* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Integrated Circuits

Resistive opto-isolator wikipedia , lookup

Fault tolerance wikipedia , lookup

Microprocessor wikipedia , lookup

Mathematics of radio engineering wikipedia , lookup

Electronic musical instrument wikipedia , lookup

Printed circuit board wikipedia , lookup

Opto-isolator wikipedia , lookup

ETU 07210

LECTURE

ONE

Lecture_1

Linear ICs applications Lab

1

Coverage

Integrated circuits (ICs)

•

•

•

•

•

Introduction

Advantages and disadvantages of ICs

Scale of integration

Classification of Ics

ICs fabrication

references

• Electrical Technology Volume IV - Electronic Devices and

Circuits - B.L.Theraja. (Pg. 2472-2500)

• Electronic Devices and Circuit Theory, 6th Edition – Robert

L. Boylestad. (Pg. 588-608)

Lecture_1

Linear ICs applications Lab

2

Integrated Circuits

Introduction

•

•

•

•

Lecture_1

Electronic circuitry has undergone tremendous changes

since the invention of a triode in 1907.

With the invention of the transistor in 1948, the

electronic circuits became considerably reduced in size.

Development of printed circuit boards (PCBs) further

reduced the size of electronic equipment by eliminating

bulky wiring and tie points.

In the early 1960s, a new field of microelectronics was

born with the aim of reducing the size, weight, and

power of military electronic systems because of the

increase use of these systems.

Linear ICs applications Lab

3

Integrated Circuits Continue…

•

•

•

Microelectronics is that area of technology associated

with and applied to the realization of electronic systems

made of extremely small electronic parts or elements

The extreme reduction in the size of electronic circuits

has led to the development of microelectronic circuits

called integrated circuits (ICs)

An IC is a complete electronic circuit in which both the

active and passive components are fabricated on a tiny

single chip of silicon.

Advantages of ICs

•

Lecture_1

Extremely small physical size: Thousands of times

smaller than a discrete circuit.

Linear ICs applications Lab

4

Integrated Circuits Continue…

•

•

•

•

•

•

Lecture_1

Very small weight: Many circuit functions can be packed

into a small space.

Reduced cost: Many identical circuit can be built

simultaneously on a single wafer (Batch fabrication).

Extremely high reliability: ICs works for longer periods

without giving any trouble.

Increased response time and speed: The time delay of

signals is reduced.

Low power consumption: ICs are more suitable for low

power operation.

Easy replacement: It is more economical to replace an IC

than to repair it.

Linear ICs applications Lab

5

Integrated Circuits Continue…

ICs Drawbacks

•

•

•

•

Coils or inductors cannot be fabricated.

ICs function at fairly low voltages.

They handle only limited amount of power.

They are quite delicate and cannot withstand rough

handling or excessive heat.

Scale of integration

•

•

•

•

•

•

Lecture_1

Small scale integration (SSI). < 12

Medium scale integration (MSI). 12 – 99

Large scale integration (LSI). 100 – 9,999

Very large scale integration (VLSI). 10,000 – 99,999

Ultra large scale integration (ULSI). 100,000 – 999,999

Giga scale integration (GSI). 1,000,000

Linear ICs applications Lab

6

Integrated Circuits Continue…

Classification of ICs by structure

• Monolithic ICs: Both active and passive components are

fabricated inseparably within a semiconductor substrate.

• Film ICs (Thin film and Thick film): Film components are

made of either conductive or nonconductive material that

is deposited in desired patterns on a ceramic or glass

substrate.

Film can only be used as passive circuit components,

such as resistors and capacitors.

Transistors and/or diodes are added externally as

discrete components to the substrate to complete the

circuit.

Lecture_1

Linear ICs applications Lab

7

Integrated Circuits Continue…

• Hybrid ICs: Combine two or more integrated circuit types

or combine one or more integrated circuit types and

discrete components.

Comparison between different ICs

• Each type of IC has its own advantages and disadvantages.

Advantages of monolithic Ics

- Lowest cost and highest reliability

Disadvantages of monolithic ICs

- Isolation between components is poorer,

- Range of values of passive components used in the

circuits is comparatively small,

Lecture_1

Linear ICs applications Lab

8

Integrated Circuits Continue…

- Inductors cannot be fabricated, and

- They afford no flexibility in circuit design.

Advantages of film ICs

- The passive components with broader range of

values ca be formed,

- The isolation between their components is better,

- Greater flexibility in circuit design due to the use of

external discrete active components.

Disadvantages of film ICs

- Not being able to fabricate active components,

- Comparatively higher cost, and

- Larger physical size.

Lecture_1

Linear ICs applications Lab

9

Integrated Circuits Continue…

Classification of ICs by function

• Linear integrated circuits (LICs)

LICs are also referred to as analog ICs.

Their inputs and outputs takes on a continuous range

of values and the outputs are generally proportional to

the inputs.

As compared to digital ICs, LICs are used much less.

They are frequently used in

- Operational amplifiers,

- Small-signal amplifiers,

- Power amplifiers,

- RF and IF amplifiers,

Lecture_1

Linear ICs applications Lab

10

Integrated Circuits Continue…

- Microwave amplifiers,

- Multipliers,

- Voltage comparators,

- Voltage regulators etc.

Manufacturer’s designation of LICs

- LICs with the same specifications but different code

and type number can be produced by different

manufacturers.

- For example, consider the op-amp 741 with the

following codes:

National Semiconductor — LM 741

Motorola — MC 1741

Lecture_1

Linear ICs applications Lab

11

Integrated Circuits Continue…

RCA — CA 3741

Texas Instruments — SN 5274

LICs classes

- Many LICs are available in different classes such as

A, B, C, E, S, and SC.

- For example, main classes of op-amp 741 are:

741— Military grade op-amp

741 C — Commercial grade op-amp

741 A — Improved version of 741

741 E — Improved version of 741 C

741 S — Military grade op-amp with higher slew

rate

Lecture_1

Linear ICs applications Lab

12

Integrated Circuits Continue…

741 SE — Commercial grade op-amp with higher

slew rate

• Digital integrated circuits (DICs)

DICs dominate the IC market and they are mostly

utilized by computer industry.

DICs are of the monolithic integration type due to the

fact that a computer uses a larger number of identical

circuits.

DICs contain circuits whose input and output voltages

are limited to two possible levels— low or high.

It is so because digital signals are usually binary.

Sometimes, digital circuits are referred to as switching

circuits.

Lecture_1

Linear ICs applications Lab

13

Integrated Circuits Continue…

DICs include circuits such as:

- Logic gates

- Flip-flops

- Counters

- Clock-chips

- Calculator chips

- Memory chips

- Microprocessors (µP) etc.

Reading assignment: Go through page 2478 (Electrical

Technology Volume IV - Electronic Devices and Circuits - B.L.Theraja)

and read what has been covered under “IC

terminology” heading.

Lecture_1

Linear ICs applications Lab

14

Integrated Circuits Continue…

How ICs are made?

• The ICs are manufactured in four distinct stages. These are:

Material preparation,

Crystal growing and wafer preparation,

Wafer fabrication, and

Testing, bonding and packaging.

• Material preparation

Silicon, as an element is not found in nature.

It is found abundantly in nature in the form of silicon

dioxide, which constitutes about 20% of earth’s crust.

Silicon is commonly found as quartz or sand.

Lecture_1

Linear ICs applications Lab

15

Integrated Circuits Continue…

A number of processes are required to convert sand

into pure silicon with a polycrystalline structure.

Figure 1.1 shows the different processes involved in the

preparation of polycrystalline silicon from sand.

- As seen from this figure, the sand is allowed to

react with a gas produced from the burning of

carbon.

- This produces silicon with 98% purity.

- Next silicon is further purified in a reactor to

produce electronic-grade polycrystalline silicon.

Lecture_1

Linear ICs applications Lab

16

Integrated Circuits Continue…

Fig. 1.1

Lecture_1

Linear ICs applications Lab

17

Integrated Circuits Continue…

• Crystal growing and wafer preparation

• Crystal growth

There are two methods to carryout the crystal growth:

- The Czochralski and

- The flat zone process.

The Czochralski process prepares virtually all the silicon

used for IC fabrication.

The flat zone process is used to prepare crystals for

fabricating high-power, high voltage semiconductor

devices.

The Czochralski process

- The equipment used for single crystal growth

(called puller) is as shown in Figure 1.2.

Lecture_1

Linear ICs applications Lab

18

Integrated Circuits Continue…

- The puller has three main components:

A furnace which includes quartz crucible, a

rotation mechanism (clockwise as shown), and a

radio frequency (RF) heating element,

A crystal pulling mechanism which includes a

seed holder and a rotation mechanism

(counterclockwise), and

An ambient control which includes an argon gas

source, a flow control and an exhaust system.

- In addition the puller has a computer system to

control process parameters such as temperature,

crystal diameter, pull rate and rotation speed.

- To grow crystals, the polycrystalline silicon is placed

in the crucible.

Lecture_1

Linear ICs applications Lab

19

Integrated Circuits Continue…

- The furnace is heated to a temperature of 1690 K

which is slightly greater than the melting point

(1685 K) of silicon.

- A precisely controlled amount of dopant is added to

the melt to make the silicon as P-type or N-type.

- A suitable oriented seed crystal is suspended over

the crucible in a seed holder.

- The seed is inserted into the melt and a small

portion of it is allowed to melt.

- The seed is rotated and pulled up very slowly, while

at the same time, the crucible is rotated in the

opposite direction.

Lecture_1

Linear ICs applications Lab

20

Lecture_1

Linear ICs applications Lab

21

Integrated Circuits Continue…

- The molten silicon attaches itself to the seed and it

becomes identical to the seed in structure and

orientation.

- As the seed is pulled up, the material that is

attached to the seed solidifies

- Its crystal structure becomes the same as that of

the seed and a larger crystal is formed.

- Thus using this method, cylindrical single crystal

bars (called ingots) of silicon are produced.

- The desired diameter of the silicon ingot is obtained

by controlling both the temperature and the pulling

speed.

- The resulting ingot is cooled and is removed to be

made into thin discs called wafers.

Lecture_1

Linear ICs applications Lab

22

Integrated Circuits Continue…

- The ingots have diameters as large as 200 mm with

the latest ones approaching 300 mm.

- The ingot length is of the order of 1000 mm.

• Wafer preparation

In this stage the ingot surface is grounded throughout

to an exact diameter and the top and bottom portions

are cut off.

After that one or more flat regions are ground along

the length of the ingot.

These flat regions mark the specific crystal orientation

of the ingot and conductivity type silicon material.

Refer to Figure 1.3.

Lecture_1

Linear ICs applications Lab

23

Integrated Circuits Continue…

Notice that the ingot is marked with two flats regions :

- the larger flat (called primary flat) and

- the smaller flat or secondary flat regions.

The primary flat allows a mechanical locator in

automatic processing equipment to position the wafer

and to orient the devices relative to the crystal in a

specific manner.

The secondary flat regions are used to identify the

orientation and conductivity type of the crystal.

The conductivity of the wafer could be either P-type or

N-type and the crystal orientation, {100} or {111}.

Lecture_1

Linear ICs applications Lab

24

Lecture_1

Linear ICs applications Lab

25

Integrated Circuits Continue…

The semiconductor industry uses {111} wafers for

fabricating ICs with bipolar transistor technology and

{100} wafers for MOS circuits.

Once the orientations are done, the ingot is sliced into

wafers by a high-speed diamond saw.

The wafer thickness varies from 0.4 to 1.0 mm.

After slicing, the next step is to polish the wafer

surface.

Finally the wafers are cleaned and dried for use in

fabrication of ICs.

Lecture_1

Linear ICs applications Lab

26

Integrated Circuits Continue…

• Wafer fabrication

Category of the processes that are used in the

fabrication of ICs:

- Oxidation

- Etching

- Diffusion

- Ion implantation

- Photolithography

- Epitaxy

- Metallization and interconnections.

Lecture_1

Linear ICs applications Lab

27

Integrated Circuits Continue…

• Oxidation

It consists of growing a thin film of silicon dioxide (SiO2)

on the surface of a silicon wafer.

Silicon dioxide has several uses:

- To serve as a mask against implant or diffusion of

dopant into silicon,

- To provide surface passivation,

- To isolate one device from another, and

- To act as a component in MOS structures.

Techniques for forming oxide layers on silicon wafer:

- Thermal oxidation,

Lecture_1

Linear ICs applications Lab

28

Integrated Circuits Continue…

- Vapour phase technique [chemical vapour

deposition (CVD)], and

- Plasma oxidation.

However, thermal oxidation is the more commonly

used technique in IC processing.

Figure 1.4 shows a thermal oxidation system.

- The silicon wafers are placed vertically into a quartz

boat in a quartz tube.

- The quartz boat is slowly passed through a furnace,

in the presence of oxygen, operating at 10000C.

- The oxidizing agent may dry oxygen or a mixture of

water vapour and oxygen.

Lecture_1

Linear ICs applications Lab

29

Integrated Circuits Continue…

- A computer controls the whole operation in the

thermal oxidation system.

- The operation include regulating the gas flow

sequence, automatic insertion and removal of

wafers and the furnace temperature.

Lecture_1

Linear ICs applications Lab

30

Integrated Circuits Continue…

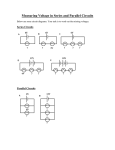

• Etching

Etching is the process of selective removal of regions of

a semiconductor, metal or silicon dioxide.

There are two types of etching :

- Wet etching; the wafers are immersed in a chemical

solution at a predetermined temperature.

- Dry (or plasma) etching; the wafers are immersed in

gaseous plasma created by a radio-frequency

electric field applied to a gas such as argon.

• Diffusion

The process of introducing impurities into selected

regions of a wafer to form junctions.

Lecture_1

Linear ICs applications Lab

31

Integrated Circuits Continue…

It occurs in two steps : the pre-deposition and the

drive-in diffusion.

Pre-deposition tends to produce, a shallow but heavily

doped layer, near the silicon surface.

Drive-in is used to drive the impurity atoms deeper into

the surface, without adding any more impurities.

Figure 1.5 shows the graph of doping profiles, during

the pre-deposition and the drive-in steps of diffusion.

The doping profiles indicate that the impurity

concentration decreases monotonically from the

surface of the substrate.

The profiles of the dopant distribution is determined

mainly by the temperature and diffusion time.

Lecture_1

Linear ICs applications Lab

32

Integrated Circuits Continue…

Common dopants are boron for P-type layers and

phosphorus, antimony and arsenic for N-type layers.

Diffusion is rarely performed using pure elements

themselves, instead compounds of elements are used.

Lecture_1

Linear ICs applications Lab

33

Integrated Circuits Continue…

Lecture_1

Linear ICs applications Lab

34

Integrated Circuits Continue…

Figure 1.6. shows the equipment used in diffusion.

The wafers are placed in a quartz boat within a quartz

furnace tube.

The furnace is heated by resistance heaters

surrounding it.

To introduce an impurity, phosphorus for example,

phosphorus oxychloride (POCl) is placed in a container

at a temperature that maintains its liquid form.

The proper vapour pressure is maintained by a control

of the temperature.

Nitrogen and oxygen gas are made to pass over the

container.

Lecture_1

Linear ICs applications Lab

35

Integrated Circuits Continue…

These gases react with the silicon, forming a layer on

the surface of the wafer that contains silicon, oxygen

and phosphorus.

At the high temperature of the furnace, phosphorus

easily diffuses into the silicon.

In order that the dopant may be diffused deeper into

silicon, the drive-in step follows.

This is done at a higher temperature of about 11000C

inside a furnace similar to that used for pre-deposition,

except that no dopant is introduced into the furnace.

The higher temperature, causes the dopant atoms to

move into silicon more quickly.

Lecture_1

Linear ICs applications Lab

36

Integrated Circuits Continue…

Diffusion depth is controlled by the time and

temperature of the drive-in process.

Figure 1.7 shows the diffusion of dopant into silicon.

Lecture_1

Linear ICs applications Lab

37

Integrated Circuits Continue…

• Ion implantation

This is a process of introducing dopants into selected

areas of the surface of the wafer by bombarding the

surface with high-energy ions of the particular dopant.

• Photolithography

It is a process in which the geometrical pattern on the

glass plate is transferred to the surface of the wafer.

This is done to open identical windows so that the

diffusion process may take place in all identical regions

of the same IC and for all ICs on the wafer.

As an illustration we assume that the first reticle is used

over an oxidized surface as shown in Figure 1.8 (a).

Lecture_1

Linear ICs applications Lab

38

Integrated Circuits Continue…

Lecture_1

Linear ICs applications Lab

39

Integrated Circuits Continue…

Lecture_1

Linear ICs applications Lab

40

Integrated Circuits Continue…

Steps taken in photolithographic process:

- To create a thin layer of silicon dioxide (SiO2)on the

surface of a silicon wafer, fig. 1.8 (a).

- To deposit a coating of photoresist (PR) material on

top of the SiO2 layer, fig. 1.8 (b).

- The PR coating is exposed to ultraviolet (UV) light

through a glass mask, fig. 1.8 (c).

- The exposed PR material is chemically removed, fig.

1.8 (d).

- The exposed SiO2 is then etched away using

hydrofluoric acid, fig. 1.8 (e).

Lecture_1

Linear ICs applications Lab

41

Integrated Circuits Continue…

- Unexposed PR material is removed and the

structure is ready for the impurity diffusion step,

fig. 1.8 (f).

Two types of PR material:

- Positive PR. Allows the windows to be opened

wherever the UV light passes through the

transparent parts of the mask.

- Negative PR. Allows the windows to be open under

the opaque parts of the mask while the exposed PR

remains on the surface.

Lecture_1

Linear ICs applications Lab

42

Integrated Circuits Continue…

• Epitaxy

Epitaxy or Epitaxial growth is the process involves

depositing a very thin layer of silicon to form a

uniformly doped crystalline region (epitaxial layer) on

the substrate.

Components are produced by diffusing appropriate

materials into the epitaxial layer in the same way as the

diffusion method.

In the processes of diffusion and ion implantation, a

dopant is driven into a substrate of doped silicon.

In epitaxy, a layer of doped silicon is deposited on top

of the surface of the substrate.

Lecture_1

Linear ICs applications Lab

43

Integrated Circuits Continue…

• Metallization and interconnections

The provision of metallic interconnections for the IC

and for external connections to the IC.

The interconnections must

- Have low resistance to minimize both the voltage

drops on the lines as well as the capacitances

between the lines so as to reduce delay times.

- Make ohmic contacts to semiconductors in the

devices such as P and N regions of a PN junction

diode.

- NB: An ohmic contact is one that exhibits a very low

resistance, allowing currents to pass easily in both

directions through the contact.

Lecture_1

Linear ICs applications Lab

44

Integrated Circuits Continue…

The most used metal for interconnections process is

aluminium due to the following reasons:

- High conductivity

- Easy to evaporate

- Can be easily etched

- Not expensive

- Adheres well to silicon dioxide.

Three important processes for depositing aluminium on

silicon substrate:

- Resistance heating,

- Electron beam heating, and

- Sputtering.

Lecture_1

Linear ICs applications Lab

45

Integrated Circuits Continue…

• Testing, bonding and packaging

Testing

- Each chip on a wafer is tested before the individual

chips are cut from the wafer.

- Multiple test probes are touched to the metal pads

and the chip is tested to verify circuit performance.

- After all the circuits are tested, the wafer is

removed from the testing machine, sawed between

the circuits, and broken apart.

- Then each die that passed the test is picked up and

placed in the package.

Lecture_1

Linear ICs applications Lab

46

Integrated Circuits Continue…

Bonding

- It means permanent attachment.

- It consists of two steps.

Die bonding. The metallurgical process by

which the die (chip) is rigidly attached to its

substrate or base.

Wire bonding. The permanent attachment of

wire leads between the pads on the chip and

terminal posts as shown in figure 1.9.

Lecture_1

Linear ICs applications Lab

47

Integrated Circuits Continue…

Lecture_1

Linear ICs applications Lab

48

Integrated Circuits Continue…

Packaging

- Packaging is the process of protecting the surface of

device (die) from environment of its intended

application.

- Packaging can be broadly classified into the

following two categories:

- Through-hole mount that involve inserting the

package pins through holes on the printed circuit

board (PCB) before soldering [Figure 1.10]

- Surface mount type where the leads do not pass

through holes in the PCB [Figure 1.11].

Lecture_1

Linear ICs applications Lab

49

Lecture_1

Linear ICs applications Lab

50

THE END

OF

LECTURE

ONE

Lecture_1

Linear ICs applications Lab

51