* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

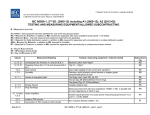

Download certification impact analysis: ul/iec 60950-1

Ground (electricity) wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Alternating current wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Sound level meter wikipedia , lookup

Flexible electronics wikipedia , lookup

Stray voltage wikipedia , lookup

Electrical substation wikipedia , lookup

Distribution management system wikipedia , lookup

Telecommunications engineering wikipedia , lookup

Earthing system wikipedia , lookup

Electromagnetic compatibility wikipedia , lookup

Rectiverter wikipedia , lookup

Voltage optimisation wikipedia , lookup

Automatic test equipment wikipedia , lookup

Surge protector wikipedia , lookup

Opto-isolator wikipedia , lookup

Portable appliance testing wikipedia , lookup

Mains electricity wikipedia , lookup