* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Monitoring & Feedback Control

Brushed DC electric motor wikipedia , lookup

Three-phase electric power wikipedia , lookup

Electrical substation wikipedia , lookup

Pulse-width modulation wikipedia , lookup

History of electric power transmission wikipedia , lookup

Thermal runaway wikipedia , lookup

Voltage optimisation wikipedia , lookup

Mercury-arc valve wikipedia , lookup

Skin effect wikipedia , lookup

Control system wikipedia , lookup

Stepper motor wikipedia , lookup

Electrical ballast wikipedia , lookup

Stray voltage wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Power MOSFET wikipedia , lookup

Mains electricity wikipedia , lookup

Opto-isolator wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

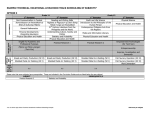

Rectiverter wikipedia , lookup

Buck converter wikipedia , lookup

Monitoring & Feedback Control Monitoring & Feedback Lesson Objectives When you finish this lesson you will understand: • Monitoring and control of power circuits • Review of sensor techniques • Sensing for weld quality Learning Activities 1. View Slides; 2. Read Notes, 3. Listen to lecture 4. Do on-line workbook Keywords Monitoring, Feedback Control, Force Gage, Piezoelectric Gage, Voltage, Manganen Shunt, Meter Calibration, Rogowski Coil, Hall Effect Transducer, Power Factor Monitoring, Automatic Voltage Control, Current Regulation, Constant Current, Nugget Expansion, Optical Fringe Sensor, Dynamic Resistance, Dynamic Power Factor, Current Stepper, Acoustic Emission, Ultrasonic, Direct Temperature, Infrared • Sensors for Monitoring • Control of Welder • Control of Weld Quality Electrode Force Gage Electrode Secondary Current Shunts • Must have geometry - no skin effect HF problems • Return Conductors not Couple with Magnetic Field • Sometime high weight for robotics • Not completely secondary impedance non-intrusive Meter Calibration Can not use: IRMS = 0.707 Ipeak Androvich “Resistance Welding Constant Current Heat Control”, AWS Sheet Metal ConfV, 1992 Non-ferromagnetic Material In Core No Saturation et MdIt / dt I et dt M X-Ray Bowling, DeLeon, Pietsch, Senior Project report, 1999 Rogowski Coils Are: • Extremely Amplitude-Linear Devices • Not Frequency Sensitive (good Coils have 8 Octaves) • Position Sensitive (Coil Winding Imperfections) • Sensitive to Return Conductor Position Hall Effect Devices Are: • Very Position Sensitive • Temperature Sensitive • Proportional to Current not Rate of Change Can Use on 3 phase • Sensitive to Location of Return Conductors Power Factor: Current Through &Voltage Across Primary Control of Welder • Automatic Voltage Control (AVC) • Current Regulation • Constant Current Androvich “Resistance Welding Constant Current Heat Control”, AWS Sheet Metal ConfV, 1992 AVC Heat Control (constant voltage) Compensates for primary voltage changes Act. % Avail Current = [Act. Volt/Set Volt] x Programmed % Current AVC: • Holds Prim & Sec Voltage Constant on a 1/2 cycle basis • Changes total available current based on voltage changes • Does not compensate correctly for change in sec Resistance or Impedance • Usually has current pick up coil to alarm problems Androvich “Resistance Welding Constant Current Heat Control”, AWS Sheet Metal ConfV, 1992 Current Regulation Heat Control Current Regulation: • Uses Current Pick-up Coil & Analog Feedback Circuit • Requires variable gain, reset, dead band, that effect current output • Normally requires 3 to 5 cycles to stabilize • Therefore, used mostly with seam welding not spot welding Androvich “Resistance Welding Constant Current Heat Control”, AWS Sheet Metal ConfV, 1992 Constant Current Heat Control Program Controller Directly in Secondary Amperes, then controller holds secondary current within +/- 1% Controller Needs to Perform: • Digital Sampling of Primary and Secondary Current or Use Turns Ratio to Calculate Secondary • Calculate RMS Current on 1/2 cycle basis • Respond to process changes on 1/2 cycle basis (Use Predictive Feedback) • Self teach relationship between current and % available current • Primary benefit is its ability to compensate for changes in secondary impedance Androvich “Resistance Welding Constant Current Heat Control”, AWS Sheet Metal ConfV, 1992 Predictive Feedback • Use Large Firing Angle (small current) for first 1/2 cycle • Read results of current • Calculate a ratio between % available current and actual • Predict where to fire the next 1/2 cycle using tables Androvich “Resistance Welding Constant Current Heat Control”, AWS Sheet Metal ConfV, 1992 Lower Resistance Note: an increase in primary voltage is required to overcome the increase in secondary resistance Longer Fire Angle Higher Resistance Shorter Fire Angle Androvich “Resistance Welding Constant Current Heat Control”, AWS Sheet Metal ConfV, 1992 Benefit Extends to Seam Welding Also Circumferential seam welders have short, small secondary with constant inductance Cuff, Seam Welding with Constant Current Controls Welding Journal, Sept 1998 Longitudinal Seam welders have large, deep secondary , and inductance changes as more ferromagnetic material goes into throat. Constant Current Adjusts Control of Weld Quality 60 Cycle AC Secondary Monitoring Tsai, Experimental Study of Weld Nugget Expan, Paper B1, Sheet Metal Welding Conf V, AWS, 1992 4 Cycle 12 Cycle 6 Cycle 14 Cycle 8 Cycle 10 Cycle 16 Cycle 22 Cycle Tsai, Experimental Study of Weld Nugget Expan, Paper B1, Sheet Metal Welding Conf V, AWS, 1992 9.8 ka 12.2 ka 10.8 ka 13.8 ka 14.0 ka Tsai, Experimental Study of Weld Nugget Expan, Paper B1, Sheet Metal Welding Conf V, AWS, 1992 Real Time Equipment Arrangement Power Supply Strain Gage Signal Conditioner Oscilloscope Voltage Leads Print Displacement Transducer Isolation Box Tap Integration Data Recorder Dynamic Resistance = Voltage/Current dI 0 dt V Current Voltage R V I Two Points per Cycle (+ & - 1/2 cycles) Liang, “Fundamental Study of Contact Behavior in RSW” OSU Dissertation, 2000 Dickinson, Welding in Auto Industry, AISI, 1981 Dickinson, Characterization of Spot Weld..” Welding Journal, 1980 continued Dickinson, Welding in Auto Industry, AISI, 1981 Expulsion Surface Expulsion • Excessive Current • Low Force • Dirty Material • Poor Fit-up • Worn Electrodes Interfacial Expulsion • Excessive Current • Excessive Time Z=Impedance X=Reactance Dynamic Power Factor Monitoring R=Resistance Power Factor = Cos = 100% if pure Resistive = 0% if pure Reactive Reactance is basically fixed; Changes only if size or shape of secondary changes So Dynamic Changes in Resistance Result in Dynamic PF Changes Power Factor Can Be Measured at Controller, No Wires at Electrode Needed } = Negative Half Cycle + = Positive Half Cycle Count # of Expulsions Per 25 Welds Boilard, “Automatic Current Steppers for Improved Weld Quality” AWS Sheet Metal Welding Conf. V, 1992 } Automatic Current Stepper Based on Dynamic Power Factor If No Expulsion Current Increase 1% If 5 Expulsions/25 Welds Current Decrease 1% Havens “Controllin Spot Welding Quality and Expulsion” SME Paper AD76-279 1976 Havens “Controllin Spot Welding Quality and Expulsion” SME Paper AD76-279 1976 Bhattacharya “Temp Measurement of Resistance Spot Welds” Welding & Metal Fabrication, Nov 1969 Snee “Infrared Monitoring of Resistance Spot Welding” Metal Construction April 1972 Beevers “Temp Measurement to Determine Post Weld Heat Treatment..” British Welding Journal, April 1963 Burbank “Ultrasonic In-Process Inspection of Resistance Spot Welds” Welding Journal May 1965 Burbank “Ultrasonic In-Process Inspection of Resistance Spot Welds” Welding Journal May 1965 Dynamic Temperature Measurements Using Ultrasonics Ultrasound Transmitter Pulse Generator Weld Control System Real Time Spot Weld Evaluation Signal Processor Ultrasound Receiver Waschkies, E. “Process-Integrated Resistance Spot-Welding Testing Using Ultrasound Techniques” Welding In the World, Vol 39, No 6, 1997