* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download New 1700V A-Series IGBT Modules with CSTBT and

Survey

Document related concepts

Thermal runaway wikipedia , lookup

Voltage optimisation wikipedia , lookup

Stray voltage wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Skin effect wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Current source wikipedia , lookup

Mains electricity wikipedia , lookup

Distribution management system wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Opto-isolator wikipedia , lookup

Rectiverter wikipedia , lookup

Transcript

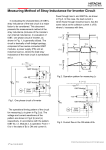

NEW 1700V A-SERIES IGBT MODULES WITHS CSTBT AND IMPROVED FWDi By Nicholas Clark1, John Donlon1, Shinichi Iura2 1) Powerex Inc., Youngwood, PA, USA 2) Power Device Works, Mitsubishi Electric Corp., Fukuoka, Japan Abstract: This paper presents a new series of 1700V IGBT (Insulated Gate Bipolar Transistor) modules using the new trench gate IGBT technology called Light Punch Through Carrier Stored Trench gate Bipolar Transistor - LPT-CSTBT and an improved FWDi (Free Wheeling Diode). This new design allows the same VCE(sat) (collector-emitter saturation voltage) at 1700V as what was available in the third generation planar devices at 1200V given the same current rating. The current ratings of new 1700V A-series IGBT modules are available at 500A for single switch types and from 75A to 400A for dual switch types and are package compatible with the 1200V NF-series and 1700V KA-series. 1. Introduction High voltage, medium current IGBT modules are widely used for industrial motor drives. These drives have a continuous trend towards higher output power and smaller equipment size._In response to these market needs, IGBT modules having an increased rated current are necessary. This has led to the development of a novel series of 1700V IGBT modules with 50% higher rated current by using a new IGBT/FWDi chip-set. This paper introduces the structure and performance of the newly developed 1700V IGBT modules. 2. New 1700V module product range In comparison with conventional modules, the features of the new 1700V A-series, which have package compatibility with the conventional modules, feature: a) 50% increased current rating in the same package size b) Reduced IGBT losses by using the carrier stored trench gate IGBT chip technology c) Suppressed diode oscillation by new soft reverse recovery FWDi Fig.1 and Table 1 show a comparison between the packages used for the conventional modules and those for the newly developed series. The new packages have the same footprint and terminal outlines in spite of a 50% increase in rated current or conversely the equivalent rated current in a significantly smaller package. NEW 1700V A-SERIES IGBT MODULES WITH CSTBT AND IMPROVED FWDi By Clark, Donlon, and Iura Table 1: Line-up of the 1700V IGBT module Ic Package size (L x W) Connection Conventional New 94 x 48mm 75A Dual — 100A Dual 108 x 62mm 200A Dual 300A Dual 400A Dual 500A Single 2 CM75DY-34A 2 94 x 48mm CM100DU-34KA 110 x 80mm 2 CM100DY-34A 2 2 108X62mm CM200DY-34A 2 140x130mm CM300DU34KA 2 140x130mm CM400DU34KA 2 110x80mm CM300DY-34A 2 140x130mm CM400DY-34A 2 — 108x93mm CM500HA-34A Fig.1 a) CM200DY-34A package b) CM200DU-34KA package The new 1700V A-series IGBTs are available in currents from 75A to 400A in dual/chopper switch modules and 500A in single switch modules, as shown in Table 1. To take an example, Table 2 shows the specification of the 200A dual/chopper module. NEW 1700V A-SERIES IGBT MODULES WITH CSTBT AND IMPROVED FWDi By Clark, Donlon, and Iura Table 2: Specification of 200A Module (CM200DY-34A) Maximum ratings: Item Conditions Ratings VCES VGE = 0V, Tjmin Tj Tjmax 1700 V VGES VCE = 0V, Tjmin Tj Tjmax ± 20 V IC TC = 109°C 200 A ICM Pulse PC TC = 25°C 400 A 1980 W Tj Viso _40 … +150°C f=60Hz 3500 Vrms Mass 400 g (typ.) Electrical/Thermal characteristics: Item Conditions ICES VGE = VGES, Tj = 125°C 1 mA VGE(th) VCE = 10V, IC = 20mA, Tj = 25°C 7.0 V VCE(sat) VGE = 15V, IC = 200A, Tj = 125°C 2.45 V VEC VGE = 0V, IC = 200A, Tj = 125°C 3.0 V Eon VCC = 1000V, IC = 200A LS = 100nH, VGE = ±15V RG =2.4 Eoff Typical 94 mJ/P 59 mJ/P 53 mJ/P Erec Rth(j-c)Q IGBT part 0.063 K/W Rth(j-c)R Diode part 0.11 K/W 3. Chip technology 3-1. IGBT chip technology The newly developed 1700V A-series IGBT modules are based on our new trench gate chip technology called “Light Punch Through Carrier Stored Trench gate Bipolar Transistor” or LPT-CSTBT. The features of LPT-CSTBT are as follows. a) Trench gate & Carrier stored structure b) Light punch through structure NEW 1700V A-SERIES IGBT MODULES WITH CSTBT AND IMPROVED FWDi By Clark, Donlon, and Iura G E p base n+ emitter VMOS Carrier stored layer Vdiode n- layer n+?@ buffer layer p + substrate VCE (sat) = VMOS + Vdiode C Fig.2: Cross section of LPT-CSTBT a) Trench Gate & Carrier Stored Structure IGBT chips used in modules with high power ratings need to be optimized for low losses and higher current density in order to increase the current rating. This reduction of losses is achieved by using the LPT-CSTBT chip technology. The development and features of this chip technology are explained in detail in references [1] and [2]. The cross section of the LPT-CSTBT is shown in Fig.2. The on-state voltage of the IGBT, VCE (sat) = VMOS + Vdiode. The VMOS is the voltage drop of the MOSFET portion between p base and n+ emitter and can be reduced by the trench gate structure. The Vdiode is the voltage drop of the diode portion between p+ substrate and n_ layer. It can be reduced by the carrier stored layer structure. As a result, the rated current of the LPT-CSTBT is increased in spite of decreasing the active chip area compared to the conventional planar IGBT design (see Fig.3) [1,2]. b) Light punch through (LPT) structure The new 1200V CSTBT chip utilizes an optimized vertical structure based on Mitsubishi’s Light Punch-Through (LPT) technology. A schematic comparison of conventional NPT, Epitaxial PT, and LPT chips is shown in Fig. 4. The key to the LPT structure is an optimized n- drift region that it is thin enough to provide low VCE(sat) while maintaining a robust switching SOA. An n buffer layer is utilized to secure a sufficiently high breakdown voltage and low leakage current in the presence of the optimally thin n- drift region. The thickness of the n- drift layer is selected so that the depletion region extends to the collector when rated voltage is applied in the off-state. However, at normal operating voltages the depletion region does not reach the buffer layer giving an operation characteristic similar to conventional NPT designs. Another feature of the LPT structure is optimized n+ buffer and p NEW 1700V A-SERIES IGBT MODULES WITH CSTBT AND IMPROVED FWDi By Clark, Donlon, and Iura collector layers that provide controlled carrier concentration in the n- region during conduction. The result is efficient switching characteristics without the need for carrier lifetime control processing. The new CSTBT chips are fabricated from low cost n-type single crystal (nonepitaxial) wafer material. [5] The LPT structure has the advantage of wide SOA and positive temperature coefficient of VCE (sat). Another advantage of LPT is its narrow VCE (sat) distribution, since no lifetime control in n- bulk is required. [1,2] 200 Rated current of chip [A] Planer IGBT LPT-CSTBT 150 100 50 0 0 50 100 150 Active chip area [mm 200 250 2] Fig.3: Comparison of the relationship between active chip area and rated collector current of LPTCSTBT versus conventional planar IGBT Fig.4: Comparison of Structures NEW 1700V A-SERIES IGBT MODULES WITH CSTBT AND IMPROVED FWDi By Clark, Donlon, and Iura 3-2. Diode Chip Technology IGBT modules need an anti-parallel, emitter to collector free-wheel diode to ensure that reverse voltage does not appear across the IGBT chip. Oscillations of current and voltage often can be observed in a conventional diode, especially during reverse recovery at low current. The oscillation may cause EMI problems for both the module itself or for the converter equipment. In order to suppress such oscillation, an optimized soft recovery diode is needed. The newly designed diode has optimized carrier density to soften the reverse recovery behavior. P N —— : conventional —— : new diode N+ Fig.5: Comparison of carrier density profile between conventional diode and new one The carrier density profile of the conventional diode and that of the new one are compared in Fig.5. The hole injection is suppressed by reduced carrier density in the P layer and the N+ layer. 4. Electrical performance The new 1700V IGBT modules with LPT-CSTBT have improved static and dynamic electrical characteristics as described below. 4-1. Static characteristics The modules use a number of positive temperature coefficient LPT-CSTBT chips in parallel in order to realize the high module current rating. The positive temperature coefficient prevents temperature and current imbalance between modules connected in parallel as well as between the parallel chips inside the module. NEW 1700V A-SERIES IGBT MODULES WITH CSTBT AND IMPROVED FWDi By Clark, Donlon, and Iura The VCE (sat) of the new modules with LPT-CSTBT is about 35% lower than the conventional one. Furthermore, the trade-off characteristic _ the relationship between VCE (sat) and turn-off switching energy, Eoff _ of LPT-CSTBT is significantly improved compared with conventional planar 1700V IGBT modules. 7 6 Vce (sat) [V] 5 4 3 2 CM200DY34A CM200DU-34KA 1 0 0 100 200 Ic [A] 300 400 Fig.6: Output characteristics (typical) of 200A (CM200DY-34A & CM200DU-34KA) [Tj=125°C, VGE=15V] 4-2. Dynamic characteristics The new 1700V A-series IGBT module has excellent dynamic performance in comparison with the conventional one. In the same operating conditions of di/dt and gate drive, turn-on and turn-off switching energy, Eon and Eoff, of the new 1700V IGBT modules are about 12% and 8% lower than those of conventional one as shown in Table 2 and Table 3. Table 2: Turn-on switching characteristics Item Conventional module CM200DU-34KA New module CM200DY-34A di/dt 1000 A/s 1000 A/s Eon 106 mJ 94 mJ [Tj=125°C, VCC=1000V, IC=200A, VGE=±15V, Inductive load] Table 3: Turn-off switching characteristics Item Conventional module CM200DU-34KA New module CM200DU-34A di/dt 250 A/s 250 A/s Eoff 64 mJ 59 mJ [Tj=125°C, VCC=1000V, IC=200A, VGE=±15V, Inductive load] NEW 1700V A-SERIES IGBT MODULES WITH CSTBT AND IMPROVED FWDi By Clark, Donlon, and Iura The total IGBT losses in inverter operation can be estimated from the above electrical (static and dynamic) characteristics and compared with the conventional modules (see Fig.7). The losses are reduced by 32% when using the new modules. 700 @ Tj=125°C, Io=140A rms , Vcc=850V, fc=5kHz, p.f.=0.8 Static 600 Dynamic 500 400 207 300 32% reduced 134 200 100 283 198 0 CM200DU-34KA CM200DY-34A Fig.7: Comparison of IGBT inverter losses 4-3. Short circuit performance In general, modules with trench gate IGBT chips tend to have quite high short circuit currents because of the trench IGBT’s large saturation current density. However, the new modules have suppressed such excessive short circuit currents by introducing an optimized trench cell design which maintains the 10s short-circuit withstand time. [1] 5. Package structure One key issue in power module assembly technology is wire bonding. The new modules use LPT-CSTBT IGBTs which have a higher current density due to the increase module current rating. If the conventional wire bonding technique is applied to LPT-CSTBT the wire temperature may become high. Such high wire temperature is a disadvantageous phenomenon for power cycling capability. Therefore, a new wire bonding technique has been introduced to suppress this temperature increase. Fig.8 shows a compared top view of IGBT chip temperature including bond wires with an infrared camera and includes a simple cross section depiction of the wire bonding: a) is the conventional wire bonding applied to an LPT-CSTBT chip and b) is the new wire bonding technique. As Fig.8 shows, the wire temperature of new IGBT module is about 12K lower than the conventional one under the same loading conditions. The improvement points of the new wire bonding technique are: - lower wire current density due to increased number of bond wires; NEW 1700V A-SERIES IGBT MODULES WITH CSTBT AND IMPROVED FWDi By Clark, Donlon, and Iura - non-cutting (“stitch”) bonding technique (see red circle in Fig.11) to decrease current density at bond sites. By using this new stitch wire bonding technique the temperature excursion is reduced and the power cycling capability of new modules is improved. a) b) Wire temperature: 110 °C maximum Wire temperature: 98 °C maximum Fig.8: Comparison of wire temperature between stitch and no stitch technique a) Conventional wire bonding technique on LPT-CSTBT chip (no stitch wire technique) b) New wire bonding technique on LPT-CSTBT chip (with stitch wire technique) 6. Conclusion A new series of high current 1700V IGBT modules using new LPT-CSTBT has been introduced. Improved loss performance allows a 50% increase in rated module current while keeping package compatibility with the previous module generation. 7. References [1] K. Nakamura, S. Kusunoki, H. Nakamura, Y. Ishimura, Y, Tomomatsu, T. Minato, “Advanced Wide Cell Pitch CSTBTs Having Light Punch-Through (LPT) Structures”, ISPSD 2002 [2] J. Yamada, S. Sasaki, T. Matsuoka, Y. Ishimura, Y. Tomomatsu, I. Merfert, E. Thal “Next Generation High Power Dual IGBT Module with CSTBT Chip and Package Concept”, PCIM Europe 2002 [3] K. Satoh, T. Nakagawa, K. Morishita, S. Koga, A. Kawakami, “4.5kV Soft Recovery Diode with Carrier Stored Structure”, ISPSD 1998 [4] S. Iura, E. Suekawa, K. Morishita, M. Koga, E. Thal, “New 1700V IGBT Modules with CSTBT”, PCIM Europe 2004 [5] Junji Yamada, Yoshiharu Yu, Y. Ishimura, John F. Donlon, Eric R. Motto, “Low Turnoff Switching Energy 1200V IGBT Module”, IAS 2002