* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Microelectromechanical Devices

Electrification wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Commutator (electric) wikipedia , lookup

Mains electricity wikipedia , lookup

Distributed control system wikipedia , lookup

Buck converter wikipedia , lookup

Resilient control systems wikipedia , lookup

Control theory wikipedia , lookup

Power inverter wikipedia , lookup

Alternating current wikipedia , lookup

Three-phase electric power wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Control system wikipedia , lookup

Voltage optimisation wikipedia , lookup

Dynamometer wikipedia , lookup

Opto-isolator wikipedia , lookup

Rectiverter wikipedia , lookup

Electric machine wikipedia , lookup

Power electronics wikipedia , lookup

Brushless DC electric motor wikipedia , lookup

Electric motor wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Induction motor wikipedia , lookup

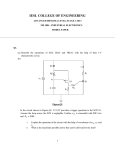

ECE 8830 - Electric Drives Topic 16: Control of SPM Synchronous Motor Drives Spring 2004 Introduction Control techniques for synchronous motor drives are similar to those for induction motor drives. We will consider both scalar and vector control for surface PM motor (both sinusoidal and trapezoidal PM motor) drives, reluctance motor drives, and wound field synchronous motor drives. Sinusoidal SPM Motor Drives The ideal synchronous motor torquespeed characteristic at a single frequency excitation is as shown below: Torque Motoring Mode 0 Generating Mode Speed Sinusoidal SPM Motor Drives (cont’d) Thus, the motor either runs at synchronous speed or doesn’t run at all. Two control approaches - open loop V/Hz control and self-control mode. In open-loop V/Hz control, the frequency of the drive signal is used to control the synchronous speed of the motor. In self-control, feedback from a shaft encoder is used to effect the control. Sinusoidal SPM Motor Drives (cont’d) Open-loop V/Hz control is the simplest control approach and is useful when several motors need to be driven together in synchrony. Here the voltage is adjusted in proportion to the frequency to ensure constant stator flux, s. An implementation of this control strategy is shown on the next slide. Sinusoidal SPM Motor Drives (cont’d) Sinusoidal SPM Motor Drives (cont’d) The control characteristics are shown in the figure below: Sinusoidal SPM Motor Drives (cont’d) Neglecting the stator resistance, and using the field flux f as the reference phasor, a phasor diagram of the synchronous motor is shown below: Sinusoidal SPM Motor Drives (cont’d) The torque developed by the motor is given by: P s f P Te 3 sin 3 s I s cos 2 Ls 2 where Iscos is the in-phase component of the stator current and is the torque angle. If e* is changed too quickly, the system will become unstable. The max. rate of acceleration/deceleration is given by: de* 1P Ter TL dt J2 where Ter = rated torque and TL = load torque. Sinusoidal SPM Motor Drives (cont’d) A self-controlled scheme for an SPM motor is shown below: Here the frequency and phase of the inverter output are controlled by the absolute position encoder mounted on the motor shaft. Sinusoidal SPM Motor Drives (cont’d) The absolute position encoder required for self-controlled drives for synchronous motors are one of two types - an optical encoder or a mechanical resolver with decoder. Sinusoidal SPM Motor Drives (cont’d) An optical encoder has alternating opaque and transparent segments. A LED is placed on one side and a photo-transistor on the other side. A binary coded disk is shown below: With 14 rings (14-bit resolution) a resolution of 0.04 electrical degrees can be achieved for a four-pole motor with this type of encoder. Sinusoidal SPM Motor Drives (cont’d) Another type of optical encoder is the slotted disk optical encoder. The below encoder is specifically designed for a 4-pole motor. Sinusoidal SPM Motor Drives (cont’d) There are many slots in the outer perimeter and two slots 180 apart on the inner radius. There are four optical sensors S1-S4. S4 is located on the outer perimeter and the S1-S3 sensors are located 60° apart on the inner radius. The sensor outputs are as shown below: Sinusoidal SPM Motor Drives (cont’d) The block diagram of a resolver with decoder is shown below: Sinusoidal SPM Motor Drives (cont’d) The analog resolver is basically a 2 machine that is excited by a rotor-mounted field winding. The primary winding of a revolving transformer is excited by an oscillator with voltage V=V0sint. The stator windings of the resolver generate amplitude-modulated output voltages: V1 AV0 sin t sin and V2 AV0 sin t cos Sinusoidal SPM Motor Drives (cont’d) The decoder converts the analog voltage outputs to digital position information. The high-precision sin/cos multiplier multiplies V1 and V2 by cos and sin respectively. An error amplifier takes the difference of these two output signals to generate the signal AV0 sin t sin( ). The phase sensitive demodulator creates a dc output that is proportional to sin( ) . An integral controller, VCO, and up-down counter together generate an estimated . Under steady state conditions the tracking error will be zero. Sinusoidal SPM Motor Drives (cont’d) Vector control of a sinusoidal SPM motor is relatively simple. Because of the large effective airgap in this type of motor, the armature flux is very small so that s m f . For maximum torque sensitivity (and therefore efficiency) we set ids=0 and I s = iqs. Sinusoidal SPM Motor Drives (cont’d) The torque developed by the motor can be expressed as: 3 P Te f iqs 2 2 where f is the space vector magnitude ( 2 f ) and f s cos s cos . A block diagram of a vector control implementation for a sinusoidal SPM motor is shown in the next slide. Sinusoidal SPM Motor Drives (cont’d) Note: This vector control scheme is only valid in the constant torque region. Sinusoidal SPM Motor Drives (cont’d) The upper limits of the available dc-link voltage and current rating of the inverter limit the maximum speed available at rated torque to the base speed (b). However, it is often desirable to operate at higher speeds (e.g. in electric vehicles). Above base speed, however, the induced emf will exceed the input voltage and so current cannot be fed into the motor. By reducing the induced emf, by weakening the air gap flux linkages, higher speeds can be obtained. Sinusoidal SPM Motor Drives (cont’d) In order to achieve the field weakening, a demagnetizing current -ids must be injected on the stator side. However, this ids must be large because of low armature reaction flux, a. This small weakening of s results in a small range of field-weakening speed control. Let us consider next how to extend the vector control scheme to speeds beyond base speed (b), i.e. into the field-weakening region. Sinusoidal SPM Motor Drives (cont’d) A phasor diagram for field-weakening control is shown below: Sinusoidal SPM Motor Drives (cont’d) The injected -ids which provides the flux weakening results in a rotation of the I s vector. At a’, I s ids which corresponds to zero torque and maximum speed, r1. At this condition, =0, s=s’, Vf=Vf’ and Vs=Vs’ (see phasor diagram). The field weakening region can be increased by increasing the stator inductance (see torque-speed diagram on next slide). Sinusoidal SPM Motor Drives (cont’d) Sinusoidal SPM Motor Drives (cont’d) A block diagram of a vector control drive for a sinusoidal SPM motor including the field weakening region is shown below: Sinusoidal SPM Motor Drives (cont’d) In constant torque mode, ids*=0 but in field-weakening mode, flux s is controlled inversely with speed with -ids* control generated by the flux loop. Within the torque loop, iqs is controlled to be limited to the value, * qsm i 2 s I ids 2 where I s is the rated stator current. Control of Brushless DC Motor Drives Trapezoidal synchronous permanent magnet motors have performance characteristics resembling those of dc motors and are therefore often referred to as brushless dc motors (BLDM). Concentrated, full-pitch stator windings in these motors are used to induce 3 trapezoidal voltage waves at the motor terminals. Thus a 3 inverter is required to drive these motors as shown in the next slide. Control of BLDM Drives (cont’d) The inverter can operate in two modes: 1) 2/3 angle switch-on mode 2) Voltage and current control PWM mode Control of BLDM Drives (cont’d) The 2/3 angle switch-on mode is shown in the below figure: Control of BLDM Drives (cont’d) The switches Q1-Q6 are switched on so that the input dc current Id is symmetrically located at the center of each phase voltage wave. At any instant in time, one switch from the upper group (Q1,Q3,Q5) and one switch from the lower group (Q2,Q4,Q6) are on together. The absolute position sensor is used to ensure the correct timing of the switching/commutation of the devices. At any time, two phase CEMF’s (2Vc) of the motor are connected in series across the inverter input. The power into the motor is 2VCId. Control of BLDM Drives (cont’d) In addition to controlling commutation by the timing of the switches in the PWM inverter, it is also possible to control the current and voltage output of the inverter by operating the PWM in a chopper mode. This is the voltage and current control PWM mode of operation of the drive. Control of BLDM Drives (cont’d) The average output current and voltage are set by the duty cycle of the switches in the PWM inverter. Varying the duty cycle results in variable average output current/voltage. Two chopping modes can be used - feedback mode and freewheeling mode. In feedback mode, two switches are switched on and off together (e.g. Q1 and Q6) whereas in freewheeling mode, the chopping is performed only on one switch at a time. Control of BLDM Drives (cont’d) Control of BLDM Drives (cont’d) Consider the feedback mode with Q1 and Q6 as the controlling switching devices. During the time that these switches are on, the phase a and b currents are increasing but during the time that they are off, the currents will decrease through feedback through the diodes D3 and D4. The average terminal voltage Vav will be determined by the duty cycle of the switches. Control of BLDM Drives (cont’d) Now consider the freewheeling mode of operation. When Q6 is on Vd is applied across ab and the current increases. When Q6 is turned off, freewheeling current flows through Q1 and D3 (effectively shortcircuiting the motor terminals) and the current decreases (due to the back emf). Control of BLDM Drives (cont’d) The steady state torque-speed characteristics for a brushless dc motor can be easily derived. Ignoring power losses, the input power is given by: Pin eaia ebib ecic 2I dVc The torque developed by the motor is simply, Te Pin e Control of BLDM Drives (cont’d) The back emf is proportional to rotor speed and is given by: Vc K r where K is the back emf constant and r is the mechanical rotor speed (=P/2) e. The steady state (dc) circuit equation for any switch combination is: Vd 2 Rs I d 2Vc Control of BLDM Drives (cont’d) The torque expression can be rewritten as: Te K .P.I d K1I d where P= # of motor poles. If we define the base torque as: Teb K1 I d I d I sc where Isc is the short-circuit current given by: Vd K1Vd I sc => Teb 2 Rs 2 Rs Control of BLDM Drives (cont’d) The rotor base speed rb can be defined as: rb r Id 0 Vd 2K The torque-speed relationship can be derived by combining these equations, yielding: r Te rb 1 => Te(pu)=1-r(pu) Teb where Te(pu)=Te/Teb and r(pu)= r/ rb Control of BLDM Drives (cont’d) This normalized torque-speed relation is plotted below. Note the droop in the no-load speed due to the stator resistance voltage drop. Control of BLDM Drives (cont’d) A closed loop speed control system for a BLDM drive with a feedback mode operation of the PWM inverter is shown below: Control of BLDM Drives (cont’d) Three Hall effect sensors are used to provide the rotor pole position feedback. This gives three 2/3-angle phase shifted square waves (in phase with the phase voltage waves). The six step current waveforms are then generated by a decoder. The speed control loop generates Id* from the r* command speed. The actual command phase currents are then generated by the decoder. Hysteresis current control is used to control the phase currents to track the command phase currents. Control of BLDM Drives (cont’d) A freewheeling mode close loop current drive for a BLDM is shown below: Control of BLDM Drives (cont’d) In this case the three upper devices (Q1, Q3, and Q5) are turned on sequentially in the middle of the positive half-cycles of the phase voltages and the lower devices (Q2,Q4 and Q6) are chopped sequentially in the middle of the negative half-cycles of the phase voltages to achieve the desired current Id*. This is all timed through the use of the Hall sensors and the decoder logic circuitry. One dc current sensor (R connected to ground) is used to monitor all three phase currents. Control of BLDM Drives (cont’d) The controller section and power converter switches outlined by the dotted line can be integrated into a low-cost power integrated circuit. An example of a commercial BLDM controller IC is the Apex Microtechnology BC20 (see separate handout). Control of BLDM Drives (cont’d) Pulsating torque can be a problem with BLDM motors (see figure below). Control of BLDM Drives (cont’d) The high frequency component is due to ripple current from the inverter and is filtered out by the motor. The rounding of the torque is due to the rounding of the phase voltages (caused by leakage flux adjacent to the magnet poles) and this generates significant 6th harmonic torque pulsation. A higher number of poles in the machine can help to alleviate this problem. Control of BLDM Drives (cont’d) The speed range of a BLDM motor can be extended beyond the base speed range (just as in the case of the sinusoidal SPM motor). This can be achieved by advancing the angle which is used to locate the position of the current waveforms with respect to the phase voltage waveforms (=0 locates the current waveforms in the center of the voltage waveforms). Also, if we change from a 2/3 conduction mode to a conduction mode. Control of BLDM Drives (cont’d) The normalized torque-speed curve for extended range is shown below for different angles for 2/3 conduction mode (solid lines) and conduction mode (dotted lines). Simulation of PM Synchronous Motor Drives Project 5 at the end of Ch. 10 Ong provides a study of a self-controlled permanent magnet synchronous motor. The motor parameters for the 70 hp, 4-pole PM motor are given in the table below: Simulation of PM Synchronous Motor Drives (cont’d) The steady state equations used in the simulation are given in the following table: Simulation of PM Synchronous Motor Drives (cont’d) If we assume that the output torque varies linearly with stator current Is, the torque expression can be rewritten as: Vs K x q 2 Vs cos Em Vs cos Em EmVs 2 sin ( x x ) sin d q xd xd xq 2 This is a nonlinear equation with a single unknown, . Once is found, the current and voltage components in the q and d rotor reference frame and the power factor angles and the stationary q, d current components can be calculated. Simulation of PM Synchronous Motor Drives (cont’d) The steady state curves are shown below: Simulation of PM Synchronous Motor Drives (cont’d) Some observations from these curves: Output torque Iqe and Iq (almost linear); thus torque control can be accomplished by controlling Iqe (or Iq) with Id controlled as shown. The power factor angles = 1/2 torque angle. This results in the phasor diagram shown (for the motoring mode): Simulation of PM Synchronous Motor Drives (cont’d) A Simulink simulation model for a selfcontrolled PM drive is shown below: Simulation of PM Synchronous Motor Drives (cont’d) Some points regarding this simulation model: iq and id are used to control the output torque. Torque command is implemented using a repeating sequence source. A rate limiter is used to limit the reference torque input to the torque controller. The inner id and iq control loops are closed loops. Simulation of PM Synchronous Motor Drives (cont’d) The feedback block uses the stator phase currents and rotor position to generate id and iq. The coordinated reference values for id* and Vs* are generated by separate function generator blocks (Id-Iq and VsTem, respectively) implemented using a curve fit to the steady state data shown earlier. Dynamic simulation results are shown on the next slide. Simulation of PM Synchronous Motor Drives (cont’d)