* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Lecture 25 Other Phosphate Fertilizers – Part 1

Survey

Document related concepts

Transcript

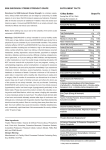

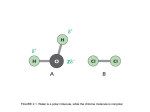

Lecture 25 Other Phosphate Fertilizers – Part 1 Enriched Superphosphate “Enriched” superphosphate is essentially a mixture of SSP and TSP, usually made by acidulation of phosphate rock with a mixtur of sulfuric and phosphoric acids. Theoretacally, any grade between SSP and TSP can be produced, but the usual range is 25% - 35% P2O5. Processes and equipment are about the same as for SSP[4]. Enriched superphosphate may be a useful product for application in sulfur-deficient areas where SSP would supply more sulfur than necessary. One advantage is that mixed acid of the proper concentration can be obtained by mixing concentrated sulfuric acid(93% or 98% H2SO4) with dilute phosphoric acid(30% P2O5), thereby avoiding the need for concentrating the latter. Ground Phosphate rock is effective only on acid soils (pH 6 or less). This statement applies to apatitic rocks not to calcined aluminum phosphate ores that are effective on neutral or calcareous soils. Phosphate rocks are also more effective in warmer climates, in moist soils, and on crops that have fairly long-term growing patterns. They are less effective for short-season crops grown under cool soil temperatures, particularly in the first year of application. It is generally agreed that the rock should be finely ground and well mixed with the soil. However, there is some difference of opinion as to the usefulness of very fine grinding. The majority opinion seems to be that there is little to be gained by grinding finer than about 90% through 100-mesh (0.147 mm), although there are some who claim that very fine grinding such as 80% through 320-mesh (0.043 mm) is worthwhile. Ground rock that has been granulated after grinding has given rather poor first-crop results even when the granules disintegrate in the soil, presumably because granulation reduces the area of contact with the soil. However, in most of the tests, the granules have been in the range of 1-4 mm. While it is generally agreed that reactivity is important, there is some disagreement as to how important it is and how to measure it. Chemical methods for evaluating reactivity are discussed later. The importance of reactivity is greatest for the first crop or season; the long-term or residual effectiveness does not seem to be closely related to reactivity. Rocks of relatively low reactivity have shown good long-term effectiveness. Some investigators have attributed the response to phosphate rock to annul rainfall; better results were obtained on well-watered soils. Ground phosphate rock has been advocated and used for reclaiming low-phosphorus soils of abandoned farms or of new (previously uncultivated) land of low native phosphorus fertility. Calcination is carried out in a fluidized bed. Experiments showed that maximum citrate solubility was obtained in the range of 4000 – 6000C. The maximum solubility in alkaline ammonium citrate solution was about 70%; the solubility in 2% citric acid solution is much lower, about 20% - 30% [5]. The product is used for direct application after being ground to pass a 100-mesh (0.15mm) screen. 14.3 Basic Slag Basic slag, also called Thomas slag, is a byproduct of the steel industry. Iron made from high-phosphorus ore is converted to steel in a Thomas converter by oxidation in contact with a basic (high CaO) slag. The usual range of P2O5 content in slag that is used for phosphate fertilization is 10% - 20%. Sometimes phosphate rock is deliberately added to the blast furnace charge to increase the phosphorus content of the iron and thereby increase the P2O5 content of the slag. Basic open-hearth slag also may contain P2O5 up to 10% - 20%, and it is used in agriculture in some countries, both for liming and phosphorus supply. The P2O5 in basic slag is mainly present as calcium silicophosphates – silicocarnotite (5CaO•P2O5•SiO2) and nagelschmitite (7CaO•P2O5•SiO2). Small amounts of fluorspar (CaF2) may be added to slags to decrease their viscosity during the steel-refining process. Such slags contain fluorapatite and are likely to be less suitable for fertilizer use. Potassium Phosphates Potassium Phosphates are excellent fertilizers, and their very high analysis is an advantage that has stimulated much research in an effort to find an echonomical production process. However, no process has been developed that is economical enough to result in widespread production; therefore, present use is limited to special purposes for which the high cost can be justified. At present, most of the potassium phosphates used in fertilizers are produced from potassium hydroxide or carbonate and phosphoric acid and are used in liquids for foliar application or other specialty uses. Some of the alternative salts of potassium phosphates are given in table 14.7. Phosphate Potassium Salts Compound Formula Grade Monopotassium phosphate KH2PO4 0-52-35 Dipotassium phosphate K2HPO4 0-40-54 Tetra potassium pyrophosphate K4P2O7 0-43-57 Potassium metaphosphate KPO3 0-60-40 In addition, a potassium polyphosphate solution of 0-26-27 grade has been produced from superphosphoric acid and potassium hydroxide; it contains a mixture of ortho, pyro, and higher polyphosphates. TVA, SAI, and others have produced potassium metaphosphate in pilot plants by hightemperature reaction of KCl and phosphoric acid. The pure material, KPO3, has a grade of about 0-60-40 and, thus, a 100% nutrient content (on an oxide basis). Bone Meal Bone meal is a mixture of crushed and coarsely ground bones that is used as an organic fertilizer for plants and formerly in animal feed. As a slow-release fertilizer, bone meal is primarily used as a source of phosphorus. As a fertilizer, the N-P-K ratio of bone meal is generally 4-12-0, though some steamed bone meals have N-P-Ks of 1-13-0. Bone meal is also an excellent organic source of calcium. Organic fertilizers usually require the use of microbes/bacteria in the soil in order to make the nutrients in the fertilizer bio-available. That can result in irregular release of phosphorus/calcium. In sterile potting soil, there may be no microbes to release the nutrients. Finely ground bone meal may provide quicker release than coarsely ground. Phosphates do not easily pass through soil. So mixing the bone meal with the soil or putting it in the planting hole can help. Fused Calcium Magnesium Phosphate If a mixture of phosphate rock and olivine or serpentine (magnesium silicate) is fused in an electric furnace [11]. The molten product is quenched with water and used in a finely divided state as a fertilizer. The product, a calcium magnesium phosphate (CMP) glass, contains about 20% P2O5 and 15% MgO. Over 90% of the product is soluble in citric acid. The theoretical compositions of some magnesium-containing minerals that can be used to produce CMP are: Olivine (Mg, Fe)2 SiO4 Serpentine Mg3 H4SiO9 Garnierite (Mg, Ni) H2SiO4 Magnesite MgCO3 The minerals are variable in compositions; iron, nickel, and sometimes manganese may substitute for magnesium. Magnesium oxide, obtained by calcining magnesite or extracting it from sea water, can be used in the process; in this case, silica must be added in sufficient quantity to result in 20% - 30% SiO2 in the product.