* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Chandra Theegala

Survey

Document related concepts

Occupancy–abundance relationship wikipedia , lookup

Latitudinal gradients in species diversity wikipedia , lookup

Introduced species wikipedia , lookup

Renewable resource wikipedia , lookup

Overexploitation wikipedia , lookup

Biodiversity action plan wikipedia , lookup

Transcript

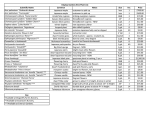

Dr. Chandra Theegala Department of Biological and Agricultural Engineering Louisiana State University ARE WE THERE YET ON ALGAL BIOFUELS: WHAT REMAINS TO BE DONE? Chandra Theegala*, Adam Dassey, Beatrice Terigar, Javed Iqbal, Ronald Malone *Chandra S. Theegala, Ph.D. Associate Professor Biological and Agricultural Engineering LSU AgCenter & LSU Baton Rouge, LA Overview of Presentation Biodiesel facts and need for biodiesel lipids Potential of algae as a biodiesel feedstock Primary challenges and my research solutions Cost-effective cell harvesting & dewatering* High infrastructure cost* Need for intensification of aerial productivity* Benign and cost-effective lipid extraction # Contaminant mitigation and species dominance (PhD work) Questions & Answers (slide number will help) * Critical today # Excluded due to time limitations 3 Biodiesel Facts and Need for Lipids US diesel needs: ~ 60 billion gal/year Total US transportation fuel needs ~ 200 billion gal/year Biodiesel production (2011-12) ~ 1.1 billion gallons/year Biodiesel production limited by feedstock availability Biodiesel – Advanced/non-starch fuel. RFS2: 21 billion gallons Bottomline: Need new and non-food/feed sources of oil Microalgae has potential to produce 2,000 - 3,000 (or more) gallons/acre/year (compared to ~70-80 gal/acre/year from soybean) Several limitations exist for microalgal biofuels Reality Snapshot/In a Nutshell: US Navy Contract to Solazyme: ~$425/gal (20,000 gal, heterotrophic direction) 4 Biodiesel Economics ~ Approx. Production Figures Description Oil (1 gallon, 7.5 lb) Methanol (0.11 gal x 1.5) Catalysts + Chemicals Natural gas + Electricity Labor + Maintenance Interest/Depreciation Final Cost: Unit Cost $0.53/lb $1.45/gal Cost/gallon $3.97 $0.24 $0.10 $10/mmbtu; $0.10/Kwh $0.03 $0.10 $0.15 -----------------------$4.59 = Oil cost + $0.60 Govt. Incentives/Subsidy (-) Distributor/retailer profit (+), Transportation (+) 5 Oil Productivities of Various Crops Crop Oil Yield [gal / acre] Total Cropping Area Required for Meeting 100% Transportation Fuels Needs Corn Soybean Canola 18 48 127 1,692% 652% 244% Jatropha Coconut Oil palm Microalgae (Estimate) 30% lipids 70% lipids 202 288 636 144% 108% 48% 6,275 14,633 5% 2.2% Source: Modified from Chisti, 2007. 6 Sustainability – Practicality?? Crop Oil Yield [gal / acre] Acreage Needed for Average Family (~1200 gallon per year) Soybean Canola Jatropha Coconut 48 127 202 288 25 acres 9.5 acres 6 acres 4.2 acres Oil palm Microalgae Chisti’s Estimate 30% lipids 70% lipids My Estimate 636 2 acres 6,275 14,633 2,000 0.2 acres 0.08 acres 0.6 acres 7 Microalgal Facts Several species have up to 40-60 % lipids contents. Several species can grow at extremely fast growth rates. (think of 1 foot plant going 7 to 10 feet by end of the day) High biomass productivity & high lipids contents are mutually exclusive High lipid strains are slow growing and highly susceptible to contamination Several thousands of recognized species of microalgae. But less than a handful can be mass produced outdoors (Weeds & predation). Production from microalgae is not straight forward (several challenges exist). Low solar energy conversion efficiencies (~2-3%). So surface area and open ponds are important (PBRs????, for biofuels? ) 8 Primary Limitations for Microalgal Biofuels High harvesting costs (Think – Removing color in water!) High infrastructure costs Need for intensification (70 gal/acre works, but 2000 does not?) Need for benign and cost-effective lipid extraction # Species dominance & contaminant control in open cultures (PhD) # Not covered due to time limitations 9 Cost Effective Harvesting & Dewatering Very challenging task. Think – Removing color in water! 100 mg-dry/L (0.01%) to 20% solids. 2000 times for <$2-3/g-oil Need 50-100 harvest cycles per year. Why? Low culture density (100-150 mg/L) is key for fast growth Specific growth rates plummet with increasing density Each cycle - Huge volume to process (660,000 gal). Yield ~22 gal (assuming 150 mg/L density and 20% lipids, 2 ft. depth). This is a money loser! Economics will not improve with more harvest cycles (1 cycle loss will project to bigger loss on 100 cycles) Centrifuges – effective but costly Microscopic & unicelluar~5 microns Marginal density differences (SP ~1) 2000-3000+ g forces > $25/gal oil 10 LSU BAE - Microalgal Research Team (Spring 2012) Covering all bases!! Adam, PhD*Harvesting Mostafa Jacob Beatrice, PhD* Lipid Intensification/ Light Optimization PhD – Species Dominance/ Contaminant Control Javed, PhD – Lipid Extraction Nick, MS*- Species Screening 11 Dissolved Air Flotation Prototype 12 Electro-flocculation •100 times concentration from 0.01% to 1% •But not a complete solution •Cost of aluminum (coagulant) released – high •Cheaper metal electrodes - promising 13 Proprietary 3-stage Harvesting System (Disclosure and Possible Patent) Cheapest way from 0.01% to 20% Operating at ultra-lean modes Major synergistic benefits Target price < $2-3/gallon (Final runs this week ! ?) 14 High Infrastructure Cost Pond and raceway construction costs are higher Ocean based culture systems to lower construction costs Indirect approach to address high infrastructure costs Intensify lipid yield from 2,000 to 8,000–15,000/gal/acre/year Will this effectively lower the burden of high infrastructure costs? Source: Sapphire Energy Source: Algenol Source: Popular Mechanics.com 15 Lipid Intensification, Light Optimization, Improved Pond Designs Full sunlight is PAR ~ 2,000 µmol/m2/s. Is this really needed? Are the current raceways and ponds ideal for high aerial productivity? DOE’s FOA 0000811, Target for 2018: 2,500 gal/acre/year We have a developed novel techniques that shows major promise Already proven at 2 levels (indoor 2 L bench-scale, outdoor 25 L prototype scale) Awaiting final field-scale test results this summer. Anticipating lipid yields of 8,000-15,000 gal/acre/year Operational costs? If proven successful, this will be a major breakthrough for algal biofuels. The Contamination Problem & Species Dominance Facts Several thousands of microalgal species But only a handful can be mass cultivated. High lipid and weaker strains – gets replaced in outdoor ponds Spirulina – high alkalinity Contamination Problem 1) Replacement by faster growing algal species 2) Predation by higher organisms. Ideal Plug Flow CONTAMINANT SLUG (Non-multiplying) TIME CONTINUOUS % WASHOUT IN ONE HRT = 100 % 18 Series of CSTRS Mimics Plug Flow Contaminant 10 cells Algae Contaminant may grow But never displaces the main species Higher Density 1000 cells 19 108 Cells Hydraulically Integrated Serial Turbidostat Algal Reactor (HISTAR) : My PhD work. Co-Advisors: Dr. Ronald Malone & Dr. Kelly Rusch media Inoculum media water Turbidostat Series of CFSTRs Pure inoculum Outdoor- amplifier Biomass increases with CSTR Open to atmosphere 20 Computer Automated 3,000 gallon - HISTAR System 21 22 Contaminant Washout Demonstrated Purposefully added 300 million rotifers System did not collapse Algal species and predators got flushed out 23 Are We There Yet? Microalgae has lots of potential. 30x soybean yield (200x?) - Yes Cost-effective harvesting – No (not yet) Reduce frequency of harvesting from 50-100 harvest cycles/year Get more oils per each harvest Economics should be favorable at 1 harvest cycle Bottomline: Lower harvesting/dewatering cost to < $1-2/gallon-oil Intensification of lipids to 5,000 gal/acre/year – No (not yet) Species and contamination control - Yes Methods exist for species and contaminant control DOE-ASP report (20 years research) - Grow native species Control is preferable for maximizing yield & lowering harvest frequency Are We There Yet? Lipid Extraction - Yes Bio-refinery Model – Not There, But Can Happen Effective methods do exist But need more benign techniques (non-hexane based, biodiesel solvent) Other value added products – critical for industry (say proteins, nutraceuticals, animal feeds, etc. Genetic/Novel Research – Futuristic (this is all we need!) Can drastically change the bioenergy scenario High lipids in proven and strainable Spirulina! Will be a winner!! No more bioenergy solutions needed Questions? Chandra Theegala Associate Professor Bio & Ag Engineering LSU AgCenter/LSU Email: [email protected] Phone: (225) 578 1060 Dr. Chandra Theegala Department of Biological and Agricultural Engineering Louisiana State University