* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download 1 M.Sc./P.G. Diploma Course in Industrial Automation Document 1

Survey

Document related concepts

Transcript

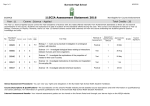

M.Sc./P.G. Diploma Course in Industrial Automation Document 1: Eligibility Requirements 1.1 The degree of the Bachelor of Science of Engineering of University of Moratuwa in a relevant field of specialization; the relevancy of the field to be judged by the Faculty and approved by the Senate of University of Moratuwa. OR 1.2 Any other Engineering degree of at least four years duration, in a relevant field of specialization, from a recognized university; the recognition of the university, the acceptability of the course, and the relevancy of the field to be judged by the Faculty and approved by the Senate of University of Moratuwa. OR 1.3 Any other Science degree (preferably with Mathematics or Physics as a subject) of at least four years duration from a recognized university, AND a minimum of one year of appropriate experience in a relevant field after obtaining such degree; the recognition of the university, the acceptability of the course, and the relevancy of the experience to be judged by the Faculty and approved by the Senate of University of Moratuwa. OR 1.4 Any other Science degree (preferably with Mathematics or Physics as a subject) of at least three years duration from a recognized university, AND a minimum of two years of appropriate experience in a relevant field after obtaining such degree; the recognition of the university, the acceptability of the course, and the relevancy of the experience to be judged by the Faculty and approved by the Senate of University of Moratuwa. OR 1.5 At least the Associate Membership (satisfying the educational requirements for Corporate Membership or similar graduate membership) of a recognized professional engineering institute in a relevant field AND a minimum of one year of appropriate experience after obtaining such membership; the acceptability of the Associate Membership status of the candidate, the recognition of the institute and the relevancy of the field for this purpose shall be judged by the Faculty and approved by the Senate of University of Moratuwa. 1 Document 2: Curriculum and Scheme of Evaluation Curriculum of Postgraduate Course Code Credits1 Course Unit Evaluation2 (%) Final Exam Assignments Core Modules EE 5061 State Space Design 2.5 60±20 40±20 EE 5062 Digital Control 2.5 60±20 40±20 EE 5201 Sensors Systems 2.5 60±20 40±20 EE 5202 Modern Power Electronics and Drives 2.5 60±20 40±20 ME 5124 Automation and Control of Manufacturing Systems 3.0 60±20 40±20 ME 5144 Mechatronics and Robotics 3.0 60±20 40±20 ME 5201 System Automation 3.0 60±20 40±20 ME 5202 Advanced Controls 3.0 60±20 40±20 and Actuators Engineering for Automatic Mathematics for Elective Modules EE 5071 Microprocessor Based Systems 2.5 60±20 40±20 EE 5073 Computer Networks 2.5 60±20 40±20 EE 5074 Internet Applications 1.5 60±20 40±20 EE 5075 Artificial Intelligence Applications (or ME 5145) 2.5 60±20 40±20 EE 5081 Operations Research 2.5 60±20 40±20 EE 5082 Numerical methods (or ME 5001) 2.5 60±20 40±20 EE 5084 System Identification and Modelling 1.5 60±20 40±20 EE 5203 Robotics Technology 2.5 60±20 40±20 EE 5204 Hardware and Software for Systems Control 2.5 60±20 40±20 EE 5086 Project Management 1.5 60±20 40±20 EE 5087 Human Resource Management (or ME 5146) 1.5 60±20 40±20 ME 5103 Computer Integrated Manufacturing 3.0 60±20 40±20 ME 5121 Industrial Management (or ME 5122) 3.0 60±20 40±20 ME 5122 Quality Management (or ME 5121) 3.0 60±20 40±20 ME 5123 Supply Chain Management 3.0 60±20 40±20 ME 5125 Manufacturing Process: Advanced Concepts 3.0 60±20 40±20 ME 5145 Artificial Intelligence in Manufacturing (or EE 5075) 3.0 60±20 40±20 2 ME 5146 Human Factors in Engineering (or EE 5087) 3.0 60±20 40±20 ME 5001 Mathematical Techniques (or EE 5082) 3.0 60±20 40±20 ME 5220 Machine Intelligence and Robotics 3.0 60±20 40±20 ME 5290 Research Seminar 3.0 - 100 Project (only for those who plan for PGDip) 10 - 100 EE 5099 or ME 5299 Code EE 6099 or ME 6299 1 2 Evaluation Module Dissertation Exam. Assignments Viva Thesis 1 credit corresponds to 14 hours of lectures or equivalent The mean value in the evaluation scheme is the default value. It can be changed by the Lecturer/Examiner concerned, within the specified range, by announcement to the students at the commencement of the course unit. 3 Document 3: Syllabi of Course Units 3.1 EE 5061 – State Space Design (2.5 credits): Learning Objectives: To provide the necessary exposure to design a control system using state space design methodology. Outline Syllabus: Linear Systems theory, Concept of state, Linear differential equations, State transition matrix for linear time-invariant and time-variant systems, Controllability, Observability, Duality, Canonical forms, Input/output models, State feedback and modal control design, State observers and their design, Optimal controller design. 3.2 EE 5062 - Digital Control (2.5 credits): Learning Objectives: To provide the students with an understanding of the fundamentals of Digital Control theory and the theoretical and practical principles for design. To provide guidelines of current trends in the field. Outline Syllabus: Basics of sampled data systems, Samplers, Data holds and digital compensators, The z-transform and extended z-transform, Block representation of sampled data feedback systems, Stability analysis via the root locus and Nyquist plot techniques, Compensator design for deadbeat response. Practical system designs. 3.3 EE 5201 - Sensors and Actuators for Automatic Systems (2.5 credits): Learning Objectives: To enhance the knowledge and understanding of sensors and actuators for automating systems. Outline Syllabus: Sensors: Digital sensors, analog sensors, and sensor specifications. Actuators: An introduction to different types of actuators including servomotors, dc motors, ac motors, grippers, manipulators, and linear actuators. Data sampling, A/D, D/A, Interfacing and systems development using sensors and actuators. 3.4 EE 5202 - Modern Power Electronics and Drives (2.5 credits): Learning Objectives: To enhance the knowledge and understanding of commonly used drive systems and their power electronics control in automation applications. Outline Syllabus: Adjustable voltage dc-dc converting systems of different types, switch mode and resonant mode. Adjustable voltage and adjustable frequency dc-ac converting systems of different types. Drive systems of brushless dc, conventional dc, induction steppers, switch reluctance, linear etc. and their power electronics applications. Design aspects of overall drive systems. Open loop and closed loop operation of position and speed drives, improvement of bandwidth. 3.5 ME 5124 - Automation and Control of Manufacturing Systems (3.0 credits): Learning Objectives: To provide the knowledge and skills required automating and controlling the functions of the manufacturing process. Outline Syllabus: Planning and implementation of Automation; Automated assembly; Automated materials flow and storage systems; Control theory; PID controllers; Programmable Logic Controllers (PLC’s); Adaptive control in manufacturing; Hierarchical control concepts; Hardware and software process integration; Instrumentation; Maintenance and diagnosis; Integration of machine tools. 4 3.6 ME 5144 - Mechatronics and Robotics (3.0 credits): (Pre-requisite: PME/MSE 205 - Automation and Control of Manufacturing Systems) Learning Objectives: To introduce students to the engineering and management techniques of the design and development process of a mechatronics product/system Outline Syllabus: Introduction of mechatroncis; Revision of basic mechanics, electricity and electronics, Introduction to programming; Study of components of a mechatronics system such as stepper motors, A/D converters, Op-amps. solid-state devices; Conceptual design of a mechatronics system; Implementation of robot systems; Robot programming; Machine vision. 3.7 ME 5201 - Systems Automation (3.0 credits): Learning Objectives: Understanding of system automation for a given requirement Outline Syllabus: Introduction to system automation, hardware and software for general automation, micro-controller based system design, plant automation for large-scale factories, and Industrial applications in automation. 3.8 ME 5202 - Advanced Engineering Mathematics for Controls (3.0 credits): Learning Objectives: To provide the mathematical knowledge and skills required for developing control systems. Outline Syllabus: Linear matrix inequalities (LMIs), Stability analysis of dynamic systems, Adaptive filtering, Prediction and correction methods, Numerical methods for control algorithms, Vector spaces, Riccati equation, Fractals and chaos, Conformal mapping, Applications on the above topics 3.9 EE 5071 - Microprocessor Based Systems (2.5 credits): Learning Objectives: Understand the Principles and Technologies used in microprocessorbased systems Outline Syllabus: Uniprocessor, coprocessor and multiprocessor systems, RISC and CISC architectures. Digital Data Manipulation: Error codes, parity, Hamming code. Computer Organization and Control: Polling, interrupts, DMA, bus control, and priority levels. Peripheral Devices and data communication standards: RS232, IEEE488, VME. Operating Systems and Memory Management: Virtual memory, compilers, linkers, interpreters, network operating systems. 3.10 EE 5073 - Computer Networks (2.5 credits): Learning Objectives: Understand the Principles and Technologies used in computer networks Outline Syllabus: Communication networks; LANs, WANs, MANs, Internet, Intranets, protocols, layered architecture of networking; ethernet, token ring, token bus, X.25, Use of modems 3.11 EE 5074 - Internet Applications (1.5 credit): Learning Objectives: To provide the knowledge and skills for internet based applications. Outline Syllabus: Overview of the Internet, Browser, Client and Server. Introductory-level overview of the technologies involved in building a web application. (No previous experience with web design or HTML is assumed.) Creating a Web-page - Basic Document Structure. Hand coded HTML: tags and tag attributes, Lists, Images, Hyperlinks, Tables, Forms, Links and Anchors. Document Header, Meta tags. Frames. Class information, Style sheets. Authoring Tools. HTML Validation. Exercise: Creating an interactive web-page for ones-self. 5 3.12 EE 5075 - Artificial Intelligence Applications [or ME 5145] (2.5 credits): Learning Objectives: Understanding of artificial intelligence (AI) and apply AI techniques in real world problems. Outline Syllabus: Background, Natural and Artificial Intelligence, Turing Test, Applications in AI, Future of AI. AI Agent, PEAS (Performance-Environment-Actuators-Sensors), Hardware and Software agents, Simple reflex agent, Learning Agent for complex systems. Search Algorithms, Depth First Search (DFS), Hill Climbing, Constraints, Quasigroup Completion Problems (QCP), Genetic Algorithms (GA): Population, Crossover, Mutation and other parameters. Introduction to FL, Applications, Why Use Fuzzy Logic, Fuzzy Sets, Mamdani-type and Sugeno-type fuzzy systems, Development of an AI Agent using Fuzzy reasoning: fuzzy operators and Implication Methods, Takagi- Sugeno Fuzzy Model. Neural network architectures and learning rules, Back propagation, Application of neural networks Knowledge based systems and expert systems Artificial Intelligence applications 3.13 EE 5081 - Operations Research (2.5 credits): Learning Objectives: To enable graduates to play an effective role in providing decision support to managers Outline Syllabus: Linear and dynamic programming, Sensitivity analysis, Network analysis, Integer programming. 3.14 EE 5082 - Numerical Methods [or ME 5001] (2.5 credits): Learning Objectives: To enable graduates to apply numerical methods to solve real world problems. Outline Syllabus: Fast Fourier Transforms (FFT), Numerical methods for solving elliptic equations, Finite difference methods, Finite element methods and variational methods, Modal matrix analysis, 3.15 EE 5084 - System Identification and Modeling (1.5 credit): Learning Objectives: To provide the knowledge for analyzing systems for control and automation purposes. Outline Syllabus: Deterministic modeling, Data analysis and sampling, Windowing, Parametric and non-parametric spectral analysis, Off-line system identification, On-line system identification, AR, ARX, ARMA, ARMAX modeling, Model order determination, Model validation, Prony signal and transfer function identification techniques. 3.16 EE 5203 - Robotics Technology (2.5 credits): Learning Objectives: To introduce students to the fundamentals on robotics and provide them with essential knowledge about theoretical & practical background on robotics, so that, in the future, the students will be able to readily apply their knowledge in industry or research or further enhance it by self study. Outline Syllabus: Spatial Descriptions and Transformations, Manipulator Kinematics and Inverse Kinematics, Force/velocity propagation along manipulator links, Manipulator dynamics, Trajectory Planning Mechanical design of robot manipulators, Robot manipulator control, Robot system integration and programming, Robot sensors and actuators, Robot vision, Sensor fusion. 6 3.17 EE 5204 - Hardware and Software for Systems Control (2.5 credits): Learning Objectives: To familiarize with standard software and hardware components related to systems control and automation. Outline Syllabus: Examples of computer controlled systems, Basic sampling theory, D/A and A/D conversion, Hardware components of data acquisition, Device interfacing, control registers, instruction set and assembler programming for DAQs, Concurrent programming for on-line control, real-time executives and applications, Distributed systems. 3.18 EE 5086 - Project Management (1.5 credit): Learning Objectives: To provide the necessary exposure to the application of the project management knowledge, skills, tools and techniques to meet or exceed stakeholder needs and expectations. Outline Syllabus: Definition of Project Management and relationship to other management disciplines. Project Appraisal: Financial, technical, environmental etc. Project Management Context: Project phases and project life cycle, project strategy development, project stake holders. Organizational and socio-economic influence, key management skills, project initiation and modelling, project management process, project procurement management and project scheduling. Project cost estimation and control, project quality management, project risk management, project assessment and stakeholder marketing and case studies. 3.19 EE 5087 - Human Resource Management (1.5 credit): Learning Objectives: To appreciate the role of Human Resource Management in an organization and it’s various facets and to evaluate HRM practices in an organization. Outline Syllabus: Human resources planning, Job Analysis and Job design, Recruitment & Selection, Training & Development, Managing Performance, Reward Management, Human Resource Information Systems, Strategic Human resource management, Managing Labour Relations. 3.20 ME 5103 - Computer Integrated Manufacturing (3.0 credits): Learning Objectives: To acquaint the student with the integration of the elements of CAD and CAM and the integration of manufacturing functions. Outline Syllabus: Integrated approach in manufacturing systems; Concurrent engineering; Production process design; Group technology; Computer aided process planning; Production management aspects of CIM; Implementation of CIM; Flexible manufacturing systems (FMS); Factory of future; Communication networks, DBMS, Interfacing, Data logging and acquisition. 3.21 ME 5121 - Industrial Management [or ME 5122] (3.0 credits): Learning Objectives: To provide the general management background needed by the manufacturing executive for effectively participating in the total business environment of a firm. Outline Syllabus: Human factors in industry: Organization structure, Cultures and management styles, leadership and characteristics of individuals, group behavior, Manpower requirements and skill needs- selection recruitment and training, Motivation, Rewards strategies- reward and job evaluation, Implementing changes in organization; Financial decision making: Financial analysis, Profitability analysis, and Investment appraisal; Marketing: Concepts and importance of marketing, Marketing system, Market types, Marketing research and analysis, Managing marketing mix, Four P’s (Product, Price, Place, Promotion) 7 3.22 ME 5122 - Quality Management [or ME 5121] (3.0 credits): Learning Objectives: To present quality as a strategic tool for competitiveness and to provide knowledge of the ways and means to achieve quality in manufacturing. Outline Syllabus: Quality management systems: Quality management philosophies, Total Quality Management, Quality awards (Malcom Baldrige award, National Quality award), Quality certification (ISO 9000, SLS) HRM for quality, Vendor quality; Statistical quality control: Statistical methods in QC, Statistical process control, Acceptance sampling, Taguchi method, Product reliability; Design for quality, Quality function deployment. 3.23 ME 5123 - Supply Chain Management (3.0 credits): Learning Objectives: To support the globalisation trends in manufacturing systems by developing the management know-how required by the students aspiring to work in international business. Outline Syllabus: The concept and structure of Global Supply Chain; International trade; Supply organisation; The procurement process; Distribution management; Transportation systems; Enterprise resource planning; Management and organisation of information systems; Strategic considerations. 3.24 ME 5125 - Manufacturing Processes: Advanced Concepts (3.0 credits): Learning Objectives: To provide an overview (and a review) of the manufacturing methods for metallic and non-metallic materials covering their critical aspects and with reference to local manufacturing industry. Outline Syllabus: An overview of local manufacturing industry; Mechanical behaviour and manufacturing properties of materials; Casting Technology: Metals and melting practice, Design aspects of product/mould, product quality; Forming Technology: General characteristics, bulk forming vs sheet-metal working, formability, analysis of process with respect to machinery and tooling, forming loads and energy requirements, product quality concerns; Joining Processes (for metals): Process classification, fusion weld quality and weld metallurgy, testing and inspection; Forming and shaping of fibre reinforced materials; Processing of powder materials and ceramics: Sintering technology; Non-conventional Machining Processes: CM, ECM, EDM, laser/electron beam machining, water/abrasive-jet machining, etc.; Surface treatment and coating: methods and technology. 3.25 ME 5145 - Artificial Intelligence in Manufacturing [or EE 5075] (3.0 credits): Learning Objectives: To gain an understanding of expert systems and AI techniques and how it can be applied in control, automation, manufacturing, design and operational management. Outline Syllabus: Knowledge based systems, Expert systems, Fuzzy systems and fuzzy control, Artificial Neural Networks, Genetic Algorithms, Selection of AI techniques, AI based applications in control, automation, manufacturing, design and operations management. 3.26 ME 5146 - Human Factors in Engineering [or EE 5087] (3.0 credits): Learning Objectives: To gain an understanding of the impact of human capabilities and limitations on the design and development of products and equipment. To appreciate the contemporary approaches to the design of safe and fatigue free work environments. Outline Syllabus: The scope of human factors engineering and its relationship with product design and manufacture; Systems Ergonomics; Human characteristics; Principles of anthropometry; Application of ergonomics to product design; Biomechanics and safety engineering; Introduction to Ergonomics CAD in product design; Practical case studies taken from the fields of consumer product design, work place and work design. 8 3.27 ME 5001 - Mathematical Techniques [or EE 5082] (3.0 credits): Learning Objectives: To enable graduates to apply mathematical techniques to solve real world problems Outline Syllabus: Partial differential equations – classification, modelling, solutions using Fourier series, Fourier transform; Numerical methods – finite difference methods, finite element methods, solutions of ordinary and partial differential equations, applications using computer software; Optimisation – Non-linear optimisation involving multivariate function, dynamic programming; Methods of applied statistics – sampling, hypothesis tests, basic ideas of linear models, time series modeling. 3.28 ME 5220 - Machine Intelligence and Robotics (3.0 credits): Learning Objectives: To enable graduates to apply intelligent techniques to develop intelligent machines. Outline Syllabus: Introduction to Intelligent Systems, Hardware and software agents, Kinematics and dynamics for controlling robots, Modeling and Control of Dynamical Systems, Mobile robots and their autonomous navigation, Machine Learning, Intelligent Systems Control Techniques like Behavior Based Controls, Neuro-Fuzzy controllers. 3.29 ME 5290 - Research Seminar (3.0 credits): Learning Objectives: To develop the ability of students to do unsupervised work at graduate level, especially on research paper reading and understanding related to automation. Outline Syllabus: Critical reading of technical literature and summarizing contents. Verbal communications and writing skill development. Adapting the speech and the written material for the intended audience. Making Seminar type presentations as a tool for interpersonal communication, projects presentation, public speaking, and report writing. 3.30 EE 5099 - Project (Only for those who plan for PGDip) (10 credits): Learning Objectives: To allow students to apply skills gained in the course to a related project. To gain the ability to learn and apply new ideas as needed to meet project goals. Outline Syllabus: The student is expected to work individually to develop a given project at a greater depth than in EE5199 and may be allowed to be done in lieu of courses in special cases. They shall be carried out for a period of not less than three months, on a part time basis (or equivalent period full time) under the supervision of a senior staff member. All students must make a written and verbal presentation at the completion of the module. 3.31 EE 6099 - Dissertation (25 credits): Learning Objectives: To allow students to apply skills gained in the course to a multidisciplinary project. To develop specific skills in project definition, planning, and scheduling, effective written and oral communication of technical ideas. To incorporate realistic constraints and engineering standards. Outline Syllabus: The student is expected to work individually on a research dissertation on a topic assigned or agreed by the Department. It is to be carried out for a period of not less than one academic year, on a part time basis (or equivalent period full time) under the supervision of a senior staff member and/or industrial supervisors. The student is expected to develop a complete plan from feasibility study, cost analysis, through electrical design and documentation to the building of a prototype or developing of a model as applicable. All students must make a formal written and verbal presentation to a panel. Document 4: Performance Criteria 9 4a: For Postgraduate Diploma 4a.1 Title of the Award: Postgraduate Diploma in Industrial Automation 4a.2 Participation in Academic Program: 1. The candidate is required to have attended at least 80% in lectures, tutorial classes, seminars and other components. 2. Undertake an individual project, as assigned by the Department, on a specific subject area. 3. No postponement of the course is allowed without the prior approval of the Senate. 4a.3 Pass in the Postgraduate Examination: 1. A candidate is deemed to have passed the Postgraduate Examination if the candidate has: 1. successfully completed the required course units, including compulsories, totalling a minimum of 40 credits AND 2. successfully completed the prescribed seminars AND 3. successfully completed all the prescribed assignments, laboratory work, AND 4. successfully completed the prescribed project. Note: In order to be considered successful and earn credit for the course unit, the candidate must earn grade C or above. Where a course unit consists of more than one component (written examination, seminars, laboratory work, assignments etc) the pass mark for each component is 40%. 2. If the candidate is unsuccessful in any of the parts 1.(a) through 1.(d), he/she may be re-examined. Normally only one re-examination will be allowed and this shall be at the next holding of the examinations or assessments. No postponement shall be allowed without approval from the Senate. 3. Classes will not be awarded. 4a.4 4a.5 Credit Rating: A credit is defined as one hour of Lectures per week for the duration of one Semester which will usually be of 14 weeks duration. A Credit will also be equivalent to about 2 hours of assignments per week for one semester. Grading of Marks: Performance of the candidate in each course unit shall be graded based on the following benchmarks: Grade Benchmark Grade Point Description A+ >= 85% 4.2 A 75% - 84% 4.0 A- 70% - 74% 3.7 B+ 65% - 69% 3.3 B 60% - 64% 3.0 B- 55% - 59% 2.7 C+ 50% - 54% 2.3 Pass C 50% - 54% 2.0 Pass (Repeat Candidate) Excellent Good I 0 Incomplete F 0 Fail N 0 Academic Concession A candidate who has not earned a grade of C+ or above in a particular course unit at the first attempt, but has obtained minimum marks for at least one component, receives the grade I 10 otherwise he receives the grade F. By repeating the incomplete component for those obtaining the grade I, or all the components for those obtaining the grade F, the candidate can upgrade grade C only and this will be used for calculating the grade point average (GPA). The grade N signifies the academic concession granted with the approval of the Senate. 4a.6 Calculation of Grade Point Average: The overall grade point average (GPA) of the postgraduate examination will be calculated according to the following formula. Overall GPA = ∑ [GradePoints × Credits] ∑ Credits Note: All credits offered by the student, irrespective of whether completed or not will be considered in the evaluation of the Overall GPA. 4a.7 Release of Result of Written Examination: Performance of a candidate at the written examination shall be released after the Board of Examiners meeting, subject to confirmation of the Senate, unless the Board of Examiners recommends withholding of the results for specific reasons. 4a.8 Criteria for the Award of the Postgraduate Diploma: 1. Passed the Postgraduate Examination as specified in clause 4a.3 AND 2. Not desirous of proceeding to the Master's dissertation, either before commencement or thereafter, as indicated in writing to the head of department OR Not able to undertake/complete the Master's dissertation under the prescribed conditions. 4a.9 Date of Award: The effective date of the Postgraduate Diploma shall be the first day of the following month after the successful completion of all of the following components of the postgraduate examination: 1. written examinations 2. seminars 3. assignments and laboratory work and projects 4b: Performance Criteria for Master of Science Degree 11 4b.1 Title of the Award: Master of Science - Specialization Industrial Automation 4b.2 Participation in Academic Program: 1. Passed the postgraduate examination as specified in clause 4a.3 but has not been awarded the Postgraduate Diploma 2. Has obtained an overall GPA of at east 3.0 at the postgraduate examination. 3. Undertake an individual research dissertation, as assigned by the Department, on a specific subject area, for a period of not less than one academic year duration on a part time basis or equivalent. 4. The postponement of the dissertation will only be allowed with prior approval from the Senate. 4b.3 Pass in the Dissertation: 1. The candidate will be graded based on the evaluation of the final seminar and oral examination by a panel of examiners. 2. The grading of the dissertation is directly on a letter Grade. The benchmark performance given in clause 4a.5 may be used for guidance. 3. A candidate is deemed to have passed the dissertation, if the candidate earns the Grade C+ or above at the first attempt. 4. If the candidate is unsuccessful in dissertation, he/she may be re-examined and given the pass grade C if successful. Normally only one re-examination will be allowed, usually after a minimum of three months but not exceeding 12 months after the initial examination/assessment. 4b.4 Criteria for the Award of the M.Sc. Degree: 1. Passed the Postgraduate Examination as specified in clause 4a.3 AND 2. Successfully completed any additional prescribed seminars and assignments AND 3. Successfully completed the research dissertation assigned to the candidate. 4b.5 Date of Award: The effective date of the MSc degree shall be the first day of the following month after the successful completion and evaluation of all of the following components: 1. Postgraduate Examination as specified in clause 4a.3 2. Research dissertation 3. Submission of final bound copies of dissertation (after corrections if any). Document 6: Resource Persons 12 CODE SUBJECTS (CREDITS ) Resource Persons EE5061 State Space Design Dr. Trishantha Nanayakkara EE5062 Digital Control Dr. Sisil Kumarawadu EE5201 Sensors and Actuators for Automatic Systems Dr. Nalin Wicramarachchi EE5202 Modern Power Electronics and Drives Dr. JP Karunadasa PME/MSE205 Automation and Control of Manufacturing Systems Dr. Palitha Dasanayake Dr. Thrishantha Nanayakkara PME/MSE304 Mechatronics and Robotics Dr. Palitha Dasanayake Dr. Rohan Munasinghe PME/IA101 System Automation Dr. Chulantha Kulasekara Dr. Lanka Udawatta PME/IA102 Advanced Engineering Mathematics for Controls Dr. Thrishantha Nanayakkara Dr. Rohan Munasinghe Dr. Sisil Kumarawadu Mr. Shantha Fernando E E5071 Microprocessor Based Systems Dr. Chathura De Silva EE5073 Computer Networks Mr. Mohommad Firdhous EE5074 Internet Applications Prof. JR Lucas EE5075 Artificial Intelligence Applications Dr. Lanka Udawatta EE5081 Operations Research Dr. M. Indralingam. EE5082 Numerical Methods (or PME/ET101) Dr. G.T.F. de Silva EE5084 System Identification and Modelling Dr. Nishantha Nanayakkara 13 EE5203 Robotics Technology Dr. Rohan Munasinghe EE5204 Hardware and Software for Systems Control Dr. Thrishantha Nanayakkara PME/MSE305 Artificial Intelligence in Manufacturing Dr. Palitha Dasanayake Dr. Lanka Udawatta PME/MSE103 Computer Integrated Manufacturing PME/MSE203 Quality Management Mr. ACM Naeem* Dr. Udaya Kahangamage Mr. HKG Punchihewa PME/MSE202 Industrial Management Dr. Chandana Perera PME/MSE306 Human Factors in Engineering Mr. HKG Punchihewa PME/MSE204 Supply Chain Management Mr. ACM Naeem* PME/MSE206 Manufacturing Processes: Advanced Concepts Dr. MARV Fernando Dr. Rohan Tittagala Dr. Thrishantha Nanayakkara PME/IA103 Machine Intelligence and Robotics Dr. Lanka Udawatta Dr. Thrishantha Nanayakkara PME/IA104 Research Seminar EE5099 Project ( Only for those who plan for PGDip) Dr. Lanka Udawatta All staff members from EE & ME *Mr. ACM Naeem BSc. Eng. (Hons), M.Eng. (AIT) Manage, Projects, Kingslake Engineering Systems, Colombo 2 14