* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download 4. Electrical Work General

Electric machine wikipedia , lookup

Alternating current wikipedia , lookup

Electrical substation wikipedia , lookup

History of electric power transmission wikipedia , lookup

Mechanical filter wikipedia , lookup

Voltage optimisation wikipedia , lookup

Power engineering wikipedia , lookup

Electrification wikipedia , lookup

Electrical connector wikipedia , lookup

History of electromagnetic theory wikipedia , lookup

Anastasios Venetsanopoulos wikipedia , lookup

Earthing system wikipedia , lookup

Telecommunications engineering wikipedia , lookup

Electronic engineering wikipedia , lookup

Mechanical-electrical analogies wikipedia , lookup

Electromagnetic compatibility wikipedia , lookup

Stray voltage wikipedia , lookup

Ground (electricity) wikipedia , lookup

Mains electricity wikipedia , lookup

National Electrical Code wikipedia , lookup

Electrical engineering wikipedia , lookup

Electrical wiring wikipedia , lookup

Electrical wiring in the United Kingdom wikipedia , lookup

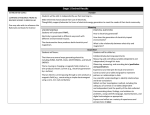

Port Macquarie – Hastings Council Electrical Work Draft - June 2006 Contents Page 1. Introduction 3 2. Definitions 3 3. Responsibilities 3,4 4. Electrical Work General 5. “Test Before Touch” Policy 6. Emergency Situations and Live Work 7. Equipment Inspection & Testing 8. Electrical Hazards for Plumbers 9. Asbestos Meter Boards 10. Thermal Imaging 11. Tiger Tails on Powerlines 12. Static Electricity 13. Electrical Equipment in Hazardous Zones 4 5 5 5 5,6 6 7 7 7 8 14. Contractors 8 15. Policy Links 8 16. Audit Records 8 17. Further Reading 9,10 2 1. Introduction Council is responsible for ensuring all electrical installation and equipment is safe to use, and where required regularly inspected, tested and maintained in accordance with relevant legislation. Electricity has great potential to seriously injure or kill. Unfortunately there are not many people who are alive today that have had a second chance when coming in contact with a significant volt of electricity. It is a significant “sight unseen” hazard that needs to be controlled when working in the vicinity of any ‘live’ wires or associated infrastructure. There is extensive legislation and industry codes of practice, guidelines and Australian Standards covering electricity work. For more information refer to the ‘Further Reading’ heading at the end of this document or contact Council’s Safety Coordinator or Specialist Trade-Electrical Services Coordinator. 2. Definitions Electrocution – Mainly results from a ‘live’ appliance or wire being touched causing the current to flow through the body to earth. The body forms an unwilling part of an electrical circuit. The seriousness of an electrical shock is directly related to the length of time of ‘live’ contact, ‘current’ path taken through the body and voltage level (high or low). Hostile Operating Environment – a place of work where electrical equipment or flexible supply cord is in its normal use, subject to conditions that are likely to result in damage to the equipment. E.g. exposure to moisture, heat, corrosive substances, dust etc. Thermal Imaging – literally taking a ‘heat photograph’ of an object with a specialised thermal imaging camera. ELV (Extra Low Voltage) - not exceeding 50 volts a.c. or 120 volts ripple free d.c. Council: Is any Port Macquarie - Hastings Council employee with authority to act or supervise. Elected Councillors are not included in this category. 3. Responsibilities 3.1 Managers Ensure that any electrical installation / use of electrical wiring, portable tools and extension leads comply with the requirements of the relevant legislation. E.g. Code of Practice – Electrical Practices for Construction Work. AS 3000 Wiring Rules. 3 3.2 Supervisors Ensure any electrical work performed by Council employees or contractors, that the person performing the task is a qualified Licensed Electrician. Trainees or apprentices must be appropriately trained and supervised at all times. Specifically, site Supervisors shall ensure: Electrical equipment without a current test tag will not be used. Ensure that all electrical equipment brought on to Council work sites by Contractors, has current and valid tag. Electrical equipment used on site should be connected through an RCD (Residual Current Device) at all times. Where practicable, all electrical leads will be kept off the ground on insulated hangers or on insulated lead stands. One extension lead preferably spanning the full distance to the power source without numerous leads being joined together. All plugs and sockets should be transparent or non-rewireable (molded) where there is risk of interference by unqualified persons. Electrical equipment is not placed on or near wet areas unless the equipment is designed for the specific purpose (e.g. pump) 3.3 Employees Must ensure that the Specialist Trade-Electrical Services Section or the Building Services Section of Council (depending on who controls the asset), is contacted to carry out any electrical works by a Licensed Electrical Tradesmen, when installing, repairing or maintaining any electrical items. Must report damaged electrical tools / equipment or installations as soon as possible to relevant supervisors and “tag out” the hazard immediately to avoid inadvertent use by others. 4. Electrical Work General Council staff must ensure that all premises controlled by Council where electrical installation is required, that it is safe for use. Specifically, a safe system of work must be followed when working on or testing electrical installations and equipment, which includes risk assessment, elimination & control of the risk, Safe Work Method Statements (SWMS), appropriate testing equipment and PPE supplied and used. The main guidance documents to be referred to for electrical work are, the Code of Practice – Electrical Practices for Construction Work and AS 3000 Wiring Rules. 4 5. “Test Before Touch” Policy Electrical workers must prove circuits are de-energised before working with electrical infrastructure, by using a fit for purpose multi meter and / or non-contact voltage detecting device. New, modified or repaired installations must follow strict commissioning or re-commissioning tests to ensure optimal operating safety and compliance. 6. Emergency Situations and Live Work Clause 207 of the OH&S Regulation requires that no electrical work can be carried out while that part of the electrical installation’s circuits and apparatus are energised. Generally, live electrical work cannot be justified as being as safe as working deenergised. The only variation to this requirement is where there is an emergency situation and the risk of harm would be greater if the circuits and electrical apparatus are de-energised before the electrical work commenced. In this situation work can proceed, but only in accordance with a safe system of work that encompasses a list of mandatory safety measures. Refer to Council’s Specialist Trade-Electrical Services Section for more information. 7. Equipment Inspection & Testing Council must ensure that all electrical installations, electrical appliances and associated equipment is inspected, tested and maintained or replaced if unsafe. Appropriate testing, maintenance and inspection records must be kept and produced if requested. Council currently conducts a regular inspection and testing program for electrical equipment (rescue kits / PPE, instrument calibration). It is done in conjunction with various Australian Standards and industry guidelines E.g. Electricity Association of NSW – Guide to Electrical Workers Safety Equipment. For testing requirements regarding electrical appliances / tools etc, refer to Council’s Electrical Appliance Testing Procedure No.15. Any ladder used when working with or near electricity should be non-conducting, preferably reinforced plastics / fibreglass, NOT aluminium or any metal. 8. Electrical Hazards for Plumbers Plumbers and associated workers can obtain a serious or fatal electric shock when removing water meters, cutting through or disconnecting metallic water pipes on residential or commercial premises. Prior to 1976 the water system was used as the main earthing circuit. Property service (main-to-meter) is generally maintained by Council and can be hazardous as well. 5 The main contributing factor in these types of incidents is that a fault with the electrical supply in the area (on the premises or in the street) has occurred causing the metallic piping used to connect the water supply to become part of the electrical circuit. When the pipe is cut or disconnected, either side of the pipe could become “240 volt live” causing workers to receive a serious or fatal electric shock. Prior to the removal of water meters, or the repair/replacement of metallic water piping at premises, Supervisors should refer to Clause 5.2, Electrical safety precautions and earthing outlined in the AS/NZS 3500.1 Plumbing and Drainage Part 1: Water Services. Before commencing work discuss with the customer the operational condition of the electrical installation, if any electrical fault is suspected, e.g. minor electric shocks from pipes, taps, etc. Do not commence work on the water service. Immediately notify the customer and Specialist Trade-Electrical Services Section or the local electricity network operator of any suspected electrical fault. 9. Asbestos Meter Boards Lebah, Zelemite & Ausbestos are trade names of panels manufactured from an asbestos / resin composite and used in electrical applications (they contain white asbestos). Council has a specialised equipment list / kit of equipment which will only be used on asbestos electrical mounting board maintenance or removal. The kit will be used & maintained by Council’s Specialist Trade-Electrical Services Section. All identified meter boards containing asbestos must be labeled with a specially purchased “asbestos caution sticker” (sample following), which indicates the board contains asbestos to anyone that may work on the board’s electrical components. Reference guide - NSW Electrical Industry Asbestos Awareness Committee (EIAAC) – Minor works on asbestos based electrical mounting boards for domestic and commercial metering / electrical installations. See also Council’s Asbestos Procedure No.13. 6 10. Thermal Imaging Thermal imaging photos are accurate to one tenth of a degree, and will show if any components such as electrical switches or connections are running ‘extremely hot’. If these components were to fail, they could result in major plant shutdowns or electrical fire. Country Energy can supply a thermal imaging service. 11. Tiger Tails on Powerlines Tiger tails may be used to provide a useful visual indication to people working in the area of overhead electrical power lines. They do not provide adequate protection against mechanical interference or provide electrical protection from electrical hazards. The preferred option when work is carried out in close proximity to power lines is to have the power lines de-energised or re-directed away from the work area. Whenever there is a risk of workers being exposed to electrical hazards from power lines, Supervisors must consult with the local electricity network operator to determine the appropriate safeguards. 12. Static Electricity Static electricity is the imbalance of positive and negative charges. It is called “static” because there is no current flowing as in AC or DC electricity. Hazards of Static Electricity The main hazard of static electricity is the creation of sparks in an explosive or flammable atmosphere. These sparks can set off an explosion or fire. The danger is greatest when flammable liquids are being poured or transferred. For static electricity to be a hazard, four conditions must be met: 1. There must be a means for a static charge to develop. 2. Enough energy must build up to cause ignition. 3. There must be a discharge of this energy (a spark). 4. The spark must occur in an ignitable vapour or dust mixture. Control of Static Electricity Most static electricity control measures provide ways for the static charges to dissipate harmlessly before sparks occur. Some ways to prevent static charges from accumulating on materials are: Bonding and grounding Humidification Static collectors Additives Contact Council’s Specialist Trade-Electrical Services Section and refer to AS 1020 The Control of Undesirable Static Electricity for more information. 7 13. Electrical Equipment in Hazardous Zones Controlling Ignition Sources The ignition risks of electrical equipment located within a hazardous area can be controlled by providing wiring, switching and equipment protection suitable for use in the particular hazardous zone. Guidance on electrical protection systems is provided in AS 1482, AS 1826, AS 2431 Electrical equipment for explosive atmospheres, and Council’s Specialist Trade-Electrical Services Section must also be consulted when proposing new electrical installations. 14. Contractors All Contractors engaged on Council work sites shall be responsible for ensuring that Electrical safety is a priority and comply as per regulations and relevant Australian Standard requirements and at their own expense. Council’s electrical contractors work under the direct administrative supervision of the Specialist Trade Services Section, and must comply with all PMHC’s OH&S, site security and safe work procedures / requirements as detailed in their contracts. Failure by contractors to provide approved Electrical Work safety systems in accordance with Council requirements shall be deemed as non-compliance, and dealt with by the appropriate Contract Manager within Council. 15. Policy Links Pre Purchase Assessment No.11 Asbestos No.13 Electrical Appliance Testing No.15 Confined Spaces No.16 Working at Heights No.17 Personal Protective Equipment & Clothing No.18 Construction Work No.21 Manual Handling No.22 Plant & Equipment No.24 Hot Work No.26 Certification & Licensing of Workers No. 28 Managing Contractors OH&S Risks No.29 Isolation & Out of Service Tagging Policy 16. Audit Records Risk Assessment Forms completed. Appropriate PPE on site and being worn by employees. Test results for High Voltage Testing of electrical PPE and Instrument Calibration. Asbestos meter boards identified & asbestos notification sticker applied. SWMS’s completed and understood by employees. Maintenance & repair documentation for each asset job completed. 8 17. Further Reading Country Energy Fact Sheet – Electrical Safety for Plumbers. Electricity Association of NSW - Guide To Electrical Workers’ Safety Equipment www.dialbeforeyoudig.com.au www.esaa.com.au (Energy Supply Association of Australia) www.ena.asn.au (Energy Networks Association) ESAA NENS 09-2004 – ESAA National Guidelines for the Selection, Use and Maintenance of Personal Protective Equipment for Electrical Hazards. NSW Electrical Industry Asbestos Awareness Committee (EIAAC) – Minor works on asbestos based electrical mounting boards for domestic and commercial metering / electrical installations. Australian Standards: AS 1020 The control of undesirable static electricity AS 1482 Electrical equipment for explosive atmospheres - Protection by ventilation AS 1826 Electrical equipment for explosive gas atmospheres - Special protection AS 1892.3 Portable ladders - Reinforced plastic AS 1939 Degrees of protection provided by enclosures of electrical equipment (IP code) AS 2225 Insulating gloves for electrical purposes AS 2380.1 Electrical equipment for explosive atmospheres - Explosion-protection techniques - General requirements AS 2431 Electrical equipment for explosive atmospheres – Encapsulated apparatus AS 2790 Electricity Generating sets - Transportable (Up to 25 kW) AS 2978 Insulating mats for electrical purposes AS 3000 Electrical Installations (known as the Australian/New Zealand Wiring Rules) AS 3002 Electrical Installations - Shows and Carnivals AS 3008 Electrical installations - Selection of cables - Cables for alternating voltages up to and including 0.6/1 kV - Typical Australian installation conditions AS 3012 Electrical Installations - Construction and Demolition sites AS 3013 Electrical installations - Classification of the fire and mechanical performance of wiring system elements AS 3017 Electrical Installations - Testing and inspection guidelines AS 3018 Electrical installations - Domestic installations AS 3100 Approval & test specification - General requirements for electrical equipment AS 3105 Approval and test specification - Electrical portable outlet devices AS 3190 Approval and test specification - Residual current devices (current-operated earth-leakage devices) AS 3500.1 Plumbing and Drainage Part 1: Water Services AS 3527 Hand-operated screwdrivers and screwdriver bits - Insulated screwdrivers AS 3760 In-service safety inspection and testing of electrical equipment AS 3820 Essential safety requirements for low voltage electrical equipment AS 4202 Insulating covers for electrical purposes AS 4507 Cables - Classification of characteristics when exposed to fire AS 4836 Safe working on low-voltage electrical installations AS 5000 Electric cables - Polymeric insulated - For working voltages up to and including 450/750 V AS 5762 In-service safety inspection and testing - Repaired electrical equipment 9 AS 60079 Electrical apparatus for explosive gas atmospheres AS 61241 Electrical apparatus for use in the presence of combustible dust I.S. EN 60855:1999 Insulating Foam-filled Tubes And Solid Rods For Live Working NSW WorkCover : Code of Practice: Electrical Practices for Construction Work. Code of Practice: Low Voltage Electrical Work Stay Alive by Working Dead Brochure Code of Practice: Excavation Identification Tool for Electrical – Hazard Profile 2001 Guidelines To Working On Electrical Meter Panels Identified As Containing Asbestos. 10