* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download ATE1120: Electrical Fundamental-II

Three-phase electric power wikipedia , lookup

History of electric power transmission wikipedia , lookup

Stray voltage wikipedia , lookup

History of electromagnetic theory wikipedia , lookup

Voltage optimisation wikipedia , lookup

Mains electricity wikipedia , lookup

Skin effect wikipedia , lookup

Power engineering wikipedia , lookup

Brushless DC electric motor wikipedia , lookup

Resonant inductive coupling wikipedia , lookup

Galvanometer wikipedia , lookup

Alternating current wikipedia , lookup

Electrification wikipedia , lookup

Electric motor wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Stepper motor wikipedia , lookup

Induction motor wikipedia , lookup

Commutator (electric) wikipedia , lookup

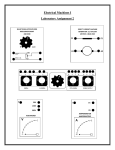

Electrical Machines Module 2: DC Machines PREPARED BY Academic Services Unit April 2012 © Institute of Applied Technology, 2012 ATE1230: Electrical Machines Module 2: DC Machines Module Objectives Upon successful completion of this module, students should be able to: 1. Describe the principle of operation of DC motors. 2. Describe the main differences and similarities between a dc generator and a dc motor 3. List the advantages and disadvantages of the different types of dc motors 4. State the principle by which generators convert mechanical energy to electrical energy 5. State what component causes a generator to produce direct current rather than alternating current 6. State the three classifications of dc generators 7. Build and test a simple DC motor. Module Contents: Topic Page No. 2.1 Introduction to DC Machines 3 2.2 DC Motors 4 2.3 DC Generators 12 2.4 Lab Activity 1 19 2.5 Review Exercises 21 Page 2 Module 2: DC Machines ATE1230: Electrical Machines 2.1 Introduction to DC Machines Converters that are used to continuously convert electrical input to mechanical output or vice versa are called electrical machines. The process of conversion is known as electromechanical energy conversion. An electrical machine is therefore a link between an electrical system and a mechanical system. In these machines the conversion is reversible. If the conversion is from mechanical to electrical energy, the machine is said to act as a generator. If the conversion is from electrical to mechanical energy, the machine is said to act as a motor. These two effects are shown in Figure 2.1. In these machines, conversion of energy from electrical to mechanical form or vice versa results from the following two electromagnetic phenomena. 1. When a conductor moves in a magnetic field, voltage is induced in the conductor. (Generator action) 2. When a current carrying conductor is placed in a magnetic field, the conductor experiences a mechanical force. (Motor action) Figure 2.1: The Energy directions in generator and motor actions Page 3 Module 2: DC Machines ATE1230: Electrical Machines Task 1: Check the following and other websites for demonstrations of the principle of operation of motors and generators http://library.thinkquest.org/27948/motor.html http://www.animations.physics.unsw.edu.au/jw/electricmotors.html 2.2 DC Motors DC motors have been used in industrial applications for years. Coupled with a DC drive, DC motors provide very precise control. DC motors can be used with conveyors, elevators, marine applications, material handling (paper, plastics, rubber, steel) and textile applications to name a few. 2.2.1 CONSTRUCTION DC motors as shown in Figure 2.2 consist of one set of coils, called armature winding, inside another set of coils or a set of permanent magnets, called the stator. Applying a voltage to the coils produces a torque in the armature, resulting in motion. The main parts of the DC motor are : 1. STATOR: The stator consists of either a permanent magnet or electromagnetic windings. The stator generates a stationary magnetic field around the rotor which occupies the central part of the motor. 2. ARMATURE (Rotor): The armature shown in Figure 2.3 is made up of one or more electric windings around armature arms. These electric windings generate a magnetic field when energized by the external current. The magnetic poles thus generated by this rotor Page 4 Module 2: DC Machines ATE1230: Electrical Machines field are attracted to the opposite poles generated by the stator field and repelled by the similar poles, which causes the armature to rotate. 3. COMMUTATOR: The DC motor doesn’t use an external current switching device, instead it uses a mechanical connector called the commutator which is a segmented sleeve usually made of copper, mounted on the rotating shaft. The current +/- is supplied to this commutator segments with the help of brushes. 4. BRUSHES: As the motor turns, the brushes slide over the commutator segments hence creating the variable magnetic field in different arms through the commutator segments attached to the windings. Hence a dynamic magnetic field is generated in the motor when a voltage is applied across the brushes. The brushes mechanism holder is shown in Figure 2.4. Figure 2.2: Permanent Magnet DC Motor Page 5 Module 2: DC Machines ATE1230: Electrical Machines Figure 2.3: Armature and Commutator Figure 2.4: Brush holder mechanism 2.2.2 Basic DC Motor Operation A. Magnetic Fields You will recall that there are two electrical elements of a DC motor, the field windings and the armature. The armature windings are made up of current carrying conductors that terminate at a commutator. DC voltage is applied to the armature windings through carbon brushes which ride on the commutator. In small DC motors, permanent magnets can be used for the stator. However, in large motors used in industrial applications the stator is an electromagnet. When voltage is applied to stator windings an Page 6 Module 2: DC Machines ATE1230: Electrical Machines electromagnet with north and south poles is established. The resultant magnetic field is static (non-rotational). For simplicity of explanation, the stator will be represented by permanent magnets in the following illustration in Figure 2.5. Figure 2.5: Simple DC motor B. Generated Force If a current carrying conductor is placed into the field of a permanent magnet as shown in Figure 2.6(c) a force F will be exerted on the conductor to push it out of the magnetic field. To understand the force, let us consider each magnetic field acting alone. Figure 2.6(a) shows the magnetic field due to the current carrying conductor only. Figure 2.6(b) shows the magnetic field due to the permanent magnet in which is placed the conductor carrying no current. Figure 2.6(c) shows the effect of the combined magnetic fields which are distorted and, because lines of magnetic flux never Page 7 Module 2: DC Machines ATE1230: Electrical Machines cross, but behave like stretched elastic bands, always trying to find the shorter distance between a north and south pole, the force F is exerted on the conductor, pushing it out of the permanent magnetic field. Figure 2.6: Force on a current carrying conductor As can be seen from the below illustration in Figure 2.7, conductors on the left side tend to be pushed up. Conductors on the right side tend to be pushed down. This results in a motor that is rotating in a clockwise direction. This is the basic motor principle, and the force F is dependent upon the strength of the magnetic field, the magnitude of the current flowing in the conductor, and the length of conductor within the magnetic field. Page 8 Module 2: DC Machines ATE1230: Electrical Machines Figure 2.7: Basic motor operation 2.2.3 Classifications of DC Motors Practical motors are constructed as shown in Figure 2.8. All DC motors contain a fffield winding wound on pole pieces attached to a steel yoke. The armature winding rotates between the poles and is connected to the commutator. Contact with the external circuit is made through carbon brushes rubbing on the commutator segments. Direct Current motors are classified by the way in which the field and armature windings are connected, which may be in series or in parallel. Figure 2.8: Industrial DC machine construction Page 9 Module 2: DC Machines ATE1230: Electrical Machines A. DC Series Motor The field and armature windings are connected in series and consequently share the same current. The series motor has the characteristics of a high starting torque but a speed which varies with load. Theoretically the motor would speed up to selfdestruction, limited only by the windage of the rotating armature and friction, if the load were completely removed. Figure 2.9 shows series motor connections and characteristics. For this reason the motor is only suitable for direct coupling to a load, except in very small motors, such as vacuum cleaners and hand drills, and is ideally suited for applications where the machine must start on load, such as electric trains, cranes and hoists. Figure 2.9: Series motor connections and characteristics. Applications : 1. electric drill motor, 2. vacuum cleaner motor, 3. electric train motor Page 10 Module 2: DC Machines ATE1230: Electrical Machines B. DC Shunt Motor The field and armature windings are connected in parallel (Figure 2.10). Since the field winding is across the supply, the flux and motor speed are considered constant under normal conditions. In practice, however, as the load increases the field flux distorts and there is a small drop in speed of about 5% at full load, as shown in Figure 2.10. The machine has a low starting torque and it is advisable to start with the load disconnected. The shunt motor is a very desirable d.c. motor because of its constant speed characteristics. It is used for driving power tools, such as lathes and drills. Figure 2.10: Shunt motor connections and characteristics. C. Compound motor The compound motor has two field windings, one in series with the armature and the other in parallel. The arrangement (short shunt and long shunt) of compound motor connections is given in Figure 2.11. The compound motor may be designed to possess the best characteristics of both series and shunt motors, that is, good starting torque together with almost constant speed. Typical Page 11 Module 2: DC Machines ATE1230: Electrical Machines applications are for electric motors in steel rolling mills, where a constant speed is required under varying load conditions. Figure 2.11: Compound motor connections Conduct Lab Activity I on page 19. 2.3 DC Generators 2.3.1 Generator principle An electrical generator is a machine which converts mechanical energy (or power) into electrical energy (or power). Induced voltage, known as electromotive force (e.m.f.) is produced in it through electromagnetic induction. This e.m.f. causes a current to flow if the conductor circuit is closed. Hence, two basic essential parts of an electrical generator are: Magnetic field. Conductor or conductors which can move as to cut the flux. Generators are driven by a source of mechanical power, which is usually called the prime mover of the generator(steam turbine, diesel engine, or even an electric motor). Page 12 Module 2: DC Machines ATE1230: Electrical Machines Simple loop generator Figure 2.12 shows a single turn rectangular copper coil (AA′BB′ ) rotating about its own axis in a magnetic field provided by either permanent magnets or electromagnets. The two end of the coil are joined to two slip-rings which are insulated from each other and from the central shaft. Two collecting brushes (carbon or copper) press against the slip-rings. The rotating coil may be called armature and the magnets as field magnets. One way to generate an AC voltage is to rotate a coil of wire at constant angular velocity in a fixed magnetic field, as in Figure 2.12, (slip rings and brushes connect the coil to the load). The magnitude of the resulting voltage is proportional to the rate at which flux lines are cut, and its polarity is dependent on the direction the coil sides move through the field. Page 13 Module 2: DC Machines ATE1230: Electrical Machines Figure 2.12(a): 0 Position: Coil sides move parallel to flux lines. Since no flux is being cut, induce voltage is zero. Figure 2.12(b): 90 Position: Coil end A is positive with respect to B. Current direction is out of slip ring A. Figure 2.12(c): 180 Position: Coil again cutting no flux. Induced voltage is zero. Figure 2.12(d): 270 Position: Voltage polarity has reversed, therefore, current direction reverses. Figure 2.13: Generated waveform Page 14 Module 2: DC Machines ATE1230: Electrical Machines 2.3.2 Construction of DC Generators The parts of a simple DC generator are shown in Figure 2.14. A rotating armature coil passes through a magnetic field that develops between the north and south polarities of permanent magnets or electromagnets. As the coil rotates, electromagnetic induction causes current to be induced into the coil. The current produced is an alternating current. However, it is possible to convert the alternating current that is induced into the armature into a form of direct current. This conversion of AC into DC is accomplished through the use of a commutator. The conductors of the armature of a DC generator are connected to commutator segments. The commutator shown in Figure 2.14 has two segments, which are insulated from one an other and from the shaft of the machine on which it rotates. An end of each armature conductor is connected to each commutator segment. The purpose of the commutator is to reverse the armature coil connection to the external load circuit at the same time that the current induced in the armature coil reverses. This causes DC at the correct polarity to be applied to the load at all times as shown in Figure 2.15. Figure 2.14: Simple diagram of a generator Page 15 Module 2: DC Machines ATE1230: Electrical Machines (a) (b) Figure 2.15(a): Pulsating DC developed by a simple single coil generator. Figure 2.15(b): Pure DC developed by a more complex generator using many turns of wire and many commutator segments. 2.16: A practical DC generator Page 16 Module 2: DC Machines ATE1230: Electrical Machines 2.3.3 Types of D.C Generators: D.C Generators are classified according to the way in which a magnetic field is developed in the stator of the machine. Thus, there are three basic classification DC generators (1) permanent-magnet field. (2) separately-excited field. (3) self-excited field. 1) Permanent-Magnet Field permanent-magnet DC machines are widely found in a wide variety of low-power applications. The field winding is replaced by a permanent magnet, resulting in simpler construction. Notice that the rotor of this machines consists of a conventional DC armature with commutator segments and brushes. 2) Separately-Excited Field Separately-excited generators are those whose field magnets are energized from an independent external source of DC current. It is shown diagrammatically in Figure 2.17. Page 17 Module 2: DC Machines ATE1230: Electrical Machines Figure 2.17: Simplified illustration of a separately excited DC generator. 3) Self-Excited Field Self-excited generators are those whose field magnets are energized by the current produced by the generators themselves. Due to residual magnetism, there is always some flux present in the poles. When the armature is rotated, some e.m.f and hence some induced current is produced which is partly or fully passed through the field coils thereby strengthening the residual pole flux. Page 18 Module 2: DC Machines ATE1230: Electrical Machines 2.4 Lab Activity 1 Objective: Motors are the fundamental driving force of the modern world. It is a very rare occasion when you do not see or use the action of a motor during your daily life. So how do they work? With this activity, you will build your own simple DC motor. Components used: a) magnet, ceramic disc b) Copper enamled wire, 20–22 gauge, 60 cm c) wire pieces, 16–18 gauge, 7–8 cm, 2Nos d) Battery clips with alligator clip leads, 9-V e) DC Power supply. f) Pliers, needle-nose with wire cutters g) Polystyrene foam or cardboard piece, 8 cm × 8 cm × 2.5 cm h) Tube or rod, approximately 2 cm in diameter Procedure: Visit the websites below and learn how to build your own DC motor http://www.youtube.com/watch?v=9Wby4aHyXJQ&feature=related www.youtube.com/watch?v=pDQUmJVMhcs Use the following hints to help you build and test the motor: 1. Set the DC power supply to give an initial output of 3V. 2. Wrap the copper wire around the tube few times and tie the two ends as seen in the video. Remove the insulation completely from one end and only on one side from the other end. 3. Increase/decrease the voltage of the power supply and observe the effect on the speed of rotation. 4. Reduce the number of turns of the coil and observe the effect on the speed of rotation. 5. Add another magnet and observe the effect on the speed of rotation. Page 19 Module 2: DC Machines ATE1230: Electrical Machines Write down you conclusions here and comment on the performance of the motor with respect to the following: The strength of the magnetic field The amount of current supplied to the motor The number of turns of the rotor coil ……………………………………………………………………………………………………................... ………………………………………………………………………………………………………………………….. ……………………………………………………………………………………………………................... ………………………………………………………………………………………………………………………….. ……………………………………………………………………………………………………................... ………………………………………………………………………………………………………………………….. ……………………………………………………………………………………………………................... ………………………………………………………………………………………………………………………….. ……………………………………………………………………………………………………................... ………………………………………………………………………………………………………………………….. ……………………………………………………………………………………………………................... ………………………………………………………………………………………………………………………….. Page 20 Module 2: DC Machines ATE1230: Electrical Machines 2.5 Review exercise Module 2 WORKSHEET DC MACHINES 1. The series motor used in many applications such as: a) constant speed steel rolling mills b) electric hand drills c) electric trains and trams d) vacuum cleaners . 2. The compound motor used in many applications such as: a) constant speed steel rolling mills b) electric hand drills c) electric trains and trams d) vacuum cleaners . 3. The advantage of a d.c. machine is: a) it is easy to control the speed b) it runs at an almost constant speed c) it requires little maintenance d) it is practically indestructible . 4. What factors determine the direction of rotation in a dc motor? 5. What is the main disadvantage of a series motor? 6. What is the main advantage of a series motor? 7. What advantage does a shunt motor have over a series motor? Page 21 Module 2: DC Machines ATE1230: Electrical Machines 8. Whenever ____________ flows through a conductor a magnetic field is generated around the conductor. 9. Identify the following motor types 10. What component causes a generator to produce dc voltage rather than ac voltage at its output terminals? 11. An elementary, single coil, dc generator will have an output voltage with how many pulsations per revolution? 12. Generators convert mechanical motion to electrical energy using what principle? 13. What is the purpose of the slip rings? Page 22 Module 2: DC Machines ATE1230: Electrical Machines Refrences: Advanced Electrical Installation Work_ 5th Edition Page 23 Module 2: DC Machines