* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download edc-module_ia-dc_generator

Electric power system wikipedia , lookup

Brushless DC electric motor wikipedia , lookup

Control system wikipedia , lookup

Transformer wikipedia , lookup

Power inverter wikipedia , lookup

Electrical ballast wikipedia , lookup

Electrical substation wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Power engineering wikipedia , lookup

Three-phase electric power wikipedia , lookup

Opto-isolator wikipedia , lookup

History of electric power transmission wikipedia , lookup

Electrification wikipedia , lookup

Current source wikipedia , lookup

Electric motor wikipedia , lookup

Surge protector wikipedia , lookup

Power MOSFET wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Power electronics wikipedia , lookup

Voltage regulator wikipedia , lookup

Stray voltage wikipedia , lookup

Induction motor wikipedia , lookup

Commutator (electric) wikipedia , lookup

Stepper motor wikipedia , lookup

Distribution management system wikipedia , lookup

Mains electricity wikipedia , lookup

Voltage optimisation wikipedia , lookup

Electric machine wikipedia , lookup

Buck converter wikipedia , lookup

Alternating current wikipedia , lookup

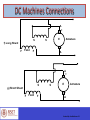

EC010504(EE) Electric Drives & Control Dr. Unnikrishnan P.C. Professor, EEE Dr. Unnikrishnan P.C. BTech. : EEE, NSS College of Engineering, 1981-85. MTech: Control & Instrumentation, IIT Bombay,1990-92. PhD. : EEE, Karpagam University, Coimbatore, 2010-2016. Dr. Unnikrishnan P.C. 1986-1996 : Assistant Professor and Associate Professor, Rajasthan Technical University, Kota, India 1996-2016 : Assistant Professor, Academic Coordinator, Registrar, Head of Section and Head of the Department at Colleges of Technology, Ministry of Manpower, Muscat, Sultanate of Oman. 2016 : Professor, EEE, RSET Module I DC Generator DC Motor DC Machines Working principle of DC Generator Working principle of DC motor Construction of DC Machines Parts of DC Machine Field winding Rotor and rotor winding DC Machines- Direction of Power Flow and Losses DC Machines- Direction of Power Flow and Losses DC Machines Analysis Symbols that will be used. = flux per pole p = no. of poles z = total number of active conductors on the armature a = no. of parallel paths in the armature winding Aside: Lap Winding -> a = p Wave Winding -> a = 2 n = speed of rotation of the armature in rpm wm = speed in radians per second DC Machines Connections + Ra If + VT E - + a) Field E F F Armature - b) Separately Excited DC Machines Connections + E Armature Field F F - c) Series A + E Armature Field F F d) Shunt A DC Machines Connections A + e) Cummulative Compound S F Field E S Armature F A A + S S E Armature d) Differential Compound F Field F A DC Machines Connections A + S E S Armature f) Long Shunt F Field F A A + S S E Armature g) Short Shunt F Field F A EMF Equation When the rotor rotates in the field a voltage is developed in the armature. - the flux cut by one conductor in one rotation = p - therefore in n rotations, the flux cut by one conductor = np EMF Equation ∅𝑧𝑛 𝑝 𝑧 𝑝 𝑛 2𝜋 𝐸𝑎 = = ∅ 60 𝑎 𝑎 2𝜋 60 = ∅ 𝐾𝑎 𝜔𝑚 =𝐾𝑎 ∅ 𝜔𝑚 where 𝑘𝑎 = 𝑧𝑝 2𝜋𝑎 EMF induced in the armature windings TORQUE EQUATION 𝐸𝑎 𝐼𝑎 = 𝑇𝑒 𝜔𝑚 𝐸𝑎 𝐼𝑎 𝑇𝑒 = 𝜔𝑚 𝑘∅𝜔𝑚 𝐼𝑎 = 𝜔𝑚 = 𝑘∅𝐼𝑎 - In the DC machine losses are expressed as rotational losses due to friction and windage (F&W). - The torque equation can then be rewritten as:- SHAFT OUTPUT TORQUE = (Te - TF&W) DC Generator Ia Ea Nz p 60 a V Ea Ia R a L V I L f R f Ia I I f L + E Rf - + If Ra L O A D VT - Note: VT = VL i.e. Terminal Voltage is the Load Voltage OPEN CIRCUIT CHARACTERISTICS The Open Circuit characteristic is a graph relating Open-Circuit Armature voltage of a D.C. Generator versus its field current when the machine is driven at it’s rated speed DC Source Field Regulator Ra ZZ FL Rf F L OPEN CIRCUIT AA Ea V Z A A Field Current Diagram showing motor connections for the open circuit test, separately excited The D.C. Generator field is excited by a separate D.C. source and the current is varied using a generator Field Regulator (a potential divider). OPEN CIRCUIT CHARACTERISTICS Rext is set to its maximum value. The D.C. Generator is driven at rated its speed. Rext is decrease to a lower value so that the machine self-excites ( i.e.. Develop an e.m.f). A Field Current Ra Rext 970 ohms Z Rf ZZ A V VT Ea AA Diagram showing the D.C. Generator as a self-excited shunt machine EXTERNAL CHARACTERISTIC OF SHUNT GENERATOR This is a graph relating terminal voltage and the load current of a D.C. Generator when driven at its rated speed with the field current maintained at its normal no-load value. A A Field Current Load Current Ra Rext 970 ohms Z Rf ZZ A V Ea Terminal Voltage AA Diagram showing connections for load test. L O A D Armature Reaction Interaction of Main field flux with Armature field flux Effects of Armature Reaction It decreases the efficiency of the machine It produces sparking at the brushes It produces a demagnetising effect on the main poles It reduces the emf induced Self excited generators some times fail to build up emf Armature reaction remedies 1. Brushes must be shifted to the new position of the MNA 2. Extra turns in the field winding 3. Slots are made on the tips to increase the reluctance 4. The laminated cores of the shoe are staggered 5. In big machines the compensating winding at pole shoes produces a flux which just opposes the armature mmf flux automatically. Commutation The change in direction of current takes place when the conductors are along the brush axis During this reverse process brushes short circuit that coil and undergone commutation Due to this sparking is produced and the brushes will be damaged and also causes voltage dropping. Losses in DC Generators 1. Copper losses or variable losses 2. Stray losses or constant losses Stray losses : consist of (a) iron losses or core losses and (b) windage and friction losses . Iron losses : occurs in the core of the machine due to change of magnetic flux in the core . Consist of hysteresis loss and eddy current loss. Hysteresis loss depends upon the frequency , Flux density , volume and type of the core . Losses Hysteresis loss depends upon the frequency , Flux density , volume and type of the core . Eddy current losses : directly proportional to the flux density , frequency , thickness of the lamination . Windage and friction losses are constant due to the opposition of wind and friction . Applications Shunt Generators: a. in electro plating b. for battery recharging c. as exciters for AC generators. Series Generators : a. As boosters b. As lighting arc lamps DC Generator Characteristics In general, three characteristics specify the steady-state performance of a DC generators: 1. Open-circuit characteristics: generated voltage versus field current at constant speed. 2. External characteristic: terminal voltage versus load current at constant speed. 3. Load characteristic: terminal voltage versus field current at constant armature current and speed. DC Generator Characteristics The terminal voltage of a dc generator is given by Vt Ea I a Ra f I f , m Armature reaction drop I a Ra Open-circuit and load characteristics DC Generator Characteristics It can be seen from the external characteristics that the terminal voltage falls slightly as the load current increases. Voltage regulation is defined as the percentage change E V Voltage regulation 100 in terminal voltage when full load is V removed, so that from the external characteristics, a t t Ea Vt Voltage regulation 100 Vt External characteristics Self-Excited DC Shunt Generator Maximum permissible value of the field resistance if the terminal voltage has to build up. Schematic diagram of connection Open-circuit characteristic Shunt motor: Speed Control in DC Motors Electromagnetic torque is Te=Ka d Ia, and the conductor emf is Ea=Vt - RaIa. Te Ra K a d m Vt K a d Vt Te Ra m K a d K a d 2 1 For armature voltage control: Ra and If are constant 2 m K1Vt K 2Te For field control: Ra and Vt are constant m Vt Ra KfIf KfIf T 2 e 3 For armature resistance control: Vt and If are constant Ra Radj Vt m Te K a d K a d 2 4 Speed Control in Shunt DC Motors Armature Voltage Control: Ra and If are kept constant and the armature terminal voltage is varied to change the motor speed. m K1Vt K 2Te K1 1 1 ; K2 ; d is const . 2 K a d K a d For constant load torque, such as applied by an elevator or hoist crane load, the speed will change linearly with Vt. In an actual application, when the speed is changed by varying the terminal voltage, the armature current is kept constant. This method can also be applied to series motor. Field Control: Speed Control in Shunt DC Motors Ra and Vt are kept constant, field rheostat is varied to change the field current. m Vt Ra KfIf KfIf 2 Te For no-load condition, Te=0. So, no-load speed varies inversely with the field current. P Vt I a const Ea I a Te m Speed control from zero to base speed E Iis usually const . Te a a obtained by armature voltage control.m Speed control m beyond the base speed is obtained by decreasing the field current. If armature current is not to exceed its rated value (heating limit), speed control beyond the base speed is restricted to constant power, known as constant power application. Speed Control in Shunt DC Motors Armature Resistance Control: Vt and If are kept constant at their rated value, armature resistance is varied. m Ra Radj Vt Te K 5 K 6Te 2 K a d K a d The value of Radj can be adjusted to obtain various speed such that the armature current Ia (hence torque, Te=KadIa) remains constant. Armature resistance control is simple to implement. However, this method is less efficient because of loss in Radj. This resistance should also been designed to carry armature current. It is therefore more expensive than the rheostat used in the field control method. Speed Control in Series DC Motors Armature Voltage Control: A variable dc voltage can be applied to a series motor to control its speed. A variable dc voltage can be obtained from a power electronic converter. d K s I a Vt Ea I a Ra Rs K a d m I a Ra Rs K a K s I a m I a Ra Rs Ia Vt K a K s m Ra Rs Torque in a series motor can be expressed as Te K a d I a K a K s I a2 K a K sVt2 K K a or , m s m Ra Rs 2 Vt R Rs Vt a Ka K s Te K a K s Te K a K s Speed Control in Series DC Motors Armature Voltage Control: A variable dc voltage can be applied to a series motor to control its speed. A variable dc voltage can be obtained from a power electronic converter. d K s I a Vt Ea I a Ra Rs K a d m I a Ra Rs K a K s I a m I a Ra Rs Ia Vt K a K s m Ra Rs Torque in a series motor can be expressed as Te K a d I a K a K s I a2 K a K sVt2 K K a or , m s m Ra Rs 2 Vt R Rs Vt a Ka K s Te K a K s Te K a K s Speed Control in Series DC Motors Field Control: Control of field flux in a sries motor is achieved by using a diverter resistance. The developed torque can be expressed as. Rd 2 I a KI a2 Te K a d I a K a K s Rs Rd Rd where , K K a K s and Rs Rd Rs Rd Vt Ea I a I a Ra R R s d K a d m I a Rs I a Ra K a K sI a m Rs Ra I a Km Rs Ra I a or , I a Vt Km Rs Ra Speed Control in Series DC Motors Vt Te K Km Rs Ra 2 Speed Control Armature Resistance Control: in Series DC Motors Torque in this case can be expressed as Te KVt2 Ra Radj Rs Km 2 Rae is an external resistance connected in series with KVt2 2 the armature. Ra Radj Rs Km Te For a given supply voltage and a constant developed torque, the term (Ra+Rae+Rs+Km) should remain K or , R R R K Vt constant. Therefore, an increase in aRae must adj be s m Te accompanied by a corresponding decrease in m. Ra Radj Rs Vt or , m K KTe Power Division in DC Machines Arm. copper loss Ia2Ra+brush contact loss DC Generator Input from Elec-magnetic Arm. terminal Output power prime-mover Power =EaIa power = Vta Ia = V t IL No-load rotational loss (friction +windage+core)+stray load loss Series field loss IL2Rs +shunt field loss If2Rf Arm. copper loss Ia2Ra+brush contact loss DC Motor Input power from Arm. terminal Elec-magnetic Output available mains =Vt IL power = Vta Ia Power =EaIa at the shaft Series field loss IL2Rs +shunt field loss If2Rf No-load rotational loss (friction +windage+core)+stray load loss Efficiency Power Output Power Input Power Input Losses Power Input Losses 1 Power Input The losses are made up of rotational losses (3-15%), armature circuit copper losses (3-6%), and shunt field copper loss (1-5%). The voltage drop between the brush and commutator is 2V and the brush contact loss is therefore calculated as 2Ia. DC Machines Formulas Summary E a V - IaR a ´ ´ ´ n z p Ea 60 ´ a V - I a R a ÷÷ ´ 60 ´ a Speed n z´ ´ p Ea a n I 2 R a -- Windings(Armature) a I2 R -- Windings(Field ) f f and Rotational Losses (Windage and Friction) Losses