* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download 56/57.12028 Testing of Grounding Systems

Telecommunications engineering wikipedia , lookup

Fault tolerance wikipedia , lookup

Aluminium-conductor steel-reinforced cable wikipedia , lookup

Mains electricity wikipedia , lookup

Skin effect wikipedia , lookup

Alternating current wikipedia , lookup

Single-wire earth return wikipedia , lookup

Ground loop (electricity) wikipedia , lookup

Electromagnetic compatibility wikipedia , lookup

Transmission tower wikipedia , lookup

Electrical wiring wikipedia , lookup

Portable appliance testing wikipedia , lookup

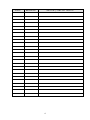

56/57.12028 Testing of Grounding Systems Continuity and resistance of grounding systems shall be tested immediately after installation, repair, modification, and annually thereafter. A record of the resistance measured during the most recent test shall be made available on a request by the Secretary or his duly-authorized representative. Tests are required of grounding systems to determine adequacy in preventing a shock hazard on electrical equipment under fault conditions. Grounding systems typically include the following: 1. Equipment grounding conductors – The conductors used to connect the metal frames or enclosures of electrical equipment to the grounding electrode conductor. 2. Grounding electrode conductors – The conductors connecting the grounding electrode to the equipment grounding conductor. 3. Grounding electrodes – Usually driven rods connected to each other by suitable means, buried metal, or other effective methods located at the source, to provide a low-resistance earth connection. Testing of equipment grounding conductors and grounding electrode conductors are not required if operators use a fail-safe ground wire monitor to continuously monitor the grounding circuit. The ground wire monitor shall cause the circuit protective devices to operate when the grounding conductor is broken. MSHA wants to make certain that in the event of a broken grounding conductor, the circuit protective devices operate, thus preventing a death or serious injury to a miner. OPERATORS MUST CONDUCT THE FOLLOWING TESTS 1. Equipment grounding conductors, and grounding electrode conductors – Continuity and resistance must be tested immediately after installation, repair, or modification, and annually if conductors are subjected to vibration, flexing, or corrosive environments. 2. Grounding electrodes – Resistance must be tested immediately after installation, repair, modification, and annually thereafter. Conductors in fixed installation, such as in rigid conduit, cable trays, raceways, etc., and not subjected to vibration, flexing, or corrosive environments may be tested annually by visual observation to check for damage in lieu of the annual resistance test after the original installation has been tested and approved. When operators opt to conduct this visual test, MSHA needs assurance that the test has been conducted and with the required frequency of the regulation. Therefore, MSHA will require that a record be maintained of the most recent annual visual test. Operators who fail to produce this record will be cited for violation of the regulation. Grounding conductors in trailing cables, power cables, and cords which supply power to tools and portable of mobile equipment must be tested under all frequencies prescribed in the regulation. This does not apply to double-insulated tools or circuits protected by GFCI’s. 1 CONTINUITY AND RESISTANCE TESTING 1. Use a volt-ohm meter and place the test leads as shown in the diagram below. Record the results. All equipment ground conductors should be less than one ohm to properly trip the breaker in the event of a ground fault. 2. Use a long test lead and zero the meter with the long lead attached. Place the test lead between the ground rod/plate and each starter/switch box. Record the results. The test lead on the ground rod/plate may be moved forward as shown to a point already tested and found to be good. Each reading taken from this new point must be added to the value recorded between the ground rod/plate and this point. 3. Place the test lead on each motor, on each starter/switch box, on each push button console, and record the results. SWITCHGEAR, MCC OR CONTROL TRAILER TRANSFORMER OR GENERATOR ● ● GROUNDING ELECTRODE CONDUCTOR □ □ □□ MOTORS ○ ○ □ □ □□ ○CRUSHERS ● ● TEST LEAD GROUND ROD (ELECTRODE) GRID ○ ○SCREENS VOLT OHM METER / POWER CABLES W GROUNDING CONDUCTORS TO ALL MOTORS 2 ○ PUMPS ○ CONVEYORS EARTH RESISTANCE TESTING Caution: Do not conduct this test if your power source is line power and your grounding system is connected to the power company grounding. Never disconnect your grounding from the power company grounding system; this must only be done by the power company personnel. 1. Shut down and lock out the electrical power supply, disconnect the electrode conductor from the ground rod or plate. 2. Drive test rods 1 and 2 securely into the earth 20 and 40 feet from the ground rod/plate. The test rods should be about 20” x 3/8”. (Refer to diagram below) 3. Use a 12-volt auto battery as the power source. Wearing dry leather gloves, connect a wire from the positive (+) terminal to the ground rod/plate. Connect a wire from the negative (-) terminal to one of the test leads of the D.C.Ammeter (unless a hook-on type meter), connect the other ammeter lead to test rod 2. 4. Record the ammeter value (milliamp values are not uncommon, so don’t be discouraged). Use a reliable voltmeter, set on a D.C. scale, test for the voltage drop between the ground rod/plate and test rod 1. Record the voltage measurement. 5. Disconnect all leads and meters, reconnect the grounding electrode conductor to the ground rod/plate. Test the connection for continuity with an ohm meter, and record the value. Pull up the test rods and save them for future use. 6. Using ohm’s law: R=E/I, solve for the resistance of the ground rod/plate in the earth (resistance=volts/amps). Write down the reading, date of test, and the continuity value of the grounding electrode conductor. Keep this record for review by MSHA. GenSet 12V Battery (shut down for test) ~ A Grounding Electrode Conductor (disconnect from electrode) V 20 ft 20 ft Ground Rod or Plate (24” x 24” x ¼”) Rod 1 V = D.C. Voltmeter A = D.C. Ammeter 3 Rod 2 DATE READING MOTOR / CIRCUIT TESTED 4