* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download WHY MODIFY THE HEADLIGHT?

Three-phase electric power wikipedia , lookup

Electrical substation wikipedia , lookup

Stepper motor wikipedia , lookup

History of electric power transmission wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Power MOSFET wikipedia , lookup

Semiconductor device wikipedia , lookup

Photomultiplier wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Current source wikipedia , lookup

Electrical ballast wikipedia , lookup

Voltage regulator wikipedia , lookup

Stray voltage wikipedia , lookup

Rectiverter wikipedia , lookup

Buck converter wikipedia , lookup

Surge protector wikipedia , lookup

Voltage optimisation wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Mains electricity wikipedia , lookup

Alternating current wikipedia , lookup

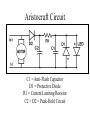

What is an LED? • An LED (Light Emitting Diode ) is a semiconductor DIODE that has been optimized to create and emit photons of light. • A semiconductor diode is an interface between two slightly different compounds selected to pass current only in one direction. How Does an LED Work? • Electrons crossing the diode junction in the forward direction must give up energy. Emitting photons of light is one option. • Analogy: Water going over a waterfall. • The energy lost by each electron is a function of the diode materials, and that determines the LED’s color. Hence, LEDs are essentially monochromatic (one color). How Does an LED Work? • LED wavelength and energy are related by Planck’s Constant h : E = h c / l. Note that long wavelength ( l ) photons are less energetic. • When an LED gets hot, the color tends to change toward the red (low energy) end of the spectrum. How Does an LED Work? • Photon energy is expressed in electronvolts (eV ) , the energy an electron acquires when experiencing a voltage difference of one volt. Visible photons are in the range between 1.8 eV and 2.5 eV. • LED intensity (photons per second) is a linear function of current (electrons per second). Why Use an LED? • Lamps burn out --- an LED may never burn out if used conservatively. • Small lamps may be too dim --- small LEDs can be painfully bright. • Lamps may use excessive current or get hot in an application --- LEDs and their resistors rarely generate much heat. Why Use an LED? • Lamps may have poor optics --- LEDs can have excellent optics. • Lamp color may not be pleasing --- LED colors are “pure”. • For a DC locomotive headlight, the lamp intensity varies a great deal with track voltage. LED intensity appears to vary far less. LED Colors and Voltage • LED color (wavelength, in nanometers ) is essentially monochromatic (one color). • The color and forward voltage are determined by the diode’s materials. • Generally the color is specified by a vague descriptive term and by a precise wavelength. Ex: “Deep Red” = 660 nm. • Forward voltage increases slightly with current due to internal resistance. LED Colors and Voltage • • • • • • • • Infrared: ~920 nm, 1.3 V Deep Red: ~660 nm, 1.7 V * Amber: ~590 nm, 2.0 V * Yellow-Green: ~565 nm, 2.2 V * Kelly Green: ~525 nm, 2.5 V Aqua Green: ~505 nm, 2.8 V Blue: ~470 nm, 3.0 V “White”: many wavelengths, 3.0 V * The colors most often encountered. LED Colors and Voltage • “White” LEDs generally use blue LEDs to excite a phosphor coating on the LED chip. • The phosphor mix is chosen to re-emit several photon colors when excited, resulting in light that appears to be “white”. • Excess blue tint is from insufficient absorption of blue photons by the phosphor. LED Colors and Voltage • Early “Bright White” LEDs had an undesirable blue tint. • “White” LEDs with a warm white color typically have a filter to absorb the excess blue photons and remove the blue tint. • Golden White LEDs have orange pigment mixed into the package’s epoxy lens to remove the excess blue tint. LED Packages • The package controls the optics. • The package’s “beam angle” is that angle from the axis at which the light intensity is half of the on-axis intensity. • Typical 3 mm (“T1”) and 5 mm (“T1-3/4”) LEDs have beam angles around 30 degrees --- well focused beams of light result. LED Packages • Typical surface mount LEDs emit light from all sides except the bottom, resulting in very large beam angles. • Consequently, since surface mount LEDs typically spread their photons over a much wider angle, the on-axis intensity is less than for the 3 mm and 5 mm packages when the total photon flux is the same. LED Packages • Surface mount LED packages may be industry standard sizes or special. • Typical “standard” sizes are the same as for surface mount capacitors and resistors: “402”, “603”, “805”, etc. • These sizes represent the bottom dimensions: 0.060” x 0.030” for “603”. Things to Remember about LEDs • An LED is a diode - that’s what the “D” is. • Thus, current normally only flows through an LED in one direction. • Generally LEDs cannot withstand very high reverse voltages. • “White” LEDs are particularly poor at withstanding reverse voltages. Things to Remember about LEDs • You don’t drive LEDs the same way you drive lamps. • Circuits meant to drive lamps are often not good for driving LEDs. • Generally you MUST limit an LED’s current with a resistor. • LEDs can be bright , needing little current. Things to Remember about LEDs • To drive an LED, sufficient voltage must be available, and then you must control the applied current. • (To drive a lamp, sufficient current must be available, and then you must control the applied voltage.) • An LED’s forward voltage is a function of its material, which determines its color. White LEDs in Locomotives • Limit the Current • Remember that the typical white LED voltage drop is about 3 V at low currents.. • Use Ohm’s Law to calculate resistance. • R = V(Res) / I, V(Res) = V(applied) - V(LED) • Example: If track voltage = 8.0 Volts and desired current = 3 mA, R = 5.0 V / .003 A = 1666 ohms. (Use 1500 or 1800 ohms.) White LEDs in Locomotives • When the current to a locomotive motor is briefly interrupted, the motor will create a very high inductive voltage spike. • This is NOT “Back EMF”. The inductive voltage is V = L dI/dt, proportional to the motor inductance (L) and the rate of change of the current (dI/dt). It can easily be 60-80 volts, generally very brief. A Digression: Understanding BACK-EMF • Back EMF: the generator voltage produced by a turning motor armature, regardless of whether voltage is externally applied. • Eg = kg w f = Back EMF = machine constant kg x rotational speed w x magnetic flux f. • The Back EMF OPPOSES the applied voltage and varies with ROTATIONAL SPEED ONLY ( kg and f are constant ). White LEDs in Locomotives • When the inductive voltage spike from a motor reverse biases an unprotected white LED, it is likely to destroy the white LED. • When the inductive voltage spike forward biases a white LED, the LED will emit a very brief and bright flash. • Example: Headlight in early Kato E8 running backwards will flash. White LEDs in Locomotives • Protect the LED from the motor !!! • Protection can be in the form of a decoder, a lighting circuit, or a diode/capacitor circuit. • That diode can be another LED (for example, the backup LED protecting the headlight and vice versa.) • If you can’t find two diodes in a DC locomotive, your white LED is doomed. White LEDs in Locomotives • DCC Decoders appear to have all the reverse voltage protection needed. They seem better at driving LEDs than lamps. • Locomotives delivered with white LEDs generally have all the protection needed IF NEITHER LED IS REMOVED. • Locomotives with separate LED boards (ex: Kato 77A) are probably not protected. White LEDs in Locomotives • To prevent the flashing, connect a small ceramic capacitor across the LED at the LED’s base. • Capacitors look like short circuits to high frequencies and pulses. • Ceramic capacitors rated at 3.3 microfarads and 6.3 volts work very well as anti-flash capacitors and are small enough to fit between the LED’s leads. White LEDs in Locomotives • Anti-flash capacitors tend to short out the LED voltage on Aristocraft / Crest systems, which apply 15 kHz pulses to the rails. • Adding a diode and capacitor in front of the current limiting resistor can store the Aristocraft’s pulse energy, and provide nearly constant intensity headlights at all non-zero throttle settings. Aristocraft Circuit C1 = Anti-Flash Capacitor D1 = Protective Diode R1 = Current Limiting Resistor C2 + D2 = Peak-Hold Circuit LEDs for Car Lighting • Using high-efficiency LEDs, currents can be VERY LOW (less than 1 mA per LED in N Scale, a few mA in HO Scale). • Multiple LEDs can distribute lighting. • Anti-flicker circuits using reasonable capacitors can back up low current LED lighting circuits. LEDs for Car Lighting • White LEDs are excellent for tail signs and markers with colored lenses (Ex: Tomar). • Colored LEDs emit pure colors and they can be very small. They are excellent for tail lights and marker lights. • Special effects like Mars Light tail lights can be achieved using LEDs with appropriate electronics. Mounting LEDs • Pick a shape to fit the application. • Can sometimes modify the lens of a 3 mm LED to fit the mounting hole. • Can sometimes mount a surface mount LED completely inside the mounting hole. • Can superglue a surface mount LED to the back surface of an MV lens after removing the backing from the lens. Mounting LEDs • Recommended wire for surface mount LEDs: Belden Type 8058 #36 “solderable” magnet wire (strip using hot solder). • Recommended adhesive and sealer: Pacer’s Formula 560 Canopy Glue --- cures clear and remains pliable. • Recommended paint for blocking unwanted light: Pactra Racing Finish BLACK.