* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Slide - (SDM) Program

Survey

Document related concepts

Transcript

Supply Chain Coordination and

Influenza Vaccination

David Simchi-Levi

Massachusetts Institute of Technology

•Joint work with Stephen E. Chick (INSEAD) and

Hamed Mamani (MIT)

March 2007

The Influenza Pandemic

Globally, annual influenza outbreaks

result in 250,000 to 500,000 deaths

20,000 deaths and 100,000

hospitalizations in the US

Social costs of influenza vary

between $1M-$6M per 100,000

inhabitant yearly in industrialized

countries

The “Spanish flu” (H1N1) of 1918

killed 20–40 million people

worldwide

Source: Report by the World Health Organization, 2005

Influenza Vaccination

Vaccination is a principal tool for

controlling influenza

Reduces the risk of infection to exposed

individuals (Longini et al., 1978)

Reduces the probability of transmission from a

vaccinated individual infected with influenza

(Longini et al., 1978)

Vaccination is cost effective

Immunization in elderly saved $117 per person

in medical costs (Nichol et al 1994)

Systematic children vaccination can result in

significant population-wide benefits (Weycker

at al 2005)

The Production and Delivery Process

Flu season

Growing viruses in millions

of fertilized eggs

Northern hemisphere

Immunity takes

About 2 weeks

Flu vaccine supply chain challenges

Operational challenges

Beginning of the value chain

End of the value chain

Strain selection

Vaccine allocation and delivery logistics

Middle of the value chain

Align incentives of the different parties

involved

Flu vaccine challenges

Change of virus over time

Antigenic drift

Seasonal epidemics

Antigenic shift

strain selection

Global pandemics

Wu et al. develop an optimization

model of antigenic changes

Current vaccination policy is reasonably

effective

Develop some heuristics to improve

selection process

Flu vaccine supply chain challenges

Operational challenges

Beginning of the value chain

End of the value chain

Strain selection

Vaccine allocation and delivery logistics

Middle of the value chain

Align incentives of the different parties

involved

Influenza vaccine challenges allocation and delivery

Vaccine allocation to different

subpopulations

(Hill and Longini 2003): mathematical

model of optimally allocating vaccine to

different subpopulations

(Weycker et al 2005): stochastic

simulation model to illustrate the benefit

of vaccination of certain individuals

(children)

Flu vaccine supply chain challenges

Operational challenges

Beginning of the value chain

End of the value chain

Strain selection

Vaccine allocation and delivery logistics

Middle of the value chain

Align incentives of the different parties

involved

The different players and their objectives

Governments (CDC in US), State

health departments

Balance the public health benefits and

the vaccination program costs

Focus on high-risk individuals.

In the US, in 1999, 66.9% of individuals

of age 65 and older were vaccinated

(GAO-2001).

The different players and their objectives

Manufacturer

Production volume and the need for

profitability

Highly uncertain production yield due to

biological nature of production process

Considerable shortage of flu vaccination in

2000-01. According to the US GAO

Considerable shortage in 2003-04

Unanticipated problems growing the new influenza

strains

Quality control issues raised by FDA

Early break of the epidemic

Significant shortage in 2004-05

Chiron’s manufacturing plant in the U.K. was shut

down due to bacterial contamination

Research on Supply Contracts

Focus on supply chain with

Single supplier and single retailer

Order Quantities; Production levels

Coordinating contracts

Global optimization

Nash equilibrium

Flexible

Supply Contracts

Fixed Production Cost =$100,000

Variable Production Cost=$35

Wholesale Price =$80

Selling Price=$125

Salvage Value=$20

Manufacturer

Manufacturer DC

Retail DC

Stores

Demand Scenarios

Sales

18

00

0

16

00

0

14

00

0

12

00

0

10

00

0

30%

25%

20%

15%

10%

5%

0%

80

00

Probability

Demand Scenarios

Distributor Expected Profit

Expected Profit

500000

400000

300000

200000

100000

0

6000

8000

10000

12000

14000

Order Quantity

16000

18000

20000

Distributor Expected Profit

Expected Profit

500000

400000

300000

200000

100000

0

6000

8000

10000

12000

14000

Order Quantity

16000

18000

20000

Supply Contracts (cont.)

Distributor optimal order quantity is

12,000 units

Distributor expected profit is

$470,000

Manufacturer profit is $440,000

Supply Chain Profit is $910,000

–IS there anything that the distributor and

manufacturer can do to increase the profit

of both?

Supply Contracts

Fixed Production Cost =$100,000

Variable Production Cost=$35

Wholesale Price =$80

Selling Price=$125

Salvage Value=$20

Manufacturer

Manufacturer DC

Retail DC

Stores

Retailer Profit

(Buy Back=$55)

Retailer Profit

600,000

500,000

400,000

300,000

200,000

100,000

0

00 00 00 00

00 00 00 00 00

00 00 00 00

60 70 80 90 100 110 120 130 140 150 160 170 180

Order Quantity

Retailer Profit

(Buy Back=$55)

Retailer Profit

600,000

$513,800

500,000

400,000

300,000

200,000

100,000

0

00 00 00 00

00 00 00 00 00

00 00 00 00

60 70 80 90 100 110 120 130 140 150 160 170 180

Order Quantity

Manufacturer Profit

(Buy Back=$55)

500,000

400,000

300,000

200,000

100,000

0

60

00

70

00

80

00

90

00

10

00

0

11

00

0

12

00

0

13

00

0

14

00

0

15

00

0

16

00

0

17

00

0

18

00

0

Manufacturer Profit

600,000

Production Quantity

Manufacturer Profit

(Buy Back=$55)

500,000

$471,900

400,000

300,000

200,000

100,000

0

60

00

70

00

80

00

90

00

10

00

0

11

00

0

12

00

0

13

00

0

14

00

0

15

00

0

16

00

0

17

00

0

18

00

0

Manufacturer Profit

600,000

Production Quantity

Industrial supply chains

Supply contracts:

Wholesale price

Buyback

Revenue sharing

Options

…

Linear cost models

Deterministic production

Flu vaccine supply chain features

nonlinear cost function

•Nonlinear effect of infection dynamics

Nonlinear cost value

Flu vaccine supply chain features

uncertain production

Inactivated virus vaccine

eleven day old embryonated eggs

Prediction of number of eggs well in

advance

egg yields are stochastic based on the

strain and eggs

Uncertain production yield

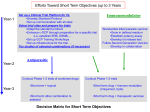

Introduction

Epidemic

Modeling

Industrial

Supply

Chains

Outline

Model description

Current challenges

Effective supply contracts

Infection dynamics

Key components in epidemic

modeling

Initial infected fraction introduced to

the population (I0)

Basic reproduction number (R0):

expected number of secondary

infections caused by one infected in an

otherwise susceptible, unvaccinated

population

Infection dynamics

Vaccine role:

Decreases the probability of infection

for a susceptible person by Φ

Probability of getting the infection will be

multiplied by 1 - Φ

If fraction f of population vaccinated

R0 decreases to Rf

If Rf ≤ 1

outbreak is prevented

Critical vaccine fraction: f 0 = min { f : Rf ≤ 1}

Infection dynamics

f0

Supply chain costs

Social costs of the

disease

On The Counter

meds (OTC)

Outpatient visit

Hospitalization

Indirect costs:

work days loss

Vaccination costs

Direct costs:

Vaccine purchase

Administrative costs

Production costs

Model Description

Government &

Healthcare provider

Manufacturer

Model description

assumptions

A single manufacturer

Homogeneous population

Perfect information

Government is the purchaser of

vaccine

determines how many people to

vaccinate

Game Setting

Government &

Healthcare provider

Manufacturer

Model Description

system problem

System setting

Ignores the transaction between the

different parties

Optimizes the system wide cost

Might not be beneficial for one of the

parties

Model Description

system problem

Government &

Healthcare provider

Manufacturer

Game Setting vs. System Setting

(convex case)

Assumption:

Manufacturer under produces

production risk

Potential Insufficient order by the government

Supply chain coordination

Wholesale price contract:

supply contracts

Proposition: There is no wholesale price

contract that coordinates the supply chain

Payback contract:

Government agrees to buy any excess

production, beyond the desired volume

Shifts some of the risk of excess production

from the manufacturer

Proposition: There is no Payback price

contract that coordinates the supply chain

Problem: Payback contracts are based on the

manufacturer output not on its effort

Supply chain coordination cost sharing +

(convex case)

wholesale discount

Wholesale discount / cost sharing

contract:

Incentive for government to order more

Wholesale discount

pr(f)

Incentive for manufacturer to produce more

Cost share pe(f)

Theorem: The contract defined above

coordinates the supply chain:

The optimal government action is f S while the

manufacturer production volume is nEs

The contract is flexible, that is, it allows any split of

the cost benefit within a certain range

Summary

Uncertain production yield is an

important reason for insufficient

supply of vaccine

Cost sharing contracts can have a

major impact on the influenza

vaccination supply chain

Production risk taken by the

manufacturers maybe the reason

why only a small number of

manufacturer exists