

6

11

6

11

7

10

7

10

8

9

8

9

Lamp

Test

TTL

Output

Figure 16. P-MOS to Load

ULN2004A

ULQ2004A

VDD

Figure 17. TTL to Load

ULN2003A

ULQ2003A

VCC

V

V

1

16

1

16

2

15

2

15

3

14

RP 3

14

4

13

4

13

5

12

5

12

6

11

6

11

7

10

7

10

8

9

8

9

CMOS

Output

TTL

Output

Figure 18. Buffer for Higher Current Loads

POST OFFICE BOX 655303

Figure 19. Use of Pullup Resistors to

Increase Drive Current

• DALLAS, TEXAS 75265

9

IMPORTANT NOTICE

Texas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgment, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its products to the specifications applicable at the time of sale in accordance with

TI’s standard warranty. Testing and other quality control techniques are utilized to the extent TI deems necessary

to support this warranty. Specific testing of all parameters of each device is not necessarily performed, except

those mandated by government requirements.

Customers are responsible for their applications using TI components.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

products or services might be or are used. TI’s publication of information regarding any third party’s products

or services does not constitute TI’s approval, license, warranty or endorsement thereof.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations and notices. Representation

or reproduction of this information with alteration voids all warranties provided for an associated TI product or

service, is an unfair and deceptive business practice, and TI is not responsible nor liable for any such use.

Resale of TI’s products or services with statements different from or beyond the parameters stated by TI for

that product or service voids all express and any implied warranties for the associated TI product or service,

is an unfair and deceptive business practice, and TI is not responsible nor liable for any such use.

Also see: Standard Terms and Conditions of Sale for Semiconductor Products. www.ti.com/sc/docs/stdterms.htm

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2001, Texas Instruments Incorporated