* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download TORODIAL TRANSFORMER In 1831, Michael Faraday wound three

Electronic engineering wikipedia , lookup

Utility frequency wikipedia , lookup

Electrification wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Telecommunications engineering wikipedia , lookup

Electric machine wikipedia , lookup

Power inverter wikipedia , lookup

Mains electricity wikipedia , lookup

Opto-isolator wikipedia , lookup

Amtrak's 25 Hz traction power system wikipedia , lookup

Magnetic-core memory wikipedia , lookup

Power engineering wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Three-phase electric power wikipedia , lookup

Electrical substation wikipedia , lookup

Single-wire earth return wikipedia , lookup

Resonant inductive coupling wikipedia , lookup

Alternating current wikipedia , lookup

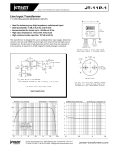

TORODIAL TRANSFORMER In 1831, Michael Faraday wound three lengths of wire 24 ft. long for the primary winding and two lengths of wire 30 ft. long for the secondary winding, to shape the world’s first transformer which was Toroidal. Development in the mid 1900s have since made toroids a practical possibility. Today experts worldwide rate Toroidal Transformers far higher than all other transformers. The reasons are simple. Compact size , superior performance. Durability and cost efficiency. Yet the Indian electronic and electrical industries are forced to use ‘E & I ‘ core transformers because of unavailability of indigenous Toroidal Transformers. Wherever design parameters dictate the use of Toroidal Transformers, import till now was the only answer. This is ESPEE ELECTRICALS can make a difference. And provide winning solutions in the world of transformers. The Company ESPEE is a pioneer in the manufacture of Toroidal Power Transformers in India. Its thrust is towards customized Toroidal Transformers for the domestic and international markets. The Product Espee Toroidal Transformers have a Va rating between 50 to 3 KVA. Their tape wound CRGO silicon steel core are constructed with metal tape wound onto a mandrel under closely controlled tension, then annealed and treated to fully develop the required magnetic characteristics of Torodial cores are never dependent on their assembly. The air gap in this core is zero. The super enameled copper wire is then wound by an automatic winding machine uniformly around the entire length of the toroid, assuring uniform quality. The shape of the core is such that the magnetic field of the toroid is contained within itself. Hence there’s no radiation of stray magnetic flux and the Transformer can be placed in high density electronic circuitry without any interfering hum. Leakage inductance and stray capacitance are also very small. And when the Toroidal Transformer is placed in an interfering field, the interfering forces tend to act equally all around the toroid, resulting in the cancellation of interfering voltages in the coils in a manner similar to the astatic windings. The Advantages ESPEE Toroidal Transformers have a number of obvious advantages over the conventional ‘E & I’ core transformers. They are as follows. Maximum utilization of the flux density generated leads to higher efficiency and lower percentage regulation. Lack of interfering hum eliminates the need for magnetic shielding , which is required by conventional transformers, and also enables the toroid to be fitted into electronic circuitry without causing electrical interference. The winding covers the entire length of the core thus further minimizing the leakage inductance by maintaining all the lines of flux within the core itself. The air gap losses in a Toroidal Transformer are nil and the superior CRGO core results in negligible energy loss leading to greater efficiency and superior performance and that too at a lower cost. The height of a Toroidal Transformer is considerably lower than the ‘E’ & ‘I’ core transformer. Which means that it’s ideal for ‘Slimline’ electronics. Moreover, the variable core geometry ensures that a Toroidal Transformer can be designed to fit in a specific space – a tremendous advantage where space is a constraint. Its compact size makes the Toroidal Transformer lighter than other transformers. A single bolt mounting eliminates the need for an additional bracket and mounting bolts leading to easier mounting and a lighter end product. The Toroidal Transformer is cooler because its surface area is greater than other transformers. The characteristics of toroids are never dependent on the way the use assembles the core; they are assembled and treated at the factory for optimum results which enhances performance. Toroidal Transformers come in a variety of finishes. You can chose from metal case, thermoplastic resin filled case, thermosetting varnish glass cloth, cotton cloth and plastic tape finishes. The Applications Toroidal transformers enjoy diverse applications. They can be used as Power Transformers, Impedance Transformers, Isolation Transformers, and Inverter/Converter Transformers various sizes and specifications. Toroidal Transformers can replace ‘E” & ‘I’ transformers as a cheaper and far better alternative. For example, they can be used in Power Supplies for Consumer Electronics, Industrial Electronics (Control Panels, Automation), Analytical Equipment (Medical, Engineering , Electronics etc.) Communication and Broadcast, equipment (Receivers Transmitters, EPBAX , Electronic Switching Systems etc.,) D.C. regulated and unregulated Power Supplies, Laboratory Power Supplies, Voltage Stabilizers, DC Converters, Inverters, Battery Chargers, Battery Eliminators, Uninterrupted power supplies. The Services A toroidal transformer is designed and developed by Espee Electricals only after it receives specifics from the clients. A detailed report accompanies the transformer design to the client . Espee also has the capability to assist in mounting, chassis design and incorporation of Toroidal Transformers into existing or new equipment.