* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

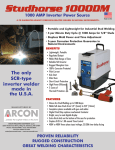

Download GMAW Power Sources

Power factor wikipedia , lookup

Electrical ballast wikipedia , lookup

Spark-gap transmitter wikipedia , lookup

Power over Ethernet wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Electrical substation wikipedia , lookup

Electric power system wikipedia , lookup

Audio power wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Mercury-arc valve wikipedia , lookup

Three-phase electric power wikipedia , lookup

Electrification wikipedia , lookup

Current source wikipedia , lookup

Power inverter wikipedia , lookup

Distribution management system wikipedia , lookup

Power engineering wikipedia , lookup

Amtrak's 25 Hz traction power system wikipedia , lookup

Surge protector wikipedia , lookup

Stray voltage wikipedia , lookup

Voltage regulator wikipedia , lookup

Power MOSFET wikipedia , lookup

History of electric power transmission wikipedia , lookup

Buck converter wikipedia , lookup

Opto-isolator wikipedia , lookup

Voltage optimisation wikipedia , lookup

Power electronics wikipedia , lookup

Alternating current wikipedia , lookup

Rational In order to have any electric arc welding process at a high level, the operator should have a base understanding of the type of power source that is being used to drive the welding process. Power Source Output All power sources used to perform the GMAW and FCAW process are of the Constant Voltage or Constant Potential output type. Simply stated, constant voltage output sources are designed to deliver a set amount of delivered voltage during the welding process in an effort to maintain the welding arc. Although all constant voltage output welding power sources are capable of delivering large surges of welding current (amperage), the output voltage remains constant. Given their design, constant voltage power sources used to perform the GMAW process are often referred to as having a “self regulating” welding arc. In order to maintain this self regulating arc, the following five items are necessary: The proper voltage setting for a given type and size electrode. Current going through the electrode (a good ground). Appropriate wire feed speed to continuously replace melted electrode wire. A proportional burn-off rate. Welding action proportional to the welding (arc) voltage. Power Source Types There are three basic types of welding power sources used to provide constant current voltage welding output. Transformer-rectifiers This type of welding power source uses a transformer to step down the AC line power voltage to AC welding voltage and utilizes a rectifier to change the output current from AC to DC. Inverters This type of welding source converts the incoming AC power line from 60 hertz to 50 kilohertz. The AC welding power is then supplied to a transformer/rectifier unit to create welding output power. Engine Driven Generator This type of welding power source uses a internal combustion engine to drive a generator which creates DC welding power.