* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Miniaturized Fiber-Optic Fabry-Perot Interferometer for Highly

Magnetic circular dichroism wikipedia , lookup

Harold Hopkins (physicist) wikipedia , lookup

3D optical data storage wikipedia , lookup

Optical rogue waves wikipedia , lookup

Optical aberration wikipedia , lookup

Optical coherence tomography wikipedia , lookup

Optical amplifier wikipedia , lookup

Ellipsometry wikipedia , lookup

Phase-contrast X-ray imaging wikipedia , lookup

Nonlinear optics wikipedia , lookup

Nonimaging optics wikipedia , lookup

Optical tweezers wikipedia , lookup

Surface plasmon resonance microscopy wikipedia , lookup

Optical fiber wikipedia , lookup

Passive optical network wikipedia , lookup

Retroreflector wikipedia , lookup

Interferometry wikipedia , lookup

Silicon photonics wikipedia , lookup

Photon scanning microscopy wikipedia , lookup

Dispersion staining wikipedia , lookup

Birefringence wikipedia , lookup

Anti-reflective coating wikipedia , lookup

Fiber-optic communication wikipedia , lookup

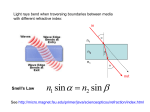

365 JOURNAL OF ELECTRONIC SCIENCE AND TECHNOLOGY OF CHINA, VOL. 6, NO. 4, DECEMBER 2008 Miniaturized Fiber-Optic Fabry-Perot Interferometer for Highly Sensitive Refractive Index Measurement Ming Deng, Tao Zhu, Yun-Jiang Rao, and Hong Li Abstract⎯This paper presents a novel miniaturized fiber-optic Fabry-Peort interferometer (FPI) for highly sensitive refractive index measurement. This device was tested for the refractive indices of various liquids including acetone and ethanol at room temperature. The sensitivity for measurement of refractive index change of ethanol is 1138 nm/RIU at the wavelength of 1550 nm. In addition, the sensor fabrication is simple including only cleaving, splicing, and etching. The signal is stable with high visibility. Therefore, it provides a valuable tool in biological and chemical applications. TPF FPT Index Terms⎯Fiber optic sensors, Fabry-Perot, miniature sensor, photonic crystal fiber, refractive index measurement. range of the RI measurement is also limited. In addition, many existing devices have shown large temperature cross-sensitivity. As a result, temperature variation induced errors need to be corrected in real time. Fiber-optic Fabry-Perot interferometers (FPI) have been successfully commercialized and widely used for measurement of temperature, strain, pressure, displacement, ultrasonic waves, and RI [7] . Especially, the measurement of RI using the FPI sensors has attracted great attentions as they can offer a number of desirable advantages over other optical fiber sensors, such as high sensitivity, large measurement range, ability for multi-parameters measurement, rapid response, etc. [8] . Xiao, et al. [9] reported a FPI refractive-index sensor formed by two polished fiber end-faces hosted in a holey sleeve. A resolution of 10 −5 was estimated in monitoring the changes in the refractive index of gases. However, the sensor assembly was complicated and required the use of epoxy and various components made of different materials. As a result, the device had a strong dependence on temperature. Recently, Wei, et al. [10] described a FPI refractive-index sensor by fabricating an open micro-notch FP cavity in a single-mode fiber. This device is insensitive to temperature with the temperature cross-sensitivity of 1.1×10 −6 RIU/ ° C. But in this scheme, the mechanical strength of this device is significantly reduced due to stress concentrations resulting from its nonsymmetrical structure. Moreover, this sensor is too expensive in fabrication, the open FP cavity is very easy to be contaminated, lowering its measurement accuracy and reliability. In this paper, we present a novel in-line fiber optic FP structure with a micrometric tip that are used to precisely measure the refractive indices of different liquids. Compared with other FP refractive-index sensors, the sensor fabrication is simple, including only cleaving, splicing, and etching. The signal is stable with high visibility. Therefore, it provides a valuable tool in biological and chemical applications. P P P P P P P 1. Introduction Miniaturized and robust optical sensors capable of accurate and reliable measurement of refractive index (RI) have attracted considerable attentions in biological and chemical applications since density, concentration, temperature, and stress, and so on [1] can be detected through measurements of the refractive index. Many optical RI sensors have been employed in recent years, such as grating-based RI sensors [2]-[4] , fiber surface plasmon resonance (SPR) RI sensors [5] , photonic crystal fibers [6] , and so on. These devices have shown excellent advantages of small size, corrosion resistance, immunity to electromagnetic interference, high accuracy, high sensitivity, and fast response time, etc. However, they are based on evanescent field, which resulted in a nonlinear response wavelength to refractive index, meaning that the sensitivity varies at different refractive index ranges. The dynamic P P P P P P P P Manuscript received September 18, 2008; revised October 20, 2008. This work was supported by the Key Project of Natural Science Foundation of China under Grant No. 60537040 and the Natural Science Foundation Project of CQ CSTC under Grant No. 2007BB3125. M. Deng and H. Li are with the Key Laboratory of Optoelectronic Technology and Systems, Chongqing University, Chongqing, 400044, China (e-mail: [email protected] ). Y.-J. Rao and T. Zhu are with the Key Laboratory of Optoelectronic Technology and Systems, Chongqing University, Chongqing, 400044, China and the Key Lab of Broadband Optical Fiber Transmission & Communication Networks Technology (Ministry of Education of China), University of Electronic Science& Technology of China, Chengdu, 610054, China (e-mail: [email protected] and [email protected] ). TP PT HT TH HT TH HT TH P P P P P P P 2. Sensor Fabrication and Operating Principle Three types of commercial fibers are used in the experiment: single-mode fiber (Corning Inc.), graded-index multimode fiber (Lucent Inc.), and photonic crystal fiber JOURNAL OF ELECTRONIC SCIENCE AND TECHNOLOGY OF CHINA, VOL. 6, NO. 4, DECEMBER 2008 366 (Crystal Fiber Inc.). Here, the graded-index multimode fiber (MMF) is germanium-doped in the core with pure fused silica cladding. The core diameter of the MMF is 62.5 μm and the cladding diameter is 125 μm. The structure of the photonic crystal fiber (PCF) is shown in Fig. 1. The cladding of the fiber is composed of elementary triangle cells, each having an air channel in the center. The central cell has no holes and it continues the fiber core. The pith length ( Λ) of the PCF is 8μm, the diameter of its air hole (d) is 3.68 μm and its external diameter is 125 μm. P P Fig. 3. The novel FPI with a cavity length of 60 μm. Due to the low reflectivity of the cavity surfaces, the sensor can be described as low finesse FPI and therefore the total reflective intensity I R (λ) can be derived using the two-beam optical interference equation: B B ⎡⎛ 4π nL ⎞⎤ I R (λ )= I1 +I 2 +2 I1 I 2 cos ⎢⎜ +Φ0 ⎟ ⎥ ⎠⎦ ⎣⎝ λ (1) where I 1 and I 2 are the reflections at the cavity surfaces, n is the refractive index of the medium filling the cavity, L is the cavity length, λ is the optical wavelength in vacuum, and Φ0 is the initial phase of the interference. B MMF PCF I1 B Light B I2 B B B B According to (1), we can see that the interference signal reaches its maximum when the phase of the cosine term becomes an even number of 2π , namely: Fig. 1 The structure of PCF. SMF B Filling liquid (n) I R (λ )= I max (λ ) , Fig. 2. The schematic diagram of novel FPI. Since the doped silica will be etched much faster than pure region, a section of the graded-index MMF is immersed in the hydrofluoric acid (HF 50%) to remove the core of the fiber. One end of the etched graded-index MMF is cleaved and spliced to a single-mode fiber (SMF), forming the first interference mirror, the other end of the graded-index MMF is also cleaved with a desirable length under a microscope and then spliced to a section of PCF, forming the second interference mirror. The pigtailed PCF is cleaved as thin as possible and cleaved with an angle. Hence, the reflective light from the end face is too weak to interfere with other light from the former two reflecting surfaces. Fig. 2 shows the schematic of the FP structure. Fig. 3 shows the scanning electron microscope (SEM) image of the novel FP structure with a micrometric tip. The cavity length is about 60 μm as estimated from the SEM image. λm +Φ0 = 2mπ (2) where m is an integer and λ m is the wavelength corresponding to the mth FPI reflection peak. The two adjacent interference maximums have a phase difference of 2π. Therefore the optical length of the cavity can be given by λm1λm 2 (3) Ln = 2 λm1 − λm 2 B Filling liquid (n) 4π nL when B where λ m1 and λ m2 are the peak wavelengths of the adjacent fringes of the FPI. The optical length of the cavity can also be calculated by using the Fast Fourier Transform (FFT) of the reflection spectrum, which is given as B B B Ln = B k , 2 N δν k = 0,1, 2," N − 1 (4) where N is the sample point number of FFT, k is the abscissa corresponding the maximum FFT value, and δν = δλ / λ 2 . In theory, (3) and (4) can be used to calculate either the absolute refractive index n or the absolute cavity length L if one of them is known. In many cases, only the relative refractive index change is of interest and the range of refractive index variation is 367 DENG et al.: Miniaturized In-Line Fabry-Perot Interferometer for Highly Sensitivity Refractive Index Measurement small so the phase shift is less than 2π. In this case, the phase ambiguity issue can be avoided. Rearranging (2), we obtain the changes in the refractive index of the cavity of the fiber optic FPI, given by Δλm Δn = λm 0 (5) n0 The interrogation of the FPI sensor is schematically shown in Fig. 5. A broadband source was used to excite the FPI sensor through a 3 dB fiber coupler. The reflected interference signal from the sensor was detected by a high-accuracy optical spectrum analyzer (OSA, Si720, Micron Optics, USA). The wavelength resolution and precision of OSA are 2.5 pm and 1 pm, respectively. T P where Δn is the change in the refractive index of the cavity, n0 is the initial refractive index of the cavity, λm 0 is the 3dB Coupler n0 changes to n0 + Δn . It can be seen that the relative P P 3. Experiments and Discussion The interference spectrum of the fabricated novel FPI in air at room temperature is shown in Fig. 4. The fringe visibility of this particular device is about 10 dB higher than that of a FPI formed by femtosecond laser [10] . The loss of the FPI was about 34 dB, which was sufficient for most sensing applications. The length of the FP cavity was found to be 61.262 μm using (4) with n set to be 1.0003 for air at the wavelength of 1550 nm [9] . The calculated value was very close to the cavity length estimated by the SEM image. P P P air Air Acetone acetone Ethanol ethanol Intensity(dBm) −15 −25 −35 −45 −55 −65 1520 1530 1530 P P FPI sensor PC Fig. 5. Experimental setup for RI measurement. The interference spectra of the FPI sensor immersed into various liquids are also shown in Fig. 4 for comparison. The signal intensity decreases with the increment of liquid refractive index, which is mainly because the power reflective coefficients at the surfaces decreased and thus lowered the reflective intensity when the device was immersed in liquids. The spectral distance between the two adjacent peaks also decreased, indicating the increase of refractive index of the medium inside the cavity. Calculating (4), we obtain the refractive indices of the liquids: n acetone =1.3571 and n ethnol =1.3619, which are close to the commonly accepted values. B B B B P −5 −75 1520 Optical spectrum analyzer P P T Broadband source wavelength corresponding to the mth reflectance maximum being monitored, and Δλm is the drift of λm 0 , when index change is proportional to the spectral shift of the interfeogram. When monitoring the relative index change of ethanol with a nominal refractive index of 1.362, the sensitivity of the measurement is 1138 nm/RIU at the wavelength of 1550 nm according to (5). The actual detection limit depends on the resolution with which the spectral shift of the interferogram can be determined. If a resolution of 2.5 pm is achieved in the determination of interferogram shift, a detection limit of 2.2×10 −6 RIU is attained. P 1540 1550 1540 1550 Wavelength (nm) P P 1560 1560 1570 157 Fig. 4. Interference spectrum of the FPI sensor in air, acetone, and ethanol. To evaluate its capability for refractive index measurement, the fiber FPI sensor was tested using different liquids including acetone and ethanol at room temperature. 4. Conclusions We have presented a novel in-line Fabry-Perot interferometer with a micrometric tip for highly sensitive refractive-index measurement. By demodulation of the interference spectrum, the change of optical path distance caused by the environment can be obtained. This effect can be very useful in a broad range of biomedical applications, such as refractive index measurement and concentration monitor. The sensor was evaluated for refractive index measurement of various liquids and the results agreed on with the reported data. More importantly, the device provides advantages such as small size, all-fiber inline structure, easy fabrication, linear response, high sensitivity, and high resolution; therefore, it is possible to stably work in harsh environments. Acknowledgment The authors would like to thank the support by the Key Teacher Foundation of Chongqing University. 368 JOURNAL OF ELECTRONIC SCIENCE AND TECHNOLOGY OF CHINA, VOL. 6, NO. 4, DECEMBER 2008 References [1] J. C. Owens, “Optical refractive index of air: dependence on pressure, temperature and composition,” Appl. Opt., vol. 6, no. 1, pp. 51-59, 1967. [2] T. Zhu, Y.-J. Rao, and Q.-J. Mo, “Simultaneous measurement of refractive index and temperature using a single ultra long-period fiber grating,” IEEE Photon. Technol. Lett., vol. 17, no. 12, pp. 2700-2702, 2005. [3] K. S. Chiang, Y. Liu, M. N. Ng, J. H. Yan, and S. L. He, “Analysis of etched long-period fiber grating and its response to external refractive index,” Eletron. Lett., vol. 36, no.11, pp. 966-967, 2000. [4] A. N. Chryssis, S. M. Lee, S. B. Lee, S. S. Saini, and M. Dagenais, “High sensitivity evanescent field fiber Bragg grating sensor,” IEEE Photon. Technol. Lett., vol. 17, no. 6, pp. 1253-1255, 2005. [5] D. Monzon-Hernandez and J. Villatoro, “High-resolution refractive index sensing by means of a multiple-peak surface plasmon resonance optical fiber sensor,” Sensors & Actuators B, vol. 115, pp. 227-231, Sep., 2006. [6] N. Skivesen, A. Tetu, M. Kristensen, J. Kebashin, and M. A. Skorobogatiy, “Photonic-crystal waveguide biosensor,” Opt. Express, vol. 15, no. 6, pp. 3169-3176, 2007. [7] Y.-J. Rao, “Recent progress in fiber-optic extrinsic Fabry-Perot interferometric sensors,” Opt. Fiber Technol., vol. 12, pp. 227-237, April, 2006. [8] Y.-J. Rao, M. Deng, D.-W. Duan, X.-C. Yang, T. Zhu, and G.-H. Cheng, “Micro Fabry-Perot interferometers in silica fibers machined by femtosecond laser,” Opt. Express, vol. 15, no. 21, pp.14123-14128, 2007. [9] G.-Z. Xiao, A. Adnet, Z.-Y. Zhang, F.-G. Sun, and C. P. Grover, “Monitoring changes in the refractive index gases by means of a fiber optic Fabry-Perot interferometer sensor,” Sensors & Actuators A, vol. 118, pp.177-182, Oct. 2005. [10] T. Wei, Y.-K. Han, Y.-J. Li, H. L. Tsai, and H. Xiao, “Temperature-insensitive miniaturized fiber inline FabryPerot interferometer for highly sensitive refractive index measurement,” Opt. Express, vol. 16, no. 8, pp. 5764-5769, 2008. Ming Deng was born in Shannxi Province, China, in 1979. She received the B.S. and M.S. degrees from the Xi’an University of Science and Technology, Shannxi, in 2003 and 2006, respectively, both in communication and information engineering. She is currently pursuing the Ph.D. degree with the Department of Optoelectronic Engineering, Chongqing University. Her research interests include fiber-optic passive and active optical sensors. Tao Zhu was born in Sichuan Province, China, in 1976. He received the M.S. and Ph.D. degrees from the Chongqing University, Chongqing, in 2003 and 2008, respectively, both in optical engineering. He is a member of the Optical Society of America. His research focuses on passive and active optical components and optical sensors. Yun-Jiang Rao received his M.Eng and Ph.D. degrees in optoelectronic engineering from Chongqing University in 1986 and 1990, respectively, where he led a team to develop the first fully-automatic optical fiber fusion splicing machine in China. He joined the Optoelectronics Division of Electric and Electronic Engineering Department in Strathclyde University, U.K., as a post-doctoral research fellow in 1990. He was employed by Kent University in U.K. as a research fellow and then a senior research fellow during 1992 to 1999, where he made important contributions to fiber-optic low-coherence interferometry and in-fiber Bragg grating sensors. During 1999 to 2004, he was a Chang-Jiang Chair Professor in optical engineering with Department of Optoelec-tronic Engineering, Chongqing University, China, and established the Optical Fiber Technology Group with strong support of the Ministry of Education of China under the Program of Chang-Jiang Scholar Professorship. He is currently the Head of Optical Fiber Technology Research Centre and the Dean of School Communication and Information Engineering, University of Electronic Science and Technology of China and Chang-Jiang Chair Professor in Optical Engineering. Hong Li was born in Sichuan Province, China, in 1982. He received the B.S. degree from the Chengdu University of Information and Technology, Chengdu, in 2006. He is currently pursuing the M.S. degree with the Department of Optoelectronic Engineering, Chongqing University. His research interests focuse on novel fiber-optic communication and sensing devices.