* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

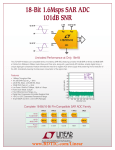

Download Design Techniques for Low-Voltage Analog-to-Digital

Negative feedback wikipedia , lookup

Ground loop (electricity) wikipedia , lookup

Three-phase electric power wikipedia , lookup

Electronic engineering wikipedia , lookup

Power inverter wikipedia , lookup

Flexible electronics wikipedia , lookup

Current source wikipedia , lookup

Electrical substation wikipedia , lookup

Signal-flow graph wikipedia , lookup

Alternating current wikipedia , lookup

Stray voltage wikipedia , lookup

Dynamic range compression wikipedia , lookup

Flip-flop (electronics) wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Voltage optimisation wikipedia , lookup

Time-to-digital converter wikipedia , lookup

Regenerative circuit wikipedia , lookup

Oscilloscope types wikipedia , lookup

Voltage regulator wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Power electronics wikipedia , lookup

Two-port network wikipedia , lookup

Mains electricity wikipedia , lookup

Power MOSFET wikipedia , lookup

Oscilloscope history wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Schmitt trigger wikipedia , lookup

Buck converter wikipedia , lookup

Integrating ADC wikipedia , lookup