* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

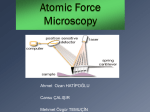

Download THE DESIGN AND CONSTRUCTION OF AN ATOMIC FORCE MICROSCOPE By

Survey

Document related concepts

Transcript