* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Propulsion systems

Orbital mechanics wikipedia , lookup

Photonic laser thruster wikipedia , lookup

Ion thruster wikipedia , lookup

Gravity assist wikipedia , lookup

Polar Satellite Launch Vehicle wikipedia , lookup

Reusable launch system wikipedia , lookup

Rocket engine wikipedia , lookup

Saturn (rocket family) wikipedia , lookup

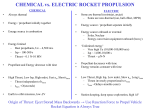

Flight dynamics (spacecraft) wikipedia , lookup

Spring 2011: [F&S, Chapter 6] Q; What velocity, v, do I need to just escape the gravitational pull of the planet? (the escape velocity). A: Think about the energies involved! Initial state: 1 2 mv Kinetic energy = 0 (planet) + 2 Gravitational potential energy = GMm r Final state: Kinetic energy = 0 (planet) + 0 (spacecraft) GMm 0 Gravitational potential energy = Initial state energy must equal final state energy 1 2 GMm mv 00 Therefore: 2 r 1 2 GMm mv 2 r 1 2 GM v 2 r 2GM 2 v r 2GM LEARN THIS DERIVATION v AND THE FINAL EQUATION! r Conceptually The various phases of a space mission from ‘concept’ through to ‘end-of-life’ phase. An appreciation of some of the details of each of these phases and how financial, engineering and science constraints etc. affect mission design. How a spacecraft’s environment changes from ground level, near earth orbit and deep space. How these environments (radiation, thermal, dust etc.) feedback into the final mission design. Mathematically Understand how to use the drag equation to work out the force on a body as it travels through the atmosphere Calculate the solar constant for Earth and (other bodies) making justifiable assumptions. Derive the escape velocity of a body. Spring 2011: [F&S, Chapter 6] 4 major tasks: 1. Launch 2. Station/trajectory acquisition 3. Station/trajectory keeping (staying where it should be, or going in the correct direction). 4. Attitude control (pointing in the correct direction) Launch Need lift-off acceleration, a, to be greater than gravitational acceleration, g. (“a>g”) for an extended period. This implies a very high thrust for a long duration. E.g., the shuttle main engine: 2 x 106 N for 8 minutes. Typical Δv ≥ 9.5 km s-1 (including drag and gravity losses). Launch phase (continued) Still difficult to achieve with current technology Only achievable with chemical rockets Massive launch vehicles required for relatively small payloads Major constraint for spacecraft and mission design is the mass cost: £1000s - £10,000s per kilogram. Station/trajectory acquisition Apogee motors (apogee = ‘furthest point’) ◦ Orbit circularisation ◦ Inclination removal ◦ Requires a force of ~75 kN for 60 seconds. Δv = 2 km s-1. Perigee motors (perigee=‘nearest point’) ◦ ◦ ◦ ◦ Orbit raising Payload Assist modules (‘PAM’) Interial Upper Stages (‘IUS’) Δv ~4.2 km s-1 (30° inclination parking orbit -> equatorial geostationary). Earth Escape Δv ~ 7.6 km s-1 (Mars flyby) Δv ~ 16 km s-1 (Solar system escape velocity) ◦ Without using gravity assist manoeuvres. Station/trajectory keeping Low thrust levels required (mN – 10s N) pulsed for short durations. Δv ~ 10s – 100s m s-1 over duration of mission. Attitude control (‘pointing’) Very low thrust levels for short duration Small chemical rockets Reaction wheels (diagram). Principle of operation of all propulsion systems is Newton’s third law “...for every action, there is an equal and opposite reaction...” Derivation: Need to balance exhaust (subscript ‘e’) momentum with rocket momentum. ∑momenta = 0 (Conservation of linear momentum) (Recall: momentum = mass x velocity) ∴ m dV = -dm Ve dV = -Ve dm/m So, now some maths... V m •dm is the mass ejected dm V dV Ve m m o o V Ve ln m V Vo m mo V Vo Ve [ln m ln mo ] V Vo Ve ln mo ln m mo V Vo Ve ln m •dV is the increase in speed due to the ejected mass (dm) •Ve is the exhaust velocity (ie. the velocity of the ejected mass relative to the rocket) •m is the rocket mass (subscript ‘o’ denotes initial values) In practice, drag reduces Vmax by ~0.3 – 0.5 km s-1. Tsiolkovsky’s Equation (the rocket equation). Recall (in zero g): dV dm m Ve dt dt dV dm Now add gravity: m Ve mg dt dt (diagram) dV 1 dm Ve g dt m dt 1 dV Ve dm gdt m mo m f Vs dV V e 0 mo tB 1 dm gdt m 0 Integrating previous equation: mo m f Vs tB 1 dm gdt m 0 dV V e 0 mo Vs Ve ln m gt B m o Vs Ve ln mo m f gt B mo m f mo Vs Ve ln mo ln mo m f gt B Define R as: •Vs =spacecraft velocity •Ve= exhaust velocity •gs = accl. of gravity acting on spacecraft •tB = rocket burn time •mf= mass of fuel R’ is the “effective mass ratio mo R mo m f Vs Ve ln R g s t B Ve g s t B Vs Ve ln R Ve g s t B Vs Ve ln R exp Ve Vs Ve ln R g stB R R exp Ve Therefore, want a short burn time as possible to minimise gravitational losses. Gravitational losses reduce V by ~1 km s-1 This conflicts with the requirements to reduce drag effects at low atmosphere (low speed at low altitude) Resolve conflict by using non-vertical ascent. ge = net downward accl. = gravity - centrifugal Retarding gravitational force = ge cos θ Typical launch sequence: ◦ Lift-off (straight up!) ◦ Clear tower ◦ Roll to correct heading ◦ Pitch to desired trajectory ◦ Recall space shuttle launch sequence. Rolls and pitches almost immediately after clearing tower. Reason to minimise loss dues to drag and gravity! Assume a single stage, liquid propellant chemical rocket. ◦ Fuel – kerosene ◦ Oxidiser – liquid oxygen ◦ Typical of fuel used for Atlas, Thor, Titan and Saturn rockets. Ve ~2.5 km s-1, assume mass: 20% structure, 80% fuel Recall, mo R m m f o 5 (In this case) Vmax Ve ln R 4 km s-1 •Compare with Earth’s escape velocity ~ 11 km s-1! •Velocity required for 300 km altitude Earth orbit ~7.8 km s-1. •Taking into account drag and gravity losses implies a required Vmax ≥ 9.3 km s-1 •Best performance from a fully cryogenic fuel system get Vmax ~9.5 km s-1. SOLUTION: Multi-Staging! Parallel staging ◦ Partially simultaneous operation (e.g. Space Shuttle) Series staging ◦ Sequential operation (e.g. Ariane, Saturn V etc.) Principle: jettison inert mass to reduce load for subsequent rocket stages. Stage velocity, Vs = Vmax – Vo = Ve ln R = -Ve ln (1-R) Stage velocity, Vs = Vmax – Vo = Ve ln R = -Ve ln (1-R) Jettisoning structure from stage ‘n’ increases R (the mass ratio) and thus Vs for the subsequent stages, n+1, n+2 etc. However, since Vs ∝ ln R, improvement is slow with R Assume a simple rocket where: mf = mass of propellant ms = mass of structure mo mo mp = mass of payload R m p ms mo m f mo = mf + ms + mp mo Define mass ratio, R: P mp Payload ratio, P: Structure ratio, S: m f ms mf S 1 ms ms S 1 P R SR Assume a liquid propellant chemical rocket. ◦ Fuel – kerosene ◦ Oxidiser – liquid oxygen ◦ Typical of fuel used for Atlas, Thor, Titan and Saturn rockets. Ve ~2.5 km s-1, assume: 1t structure, 8t fuel, 1t payload Recall definition of payload ratio, R mo R m m f o 1 1 8 10 5 (1 1 8) 8 2 (In this case) Now calculate the payload ratio, P and the structure ratio, S. Recall: mo = 1 + 8 +1= 10, mf = 8, ms = 1 tons. mo 10 P 10 mp 1 mf 8 S 1 1 9 ms 1 mo 10 R 5 m p ms 1 1 m0 m f m p ms R mo m p ms P mo mp S m f ms ms 1 S 1 P R S R mf ms For our kerosene rocket: Ve ~ 2.5 km s-1 , R =5 Recall, Vs = Ve ln R = 2.5 x ln 5 ~ 4 km s-1 ∴ Vs = 4 km s-1 – suborbital! Now consider this 10 ton rocket to be a payload (i.e. a stage) of a larger rocket… Therefore, assume that the mass/fuel ratio is the same for the second stage, and thus we can use the same ratios (ie, this stage is just a scaled up version of the original stage): ∴ mp= 10t and thus, mo= P x mp = 10 x 10t = 100t Now our 1 ton original payload can reach: 4 + 4 = 8 km s-1 – orbital, just… using a 100t rocket! Now consider this 100 ton rocket to be a payload (i.e. a stage) of an even larger rocket… Therefore, assume that the mass/fuel ratio is the same for the previous stage, and thus we can use the same ratios: ∴ mp= 100t and thus, mo= P x mp = 10 x 100t = 1000t Now our 1 ton original payload can reach: 4 + 4 + 4= 12 km s-1 – escape velocity using a 1000t rocket! Therefore a 3-stage kerosene rocket can put a payload into orbit, and reach Earth escape velocity, whereas a single stage could not! In general: ◦ Vmax = ∑Vs Maximum rocket velocity is the total of the stage velocities. Using conventional definitions (i.e. 1st stage is the first to burn etc.), the payload ratio of the ith stage is, Pi: m Pi oi moi1 (ie. The payload ratio of stage 1 = mass of stage 1/ mass of stage 2) Thus the total payload ratio, P is: mo1 P P1P2 P3 Pn mp The structural payload, S is: Si m fi msi msi And the mass ratio, R is: moi Ri moi m fi V V ln R Therefore, Vmax And if all stages have the same Ve s ei i Vmax Ve ln Ri Vmax Ve ln R1 ln R2 ln Rn Vmax Ve ln R R R1 R2 R3 Rn (Generally, however, this is not the case) Stage Propellant Ve (km s-1) mf (tons) ms (tons) thrust (tons wgt) burn time (secs) 1st Kerosene + O2 2.32 2160 140 3400 150 2nd H2(l) + O2(l) 4.10 420 35 450 390 3rd H2(l) + O2(l) 4.25 100 10 90 480 1st Stage 2nd Stage 3rd Stage 14.40 1.08 0.21 moi 2965 665 210 Ri 3.69 2.72 1.91 Pi 4.46 3.16 2.10 Vsi (km s-1) 3.03 4.10 2.75 Fuel consumption (tons/sec) For a payload, mp, of 100 tons Note high thrust of 1st stage High efficiency of stages 2 and 3 P for a 3 stage kerosene rocket ~90 P for the Saturn V ~ 30 (more efficient). Such a rocket could lift: 100 tons into a low earth orbit 40 tons into earth escape (i.e. to the moon) 1 ton payload to Mars! For Apollo, the Saturn V lifted the Command module to LEO. ◦ The command module went to the moon and back. ◦ ◦ ◦ ◦ Optimisation of number of stages: Q: What is the optimum number of stages? Theoretically...recall: P=payload ratio R=mass ratio S=structure ratio S 1 P R S R P P1 P2 P3 Pn R R1 R2 R3 Rn Si 1 Pi Ri S i Ri S1 1 S 2 1 P R1 R2 S1 R1 S 2 R2 Now, R=R1R2...Rn and if R1=R2=...=Rn 1 n Then: Ri R And if S1=S2=...=Sn, then: S 1 P R 1 SR n n (Effectively all this says is that the mass ratios of each stage are the same, just scaled versions of each other). Optimisation of number of stages involves minimising P ∴ want to minimise: S 1 1 n SR ∴want to maximise 1/n, i.e., n→∞. Q: Why don’t we see systems with very large numbers of small stages? Each stage requires: ◦ ◦ ◦ ◦ ◦ Engine and nozzles Ignition mechanism Separation mechanism Fuel pumps (for liquid propellants) Small stages have worse P, R and S. Therefore greater cost and complexity Thus a ‘trade-off’. ‘n=3’ is usually the maximum number of stages (some ‘n=4’, but rare). Because the Earth revolves on its axis from West to East once every 24 hours (86400 secs) a point on the Earth’s equator has a velocity of 463.83 ms-1. Reason: radius of the Earth, RE = 6.3782 x 106 metres. Earth’s circumference = 2πRE = 4.007 x 107 m Equatorial velocity = 4.007 x 107 / 86400 = 463.83 ms-1 Therefore, a spacecraft launched eastwards from the Earth’s equator would gain a free increment of velocity of 463.83 ms-1. Away from the equator the Earth has a smaller circumference which is determined by multiplying the equatorial circumference by the cosine of the latitude in degrees. For example, the Russian Baikonur Cosmodrome is at 45° 55’ north. The Earth’s rotational velocity at that point is: 322.69 m s-1. System classification: Function: ◦ Various possible schemes (see F&S, Fig. 6.1) ◦ Other ‘exotic’ systems possible ◦ “Primary propulsion” – launch ◦ “Secondary propulsion” Station/trajectory acquisition and keeping Attitude control Recall: vastly different requirements for different purposes: ◦ ΔV of m s-1 – km s-1 ◦ Thrust of mN – MN ◦ Accelerations of μg - >10g Different technologies applicable to different functions/regimes. Principle: ◦ Combustion of propellants at high pressure in a small confined volume produces high temperature gas. ◦ Expansion through nozzles convert random thermal energy to directed kinetic energy: “thrust”. Propellants: ◦ And fuel and oxidiser undergoing exothermic reaction producing gaseous products. Considerations: ◦ Specific energy content, rate of heat release, storage, handling, etc. Chemical rocket types: ◦ Solid propellant ◦ Liquid propellant ◦ Hybrid (usually solid fuel and a liquid oxidiser) Solid propellant rockets: ◦ ◦ ◦ ◦ ◦ Oldest rocket technology – Chinese 12th Century. Very simple – no moving parts (nozzles?) Only needs an igniter and a douser Fuel stored in combustion chamber Relatively cheap Solid propellant rockets (continued) Advantages: ◦ ◦ ◦ ◦ Simple and cheap Reliable High thrust High energy density propellant thus small volume Disadvantages: ◦ Only limited throttling ◦ Generally only single burn (a firework effectively). Solid propellant rockets (continued) Propellant is a fuel and oxidiser matrix with aluminium powder regulator. Cast directly into casing of rocket Thrust is proportional to burn rate “Cigarette mode” – long duration, low thrust because of small combustion area. Axial ignition used to increase burn area and increase thrust. Solid propellant rockets (continued) Burn area and thrust defined by ‘grain’, produced by the mandrel during casting of the fuel. This gives a limited amount of “preprogrammed” throttling of the propellant. Ignition is via a pyrotechnic device which ignites the propellant in the igniter. Axial burn. Applications: ◦ Early launch vehicles (missiles) ◦ Launch vehicle strap-on boosters (e.g. Titan, Ariane, Shuttle) ◦ Secondary propulsion Liquid propellant rockets First flight 16th March 1926. ◦ Robert Goddard using liquid oxygen and gasoline Max altitude = 12.5 metres Flight time = 2.5 seconds Engine thrust ~ 40 N Vmax ~ 96 km/hour Landed 56 metres from launch site Advantages ◦ Long burn time ◦ Controllability Throttling On-off-on operation Emergency shutdown Redundant systems Liquid propellants (continued) Disadvantages ◦ Complexity and reliability ◦ Cost ◦ Mass Requirements ◦ Separate storage of fuel and oxidiser remote from combustion chamber ◦ Thus need propellant pump and feed system ◦ Chamber injector and mixer ◦ Igniter, combustion chamber and exit nozzle Liquid propellants ◦ ◦ ◦ ◦ ◦ (Kerosene/ethanol) + liquid oxygen + N2O4 Monomethyl hydrazine (‘MMH’) Unsymmetrical dimethyl hydrazine (‘UDHM’) Aerozine50 (50/50 mix of hydrazine and UDMH) Liquid hydrogen and liquid oxygen (cryogenic propellants) Some combinations require ignition, others (known as ‘hypergols’) are self-igniting as soon as the fuel + oxidiser mix (e.g. Aerozine50 and N2O4). Applications ◦ Most modern launch vehicles ◦ Secondary propulsion systems Manned spacecraft, mainly reusable (unlike Ariane) Expensive “launch vehicle” Designed to be multi-purpose ◦ ◦ ◦ ◦ ◦ Laboratory (‘Spacelab’) Recovery repair and return of satellites Space station servicing Launch of satellites Just about to be retired! Primary propulsion system, two elements: ◦ External fuel tanks feeding SSME (‘Space Shuttle Main Engines’, x3) ◦ Two solid rocket strap-on boosters Burn for 120 seconds, separate, parachute into ocean 300 km downrange for recovery and reuse. ◦ SSMEs use closed cycle combustion with a chamber pressure of 207 Bar (20.7 GPa) and a burn time of 480 seconds ◦ 100% thrust ~2.1 x 106 N. ◦ External fuel tank jettisoned (and burns up) pre orbital insertion. The space shuttle combines liquid and solid propellants. Solid propellants give a lower ‘specfic impulse’ (thrust per mass of propellant) but are compact, simple and stable. Once ignited it burns continuously. Thrust can only be controlled by varying the burn area. The liquid propellant in the STS combines hydrogen and oxygen and can be throttled to vary the thrust. The STS uses 2 SRBM (‘Solid Rocket Booster Motors’) and the liquid propellant in the main external tank during launch. Thrusters (secondary propulsion units). Once in space there is still a need for thrust. There are two main types: ◦ Sustained high thrust for orbital manoeuvring etc. ◦ Low thrust for atitude control (rotate the spacecraft, or to controls its spin rate etc.) Cold gas thrusters ◦ Take an inert gas (nitrogen or argon) stored at high pressure and connected to a series of valves. ◦ The thrusters are arranged off-axis to control spin/rotation. ◦ Specific impulse is low with low volumes of gas ◦ Typical thrust ~10 mN in short bursts. Monopropellant The decomposition of hydrazine (N2H4) generates heat. Expansion of the hot gas through nozzles produces a specific impulse. Hydrazine is a liquid between 275 – 387 K and is held under pressure in tanks. Can provide ~10 N for orbital control and station keeping. Bi-propellant E.g. MMH/nitrogen tetroxide Propellants burn on contact They are mixed in the thruster/apogee motor and can provide sustained thrust. Can be used for orbital rising as well as atitude control. Provides precise amounts of thrust on demand. Solid propellant apogee motors To launch into GEO etc. usually launch to a LEO and then boost with a final stage burn. To achieve a high, circular orbit at apogee, need a high thrust, short duration burn Usually provided by a solid propellant apogee motor. For a GEO satellite of 1000 kg need 900 kg of propellant and a ΔV of ~2 km s-1. Burn for 40-60 seconds with an average thrust of 50 – 75 kN Shuttle external tank and SRBs The characteristic feature of the SRB’s thrust curve’s profile is the period of reduced thrust (to about 70% of max. 50 secs. into the flight) giving a ‘sway-backed’ appearance (below). Its purpose is to reduce the thrust while the shuttle is passing through the region of maximum dynamic pressure. This is when the product of velocity and air pressure is a maximum and when the possibility of damage by aerodynamic forces is greatest. Therefore minimise risk by reducing thrust for a short period. Another term sometimes seen is the ‘thrust impulse’, Is. It is simply defined as: Ve IS g And has units of “seconds”. The larger IS the greater the effective thrust (recall Ve is the exhaust velocity). Amount of thrust generated is proportional to exposed (burning) surface area of propellant. Cross-sections of various solid propellant castings and associated thrust profiles.