* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download EE595_Team1_P3_Fall07

Electric power system wikipedia , lookup

Distributed control system wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Thermal runaway wikipedia , lookup

Three-phase electric power wikipedia , lookup

Electrical substation wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Power inverter wikipedia , lookup

Power engineering wikipedia , lookup

History of electric power transmission wikipedia , lookup

Power MOSFET wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Stray voltage wikipedia , lookup

Schmitt trigger wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Buck converter wikipedia , lookup

Control system wikipedia , lookup

Power over Ethernet wikipedia , lookup

Voltage regulator wikipedia , lookup

Surge protector wikipedia , lookup

Distribution management system wikipedia , lookup

Power electronics wikipedia , lookup

Alternating current wikipedia , lookup

Voltage optimisation wikipedia , lookup

Switched-mode power supply wikipedia , lookup

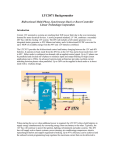

318-595 Presentation #3 – Project TEAM 1 Detector Thermal Manager 318-595 Project Presentation #3 – TEAM 1 Team 1: Expertise and Experience • Mayank Gupta - Expertise: Digital, Analog, FPGA, MATLAB - Experience: 5 years – GE Healthcare - Role: LPI, LMM • Naser Aldaihani - Expertise: Electronic, Power Systems. - Experience: Fresh after BSEE - Role: LMP • Matthew Mulvey - Expertise: Digital Design, (C,C++) - Experience: Fresh after BSEE - Role: LSD • Mohammad Habeeb - Expertise: Electronic, DSP, C++. - Experience: Fresh after BSEE - Role: LRM 318-595 Project Presentation #3 – TEAM 1 Team 1: Total Resources GE Funded Total Manhours: - 60hrs/week (15hrs/team member) - Meetings -Thursday (5:30-6:45PM), Saturday (9:30-11:00AM) - 3 hrs lab on Tuesday. GE Resources: - 3 weeks – Layout and Schematic Design - Fab. house for board build Main Project – Block Diagram Slide - PID Control - Filter Clogging Detection 12A - Fan failure Detection - Error Logs for Various reasons 100W Mechanical Size: 200*125*2.36mm Mounting Holes: 8 mounting holes 4/ Shielding: All mounting holes connected to Chassis Ground, nothing else on board will be connected GE Title or job number / to Chassis Ground. 4/30/2017 Project 1: CTD Thermal Manager (DTM) Key Performances and Interfaces: - DTM will use multiple controls like pump, thermistors, heaters and do performance prediction. - Its will incorporate ethernet based communication. - The controller will be used in next generation CT system design and will have following interface and power characteristics: - The design will use Ethernet communication with the PC based system - The controller will control Pump, Thermistors, Fans and Heaters - Total power ratings for the controller will be 48V, 10A - Design will incorporate a Microcontroller as the main controlling unit of all other interfaces. Good for the team: - The project requires good experience with Digital design, some knowledge of power and analog aspect of the design and good programming skills. The team all together has all the skills needed to make this project a success. 5/ GE Title or job number / 4/30/2017 Standard Requirements (DTM) Market - Price: $350/ board Power - Input Voltage Range: 48V (+/-5%) - Total Power: 480W Mechanical - Mechanical Size: 200*125*2.36mm - Total PCB Area: 250cm2 Environmental - Operating Temperature: 0 to 85C - Storage Temperature: -40 to 125C - Estimated Product Life: 10 yrs 6/ GE Title or job number / 4/30/2017 Performance Requirements (DTM) Power - Voltages: 12V (+/-5%) – 30mA 5V (+/-5%) – 70mA 3.3V (+/-5%) – 300mA Digital - Processor: 25MHz, 16bit resolution - Ethernet: 10MHz - Thermistor Accuracy: +/-0.2C (YSI44006) - Velocity Sensor: 5-200fpm (AssuSense F900) - Pressure Sensor: 0-500psi (+/-3% variation) (EMB 450-75-0010) - Target Temperature: 36C Mechanical - Mounting Holes: 8 mounting holes - Shielding: All mounting holes connected to Chassis Ground, nothing else on board will be connected to Chassis Ground. Other - 6 Sub-D Connectors - 2 RJ-45 Connectors - 2 LED – Performance Monitoring 7/ GE Title or job number / 4/30/2017 Business Case Category Price Comment NRE Charges $15,000 Fab. + Components PWB (Fab.) Charge $50/ Board Production Price BOM Price $240/ Board Production Price PWA Price (Finished Board) $350/ Board Production Price Category Price Comments Market Quantity 1000 Demand in the Market Production Cost $350.00 Product Price for making the controller Total Production Cost $350,000.00 Total Production cost for 1000 systems Total Man hours spent in the design with Manhours $115,200.00 $150.00/hr, 64hrs/week, 12 weeks Market Price $490.00 Market price with mark-up of 40% Total Sales $490,000.00 Total sales for 1000 systems Profit Total Profit/ first year $140,000.00 Total profit reducing production price from sales Amount gained during 1st year after subtracting $24,800.00 man-hours efforts - At 40% mark-up, it will take 10 months to make any profits. 8/ GE Title or job number / 4/30/2017 Patents 6,997,609: System and method for cooling an x-ray tube in a tomography computer system: February 14, 2006 • This patent claims a very specific physical arrangement of the fans and coolant components being used. Our project does not use the same physical arrangement, so does not violate this patent. 5,444,752: Tomography detector temperature equalization : August 22, 1995 • This patent claims a method for using a thermally massive heat-sink to equalize the temperature of the detectors. Our project uses a completely different method for temperature management (computer controlled heaters, pump and fans) so does not violate this patent. 7,261,466: Imaging inspection apparatus with directional cooling : August 28, 2007 • This patent claims a specific arrangement of fluid deflectors for directing the cooling fluid to the imaging devices. Our project does not use this method for directing the cooling fluid (water), so does not violate this patent. Most of the Patents GE patents – Patents selected on this page are not GE patents Ethics Issues 1) Device effect on medical diagnosis: • This ethical issue arises because the performance of the thermal manager has a direct impact on the accuracy of the CT detector, which in turn has a direct effect on patient diagnosis. Accurate diagnosis is a crucial part of making medical decisions which affect the health and well-being of the patient. • Possible ethical conflict arises because business concerns put pressure on Engineers to deliver a product quickly. Mitigation- Because the health and safety of human beings is involved, proper attention to ethics demands that everything within reason is done to test and confirm the performance of the thermal manager, even if there is some negative impact on business (financial) concerns. 2) Environmental Damage: • On the national level, nearly 70 percent of a typical landfill's heavy metals come from electronic components. Materials such as lead, cadmium, chromium, and mercury. Mitigation - Buying components from legitimate suppliers to insure components met with safety standards. Electric Shock Mitigation Design/Devices/Materials/Packaging − − − Proper wiring and wire are used. Proper power cord is used. All cables and leads at 48V should be sheilded with insulation. Affected Blocks − Blocks 1,2 (All blocks have 48V components) Test(s) Required to Verify Protection • • Check wire requirements. Check grounding requirements for systems, circuits, and equipment. 11 / GE Title or job number / 4/30/2017 Fire, Explosion or Shattering Mitigation Design/Devices/Materials/Packaging • • • Fuse Proper wiring and wire are used. No overload wiring circuits. Affected Blocks • Block 1 Test(s) Required to Verify Protection • • • Check wire requirements. Check grounding requirements for systems, circuits, and equipment. 61000-3-3 EMC Part 3: Limits - Section 3: Limitation of voltage fluctuations and flicker in low-voltage supplies <16A 12 / GE Title or job number / 4/30/2017 Electro-Static Discharge Mitigation Design/Devices/Materials/Packaging • Shunts or diodes to protect against large voltages. • Choosing components rated for at least 2.5KV Affected Blocks • All blocks with connector interface. Test(s) Required to Verify Protection • Test with ESD gun. • 61000-4-2 EMC Part 4: Test/measurement techniques - Section 2: ESD immunity tests 13 / GE Title or job number / 4/30/2017 Magnetic Field Energy Mitigation Design/Devices/Materials/Packaging • Careful layout for making sure no sensitive signals passing in close vicinity of inductors. Affected Blocks • Block 1,3 Test(s) Required to Verify Protection • Susceptibility Tests - Stress levels are well defined and a strategy is employed to gauge and classify the immunity response level of the product to find the highest stress sensitivities • 61000-4-8 EMC Part 4: Test/measurement techniques - Section 8: Power frequency magnetic field immunity tests 14 / GE Title or job number / 4/30/2017 Interference with Other Electronic Systems Mitigation Design/Devices/Materials/Packaging • Insulate all the wire to reduce interference. • Make sure no loops are made. Affected Blocks • All the blocks Test(s) Required to Verify Protection − Check all the wires and insulate them − IEC: 61000-4-5 EMC : Surge immunity tests 15 / GE Title or job number / 4/30/2017 Main Block Diagram Description for DTM Block # Block Name Owner 1 Power management and Processor Mayank 2 Thermistor and pressure circuits 3 4 Brief Description Of Block Function Power Interface Digital Interfaces Analog Interface Use 48V DC source and provide multiple voltages to different sections of design, also work on processor to Ethernet interface. 48V, 10A Power Supply Microcontroller, Ethernet None Naser Monitoring the temperatures and velocity sensors and interface to the processor. 5V from Block 1 Microcontroller Thermistor, Velocity Sensor Input to the board. Heater and SSR circuits Matt SSR control will be providing control signal to 1KW heater controlled by SSR, assist in Ethernet interface. 48V, 12V Power from Block 1 Microcontroller None Fan and Pump control Mohammad Control the speed of the pump and fan. Provide power to 150 W pump and design there interface to processor 48V, 12V, 5V Power from Block 1 Microcontroller, Tach None 16 / GE Title or job number / 4/30/2017 DTM - Interference Input Power PIC18 Programming 48V, 10A Thermal Manager (PCB) PIC18 Microcontroller Power Serial Pins PIC18 Memory Web Web Web page page page xyz xyz xyz Ethernet IP Configuration Main Program Pins TCP/IP services Web Server Ethernet Pins Circuits for Fan, heater, etc. Ethernet Jack Pump, 48V, 4A PC with browser Current Out Current In Power Tach SSR 5 Thermistor 1 Velocity Sensor 2 Pressure Sensor SSR Heater Control 2 Fans, 48V 2A each 17 / GE Title or job number / 4/30/2017 DTM – Overall Layout (6 Layer Board) 18 / GE Title or job number / 4/30/2017 Power management and Processor Input Power 48V, 10A 48V Filtering 12V, 30mA 5V, 70mA 3.3V, 300mA PIC18F97J60 Power to other blocks 256KB EEPROM To and From Other Blocks 19 / GE Title or job number / 4/30/2017 Power management and Processor Purpose: Use 48V DC source and provide multiple voltages to different sections of design, also work on processor to Ethernet interface. Performance Requirements: Standard Requirements Description: Market - - Price: $160/ board Input Voltage Range: 12V (+/-5%), 30mA - Input Voltage Range: 5V (+/-5%), 70mA - Input Voltage Range: 3.3V (+/-5%), 300mA - 10bits precision of A/D Converter Power - Input Voltage Range: 48V (+/-5%), 8A - Input Voltage Range: 12V (+/-5%), 30mA - Input Voltage Range: 5V (+/-5%), 70mA - Input Voltage Range: 3.3V (+/-5%), 300mA Mechanical - Mechanical Size: 120*70*2.36mm Environmental -Operating Temperature: 0 to 85C - Storage Temperature: -40 to 125C - Estimated Product Life: 10 yrs 20 / GE Title or job number / 4/30/2017 Power management and Processor - Power Power Consumption - 48V (=/-5%) – 8A -12V (+/-5%) – 30mA - 5V (+/-5%) – 70mA - 3.3V (+/-5%) – 300mA 21 / GE Title or job number / 4/30/2017 Power management and Processor - Connectors 7 Connectors Used: 1: Power 2: Ethernet 3: IP Configuration 4: PIC18 programming 5: Fan Connector 6: Thermistor Connector 7: SSR + Pressure Sensor Control 8: Pump Connector 22 / GE Title or job number / 4/30/2017 Power management and Processor Microprocessor - Inbuilt MAC and PHY layer for Ethernet. - Max Frequency: 42MHz - 10bit, 16 channel A/D Modules - Supply Voltage 2-3.6V - 5 register banks for digital, analog, input, output, and I/o interfaces. 23 / GE Title or job number / 4/30/2017 Power management and Processor Microprocessor Top Layer of 6 layer board 24 / GE Title or job number / 4/30/2017 Thermistor, Velocity Sensor, Pressure Sensor 5 Thermastor Output to micro controller Velocity Sensor Pressure Sensors Input Selector 25 / GE Title or job number / 4/30/2017 Thermistor, Velocity Sensor, Pressure Sensor Purpose: Monitor the performance of 5 Thermistors, 1 Velocity Sensor and 2 Pressure Sensors. Performance Requirements: Standard Requirements Description: Market - 5 Thermistors: - Price: $20/ board • Voltage: 5V, 1mA. Power • Accuracy (+/-0.2C at 36C - Input Voltage Range: 12V (+/-5%), 50mA - 1 Velocity Sensor: - Input Voltage Range: 5V (+/-5%), 2mA • Voltage: 5V, 1mA. Mechanical • flow ranges between 0.15-10 m/s (30-2000 fpm) • - Mechanical Size: 30*25*2.36mm Environmental -Operating Temperature: 0 to 85C Accuracy ±0.05 m/s (10 fpm) - 2 Pressure Sensor: • Voltage: 12V, 25mA. • 0-500PSI • Accuracy: +/-2% - Storage Temperature: -40 to 125C - Estimated Product Life: 10 yrs 26 / GE Title or job number / 4/30/2017 Thermistor, Velocity Sensor, Pressure Sensor Thermistor and Velocity Sensor Pressure Sensor 27 / GE Title or job number / 4/30/2017 Thermistor, Velocity Sensor, Pressure Sensor -Simulation shows 2 plots: - First Thermistor with 1K Thermistor resistance. Current always below 1mA - Second shows Pressure Sensor with 50Ohm resistance. Currant always below 20mA 28 / GE Title or job number / 4/30/2017 Thermistor, Velocity Sensor, Pressure Sensor 29 / GE Title or job number / 4/30/2017 Fan and Pump control Requirements-Block Diagram breakdown 12V, 20mA max 48V, 8A 48V, 2A, 2 Fans Tach Control Fan and Pump Block Fans 5V, 20mA max 48V, 4A Pump Control Pump Tach This block controls the fan and pump speed, using digital tach control feedback, and two voltages, 48V and 0-10V, one to power the fan/pump and the other to control the speed. 30 / GE Title or job number / 4/30/2017 Fan and Pump control Requirements Purpose: Control the speed of the pump and fan and interface to processor. Performance Requirements: Standard Requirements Description: Market - 2 DC-DC Fans: - Price: $40/ board • Voltage: 48V, 4A. Power • Control voltage: 0-10V, - Input Voltage Range: 48V (+/-5%), 8A 0.4mA/ Fan - Input Voltage Range: 12V (+/-5%), 10mA - 1 Pump: - Input Voltage Range: 5V (+/-5%), 5mA • Voltage: 48V, 4A. Mechanical • Control voltage: 0-10V, - Mechanical Size: 30*20*2.36mm 0.4mA/ Fan Environmental -Operating Temperature: 0 to 85C - Storage Temperature: -40 to 125C - Estimated Product Life: 10 yrs 31 / GE Title or job number / 4/30/2017 Fan and Pump Circuit (Circuit concept and component choice by Mayank) Part Number ADR293 LM2904 AD5314 Fuse1 Fuse2 J3 J7 Quantity Discription 1 5V Precision Voltage Reference 2 1 2 1 1 1 Low Power Dual Op-Amp DAC 125V, 3A Slow Blow 250V, 5A, Slow Blow 747845 (Amp) 747844 (Amp) Power Package 0.25 TSSOP 0.1 SOP 0.2 MSOP 0.6 0.6 Comments 5V, 15uA (max input), 5mA (max output) Single Supply, 0.25mA(max/ channel), Inout Offset 2mV max 10bit resolution, +/-2 bit Accuracy 15pin Sub-D, Amp 9pin Sub-D, Amp 32 / GE Title or job number / 4/30/2017 Fan and Pump Circuit - DAC: - Resolution: 10bits - Accuracy: +/-0.5LSB - Bit Resolution: 5/2^10 = 5mV - Om-Amp: - Single Supply: 3-32V - Offset Voltage: 2mV - DC Voltage Gain: 100dB - Voltage Reference: - Initial Accuracy: +/-0.3% - Output Voltage: 5V - Supply Current: 15uA 33 / GE Title or job number / 4/30/2017 Fan and Pump Circuit 34 / GE Title or job number / 4/30/2017 SSR Heater Control 12V Digital outputs from PIC18 + - SSR + - - Both pairs of digital inputs must be turned on. - In on state, input of SSR is connected to 12V, and heater is on. 35 / GE Title or job number / 4/30/2017 SSR Heater Control Purpose: Provide On/Off capability to the SSR to control externally a 1KW heater. Performance Requirements: Standard Requirements Description: Market - SSR: - Price: $25/ board • Power Input: Voltage: 12V, 30mA max. - Photo-relays: - Input Voltage Range: 12V (+/-5%), 30mA - Needs to supply 30mA Output - Input Voltage Range: 5V (+/-5%), 10mA current: Data-sheet value is up to Mechanical 130mA. - Mechanical Size: 25*20*2.36mm Circuit has 5V inputs from Environmental Microcontroller. Photo-relays can -Operating Temperature: 0 to 85C tolerate 50mA input current. With - Storage Temperature: -40 to 125C typical 2V input drop at photo-relay - Estimated Product Life: 10 yrs - input, I-in = 3V/10k = 0.3 mA. 36 / GE Title or job number / 4/30/2017 SSR Heater Control The device used in AQV214, PhotoMOS (Tried running simulation, but couldn’t due to unavailability of the device in P-Spice library) If = 5mA Iout = 30mA 37 / GE Title or job number / 4/30/2017 SSR Heater Control 38 / GE Title or job number / 4/30/2017 Ethernet Ethernet: network topology that defines physical connection standards and signal transmission standards, so we don’t have to. Devices with Ethernet capable Microcontrollers (PIC18F97J60) Already exists in many buildings PC Thermal manager PIC18 Other device PIC18 Other device PIC18 Ethernet Network PC File server 39 / GE Title or job number / 4/30/2017 Advantages of using an Ethernet - TCP/IP interface between the Thermal manager and the PC: • Ethernet and TCP/IP networks are everywhere. • Well established interfacing standards free the developer from the details of the Ethernet and TCP/IP guts, freeing up time for other aspects of the project. • No configuration of the PC is necessary. Any PC already has: • Ethernet connection and TCP/IP software installed • Web-browser • User interface is generated and controlled by microcontroller Thermal manager PIC18 PC with browser Ethernet – TCP/IP connection 40 / GE Title or job number / 4/30/2017 Thermal Manager (PCB) PIC18 Microcontroller Serial Pins Developers PC Compiler and TCP/IP stack source code PIC18 Memory Web Web Web page page page xyz xyz xyz Main Program TCP/IP services C++ Web Web Code page page xyz xyz Web Web Web page page page xyz xyz xyz Web Server Users PC Web Browser Pins Circuits for Fan, heater, etc. Ethernet Pins Ethernet Jack Web page xyz TCP/IP services 41 / GE Title or job number / 4/30/2017 Code example for PIC18 This code executes when the button labeled “new button” on the user interface is clicked: if (ADRESL > 100) PORTJbits.RJ4 ^= 1; •In the first line, “ADRESL” is the analog-to-digital result register. It contains the value of the analog input pin which is connected to the potentiometer on the demo board. •If this value is greater than 100, then the second line executes. •The second line toggles bit 4 of PortJ. This is a digital output pin which is connected to an LED on the demo board. 42 / GE Title or job number / 4/30/2017 DTM Project Firmware Work Team 1 and 2: (Mayank, Matthew) - Create control equations, writing of control function in C which implements the equations. The different types of interfaces are TTL, Schmit Trigger and then some analog I/O and some Digital I/O - Writes the “main” program, which handles all of the interfacing and communication between the microcontroller, PC, and other components on the board. Then based on the outputs from the control function, the main program can actually control the pins on the microcontroller, and send data to the user interface. Team 3 and 4: (Mohammad, Nasir) - Work on the web-browser for creating the interface to the PIC18 Microprocessor. - Create capability for adding graphics and creating input and output ports to specific memory locations on the processor. 43 / GE Title or job number / 4/30/2017 Thermal Manager BOM Total: $224.97 44 / GE Title or job number / 4/30/2017 DTM Project Timeline W1 W2 W3 W4 W5 W6 W7 W8 W9 W10 W11 W12 W13 W14 W15 Initial Concept Design and Schematic Layout Fab. Ready BOM PWA Ready Testing Harness Firmware Work Firmware and Hardware Integration 45 / GE Title or job number / 4/30/2017 Browser-based user interface for Thermal manager: Fan Speed Set Fan Speed Thermal Manager Therm Temp Pump Speed Set Pump Speed 46 / GE Title or job number / 4/30/2017