* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Utilisation of Whey

Survey

Document related concepts

Rosetta@home wikipedia , lookup

Circular dichroism wikipedia , lookup

Homology modeling wikipedia , lookup

Protein design wikipedia , lookup

Protein domain wikipedia , lookup

Bimolecular fluorescence complementation wikipedia , lookup

Protein folding wikipedia , lookup

Trimeric autotransporter adhesin wikipedia , lookup

Intrinsically disordered proteins wikipedia , lookup

Protein moonlighting wikipedia , lookup

Protein structure prediction wikipedia , lookup

Protein mass spectrometry wikipedia , lookup

List of types of proteins wikipedia , lookup

Nuclear magnetic resonance spectroscopy of proteins wikipedia , lookup

Protein purification wikipedia , lookup

Transcript

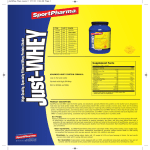

Whey A by-product of the Dairy Industry Aidan Doyle, Hugh Holland, And Mark Naughton Introduction to Whey Whey or milk plasma is the liquid remaining after milk has been curdled and strained; it is a by-product of the manufacture of cheese or casein and has several commercial uses. Whey is used to produce ricotta and gjetost cheeses and is used to make many other products for human consumption and as an animal feed. The whey protein separated from this mixture is often sold as a nutritional supplement. In addition, liquid whey contains lactose, vitamins, and minerals along with traces of fat. Because there are many types of cheese, there are many types of whey; but they fall into two major categories: sour/acid whey and sweet whey. Sweet whey. This is also termed cheese whey and is produced during cheesemaking, when rennet is used. Sweet whey forms a very large family of products. Their compositions may vary only slightly but their properties are very different. The pH value of sweet whey can range between 5.2 and 6.7 Sour whey. This can be acid whey, quark or cottage-cheese whey and sour sweet whey. Acid whey, also known as casein whey, originates from the manufacture of casein by means of lactic acid and hydrochloric acid. The origin of quark or cottage-cheese whey is self-explanatory. Lactic acid created through natural fermentation gives the whey a high acidity. The pH values of these types of whey range from 3.8 to 4.6. If insufficient care is given to the cheese whey, it becomes sourer by continued natural fermentation. Such a process is of course undesirable so that soured (not sour) whey cannot be considered a natural product Individual Whey Proteins Whey does not have a constant composition. The concentrations of individual proteins are affected by breed of cow, climate and weather, and stage of lactation. The whey composition is somewhat influenced by the type of cheese being made, as well. Carbery Group Ltd Whey Protein b -lactoglobulin 50% a -lactalbumin 20% Immunoglobulins 20% Serum Albumin 5% Minor Proteins 5% b -Lactoglobulin. This predominant whey protein naturally exists as a dimer consisting of two identical monomer units, each having a molecular weight of 18,000. It thus behaves like a protein with a MW of 36,000 and retains this form throughout most milk processing and food applications. Most of the functionality of whey products can be accurately predicted from studies of the pure b -lactoglobulin. Until recently its purpose was completely unknown, and the protein is absent from the milk of some species, including humans. Dairy scientists have now discovered that it binds very strongly to retinol, the most important form of vitamin A in food and feeds, and it is thought to play a significant role in the transport and absorption of vitamin A in the intestinal tract. a -Lactalbumin. This second most abundant whey protein has a molecular weight of about 14,400 and interacts with b -lactoglobulin on denaturation to account for virtually all of the whey protein functionality. By itself, a -lactalbumin is much more readily heat-denatured than b -lactoglobulin, but it readily reverts to its native form when the heat is removed. This led earlier researchers to report that it is very heatstable, based on their comparisons of its structure before and after heating. When both a -lactalbumin and b -lactoglobulin are present, as they are in whey protein concentrates and whey protein isolates, they form intermolecular crosslinks on denaturation which stabilize the unfolded form of a -lactalbumin after the mixture is cooled. It has been known for some time that a -lactalbumin plays an important part in the enzymic process for synthesizing lactose in mammary tissue. One should not confuse the specific protein, a -lactalbumin, with the commercial protein preparation known as "lactalbumin" which is a heat-precipitated mixture of whey proteins. Immunoglobulins. The immunoglobulins in whey are antibodies, of the types IgA, IgG, IgE and IgM, with molecular weights of 150,000 to 450,000 or greater. Some of them represent the normal antibody components of the cow and are the same as those found in the bloodstream; however, there is a secretory form of IgA which is produced in the mammary gland in response to infectious organisms. From a physiological standpoint, the immunoglobulins are important in establishing the infection-fighting capacity of the newborn calf, and they are present in very high concentrations in the first milk of lactation, called colostrum. They are of high nutritional value but do not appear to play an essential physiological role in the adult animal or in the use of bovine milk or whey for human consumption. Serum Albumin. As the name implies, serum albumin (also known as BSA) comes from the cow’s bloodstream where it is the carrier of free fatty acids and is important in maintaining the physical properties of the blood serum. It has a molecular weight of 68,000 and is quite high in the amino acid cystine. Serum albumin is present in the milks of all known species and apparently comes directly from the bloodstream. Minor Proteins. The least numerous 5% of the whey proteins are of many types, which were often simply assigned to the category "proteose peptones" before the individual components had been identified. Some of them represent breakdown products of the caseins which were formed either before or during cheese making. Others are specific enzymes or other proteins which have known physiological functions. A few of these minor proteins are worthy of more detailed discussion here. Glycomacropeptide is not normally tallied as part of the milk serum proteins because it is not present until cheese is made, but it can potentially account for more than 16% of the protein in commercial whey products. The cheese making process involves treating milk with a proteolytic enzyme of the class known as rennet’s. These enzymes break a specific peptide bond in k -casein between the phenylalanine at position 105 and the methionine at position 106, which destabilizes the casein micelle and allows the cheese curd to form. The part of k -casein consisting of amino acid residues 1-105 is known as para-k -casein and stays with the cheese. The portion consisting of residues 106-169 is released into the whey and is known as glycomacropeptide (GMP) because it usually contains a number of carbohydrate attachments (hence the "glyco-" term). Its molecular weight, based on its amino acid content, is about 7,000; however, the carbohydrate units make it behave as if it were somewhat larger. This is important because the ultrafiltration membranes used to prepare whey protein concentrates and whey protein isolates perform their function based on molecular size. GMP was not recognized as a major whey protein for many years because of two unusual characteristics. It contains no aromatic amino acids (phenylalanine, tyrosine and tryptophan) so it does not absorb ultraviolet light at 280 nm, which is the most common means of detecting proteins which are being analyzed by high-performance liquid chromatography (HPLC). Furthermore, it does not readily bind Coomassie Blue, the stain that is usually employed to detect individual protein bands on polyacrylamide electrophoresis gels. Thus, GMP is rendered invisible in the most powerful methods for studying protein mixtures unless special procedures are used to detect it. PROCESSING OF WHEY Membrane Filtration Membrane processing is a technique that permits concentration and separation without the use of heat. Particles are separated on the basis of their molecular size and shape with the use of pressure and specially designed semi-permeable membranes. There are some fairly new developments in terms of commercial reality and is gaining readily in its applications: There two main forms of membrane filtration involved in the whey processing industry Ultrafiltration (UF) and Microfiltration (MF). Ultrafilteration Ultrafiltration (UF) designates a membrane separation process, driven by a pressure gradient, in which the membrane fractionates components of a liquid as a function of their solvated size and structure. The membrane configuration is usually cross-flow. In UF, the membrane pore size is larger allowing some components to pass through the pores with the water. It is a separation/ fractionation process using a 10,000 MW cutoff, 40 psig, and temperatures of 50-60°C with polysulfone membranes. In UF milk, lactose and minerals pass in a 50% separation ratio; for example, in the retentate would be 100% of fat, 100% of protein, 50% of lactose, and 50% of free minerals. Diafiltration is a specialized type of ultrafiltration process in which the retentate is diluted with water and re-ultrafiltered, to reduce the concentration of soluble permeate components and increase further the concentration of retained components. Microfiltration Microfiltration (MF) designates a membrane separation process similar to UF but with even larger membrane pore size allowing particles in the range of 0.2 to 2 micrometers to pass through. The pressure used is generally lower than that of UF process. The membrane configuration is usually cross-flow. MF is used in the dairy industry for making low-heat sterile milk as proteins may pass through but bacteria do not. The most valuable component of whey is the whey proteins. Ultrafiltration and diafiltration membrane technology have provided the means to further concentrate and separate whey components. The protein and fat (retentate) in the whey are separated from the lactose and minerals (permeate) by these processes. Once whey is dried, a producer can provide "whey protein concentrates," or WPCs, with protein levels from 34% to 90%. Figure 1. The Whey filtration process WPCs have been around for years, but product developers can expect better performance today. A higher quality product means improved functionality for the product developer. Some of the basic properties that a WPC can provide in a food application are whipping/foaming, emulsification, high solubility, gelation, water-binding, and viscosity development. Generally, WPCs with higher protein content have improved functionality over those with lower protein content. Some very exciting work in progress involves the use of 34% WPC in various food applications. This demonstrates their ability to work well in some applications, but not in conflict with the applications designed for the higher protein ingredients. High solubility over a wide pH range makes WPCs a good candidate for a sports beverage or meal-replacement beverage. Their water-binding capabilities also make them suitable for processed meats, cakes or breads. Gelation characteristics will increase WPC benefits in some of the same products that profit from water-binding. Salad dressings, coffee whiteners, soups, cakes, infant formulas and sausages all can utilize the emulsification abilities of WPC. They also address the functional needs of viscosity in products such as soups and gravies. Cakes, desserts and whipped toppings can always use the added foam stability of a WPC. Whey protein conformation and functionality are interrelated and dictated by changes in their globular folded structure. Their functional properties are affected by several factors within a food application, including concentration, state of the whey proteins, pH, ionic environment, (pre-) heat treatment and the presence of lipids. In the native state, whey proteins are highly soluble and adeptly perform emulsification and whipping functions in a food application. However, heating whey proteins can result in a loss of solubility due to denaturation of the proteins, especially in the pH range of 4.0 to 6.5. While solubility is adversely affected by heat, emulsification can be improved through controlled heat denaturation of the protein. As the whey protein unfolds, hydrophobic amino acid residues are exposed, which enhance the ability of the protein to orient at the oil/water interface. The presence of salts during the emulsification process influences whey protein conformation and solubility. In their undenatured form, whey proteins can form rigid gels that hold water and fat, and provide structural support. The formation of disulfide bonds and ionic bonding controlled by calcium ions appears to determine gel structure. Water-binding capacity is a measure of the amount of water held in a gel under a specific set of conditions. The water-binding abilities of whey proteins can help reduce formula costs due to the added water being held by the proteins. Other properties associated with water-binding - swelling, gelation and viscosity - are primary determinants of texture in processed cheese, yogurt and reduced-fat foods. Whey proteins also contribute to browning by reacting with lactose and other reducing sugars present in a formulation, providing color to baked goods and sauces. Not only are WPCs functional, they also are bland-tasting and contribute no foreign or off-flavors to foods when used as an ingredient. The category of specialty WPCs includes demineralized and hydrolyzed versions. The demineralized products are often used in infant formula, while lactose hydrolyzed products work well in cheese-type spreads and yogurt. In this case, the hydrolysis of the lactose into glucose and galactose allows for the addition of dairy solids with some added sweetness to the product. Research involving whey protein isolates, alpha-lactalbumin, betalactoglobulin, lactoferrin, bovine serum albumin, lactoperoxidase, peptides and immunoglobulins has gained recent press attention. Research is currently in progress on the use of whey protein concentrate in the diet and its anti-tumor effects for headand neck-cancer patients. Whey protein has been shown to stimulate cell-mediated and humoral immunity; to have an antioxidant role by increasing tissue glutathione; and to improve the body's nutritional status in stressed individuals, thereby inhibiting growth of several tumor types. Whey protein isolates (WPI) are those products with a protein content of over 90%. Various processes remove the nonprotein components. These include precipitation, microfiltration and ion exchange. The composition (protein, lactose and mineral content) and product characteristics can vary with the process used. Whey protein isolates can also be manufactured by selective ion exchange processes to select the primary functional proteins, beta-lactoglobulin and alphalactalbumin. They provide high gel strength, viscosity, aeration, water binding, and high solubility to an application. In their pure form, they can be used to replace other ingredients, such as soy protein, egg whites, or gelling agents. These isolates consist of completely undenatured protein and also contain up to 10% to 12% biologically active immunoglobulins. Several whey protein fractions have been considered as dietary ingredients, with potentially greater activity against the development of colon cancer than the total whey protein product. Lactoferrin-supplemented diets have enhanced the protective effect of total whey protein in animal studies relating to colon cancer. Clinical trials with whey protein isolate have been conducted on children with AIDS. It has been demonstrated that the ability of lymphocytes to offset oxidative damage is measured by determining the capacity of these cells to regenerate glutathione. Patients in this study who started with low blood-lymphocyte glutathione exhibited a substantial increase in glutathione content after including whey protein isolate in the diet. Several protein fractions display antimicrobial, as well as antiviral, activity. These fractions include lactoferrin, lactoperoxidase, lysozyme and immunoglobulins. Technology has been developed on a commercial scale to produce these proteins for use as biopreservatives and as natural anti-infectious components for prophylactic and therapeutic treatment of bacterial and viral diseases. One fraction receiving a high level of interest for its nutraceutical properties is lactoferrin. This iron-binding protein, in addition to its bacteriostatic properties, is also associated with enhanced iron absorption, stimulation of bacterial gut organisms, such as bifidobacteria, as well as a potential immune-stimulating role. It is one of the principal whey proteins in human milk, present at a level of about 30% of total whey proteins. "Lactoferrin, as well as being an antioxidant, binds certain gastric pathogens and is bactericidal against a variety of pathogenic bacteria and yeasts," he adds. "This could lead to its use for treatment of intestinal ulcers and other gastric disorders. Not all research has focused on fractions for purely physiological functions. Currently, research is under way on the use of beta-lactoglobulin as a fat replacer in meats. Licensed technology exists for producing heat-induced, beta-lactoglobulin gels that resemble animal fat. Use of alpha-lactalbumin in infant formulas is becoming more common as research attempts to get closer to the composition of human breast milk. Alpha-lactalbumin also has been modified in attempts to perform some of the same functionalities found in egg white and its application in angel food cake. Lactose or milk sugar is in abundant supply due to increasing cheese production. Lactose can be produced from whey or whey permeate. Its primary use is in bakery and confectionery products. Similar to other components of milk or whey, interest also has focused on the development and production of new lactose derivatives. The current news concerning lactose focuses on its derivatives, the galactooligosaccharides. Commercially successful examples are lactitol and lactulose. Lactitol is produced by the chemical hydrogenation of lactose. Lactulose is produced by chemical isomerization of lactose. Galacto-oligosaccharides are an important part of the functional foods trend as a factor in the well-being of the digestive tract. Galacto-oligosaccharides are not digested or absorbed in the small intestine, so they reach the colon where they are fermented by beneficial colon bacteria, bifidobacteria. Lactulose has a considerable influence in the medical treatment of some forms of liver disease, and it aids and/or restores health after bouts of salmonellosis. When used as a food ingredient to improve nutritional value, lactulose can be added to many applications, without loss of functional or nutritional properties due to processing. Some applications include: infant formulas or baby food; yogurt; diabetic sweetener; sugar substitute in confectionery products; and dried and liquid nutritional supplements for seniors. As the nutraceutical market grows, consumers will be seeing more whey-derived ingredients on their foods. A family of perhaps more obscure products that are derived from whey, bacteriocins, comes from fermentation with lactic acid bacteria. Foodgrade bacteriocins are proteinaceous antimicrobial compounds with bactericidal or bacteriostatic activity. Nisin A is one bacteriocin produced commercially and used as a food preservative in processed cheese and canned foods to prevent growth of clostridia and other pathogens. With demands for natural food additives increasing, applied research is currently focused on producing, by economically viable means, large amounts of bacteriocins for these applications. Other areas of research on whey permeate have focused on its antioxidant activity in meat products. Drying Of Whey All types of whey can be spray-dried. Each, however, requires its own handling techniques. Layouts for spray-dried whey can vary from the very simple to the sophisticated. Generally speaking, sweet (cheese) whey is easier to dry than acid whey. The main operations used for the manufacture of whey powder are as follows: Preheating Concentration Flash cooling Precrystallization Spray drying Cooling in a vibrated fluid bed Spray Drying without Crystallization Treatment Processing consists of preheating, concentration, spray drying and pneumatic cooling. Ordinary whey powder obtained by this process is very fine, dusty, hygroscopic and therefore caking. Hygroscopicity and caking are influenced by the type of whey and by local climatic conditions. The hygroscopicity, caking and all the problems associated with the stickiness of ordinary whey powder are mainly due to lactose being present in an amorphous glassy state. In the spray drying of milk products, lactose is in an amorphous state and is not stable in atmospheric air or normal humidity. The only form of lactose that is stable to humidity is a-lactose monohydrate. Since the lactose content of whey powder comprises more than 70% of the total solids in comparison with 30% in whole milk the problem of the lactose content in whey powder is more severe. However, since the solubility of lactose is 17 g/100 cm3 H2O at 20°C, it is easy to guide the drying process in such a way that a great part of the lactose can be transformed to the stable a-lactose monohydrate form during the drying process. Fig 2. Evaporator, crystallization tanks, and spray dryer with pneumatic conveying system Precrystallization and Crystalline Treatment The basic process layout is modified by conducting a precrystallization before spray drying. During the precrystallization process, it is easy to keep ideal conditions for crystallization. Viscosity of the concentrate is reasonably low, temperatures may be exactly adjusted and controlled, displacement of used solution from the surface of crystals may be accelerated by agitation, and the required amount of suitable crystals of lactose may be ensured by proper seeding. Furthermore, there is normally time enough for the pre-crystallization process so reaching the theoretical degree of crystallization at this stage is no problem. The product made by this process is noncaking and, being agglomerated, is dustless and free-flowing. The agglomerates tend to be small and thus the bulk density is relatively high. Fig 3. Whey crystallization tanks The drying chamber with integrated fluid bed is fitted with pressure-release vents and a fire-extinguishing system. Cyclone, bag filter and external vibrating fluid bed have similar safety features. The cyclone(s) and bag filter may today be replaced by a sanitary bag filter to improve operating costs. CHOICE OF WHEY PROCESS The choice of process depends upon the type of whey available, the intended market for the whey powder and the plant location. The ability to handle sweet whey and yet produce a non-caking product permits use of a simpler layout than if sour whey is to be processed. If the dried powder is intended for dry powder mixes, flowability is essential and the process must be equipped with crystallization and cooling stages to ensure that this property is obtained. Local climate should also be considered. If the climate is too humid, it is advisable to use a process that produces a less hygroscopic product with low caking tendencies. Fermentation of Whey to Ethanol (Case study on Carbery Group) (Ethyl alcohol or grain alcohol) is a clear, colorless liquid with a characteristic, agreeable odor. In dilute aqueous solution, it has a somewhat sweet flavor, but in more concentrated solutions it has a burning taste. Ethanol, CH3CH2OH, is an alcohol, a group of chemical compounds whose molecules contain a hydroxyl group, -OH, bonded to a carbon atom. Ethanol Manufacture whey, a by product of the casein manufacturing process, containing 4 percent lactose, provides the sugar which is broken down into alcohol by lactose specific yeasts. The lactose stream produced during whey ultrafiltration is pumped into one of the eight fermentation vessels in the fermentation room. Yeast is added to each fermentation vessel at the beginning of vessel filling. Conditions in each fermentation vessel are set to enable the fast and efficient conversion of lactose to ethanol. The fermentation process is complete in each vessel within 24 hours. The yeast used for fermentation is recovered and reused a number of times before it is discarded. The yeast is recovered at the end of the fermentation by settling and mechanical clarification of the beer solution. At the end of fermentation the ethanol level is between 3.5% v/v and 4.2% v/v. Beer Still Distillation Beer liquor is pumped to the beer wash column and the ethanol level is concentrated at 96% v/v which is called feints. In addition to concentrating ethanol, congeners i.e. alcohol like compounds are also removed from feints. Alcohol Rectification This is a 3 stage distillation process which removes the smallest levels of impurities which results in the production of very clean neutral spirit. The 96% v/v ethanol feints is diluted with water and pumped into the extractive distillation column. Congeneric compounds miscible in ethanol, but immiscible in water are removed. The main ethanol stream is pumped to the final rectification column to reconcentrate the ethanol and remove the remaining impurities in the spirit. A number of side streams are drawn from the final rectifies and fed to the heads concentration column. Constant monitoring of spirit quality takes place. This involves laboratory analysis including gas-liquid chromatography analysis and spirit tasting to ensure consistent quality. Alcohol Dehydration Spirit which leaves the final distillation column is concentrated to 96% v/v. However, over 30% of Carbery ethanol is sold at actual strength of 99.5% or greater (anhydrous ethanol). Dehydration is achieved by passing 96.2% v/v ethanol (wet ethanol) over a bed of molecular sieve beads. These beads contain tiny microscopic pores which selectively remove water from the ethanol because of its smaller molecule size compared with ethanol. The ethanol drying system comprises of a double bed system which allows one bed to dry ethanol while moisture which has been extracted from the ethanol is being removed from beads in the second bed. Boru Vodka Manufacture The main ingredients used in the manufacture of Boru Vodka, finished grain spirit and Atlantic Irish Oak charcoal are prepared at West Cork Distillers Ltd., Finished grain spirit is distilled in small batches using pure spring water. Atlantic Irish Oak charcoal is prepared using fallen oak from local woodlands. The wood is cut to specific lengths and burned using a special procedure. This milestone marked the culmination of 3 years research to develop a yeast to efficiently convert lactose to ethanol. After a painstaking selection procedure a strain of yeast from the Kluyveromyces fragili s family was successfully introduced to the Carbery Lactose fermentation process. Production of ethanol has grown from over 2,500,000 litres alcohol in 1980 to over 8,000,000 litres currently. COMMERCIAL APPLICATION OF AN INNOVATIVE MEMBRANE BIOREACTOR FOR WASTEWATER TREATMENT AT THE NBIA INGREDIENTS LTD GLANBIA (Case Study) The Ballyragget site is one of the largest milk and Whey Processing facilities in the world. In 2000, almost 800 million litres of milk and almost 700 million litres of Whey (equivalent to about 45,000t of milk solids) will be processed at Ballyragget. The majority of the Whey will be processed as a co-product in the manufacture of rennet and acid caseins and Cheddar cheese. The remainder will be sourced externally from other cheese manufacturers. The Ballyragget site has been subject to an environmental discharge licence since 1977 and was the first dairy industry site in Ireland to be awarded an Integrated Pollution Control (IPC) licence in December 1998. The environmental discharge and emission values outlined in this licence, which are stringent, necessitated the identification, assessment, procurement and deployment of advanced wastewater treatment Technology to meet the imposed discharge limits during the 1999 manufacturing season. The advanced wastewater treatment Technology deployed was a membrane bioreactor system (Kubota Corporation, Tokyo, Japan) not previously used commercially in the dairy industry. The membrane bioreactor system was deployed after technical discussions with Wessex Water Ltd, who had adopted this system in 1998 at the Porlock sewage system in Somerset, England. The membrane bioreactor system deployed at Ballyragget is a high-MLSS (mixed liquor suspended solids) activated sludge process wherein 74 membrane (0.44mm pore size) treatment units are submerged within extended activated sludge tanks. Typically, the effluent feed is fed under gravity (1.0–1.5m head pressure) to the membrane bioreactor units, and the activated sludge is maintained at an MLSS concentration of 15,000–20,000mg l −1. The system has a minimum flow rate of 7200m 3per day. Flow rates of up to 9000m3per day have been achieved. The tight pore size has resulted in significant improvement in the chemical and biological quality of the discharge stream, which in turn has been correlated with improvement in the biological quality of the local watercourse. In this regard, the proportion of daily discharges failing to meet the licensed limits of 15mg l for suspended solids, 10mg l or biological oxygen demand (BOD) and 0.6mg l for orthophosphates was reduced to nil (from 75%), nil (from 72%), and 13% (from 93%), respectively, during a 3-month study period in 2000, compared with the same study period in 1999. Moreover, the discharge stream is now of a higher quality than the receiving water to the site, thus providing an opportunity for re-use/recycling. Research is ongoing to achieve this objective. Technology and Pollution Prevention Ever since the industrialization of cheese production, whey has in large amounts been dumped into rivers, lakes or similar water reservoirs. However, as the whey contains organic substances, oxygen is required for the decomposition, and dumping of whey will therefore have a great influence on the environment. If the dumping is of such a quantity that the decomposition requires all the oxygen available in the water, all life will die followed by a putrefactive process. It is therefore obvious that the amount of whey which can be dumped per hour depends on the amount of oxygen available which is again determined by the amount of water per hour and its content of oxygen. It is therefore difficult to state exact amounts of whey which may be dumped. Under some IPC license it is required by the licensee to analyse and in some cases peregrines the final whey before dumping. As a guide, the degree of organic impurities in waste water is expressed by the requirement for oxygen for biological decomposition in a 5 days' period, namely the so-called BOD5. Average waste water from households will have a BOD5 of 300 mg oxygen per liter. With an average amount of 200 liters per person per day it corresponds to 60 g oxygen, also known as a person equivalent. For whey the BOD5 is approx. 60 g oxygen/litre, i.e. 1 litre of whey corresponds to 1 person. Instead of cleaning the whey in special cleaning plants some dairies have disposed of large quantities of whey by spray-irrigating it over the fields, which is an effective method giving benefit both to the factory and to the farmer. The amount of whey per hectare depends on the pasture and the rainfall. The irrigation is usually done in a cycle with 14 days between each doze, which means there should be plenty of land near the cheese factory (but at least 200 m from nearest habitation). The amount which can be sprayed is about 7 m3/ha/day. Membrane technology is widely used in pollution prevention because of disposal cost and present and future regulations concerning groundwater, surface water, and wastewater quality. Pressure driven membrane processes that include Micro-Filtration (MF), Ultra-Filtration (UF), Nano-Filtration (NF), and Reverse Osmosis (RO) are found to be reliable technologies for water and wastewater treatment. The pressure driven processes can “separate, fractionate, and concentrate contaminants or processes components Three general categories for the applications of membrane technology in pollution prevention are as follows. Process/Operation Water Purification Waste Treatment Membrane-based separation is used to recover water and valuable materials from different processes/operations in many industries including the Whey industries. What are the benefits of membrane technology in pollution prevention? Benefits of membrane technology include: Minimal temperature changes and chemical addition Operate in either continuous or batch modes Use significantly less energy than traditional separation processes Do not alter the chemical structure of the processed materials Easy to integrate into existing processes due to their modular nature and compact size What are the limitations of membrane technology? Membrane fouling Fouling in membranes occurs because of metal oxides, precipitating salts, suspended solids and colloids, and biological growth. The effects of fouling can be minimized by “avoidance and remediation Avoidance: An adequate pretreatment (coagulation/precipitation, or slow sand filtration) Remediation: Chemical cleaning by “acids, alkalines, oxidizers, detergents, and organic solvents High investment cost as compared to conventional processes High energy consumption in RO as compared to other pressure driven processes References: [1] Bruggen, B.V., Vandecasteele, C., Gestel, T.V., Doyen, W. and Leysen, R. (April 2003). “A Review of Pressure-Driven Processes in Wastewater Treatment and Drinking Water Production.” J. Article American Institute of Chemical Engineers, New York, N.Y., USA, 22(1), 46-54. [2] Postdoctoral Research Program U.S. EPA National Risk Management Research Laboratory Cincinnati, Ohio, Project # NRMRL 2003-01 http://www.orau.gov/orise/edu/needs/NRMRL2003-01.pdf, accessed November 20, 2005. [3] GE Infrastructure Water & Process Technologies. “Application of Membrane Technology for the Recovery and Reuse of Water.” http://www.gewater.com/library/tp/771_Application_of.jsp, accessed November 21, 2004. [4] Woodside, G. (1999). “Waste Treatment and Disposal Technologies.” In Hazardous Materials and Hazardous Waste Management, Second Edition, John Wiley & Sons, Inc., # 12, 244-245 [5] Aim, R.B. and Peuchot, M.M. (1991). “Membranes for Water and Wastewater Treatment.” J. Article International Water Supply Association, Oxford, England; Elmsford, N.Y., Pergamon Press, 9, 185-194. [6] Pacific Gas and Electric Company (2004). “Membrane Technology in Industrial Processes.” http://www.pge.com/docs/pdfs/biz/rebates/express_efficiency/useful_info/membrane_ tech.pdf accessed November 15, 2005 [7] GEA Filtration and processing GEA Filtration custom designs membrane filtration systems http://www.geafiltration.com/html/product_services/membrane_filtration.html Accessed November 16 2005