* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Manual for MasterStat (Evaporative Cooler Thermostat)

Distributed control system wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Power inverter wikipedia , lookup

Control theory wikipedia , lookup

Resilient control systems wikipedia , lookup

Current source wikipedia , lookup

Three-phase electric power wikipedia , lookup

Stepper motor wikipedia , lookup

Electrical ballast wikipedia , lookup

History of electric power transmission wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Electrical substation wikipedia , lookup

Control system wikipedia , lookup

Schmitt trigger wikipedia , lookup

Power electronics wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Power MOSFET wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Distribution management system wikipedia , lookup

Rectiverter wikipedia , lookup

Buck converter wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Voltage regulator wikipedia , lookup

Surge protector wikipedia , lookup

National Electrical Code wikipedia , lookup

Alternating current wikipedia , lookup

Opto-isolator wikipedia , lookup

Stray voltage wikipedia , lookup

Specifications

MasterStat

Evaporative

Cooler

KitModelCC2000B

Control

Electrical

Ratings:

lnputvoltage

120or240VAC,60

Hz.

- I HpMax:

FanRating

16FLA,

96LRA

at 120VAC

8 FLA,

48LRAat240VAC

Pump

Rating:

10FLA,

60LRA

at 120VAC

5 FLA,

30LRA

at240VAC

Gombined

TotalLoad:

30FLAat 120VAC

15FLAat 240VAC

Installation

Instructions

TheCC2000B

Evaoorative

CoolerControlconsistsof a lowvoltage

transformer

withdualvoltFAILURETO BEADAND FOLLOWALL

CAUTION:

ageprimary;

andseparate

relaysto controlthe

INSTALLATION

AND OPERATING

INSIRUCTIONS pump,lowmotorspeedandhighmotorspeed.

COULD

CAUSE

PEBSONAL

INJUBY

AND/ ONDAMAGE

Thecontrollogicis supplied

through

a microTOPBOPEBTY.

processor

in thelowvoltage

wallthermostat

and

ALL ELECTBICAL

INSTALLATI0NS

MUST

CAUTION:

in automatic

modeallowsthe

COMPLY

WITHLOCAL

BUILDING

ANDSAFETY

CODES whenoperating

ANDMUSTBEPEHFOBMED

8Y OUALIFIED

PEBSON- pumpto activate

aheadof theblowermotor...

NELONLY.

pre-wetting

padsto eliminate

thecooling

hotair

beingsupplied

onstart-up.

InstallationChecklist

o Thevoltages

of the cooler'spumpandblower

motormustmatch(bothmustbe 120voltor

bothmustbe 240volt).Donot mixvoltages

withthiscontrolsystem.

r Thiscontrol

is designed

to be usedwitha 2speedblower

motor.Installation

witha single

speedblower

motoris notrecommended.

. Thiscontrol

is designed

forfanmotors

upto 1

n0rse0Ower.

. Donotexceed

thespecification

ratings

onthis

control.

Included

In Kit:

YourCC2000B

Evaoorative

CoolerControlKit

(tobe

consists

of a lowvoltage

wallthermostat

mountedinsideyour home)and a separate

NEMA

3Rraintightcontrol

box(tobe mounted

outside

of yourevaporative

cooler).

AdditionalRequirements:

Evaoorative

Sincethe CC2000B

CoolerControl

Kit is designed

for use with manydifferent

brandsand typesof coolersyou will needto

themethod

determine

thatbestfitsyourapplication.In addition

to thelowvoltage

wallthermostatandsenarate

controlboxincluded

withthis

ONEYEARLIMITEDWARRANTY

purAdobeAir,

lnc.,extends

thiswananty

to the original

chaserof a Masterstat

modelCC2000B

Evaporative

Kitinstalled

Cooler

Control

andusedundernormal

conditions.

Whatthis waffantyc0ve6 and f,t how long

Wewillreplace

withoutcharge

kit whichfails

anycontrol

asa resultof a defectin material

or workmanship

during

thefirstyearafterdate0f initialpurchase.

Wedonotpaythecost0fa service

callatthesiteof installationto diagnose

causeof trouble,

the costof labor,or

part.

transportation

t0 replace

a defective

Wearenotresponsible

lor anyincidental

or consequential

damage

resulting

fromanymalfunction.

Somestatesdonotallowtheexclusion

for anyincidental

or consequential

damages,

so the abovelimitations

or

maynotapplyto you.

exclusrons

Whatthis wananlydoesnot cover

Howto ohtainserviceunderthis warranty

We arenot responsible

for anydamageor malfunction Contact

yourcontrol

theDealer

whereyoupurchased

kit0r

unlesscausedby a defectin material

0r workmanship. goto www.AdobeAir.c0m

Product

Dept.,

orcontact

Service

Thisincludes,

butis notlimited

to,internal

waterdamage, AdobeAir,

Inc.,1450E.GrantStreet,

Phoenix,

AZ85034.

improper

abuse,

installation,

andtransportation

damage.

kityoumayneedthefollowing:

woodscrews,

nutsandbolts,

Sheetmetalscrews,

flat washers,

hardware

or othersuitable

to secure

thecontrol

boxto itsmounting

location.

A mounting

bracketif yourinstallation

doesnot

allowmounting

of the controlboxdirectly

to the

cooler

or itsstand.

4-wirethermostat

wireto runfromthecontrolbox

at the coolerto the wall thermostat

insidethe

n0use.

Electrical

conduit

andconnectors

to protect

wiring

powersupplyandtheconbetween

theincoming

trolboxANDbetween

thecontrolboxandthecoolersjunction

box.

Conduit

andconnectors

to orotect

the4-wirethermostatwiringfromthecontrolboxintothehouse.

(wirenuts)andwiringof the

Electrical

connectors

properlength,colorsand specifications

for your

installation.

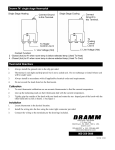

Installingthe ControlBox

T0 PREVENT

ELECTRICAL

AND/OR

CAUTI0N:

SHOCK

EOUIPMENTDAMAGE,DISCONNECT

ELECTBICPOWER

gOX

TO SYSTEMAT MAIN FUSEOB CIBCUITBBEAKEB

UNTILINSTALLATION

IS COMPLETE.

'l)

0pencontrol

boxcoverandremove

wallthermoin a safelocation

to

stat.Placewallthermostat

prevent

damage

whileinstalling

thecontrol

box.

2) Determine

a suitable

location

to mountthecontrol boxoutsideof yourevaporative

cooler.The

posicontrol

boxmustbe Installed

in a vertical

tiononlywithelectrical

knockouts

down.Some

possible

locations

include:

Totheleg(orcornerpost)of yourcooler,

making

will notinterfere

with

surethatyourinstallation

removal

of coolerpadframesor otherservicing

of thecooler.

Tothe top of yourcooler,

usingan "f' bracket

(notsupplied)

method

to assure

or othersimilar

a secure,

upright

installation.

yourcoolerontheroof.

Tothestandsupporting

you will usefor

whichknockouts

3) Determine

electricalwiring (alwaysuse the knockout

marked"Thermostat

Wire"for the 4-wirelow

voltage

wiringto the wallthermostat

insideof

thehouse).

placea screwdriver

4)Toremove

theknockouts,

on

theinnerringoftheknockout

andtapthescrewdriverto poptheknockout

outof thebox.lf it is

notcompletely

removed

usepliersto

carefully

twisttheknockout

untilit comesout.Toremove

a larger

knockout,

startwiththeinnerringfirst.

orientation

only)using

5) Mountthe box(vertical

flat washers

andscrewsor bolts(notincluded)

usingthethreeholesprovided

inthebackof the

controlbox.Twoholesareinsidethe bottomof

the caseandoneis at the outside

too of the

case.

6)Install

conduit

andrunwiringinaccordance

with

localand national

electrical

codesand ordinances.

grounding

N0fE:Non-metallic

doesnoIprovide

enclosure

hetween

conduit

connections.

Usegrounding

bushings

and jumper wires as necessatyto enswe proper grounding ol the conlrol.

(seeFigure

1).

7)Connect

wiresto proper

terminals

B)Thevoltage

selection

switchis mounted

on the

orinted

circuitboardinside

thecontrol

box.lt is

shipped

in thecenter"off"position.

Thecontrol

system

willnotoperate

untilproper

voltage

has

(120

beenselected.

Selectthe propervoltage

VACor 240VAC)

bysliding

theswitchto the120

VACor 240VACposition

thatmatches

thepower

to theunit.

supply

FIGUNE1- POWEBSUPPLY,

PUMPANDMOTOBWIEING:

GND

[

ll-)

GND GND

][-'

r-)t l{-)

L2N

]

t{-11

"ll"lL-ll.-l

L2N

L2N

E

;o

E

3

a

:o

E

6

I

H,FAN

E

6a

>-

i

>5

:

E

=

LI

l,-l l .-t-l |-,

'.,rl

.I L-l

E

>;

-

>--

Installingthe WallThermostat

Theproperlocation

is impoftant

of thethermostat

to insure

it willprovide

theproper

roomtempergeneral

ruleswhen

ature.0bserve

thefollowing

selecting

a location:

o Locateit about5 ft. abovethefloor.

. Install

it ona partitioning

wall,notonanoutside

wall.

e Never

it to directlightfromlamps,

expose

sun,

fire-places,

radiating

equipor anytemperature

menI.

. Avoidlocations

closeto doorsthatleadoutside,

windows,

or adjoining

outside

walls.

. Avoidlocations

closeto air reoisters.

or in the

directpathof airfromthem.

. Makesuretherearenopipesor ductworkin that

location.

oaftofthewallchosen

forthethermostat

o Never

locate

it in anareathatis warmer

or coolerthantherestof thebuilding.

. Avoidlocation

withlackof aircirculation,

suchas

behind

doorsor in alcoves.

. In homes,

thelivingr00m0r diningroomis norprovided

mallya goodlocation

thereis nocooksideof

ingrangeor refrigerator

ontheopposite

thewall.

o Youdo not usethe CO0L/VENT

FAN

or H|/LOW

The

ooeration.

buttonswhen in automatic

will now

Evaporative

CoolerControl

CC2000B

automatically

controlyourpumpandyourfan

temperamotorspeeds

to maintain

thedesired

possible.

tureusingtheleastamount

of energy

with Cooling

Manual0peration

. Depress

to illuminate

anyindi0N/OFF

button

catorlight.

. Depress

the

AUTO/MAN

buttonto illuminate

"Man"indicator

light.

. DeoressC00L/VENT

buttonto illuminate

AilachingThermostat

Baseto Wall

"Cool"indicator

light.

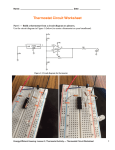

wiresfromevaporative

cooler

9) Routethermostat

. Deoress

HULOW

FANbuttonto selecteither

location

andpullwires

control

boxto thermostat

"High"

"Low"

indicator

lightdepending

on

or

inches

throughholein wallso thatabout6

of

youdesire.

thefanspeed

cableorotrudes.

. Rotate

roomtemperknobto desired

selection

10) Separate

thermostat

fromthermostat

baseby

Evaoorative

Cooler

ature.

The

CC2000B

pulling

carefully

apad,leftsidefirst.

yourcoolerat only

will nowoperate

Control

provided

inthermostat theselected

11)Pullwiresthrough

opening

thecooleron

fanspeed,

turning

baseloosely

to wall

baseandfastenthermostat

to maintain

the selected

andoff as reouired

Levelbaseby

usingmounting

screwsprovided.

temoerature.

placing

levelontopof baseandtighten

mounting

to secure

basein leveloosition.

screws

ManualOperation

WithoutCooling

12)Striobackthermostat

wires114"andconnect flenl-0nlyl

(see . Depress

colorcodedwiresto the properterminals

to illuminate

anyindi0N/0FF

button

Figure

2).D0NOTOVER-TIGHTEN

SCREWS.

catorlight.

13)Pushexcess

wireintowallandplugholewith . Deoress

the

AUT0/MAN

buttonto illuminate

non-combustible

material

to orevent

draftsJrom

"Man"indicator

light.

. Depress

"Vent"

button

to illuminate

C00L/VENT

FIGURE

2 . LOWVOLTAGE

|HERMOSTAT

WIRING:

indicator

light.Thepumpwillnotoperate.

. Depress

H|/L0W

FANbuttonto selecteither

WallThermostatv @ w @ R @ c @

"High"

lightdepending

on

or "Low"indicator

youdesire.

thefanspeed

Evaporative

will

The CC2000B

CoolerControl

speed.

nowoperate

asa fanonlyat theselected

Theblower will run conlinuouslyuntil manually turnedofl or switchedto automatic

affecting

thermostat

operation.

mode.

14)Attach

thermostat

to thermostat

basebyhooking Thermostatic

in VentOnlv

control

is inactivated

rightsideof thermostat

and baseand gently m00e.

pushing

leftsideclosed.

Pre-Wet

Cycle

Automatic0peration(recommended)

Evaporative

CoolerControl

The

CC2000B

. Depress

0N/0FF

button

to illuminate

anyindica- includes

thecirculatcycle

thatallows

a pre-wet

torlight.

before

the

ingpumpto activate

upto 2 minutes

. Deoress

AUT0/MAN

buttonto illuminate

the blower

thatonlypre-cooled

air

fan.Thisassures

"Auto"indicator

yourhome.

light.

indicaA flashing

motorspeed

enters

. Rotate

roomtemoera- torlightletsyouknowthatthepadsarepre-wetselection

knobto desired

shortly.

tingandthatthefanmotorwillactivate

ture.

ControlBox

Y@ w@ R@ cC

Specificfor MasterStat

Universal

CoolerControlKitCC2000B

to a Master0ool

ll Evaporative

Gooler

CAUTI0N:

DISCONNECT

ALLELECTRICAL

P0WERT0 THECOOLER

BEFORE

ATTEMPTING

TOINSTALL,

YOUR

OPEN,

ORSERVICE

COOLER.

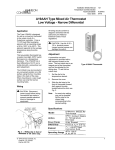

115I 120VOLTINSTALLATION

120Volt

PowerSupply

Grcund

Pr rnp Gro!il(i

^/lolor Ground

PowerSupply

N

MolorN

PUmpN

@

@

@

@

@

cND

GND

GND

L2N

L2N

ftfl L2N

P u n r pL l

@P

Molor

LowSpeed

l-Ol r-rnru

KilLT

[Ol u-rnr'r

LI

I\,4otor

H qh Speed

Gro!nd

Pump Gro!nd

Nfotor

Ground

PowerSupply

L2

l,lolorL2

Plmp L2

Punr0L

Motor

LowSpeed

PowerSupply

LI

fulolor

HiqhSpeed

oRANcE

(--

oRANGE

(-BLACK

WHITE

WHITE

BLACK

- RED

YELL0W

GREEN

GREEN

230I 240VOLTINSTALLATI

ON

240Voll

PowerS!pply

{-

@

@

@

@

@

@

@P

cND

GND

GND

L2N

L2N

L2N

[Ol r-rnru

@LT

fOl u-rnru

G-wHlTE

(___

ORANTE

BTACKYELLOW

RED

BLACK

ELUEWHITE

buttons

Manual

statuslightshould

turn

asrequired;

on (Auto,Highoff),Lowstatuslightshouldbegin

. Thisis a lowvoltage,

microprocessor

c0ntrolled

sysflashing,

indicating

thatthe pre-wetcycleis contem that makesuseof different

voltages

in con"High/Low"

tinuing.

Press

button

to change

to high

trollingthe cooler... bothAC and DC.Do not

fanspeed;

theHighstatuslightshouldbeginflashattempt

t0 testanyfunctions

0r operate

thiscontrol

pre-wetcyclecontinues

(totalPreing;indicating

thelowvoltage

byjumping

terminals.

WetCycle

time,two minutes).

YOU WILL BLOW THELOW VOLTAEE

ANCWT

to

/ Press"Cool/vent"

buttonto changeoperation

FUSELOCATED

ADJACENTfO THEWIRINGTEE"MANUAL

VENT"

mode;

Ventstatuslightshould

turn

MINALSOB MAY DAMAGETHE THEBMOSTAT

on (Cool0fl. Highstatuslightshouldstopflashing

AND/ONCONTBOLBOX IF YOUATTEMPTTO

for

turnonhighspeed.

Note:

andfanmotorshould

OPENATE

OB IEST THISCONTROL

BY JUMPING

all functions,

thereis a onesecond

delaybetween

ACNOSS

THETENMINALS.

thermostat

lightindication(s)

andrelayoperation(s).

Location

on wall is VERYimoortant.

0f thermostat

/ Press"High/[ow"buttonto changemotorto low

perguidelines

install

in Owners

Guide.

speed;Lowstatuslightshouldturnon (Highoff);

. Thevoltages

pump,fanmotorand

fan motorshouldchangefromhight0 low speed

of thecirculating

pausebetween

powersupply

witha onesecond

speedchanges.

incoming

MAICH(all120volt

MUST

Thisallowsblower

wheelto slowbefore

engaging

0r all 240volt).D0 NOTMIXV0LTAGES.

Verify

that

lowspeed,

decreasing

the"bumping"

noisewhen

voltage

selector

switchin the controlboxis setto

changing

speeds.

thecorrect

voltage.

Failureto properlysetvoltage

selectorswitchor matchvoltagesWILLcause

/ Press"Auto/Manual"

buttonto changeoperation

damageto the controlbox,thermostat,

motor

backto Automode.

Autostatuslightshould

turn0n

and/orpumpandwill V0lDwarranty.

Voltage

and

(Manualoff).lf Hiqh0r Low statuslight begins

selector

switchverification

istheinstaller's

resoonpreflashing,

waituntilflashing

stops,indicating

sibility.

wetcyclehascompleted.

Rotate

temperature

knob

. TheMasterStat

to 85'Fsetting;

allstatuslightsexcept

Autoshould

controlbox/thermostat

installati0n

is belowB5"F).

turnoff(if r00mtemperature

andwiringmustbe completed

as detailed

in the

enclosed

installation

instructions

beforeturningon

in desiredoperating

mode(Auto,

,/ Set thermostat

coolerpowersupply.

Verifythat low voltageand

Manual,

knobto desired

etc.),rotatetemperature

properly

mainpowerwiringis correctly

connected,

temperature

setting,

control

will nowoperate

autotightened

andthethermostat

is removed

fromsub

matically.

base beforebeginning

the followingStart-U0

th

IrouObsnooting

Procedure.

lI

one

or

more

statuslightson thethermostat

d0 not

/ Turn0N mainpowersupplyto cooler.

Measure

(there

functionas indicated,

replacethe thermostat

ACvoltage

terminals

L1& anyL2Nterbetween

parts).

are

no

user

serviceable

minalin controlbox,voltageshouldmeasure

'120

lf no thermostat

statuslightsturn 0N whenvarious

100and132VAC(for

Voltsupply)

between

as

functionbuttonsare pushedanddo not respond

(for

or 200and264VAC 240Voltsupply).

procedure,

indicated

in

Start-Up

check

the

following:

ACvoltage

/ Measure

behveen

terminals

R & G in

AC

Remove

thermostat

fromsubbaseandmeasure

shouldmeasure

controlbox,voltage

between

20

B and G on sub base.

voltagebetweenterminals

indiand30VAC.Anyothervoltage

0r novoltage

Voltageshouldmeasurebetween20 and 30 Vac.lt

catesa problemwith the controlbox,referto

is present,

theproblem

is in thetherguidebelow.

correctvoltage

troubleshooting

replace

mostat,

thermostat.

Thethermostat

/ Mountthermostat

to subbase.

is

No voltageindicates0pen 0r shortedthermostat

inthe"OFF,

AUT0"modeposition.

Press

shipped

low voltage

wiring(fixwires),

circuitfuseis blown

"0N/0FF"buttonto enablethermostat,

AUTO

powersupplyis non(replace

fuse),or control

system

tempermodestatuslightshould

turn0n.R0tate

(replace

controlbox).Voltages

lessthan20

functional

atureknobto 65"Fsetting.

lf roomtemperature

Vacor morethan30Vacindicates

a faultycontrol

sysis above65', the C00lstatuslightwillturnon

replace

tempowersupply,

contr0lbox.

andtheHIGH

orLOW

status

lightwillbegin

flashing, indicating

that fan m0t0r0perati0n

is

Troubleshootino

controlbox:

pumpt0 pre-wet .

to allowthecirculating

delayed

procedure

lf start-up

lowvoltage

checkis incorrecl

thepad(Pre-Wet

Cycle).

(novoltage

0r otherthanindicated),

checkthefol/ Setthermostat

in "MANUAL

C001,L0W"mode

lowing,in order:

"Auto/Manual"

and "High/Low"

by pressing

switch

/ Yerifymainpowerswitchand/ordisconnect

IMPORTANT

INFORMATION

is turned0N.Recheck

all main00werconnections

for components

and receptacles/plugs

on control

00x.

/ Remove

low voltage

wireson terminals

R & G to

isolatecontrolbox.Checklow voltagecircuit1/4

(spare

Ampfuse,replace

if necessary

inside

cover).

/ Measure

ACvoltagebetween

terminals

R & G in

controlbox,voltageshouldmeasure

between

20

and30VAC.

o lf thereis no voltage,

controlsystempowersupplyis

non-functional,

replace

controlbox.

. lf voltage

measures

between

10andl5 Vac,or40and

60Vac,thisindicates

voltage

selector

switchis in the

wrongposition

andimproper

voltage

is beingapplied

to thecontrolcircuit.

Control

system

hasbeenpermanentlydamaged;

replacement

of theconkolboxand

thermostat

is necessary.

Verifythat fan motor,cirpumpand/or

culating

drainpumphavenotbeendamaged,replace

theseitemsif necessary.

. lf a component

pump,

(circulating

fanmotor)

doesnot

turn 0N whenthermostat

function

lightis 0N, or

(low

resp0nse

t0 therm0stat

commands

is incorrect

speedstatuslightandhighfan motorspeed0N or

highspeedstatuslightandlowfanmotorspeed0N),

investigate

conkolboxasfollows:

/ Setthermostat

to "MANUAL

C001.L0W"modeand

rotatetemperature

knobto 65'F.

/ Measure

voltage

acrosscontrolboxterminals

W&

G;voltage

should

4.0to 5.0Vdc.Novoltmeasure

ageindicates

W wireis faulty(open,

checkwiring)

(replace

or thermostat

is damaged

thermostat).

lf

voltage

otherthan4.0t0 5.0Vdcis present

indicatesW wireis shoded(fixwiring)or thermostat

is

(replace

damaged

thermostat).

lf correct

DCvoltage

is present,

measure

ACvoltage

at the controlbox

terminals

PumpandL2Nandatthepumpreceptacle.lf conectvoltageis presentin bothplaces,

checkpump,replace

if necessary.

lf conectvoltage

is oresent

at thecontrol

boxterminals

butnotatthe

pumpreceptacle,

checkwiringbetween

terminals

lf no voltageis measured

andreceptacles.

at the

controlbox terminals.

relavis non-functional.

replace

control

box.

.

/ Measure

voltage

acrosscontrolboxterminals

Y&

should

G;voltage

measure

2.0to 3.0Vdc.Novoltageindicates

Y wireis faulty(open,

checkwiring)

(replace

is damaged

or thermostat

thermostat).

lf

voltageotherthan2.0 to 3.0Vdcis present

indi(fixwiring)or thermostat

catesY wireis shorted

is

(replace

damaged

thermostat).

lf correct

DCvoltageis present,

measure

ACvoltage

acrosscontrolboxterminals

Low andL2Nandat thelow

speedm0t0rreceptacle.

lf supply

voltage

is present in bothplaces,

checkfan motor,replaceif

necessary.

lf correctvoltageis presentat the

control

boxterminals

butnotatthemotorreceotacle,checkwiringbetweenterminalsand

receptacles.

lf novoltage

ismeasured

atthecontrol box terminals,

relayis non-f

unctional,

reolace

controlbox.

/ Set thermostat

to High-speed

mode,measure

voltage

across

controlboxterminals

Y & G;voltageshould

measure

4.0to 5.0Vdc.Novoltage

indicates

Y wireisfaulty(open,

checkwiring)

or

(replace

thermostat

is damaged

thermostat).

lf

voltage

otherthan4.0to 5.0Vdcis present

indi(fixwiring)or thermostat

catesY wireis shorted

(replace

is damaged

thermostat).

lf conectDC

voltageis present,

measure

ACvoltageacross

control

boxterminals

HighandL2Nandat the

high-speed

motorreceptacle.

lf supply

voltage

is

present

in bothplaces,

checkfanmotor,

replace

if necessary.

lf correctvoltage

is present

at the

control

boxterminals

butnotat them0t0rreceotacle.checkwiringbetweenterminalsand

receptacles.

lf novoltage

is measured

atthecontrol box terminals,

relayis non-functional,

reolace

control.

/ lf 1)lowfansoeed

doesnotturn0NwhenLow

is indicated

and2)lowfanspeedturns0Nwhen

Highis indicated,

checkvoltage

across

control

box terminals

Y & G with thermostat

in high

speed

mode.

lf voltage

is lessthan4.0Vdc,thermostatis damaged,

replace

thermostat.

lf voltageis 4.0to 5.0Vdc,control

boxis damaged,

replace

controlbox.

./ lf lowfanspeedturns0N whenHighis indicated andhighfanspeedturns0N whenLow is

indicated,

checkwiringat controlboxterminals

Highand Low,the m0t0rreceptacle

and the

m0t0rcordterminal

connections

forreversed

low

(red)

leads.

lf wiringis reversed,

andhigh(black)

wiring.

correct

lf the pumpand/orfan m0t0rdoesnotturn OFF

whentheC001,

Highor Lowthermostat

statuslight

is OFF(runscontinuously),

remove

from

thermostat

subbase.lf pumpand/ormotorturns0FF,replace

lf pumpand/ormotorcontinue

thermostat.

to run,

reolace

control

box.

AdobeAir,Inc.

1450E GrantSt Phoenix,

Arizona

85034USA

. Fax:

Tel:602-257-0060

602-257-1349

www.AdobeAir.com

L4210024

November

2005