* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download MAXISS: A New Servo Duty IPM With On-Chip

Power inverter wikipedia , lookup

History of electric power transmission wikipedia , lookup

Control system wikipedia , lookup

Stray voltage wikipedia , lookup

Voltage optimisation wikipedia , lookup

Current source wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Power engineering wikipedia , lookup

Mains electricity wikipedia , lookup

Electrical substation wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Semiconductor device wikipedia , lookup

Earthing system wikipedia , lookup

Thermal runaway wikipedia , lookup

Power electronics wikipedia , lookup

Alternating current wikipedia , lookup

Distribution management system wikipedia , lookup

Integrated circuit wikipedia , lookup

Buck converter wikipedia , lookup

Surge protector wikipedia , lookup

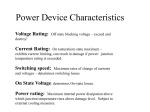

MAXISS: A New Servo Duty IPM With On-Chip Temperature Sensing E. Motto**, J. Achhammer**, M. Yamamoto*, T. Marumo*, T. Igarashi* * Power Device Division, Mitsubishi Electric Corporation, Fukuoka, Japan ** Powerex Incorporated, Youngwood, Pennsylvania, USA ABSTRACT This paper describes a new family of intelligent power modules optimized for demanding multi-axis servo drive applications. The new IPMs feature compact packages designed for convenient installation in the narrow profile (bookshelf) drives that commonly make up multi-axis servo systems. Fourth generation 1µm planar IGBT chips are utilized to provide low switching and conduction losses. The new chips are fabricated with an advanced on-chip temperature-sensing feature to provide effective protection against severe conditions such as locked rotors. I. INTRODUCTION Multi-axis servo systems often consist of a group of narrow rack mounted motor drives. In most applications these drives are required to operate at relatively high modulation frequencies to provide accurate torque and speed control. Managing the resultant switching losses requires efficient thermal designs. In addition, these drives are often required to deliver full torque under locked rotor (zero speed) conditions. This condition further complicates loss management and overtemperature protection because losses are not evenly distributed within the module. The end result is a demanding requirement for thermal management and protection in a limited amount of space. In order to simplify and reduce the cost of these drives, a new series of intelligent power modules called MAXISS (Multi-AXIS Servo) has been developed. II. PACKAGE DESIGN The new MAXISS IPMs feature packages with reduced size compared to conventional third generation IPMs. Figure 1 shows a comparison of the package size of the new IPMs compared to the conventional devices. There are only two different mechanical package designs to cover the complete line-up of MAXISS IPMs as indicated in the figure. Table 1 summarizes the packages, part numbers and device ratings for the MAXISS family of IPMs. The MAXISS family consists of six devices with current ratings ranging from 50A to 300A. All devices utilize IGBTs with 600V breakdown ratings for reliable operation on AC line voltages from 100VAC to 240VAC. Third generation Third generation Figure 1 MAXISS – Package A MAXISS - Package B Size Comparison of Third Generation and MAXISS IPMs A B IC (A) 50 75 100 150 200 300 Part Number PM50CBS060 PM75CBS060 PM100CBS060 PM150CBS060 PM200CBS060 PM300CBS060 Table 1 sink VCES (V) sink sink 600 380mm Package MAXISS Line-up Table 120mm 300mm heat pipe In many servo drive applications, the high losses resulting from the severe operating 60mm c. Thermal Design conditions combined with the need for a narrow a. Target Dimensions b. Thermal Design for Bookshelf Style Using MAXISS Using Third profile, necessitates the use of a complex and Servo Drive IPM Generation IPM expensive thermal system. Figure 2a illustrates Figure 2 Using IPM with Narrow Heat Sink the size and shape of a typical narrow profile bookshelf style servo drive. The narrow 60mm wide heat sink does not provide enough mounting area to accommodate the footprint of a conventional IPM. One solution to this problem is the addition of a heat pipe as shown in Figure 2b. Unfortunately, this method adds considerable cost and complicates inverter assembly. The MAXISS IPM’s 50mm wide base plate provides a simple cost effective solution by allowing direct mounting to the heat sink as shown in Figure 2c. To achieve the significantly smaller size illustrated in the figures, the MAXISS IPMs utilize a new package design based on the high reliability, field proven, U-Package technology developed by Mitsubishi Electric for high power IGBT modules. Figure 3 compares the cross sections of a third generation IPM to a MAXISS IPM. Like other U-Package devices the power and control electrodes are molded into the wall of the package to eliminate the need for solder joints and the chip level printed circuit board material. All connections to the substrate are made using high reliability wire bonding. This approach simplifies assembly and allows a reduction in the size of the substrate required. Aluminum Nitride (AlN) substrates with high thermal conductivity are utilized in all MAXISS IPMs to provide the low thermal impedance required in demanding servo drive applications. The IGBT and free-wheel diode power chips are soldered to the AlN substrate that is soldered to the copper base plate. The gate drive and protection circuits are constructed on two smaller printed circuit boards, rather than 1 Interconnect Terminal Control Board Case Al Wire Cu Base plate IGBT FWDi PCB Material DBC Ceramic Substrate PCB Material Control Boards Interconnect Terminal Case Al Wire IGBT FWDi DBC Ceramic Substrate a. Third Generation Figure 3 Cu Base plate b. MAXISS Cross Sections of 150A, 600V IPMs Emitter Electrode Cathode Anode SiO2 Gate Electrode Polysilicon n+ p Polysilicon Diode Collector Electrode IGBT Cell Tj sense Figure 5 Structure of Fourth Generation Chip with Tj Sensing Function Emitter Cathode Anode Gate Current Mirror Figure 4 Internal View of MAXISS IPM Figure 6 Photo of Fourth Generation Chip with Tj Sensing Function larger board, located above the power devices. One board provides gate drive and protection for the three low side IGBTs and the other provides gate drive and protection for the three high side IGBTs. Figure 4 is a photograph showing the internal design of the package “A” MAXISS IPM. III. CHIP DESIGN Another key requirement for compact servo drive applications is low loss. To meet this requirement the MAXISS IPMs utilize a specially designed fourth generation IGBT chip. The structure of the new chip is illustrated in Figure 5. The left side of Figure 5 shows one IGBT cell. A typical chip contains hundreds of thousands of these cells connected in parallel. To reduce losses a 1µm process and optimized planar cell geometry were utilized. The 1µm process allowed a significant reduction in cell pitch and increased cell density compared to the 3µm process used in third generation devices. The right half of Figure 5 shows the structure of the on-chip temperature sensing diodes. These diodes are fabricated in the polysilicon layer on the surface of the IGBT chip. Figure 6 is a photograph showing the features of the new IGBT chip. The connections for the main emitter, gate, on-chip temperature sensor and current mirror are on the top surface of the chip. The current mirror emitter provides current sensing for the IPMs short-circuit protection functions. The trade-off curve in Figure 7 illustrates the improvement in VCE(SAT) and ESW of the new fourth generation chip compared to previous generations. The fine pattern and dense cell structure of the new IGBT chip gives a VCE(sat) at rated current of 1.6V compared to 1.8V for the third generation IPM. The saturation voltage characteristic of the new IGBT chip is illustrated in Figure 8. The new IGBT chip has been optimized to provide minimum switching losses and soft switching characteristics for minimum switching noise and overshoot voltages. Figure 9 shows the total switching energy characteristic of the new chip compared to the third generation device. Figure 10 shows the inductive 2.8 VCE(sat) (V) 125°C, Jc=130A/cm2 2nd Generation (5µm planar) 2.4 3rd Generation (3µm planar) 2.0 1.6 4th Generation (1µ µm planar) 1.2 ~ ~ 0.1 1.0 Esw(off) 10.0 (mJ) 125°C, Inductive Load Figure 7 Saturation Voltage versus Turn-off switching Energy MAXISS T hird Generation Vce(sat) (V) 2 1.5 1 0.5 Tj = 125°C 0 0 25 50 75 100 125 Ic (A) Figure 8 Saturation Voltage Characteristics for 100A, 600V IPMs MAXISS T hird Generation 12 Esw(off) (mJ/pulse) 10 8 6 4 Tj=125ºC Vcc=300V Inductive Load 2 0 0 20 40 60 80 100 120 Ic (A) Figure 9 Total Switching Energy for 100A, 600V IPMs load switching waveform for a 100A, 600V MAXISS IPM. This waveform illustrates the well-behaved, low noise, switching of the new IGBT and free-wheeling diode utilized in the MAXISS IPM. IV. ON-CHIP TEMPERATURE SENSING Conventional IPMs utilize a thermistor attached to the ceramic substrate near the power chips, as shown in Figure 11.a, to provide overtemperature protection. The thermistor detects the base plate temperature of the module and its response time is limited by the thermal mass of the base plate. This type of sensor can provide effective protection against events that cause a relatively slow increase in temperature such as overloads, excessive ambient temperatures or inadequate cooling airflow. Servo drives are often designed to produce high output currents for short periods of time to provide rapid acceleration and high start-up torque. This high current condition can produce a rapid increase in junction temperature that may be too fast for a conventional base plate temperature sensor. This problem becomes even worse if the high output current is delivered at zero speed (locked rotor). Depending on the position of the rotor this condition may produce the highest losses in a single IGBT chip as illustrated in Figure 12. If this chip is located far from the base plate temperature sensor it will take even longer to detect an overtemperature condition. The MAXISS IPM uses an advanced on-chip temperature sensor, Turn-on Turn-off (VCE:100V/div, VCIN:10V/div, IC:50A/div, t:400ns/div) Tj = 125ºC, VCC = 300V, IC = 100A Figure10 Inductive Load Switching Waveforms as shown in Figure 11.b, to avoid these problems. Each IGBT chip in the MAXISS IPM has a string of diodes fabricated in the polysilicon on the surface of the IGBT chip. Chip temperature is detected by forward biasing the diode string and measuring the voltage drop. Like most silicon diodes the forward voltage drop decreases with increasing junction temperature. Figure 13 shows the typical Vf versus Tj characteristic of the temperature sensing diodes. A string of diodes is used to provide a high enough sensing voltage to avoid problems with noise. The MAXISS overtemperature protection function is implemented as shown in Figure 14. The Vf of the on-chip sensing diodes is compared to a reference voltage, which sets the overtemperature trip level (OT). If the Vf of the sensing diodes drops below the reference voltage an overtemperature condition is indicated. If the IGBT chip involved is on the low side, all three lower IGBTs will be turned off and a fault signal is generated. If the IGBT involved is on Thermistor IGBT a. Conventional IPM Gate - Emitter Sensor b. MAXISS IPM Figure 11 Diode to detect chip temperature IGBT Temperature Sensor Location Comparison Motor the high side, only that device will be turned off and a fault signal is not provided. The detection circuit provides hysteresis so that the chip must cool below the overtemperature reset level (OTr) before normal operation can resume. V. PROTECTION FUNCTIONS Figure 12 Locked Rotor Vf (V) In addition to overtemperature protection, the IPM’s 4 internal gate control circuits also provide control supply undervoltage 3.5 If = 3mA lockout, overcurrent, and short-circuit protection. The IPM's internal 3 control circuits operate from a 15V DC supply. If for any reason, this 2.5 supply voltage drops below the specified undervoltage trip level (UV), 2 the power devices are turned off and a 0 25 50 75 100 125 150 175 fault signal is generated. Normal T j (°C) operation will automatically resume Figure 13 Temperature Sensor Characteristics when the supply voltage exceeds the undervoltage reset level (UVR). The MAXISS IPM utilizes a Part of control IC two level overcurrent protection scheme. Current through each IGBT is monitored using the output from the On control board current mirror emitter on the IGBT chip. The current from the mirror emitter is diverted through a resistor network that provides voltage signals Diodes on for the gate control IC. The gate IGBT Chip control IC has comparator circuits that determine if an overcurrent or short-circuit condition is present. In the case of a severe short-circuit condition that causes the current to Figure 14 Overtemperature Sensing Circuit exceed the data sheet specified short-circuit trip level (SC) the IGBT involved will be immediately shut down. In the case of a less severe overcurrent condition that causes the current to exceed the data sheet specified overcurrent trip level (OC) the IPM will wait for a delay of tOFF(OC) that is typically 10µs before shutting down. The tOFF(OC) delay is provided to avoid false tripping of the protection on short pulses of current that are not dangerous for the IGBT. Figure 15 shows a timing diagram for the short circuit and over current protection. If the fault occurs on one of the low side IGBTs all three lower IGBTs will be turned off and a fault signal will be generated. If the fault is detected on one of the high side IGBTs the device will be shut down and gate drive is inhibited but a fault signal will not be generated. If the high currents that cause short-circuit faults are abruptly interrupted, a high di/dt will occur. This high di/dt can cause dangerous transient voltages. The MAXISS IPM avoids this condition by using controlled di/dt (soft) shutdown techniques. Figure 15 Short-Circuit and Overcurrent Protection Timing Diagram The MAXISS IPM has built-in protection circuits that prevent the power devices from being damaged should the system malfunction or be over-stressed. Fault detection and shutdown schemes allow maximum utilization of power device capability without compromising reliability. VI. CONCLUSION A new IPM designed for multi-axis servo drive applications has been presented. The new MAXISS IPM utilizes a specially designed compact package to allow optimized thermal management for narrow profile bookshelf style servo drives. A new IGBT chip with a 1µm planar structure is utilized to provide low losses with integrated temperature and current sensing features. Built in protection functions allow maximum power device utilization while maintaining high reliability. REFERENCES [1] G. Majumdar, et al. "Enhancing SOAs of IGBT Modules For Hard Switching Applications" PCIM , June 1990 [2] G. Majumdar, et al. "A New Generation High Speed Low Loss IGBT Module", ISPSD, May 1992 [3] J Yamashita, et al. "A Study on the Short Circuit Destruction of IGBT's" , ISPSD, May 1993 [4] G. Majumdar, et al. "A New Generation High Performance Intelligent Module" PCIM Europe May 1992 [5] Powerex "IGBTMOD and Intellimod Application and Technical Data Book" Second Edition, PUB#9DB-200, 1998 [6] E. Motto, et al. "A New Generation of Intelligent Power Devices for Motor Drive Applications" IEEE IAS Conference October 1993 [7] E. Motto "Protecting High Current IGBT Modules From Over Current and Short Circuits" HFPC Conference May ,1995 [8] John Donlon, et al. "A New Converter/Inverter System for Windpower Generation Utilizing a New 600 Amp, 1200 Volt Intelligent IGBT Power Module" IEEE IAS Conference October 1994 [9] T. Kajiwara, et al. "New Intelligent Power Multi-Chips Modules With Junction Temperature Detecting Function" IEEE IAS Conference October 1998