* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download 1. INTRODUCTION

Control system wikipedia , lookup

Mains electricity wikipedia , lookup

Electronic paper wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Schmitt trigger wikipedia , lookup

Regenerative circuit wikipedia , lookup

Integrating ADC wikipedia , lookup

Oscilloscope wikipedia , lookup

Wien bridge oscillator wikipedia , lookup

Printed circuit board wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Electronic musical instrument wikipedia , lookup

Buck converter wikipedia , lookup

Oscilloscope history wikipedia , lookup

Switched-mode power supply wikipedia , lookup

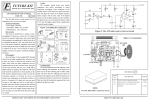

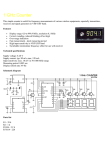

1. INTRODUCTION 1.1 General Description 1.2 Accessories 1«3 Technical Specification 1.1 General Description The LKB Novaspec is designed as a simple to operate instrument capable of producing rapid measurement of light absorption or transmission in the visible spectrum. Ease of operation is achieved by using a microprocessor to perform most of the repetitive tasks usually requiring prolonged operator action. The instrument is shown in Fig. 1.1 below. Display Panel Sample Compartment Cover Key Pad Fig. 1.1: General View The instrument is capable of performing absorbance measurements in the ranges -.30 to .999A and -.30 to 1.99A, and measurement directly in transmission units with an operational wavelength range of 325nm to 900nm. All operator inputs are made using four keys which comprise the operator key pad. A display panel mounted at the top of the unit provides instrument status information and digital displays of the selected wavelength and the measurement. Samples can be inserted into the instrument in 24mm (1") test tubes, 12mm (1/2") test tubes or 10mm cuvettes - the latter two requiring the use of the removable small test tube cuvette holder. The sample compartment is covered by a removable light tight lid. 1.2 Accessories A range of accessories is available for the LKB spectrophotometer as described below: Standard 10mm rectangular cells Tall series 10mm rectangular cells Funnel flowcell 24mm (1") and 12mm (1/2") test tubes Spectral light pipe for educational use External sample compartment cover for use with long test tubes (i50mm) Chart recorder. 1.3 Specification The instrument specification, is described below: Monochromator: 1200 lines/mm holographic diffraction grating Wavelength Range: 325-900nm Wavelength Calibration: Automatic upon switch on Wavelength Accuracy: *2nm Wavelength Reproducibility: *1 nm Light Source: Tungsten Halogen Lamp Detector: Single solid state silicon photocell Spectral Bandwidth: 12nm Stray Light: \% at 340nm measured according to ANSI/ASTM E387-72 Photometric Stability: 0.004A/Hr after warm up Photometric Noise: +0.001A near OA at 600nm Photometric Ranges: -.30 to .999A -.30 to 1.99A 1.0 to 200$T Sample Compartment: Complete with removable small test tube and cuvette holder. Accommodates 24mm (1 ") test tubes, 12mm (1/2") test tubes standard and tall 10mm Data Output: 0-1V for O - U . C O Sf-'T $ ? N T S •-;• '• 1 . •••:.';. flTBODUCTION ! ' 1.1 '= General- - B e s c r i p t i o n ' J 1 • ^ ? AccessoTies •'• 2. 1.5 T echnie a I'^Sy&c if i ca t i on -IIS^ÏIIPTIOÏÏ Oï1 OP&CAL StSTEM r - * » * * ~ — • — — — ^ - ^ T - - 2.1 j j c a l Sysfferó for 4049 Amt&matie Vavelength .C^ — • • : • T~" Kon Calibr&tion 2.4.1 Failure at Cal 1 2.4.2 lailure at Cal 2 •5.--I ':; SSÜÏOKBTER General DeacriptiQa .Slectronlo PescriptiW getting Up Procedure Circuit Diagrams Parts List IC Pin -Outfl PN4156-0184 Eöl *3/85 4. MAIH PCB 4.1 General Description 4.2 Electronic Description 4.3 5. 4.2.1 Microprocessor 4.2.2 The Analogue to Digital Converter 4.2.3 Recorder Output 4.2.4 Programmalle I/O 4.2.5 Program Memory Adjustments 4.3.1 A/D Ref. Voltage 4.3.2 Recorder Output 4.4 Circuit Diagrams 4.5 Parts List 4.6 IC Pin Outa POWER SUPPLY PCB AND LOOM 5.1 General Description 5.2 Electronic Description 5.2.1 Tungsten Lamp Supply . 5.2.2 5V Logic Supply 5.2.3 -5V Supply 5.3 Tungsten Lamp Adjustment 5.4 Circuit Diagrams 5.5 Parts List ' 5.6 IC Pin Puts 5.7 Loom Wire Run Outs . , 6. DISPLAY PCB, KEYBOARD PCB 6.1 General Description 6.2 Electronic Description 6.2.1 Display PCB 6.2.2 Keyboard PCB 6.3 Adjustments 6.4 Circuit Diagrams 6.5 Parts List 6.6 IC Pin Outs MAINTENANCE 7.1 Introduction 7.2 Safety Notes 7.3 Special Rote About The Monochromator 7.3.1 7.4 Fault Finding 7.4.1 7.5 Cleaning of the Optical System Trouble Shooting Table Mechanical Servicing 7.5.1 Removal of Top Cover 7.5.2 Removal of Wain Chassis 7.5.3 Replacement of Fan 7.5.4 Lamp Output Check 7.5.5 Tungsten Lamp Replacement 7.5.6 Drive Cord Replacement 8. OPERATION 8.1 8.2 8.3 ÏBtroduction 8.1.1 Key Pad 8.1.2 Display Panel 8.1.3 Sample Compartment Instrument Operation 8.2.1 Initial Switch-On 8.2.2 Performing a Measurement Further Operator Information 8.3.1 Introduction 8.3.2 Instrument Indications 2. DESCRIPTION OF OPTICAL SYSTEM 2.1 Light Source 2.2 Optical System for 4049 2.3 Automatic Wavelength Calibration 2.4 Reasons for Non Calibration 2.1 2.4.1 Failure at Cal 1 2.4.2 Failure at Cal 2 Light Source The light source is a single 12V tungsten lamp operating at 10.2V to increase lamp life. The lamp can easily be replaced without the removal of the instrument main cover. 2.2 Optical System for 4049 The instrument optical system is shown in simplified form in Fig. 2.1. The light output from the lamp passes through a slit to the collimator where it is converted into a single parallel beam. This light is then passed to the monochromator which contains the diffraction grating and the stray light filters. The diffraction grating in conjunction with the second collimator produce the monochromatic light which passes through the sample to the soiid state detector unit. \ I )\ r r * • MONOCHROMATOR 1 i i ^ I j^ -> ^ i !J ^ - - i co< i i i i • DIFFRACTION GRATING W STRAY LIGHT FILTERS i , | •«^ / / 1 Fig. 2.1: Optical System i 2.3 Automatic Vavelength Calibration Upon switch on Cal 1 appears on the display. During Cal 1 the grating arm is being driven to the backstop opto switch position. Upon recognition of the opto signal, the display shows Cal 2 and the grating motor reverses. The instrument now searches for its calibration peak, the zero order spectrum. Upon identifying the centre point of this peak, the instrument changes to Cal 3 and the grating motor drives to 360nm. During this period the darking solenoid actuates and the dark current is stored. 2.4 Reasons for Kon Calibration 2.4.1 Failure at Cal 1 This is due to either failure of opto switch or the breaking or disconnection of Drive Cord or a malfunction of the grating motor or associcated drive circuit. Failure is signified by staying on Cal 1. 2.4.2 Failure on Cal 2 This could be due to lamp failure, sample left in cell compartment, total misalignment of the opties. Failure is signified by automatic return to Cal 1 and display flashes. When calibrated the instrument should read >.999A, if not the lamp has moved or is faulty. 3. PHOTOMETEE PCB 3.1 Specification 3«2 General Description 3-3 Electronic Description 3-4 Setting Up Procedure 3-5 Circuit Diagrams 3-6 Parts List 3.7 IC Pin Puts 3.1 Specification Photodiode detector. OV to -4V de signal voltage output from 2 bit Programmable Gain Amplifier. Programmable gains of 1, 4, 16, 64. Gain ratiometric accuracy corresponding to 0.001A = 0.23$ +/- 5V supply. 3«2 General Description The circuit diagram is given in Section 3-5. A conventional photodiode front end stage similar to the Ultrospec II is used, but with less current to voltage gain and hence lower impedances. The lower supply voltages available make the Harris amplifier unsuitable for this application and so the Texas TLC271CP was chosen for its wide common mode input voltage range and low offset current. The amplifier is operated at the medium bias setting (pin 8 = OV) giving the best trade-off between open loop gain and noise. The programmable gain amplifier is another TLC271CP with a high accuracy pot chain made from discrete resistors and the appropriate tapping selected from a low cost CMOS multiplexer. 3.3 Electronic Description The photocurrent produced by light hitting the photodiode is converted by 1201 into a voltage proportional to the impinging light. Offset pot (R204) and gain pot (R208) are provided to control photodiode bias and to ensure that the amplifier does not saturate under maximum light levels (gain pot set to give -3V max output). The offset pot is adjusted under no light conditions so as to apply a small negative bias of 2mV across the photodiode. This is done to guarantee that the diode will not become forward biased even if the amplifier input offset voltage drifts with temperature in a positive direction. Thus the output from the first stage varies from -2mV under no light conditions to -3V under maximum light conditions. The second stage comprises the programmalle gain amplifier (1202). A 2 bit binary input to the multiplexer is used to select one of four possible gains, 1, 4, 16 and 64 by switching in the appropriate section of a precision divider ladder. An offset adjustment pot (R210) is provided to null the amplifier output when a gain of 64 is selected and there is 0V input. This prevents any amplifier input offset voltage from being gained up by the feedback resistors. 3.4 Setting Up Procedure There are three potentiometers on this PCB. The offset pots R210 and R204 are factory set and do not need adjusting. R208 is the gain pot and will only need adjusting if the lamp intensity changes greatly. This may happen if a new lamp is very much brighter than the old one. 5 Circuit Diagrams 4000 4574 Photometer Circuit 4000 4576 Component Overlay ~0 o -i o (J) m z in o ;o u n R20G R205 f3 I B 40004575 ISS 1 SIDE 1 LKB OD : RS10 CS06 1 n RS07 ru o 'I R204 CD IS03 IE01 en o > I • ICJL) RS19 o CD UI N cn RE 16 RS15 R213 RSil RE14 RS12 o REOe 3-6 Parts List Photometer PCB Quantity Part Nummer Description Location 4000 4575 Photometer PCB A3 4000 4574 Photometer Circuit A3 4000 4576 Component Overlay 1 4187 0102 1 4178 0092 10 Way Dual Row Rt. Angle Waf er Photodiode UV50 2 4181 0097 Integrated Circuit TLC271CP IC201, IC202 1 4181 0094 Integrated Circuit CD4O52B IC2O3 1 4160 0277 Resistor 100R \% Metal Film R201 2 4160 0080 Resistor 1K \% Metal Film R2O9, R218 3 4160 0022 Resistor 10K \% Metal Film R2O5, R206, R207 1 4160 0321 Resistor 90.OK \% Metal Film R215 1 4160 0322 Resistor 147K \% Metal Film R213 1 4160 0323 Resistor 332K \% Metal Film R211 2 4160 0125 1 4160 0181 Resistor 1K5 \% Metal Film R219 1 4160 0324 Resistor 100R 0.1$ Metal Film R217 1 4160 0325 Resistor 301R 0.1$ Metal Film R216 1 4160 0326 Resistor 121OR 0/1 # Metal Film R214 1 4160 0327 Resistor 4870R 0.1$ Metal Film R212 1 J201 D201 Resistor 4M7 5% Metal Film R202, R203 Quantity Part Number Description Location 4162 0098 Capacitor 100pF Ceramic 100V C202, C2O7 4162 0099 Capacitor 10nF Ceramic 100V C201 4162 0100 Capacitor 100nF Ceramic 50V C203, C204, C205, C206 4163 0008 Capacitor 10uF Electrolytic 50V C208, C2O9 4161 0030 Trimpot 20K 25 Turn R204, R208, R210 3-7 IC Pin Outs TLC271CP Programmable Low Power Op Amp BIAS SELECT V M OUTPUT DD OFFSET NULL (NO) \ï~\ 1 OFFSET NULL (NI) INV NON-INV INPUT INPUT GND CD4052 H Channel Analogue Multiplexer/Demultiplexer IN/OUT '-~*-N 'DD 16 1 2x OUT/IN lx x IN/OUT '~^-> Ox 3x 15 14 13 12 2 3 4 5 Oy 2y y 3y ly V v > ~~ OUT/IN ^"^ IN/OUT IN/OUT TOP VIEW 11 6 INH A B 10 9 7 8 MAIN PCB 4»1 General Description 4.2 Electronic Description 4.3 4.2.1 Microprocessor 4.2.2 The Analogue to Digital Converter 4.2.3 Recorder Output 4.2.4 Programmable I/O 4.2.5 Program Memory Adjustments 4.3.1 A/D Ref. Voltage 4.3.2 Recorder Output 4.4 Circuit Diagrams 4-5 Parts List 4.6 IC Pin Outs 4.1 General Description The main PCB contains the microprocessor based control system of the whole instrument. This board outputs signals to the display board, the keyboard, the photometer board, the grating motor, the analogue output and the darking flag solenoid. It also processes inputs from the keyboard and the photometer board. 4.2 Electronic Description 4.2.1 Microprocessor An Intel 8085 controls the entire instrument. All functions are pontrolled via the buses, and 1111 decodes the three highest address bits to provide the chip select signals. Timing for the 8085 is derived from a 4.433 MHz crystal. 4.2.2 The Analogue to Digital Converter The A/D converter is an Intersil ICL71O9, which is a 12 bit binary, dual slope integrating A/D converter, with low noise and drift characteristics. The end of conversion is checked by the status line from the converter to the input port of 1116. When the status is high, 1109 is still converting and when the status is low, the data is valid for reading. Each reading made by the converter consists of three cycles:a) Auto-zero Sequence Auto-zero disconnects the internal inputs and shorts them together. A reference capacitor is charged to the reference voltage and an auto zero capacitor is also charged. This compensates for offset voltages, so that the output level will be zero input. The reference voltage is set at 0.800V. b) Signal Integrate Phase The signal integrate phase connects the input signal for measurement to the internal amplifier, which has been offset corrected and also charges capacitor C119 for a period of 2048 clock counts. c) De-integrate Phase De-integrate causes the internal amplifier to be disconnected from the signal input and then connected to the reference capacitor, which causes the output of the amplifier to return to zero volts. The time taken from start of de-integrate until zero is reached, is therefore proportional to the input voltage and this is counted against the system clock (normally a maximum of 4096 counts). The A/D runs independently from the microprocessor and receives its timing from the 8253 counter/timer 1113' 4.2.3 Recorder Output For recorder output, 1113 provides a pulse train whose mark space ratio varies with the desired output signal from the detection system. 1113 is a 8253 programmable interval time/counter. 1114 accepts the pulse train from 1113 and provides drive current to charge the two pole filter network on the input of 1115. 1115 acts as a buffer amplifier to drive the analogue output. The output level is set by V121 and the output is provided at two 4mm sockets on the rear of the instrument. 4.2.4 Programmable I/O 1103 Port A Bit 0. 1 2 3 4 5 6 7 Stray light solenoid control bit (unused) Darking Flag control bit 6 display digits and indicator LED refresh bits ) ) Keyboard Scan bits Port B Bit 0 1 2 3 4 5 6 7 Display Segments refresh bits Port C Bit 0 1 2 3 4 5 4.2.5 ) ) Grating Motor ) drive ) ) Photometer gain ) control bits Program Memory The instrument control program is contained in a 2764 EPROM, 1112. This device contains 64K bits or 8K bytes of ROM. The RAM memory of the system, consisting of only 256 bytes, resides in the 8155 chip, 1103. 4.3 Adjustments 4.3.1 A/D Ref. Voltage The voltage between TP1 and TP2 should be adjusted by means of V114 to 0.800V. V114 is on the main PCB. 4.3.2 Recorder Output The voltage at the recorder output terminals should be adjusted by means of V121 to give 1V per 1A e.g. if the display reads .695A, then adjust output to give O.695V. V121 is on the main pcb. 4.4 Circuit Diagrams 4000 4560 Control Circuit Diagram 4000 4562 Component Overlay 4«5 Parts List Main PCB Quantity Part Number Description Location 4000 4561 Control PCB A1 4000 4560 Control Circuit Diagram A3 3 4160 0013 Resistor 1 OK R11 0,109,114 1 4160 0015 Resistor 22K R111 2 4160 0006 Resistor 1K R112,122 1 4160 0094 Resistor 4K7 R106 1 4160 0112 Resistor 1 80R R108 1 4160 0275 Resistor 270K R124 2 4160 0071 Resistor 15K R123,113 4 4160 0103 Resistor 100K R115,117,118 119 1 4160 0146 Resistor 39OR R120 1 4160 0269 Resistor 1 50K R116 1 4161 0060 Potentiometer 500R V121 1 4161 0058 Potentiometer 1 OK V114 1 4181 0019 Integrated Circuit 8085AH 1108 1 4181 0047 Integrated Circuit 8155AH 1103 1 4181 0042 Integrated Circuit ICL7109 1109 1 Part Number Description Location 1 4181 0014 Integrated Circuit 74LS373 1110 1 4181 0043 Integrated Circuit ULN2803A 1101 1 4181 0017 Integrated Circuit 74LS138 1111 1 4181 0010 Integrated Circuit 8253 1113 1 4181 1000 Integrated Circuit 74LS00 1107 1 4181 3140 Integrated Circuit CA3U0E 1115 1 4181 4069 Integrated Circuit MC4069UB 1114 1 4181 0089 Integrated Circuit 74LS365 1116 1 4181 0008 Integrated C i r c u i t 78L05 1104 1 4000 4927 Control Eprom A 1112 1 4174 0001 Crystal 4.433 MHz 10 4162 0100 Capacitor 0u1 C123-C132 2 4162 0093 Capacitor 22pF C113-C114 1 4162 0074 Capacitor 1uF C116 1 4162 0070 Capacitor 0.22uF C104 1 4162 0071 Capacitor O.33uF C118 1 4162 0072 Capacitor O.47uF C117 1 4162 0066 Capacitor 47nF C119 1 4163 0000 Capacitor 0.47uF C105 2 4163 0002 Capacitor 1 uF C120,C121 1 4163 0008 Capacitor 10uF C122 1 4163 0011 Capacitor 47uF C115 1 4178 4148 Diode IN4148 D101 Quantity 6 IC Pin Outs 8O85A 40 Z ] vcc 39 Zl HOLD AD2 EZ 1 EZ 2 LZ 3 LZ 4 EZ 5 EZ 6 IZ 7 EZ 8 LZ 9 EZ 10 EZ 11 LZ 12 EZ 13 EZ 14 AD3 tz 15 26 Z l A 13 AD4 25 Z ] A 12 AD, LZ 16 IZ 17 24 Z l A cz ll AD6 23 Z l A 24 v x l x2 RESET OUT SOD SID TRAP RST 7 . 5 RST 6 . 5 RST 5 . 5 INTR TNTA ADQ AD1 b 38 Z3 HLDA 37 Zl CLK (OUT) 36 ZJ RESET IN 35 Z3 READY 34 Zl 33 18 z: IO/M S 32 Z ] l ÏÏD 31 Z l WR 30 Zl ALE 29 Zl S 28 Zl A 15 27 Z ] A 14 0 10 22 Z3 A9 21 Z l A 8 LZ 19 20 V SS EZ AD7 8253 7 IZ D 1 2 6 EZ 3 D 5 EZ LZ 4 D 4 5 D 3 EZ LZ 6 D 2 D LZ 7 D l V.y 23 22 21 20 19 18 8 0 LZ CLK 0 EZ 9 16 OUT 0 LZ 10 15 GATE 0 LZ 11 14 GND LZ 12 13 D Zl Zl Z1 Zl Zl 17 Zl Zl Zl Zl Zl cc WR ÏÏD er A l A o CLK 2 OUT 2 GATE 2 CLK 1 GATE 1 OUT 1 8155/H 8156/H 8155H-2/ 8156H-2/ PC 40 3 'CC PC4 CZ 2 39 TIMER IN 3 38 RESET 4 37 PC5 5 36 TIMER OUT 6 35 IO/M 7 34 E T OR CE 8 33 RD 9 32 W 10 31 11 30 PB ] 12 29 PB ( 13 28 PA- AD O 14 27 AD 15 26 16 25 17 24 18 23 19 22 20 21 ALE EZ ADQ AD ] AD'SS CZ CZ CZ CZ L =1 Z3 2 PC PC C PB m PB PB, PA, PAr 4069 ïï. 'SS CZ 1 CZ 2 CZ 3 CZ 4 CZ 5 CZ 6 CZ 7 ^_y 14 Z3 'DD 13 Zl 12 Z] . 11 Zl 10 ZJ 9 ZI 8 Zl ÏÏ, ICL71O9 cz 1 40 d d 2 39 3 38 Zl REF CAP- LZ 4 d 5 37 Z ] REF CAP+ 36 Zl REF I N + Bil cz 6 35 Zl I N H l B1O tz 7 34 Z l I N LO d B8 d B7 d B6 LZ: B5 d B4 d B3 d B2 d BI d TEST d LBËN d ÏÏBËN d CE/LOAD d 8 33 Z ] COMMON 9 32 Zl INT 10 31 Zl AZ 11 30 =1 BUF 12 29 Z l REF OUT 13 28 14 27 15 26 Z3 RUN/HÖUÏÏ 16 25 Z ] BUF OSC OUT 17 24 Z3 OSC SEL 18 23 19 22 Z ] OSC I N 20 21 Z3 MODE GND STATUS POL OR BI 2 B9 OFFSET NULL INVERTING INPUT NON-INTERTING INPUT Zl Zl V+ REF I N - V- Z3 Zl SEND OSC OUT 7^365 CL 16 V-CC m ï? T GND [ V 10 5. POVER SUPPLY PCB AND LOOM 5.1 General Description 5.2 Electronic Description 5.2.1 Tungsten Lamp Supply 5.2.2 5V Logic Supply 5.2.3 -5V Supply 5.3 Tungsten Lamp Adjustment 5.4 Circuit Diagrams 5.5 Parts List 5.6 IC Pin Outs 5-7 Loom Wire Run Outs 5.1 General Description The power supply PCB rectifies the a.c. supplies from the transformer to provide the d.c supplies required for instrument operation. 5>2 Electronic Description The power supply consists essentially of three sections. 5.2.1 Tungsten Lamp Supply The tungsten lamp supply of 10.2V d.c. is derived from a 13.5V winding on the transformer. The regulator for this supply is an SGS L200 linear device mounted remotely on the fan bracket. This is because the L2OO generates a considerable amount of heat which must be dissipated from the instrument enclosure. 5.2.2 5V Logic Supply The second section consists of the 5V logic supply via a 78S05 regulator and a 9V unregulated supply for the display drivers, the grating motor and the darking flag solenoid. A 9V a.c. supply is tapped off before the rectifier REC2 to drive the fan. 5-2.3 -5V Supply The third section is a -5V supply via IC3, a 79LO5 regulator, for the A/D converter, the photometer amplifiers and the, analogue output driver. Note The +5V supply, denoted +5V(A), for the A/D converter, photometer amplifiers and the analogue output driver, is generated on the main PCB via 1104, a 78LO5 regulator, from the 9V unregulated supply. It is located on the main PCB because it needs to be physically close to the A/D converter to minimise noise pickup on the supply. The reference voltage on the A/D converter should be as quiet as possible. 5-3 Tungsten Lamp Adjustment This is 10.2V measured on the terminal strip and adjusted by R2 mounted on the power supply board. 5«4 Circuit Diagrams 4000 4569 Power Supply Circuit Diagram 4000 4571 Component Overlay LKB S HËCl RECS R f 8 P R 8 n r~ qJ 2 ï 3 n • e r Cll 0 y y y 8 S t fb POWER SUPPLY PCB ASSY 40004571 5.5 Parts List Power Supply PCB and ]Loom Quantity Part Number Description Location 4000 4570 Power Supply PCB A3 4000 4569 Power Supply Circuit A3 2 4178 0029 Rectifier KBL02 REC 1 ,REC 2 1 4178 0013 Rectifier W01 REC 3 4 4163 1070 Capacitor 4,700uF 25V SU C1 ,C12,C5,C6 1 4163 1071 Capacitor 1,CO0uF 25V SU C9 2 4163 0000 Capacitor 0u47 K Series C8.C11 3 4162 0070 Capacitor 0u22 MKS2 C2,C7,C10 1 4162 0068 Capacitor 0u1 MKS2 C4 1 4163 1034 Capacitor 100uF 25V C3 2 4163 0011 Capacitor 47uF K Series C13,C14 1 4160 0104 Resistor 820R R1 2 4160 0094 Resistor 4K7 R3.R4 1 4161 0026 Potentiometer 10K R2 1 4181 0091 Regulator 78S05 IC2 1 4181 0055 Regulator 79LO5 IC3 1 5.6 IC Pin Outs 100 mA fixed voltage pin view pin view Fixed-voltage 100 mA regulators with internal, overload, thermal and shortcircuit protection TO92 plastic case. Total dissipation 600 mW at T 25 C. 5-7 Loom Wire Run Outs Control Board Connector J100 Pin Number Signal Name Wire Colour Destination 1 Motor 0 2 YL/REL Motor 2 2 Motor 0 1 RD/BRN Motor 1 3 Motor 0 3 RD/BK Motor 3 4 5 Recorder + Motor 0 4 OR/BL RD/GRN Conn Block Row 8 Motor 4 6 +5V (A) Output WH/YEL Photometer J201 Pin 3 7 Darking Flag Solenoid WH/GRN Conn Block Row 4 8 +5V Input ¥H Pwr Supply J2 Pin 6 9 Polarising Key 10 +5V Input WH Pwr Supply J3 Pin 9 11 Photometer G1 WH/BRN Photometer J201 Pin 9 12 Opto Collector GY/OR Opto Switch Term C 13 Photometer G 0 WH/BK Photometer J201 Pin 10 14 -5V (A) Input WHAIO Pwr Supply J3 Pin 7 15 OV GREY Pwr. Supply J3 Pin 3 16 OV GREY Pwr Supply J3 Pin 5 17 Opto Anode GY/BL Opto Switch Term B 18 -5V (A) Output WH/VIO Photometer J201 Pin 5 19 9V Input ¥H/OR Conn Block Row 3 20 Inlo BLUE Photometer J201 Pin 2 Pin Number 21 Signal Name . Photometer G2 Wire Colour Destination ¥H/RD Photometer J201 Pin 8 22 Photometer Signal Input RED Photometer J201 Pin 1 23 Recorder - OR/BK Conn Block Row 9 24 OV (A) Output WH/GY Photometer J201 Pin 4 25 OV (A) Input WH/GY Pwr Supply J3 Pin 1 26 Photometer Signal Screen Screen of Twin Screen No Where Photometer Board Connector J201 1 Signal Out RED Control Board J100 Pin 22 2 Inlo BLUE Control Board J100 Pin 20 3 +5V (A) WHAEL Control Board J100 Pin 6 4 OV (A) ¥H/GY Control Board J100 Pin 24 5 -5V (A) WH/VIO Control Board J100 Pin 18 6 1st Stage Out Control Board J100 Test only 7 Polarising Key Control Board J100 8 G2 (Unused) WH/RD Control Board J100 Pin 21 • 9 G1 WH/BRN Control Board J100 Pin 11 G 0 ¥H/BK Control Board J100 Pin 13 10 Pover Supply Board Connector J4 Pin Number Signal Name Vire Colour Destination 1 Input WH/BRN Leg 1 of L200 Regulator 2 Limiting WH/RD Leg 2 of L200 Regulator 3 GND WH/OR Leg 3 of L200 Regulator 4 Eef WH/GRN Leg 4 of L200 Regulator 5 Output WH/BL Leg 5 of L200 Regulator 6 Polarising Key 7 Fan (C) YL/GRN Conn Block Row 10 8 Fan (B) YL/RED Conn Block Row 11 9 Fan (A) YL/BK Conn Block Row 12 WH/OR Conn Block Row 3 WH/OR Grating Motor Tags Power Supply Connector J2 1 9V 2 Polarising Key 3 9V 5 &6 4 -5V (A) Unused 5 +5V Unused 6 +5V WHITE J100 Pin 8 7 Lamp OR/BK Conn Block Row 1 8 Unused 9 Lamp OR/RD Conn Block Row 2 OV GREY Opto Switch Terminals A+D 10 Pover Supply Connector J3 Signal Name Vire Colour Destination Pin on J100 1 OV (A) VH/GY 25 2 PV GREY Conn Block Row 7 3 OV GREY 15 4 OV (A) Unused 5 OV GREY 6 OV Unused 7 -5V (A) WH/VIO 14 8 Polarising Key 9 +5V WHITE 10 Pin Number 10 16 Unused Connector Block Lamp 1 1 Lamp OR/BK Pwr Supply J2 Pin 7 Lamp 2 2 Lamp OR/RD Pwr Supply J2 Pin 9 3 9V Input WH/OR Control Board J100 Pin 19 3 9V WH/OR Pwr Supply J2 Pin 1 Solenoid 3 3 Solenoid 4 4 Darking Flag Solenoid WH/GN Control Board J100 Pin 7 Pin Number Signal Name ¥ire Colour Destination 7 OV GREY Pwr Supply J3 Pin 2 8 Recorder + OR/BL Control Board J100 Pin 4 *8 Recorder + OR/BL Rear Pnl Red Term 9 Recorder - OR/BK Control Board J100 Pin 23 *9 Recorder - OR/BK Rear Pnl Black Term 10 Fan (C) YL/GRN Pwr Supply J4 Pin 7 10 Fan RED To Fan 11 Fan (B) YL/RED Pwr Supply J4 Pin 8 11 Fan YL To Fan 12 Fan (A) YL/BK Pwr Supply J4 Pin 9 12 Fan BK To Fan 7 * Part of Rear Panel Assembly 6. DISPLAY PCB, KEYBOARD PCB 6.1 General Description 6.2 Electronic Description 6.2.1 Display PCB 6.2.2 Keyboard PCB 6.3 Adjustments 6.4 Circuit Diagrams 6.5 Parts List 6.6 IC Pin Outs 6.1 General Description The keyboard and display board are mounted on the inside of the top cover. They are connected to the main PCB via ribbon cables. 6.2 Electronic Description 6.2.1 Display PCB The instrument display is driven by 1103 on the main control PCB via the two driver chips IC307 and IC308. IC307 pulls down the numbered segment displays and IC308 drives the anodes and the sources of the individual LEDs (such as 6.2.2 Keyboard PCB The keyboard contains 4 key switches and the pull down diodes necessary for operation. 6.3 Adjustments There are no adjustments on either of these PCBs. 6.4 Circuit Magrams 4000 4563 Display PCE Circuit Diagram 4000 4565 Display PCB Component Overlay 4000 4566 Keyboard PCB Circuit Diagram 4000 4568 Keyboard PCB Component Overlay r d D4 AD3 Ó iO S2 ZD2 M S1 X D1 1 -• 2 4 -«• 5 I | KEYBOARD CIRCUIT 40 00 4566 COMPONENTS SHOWN DOTTED ARE MOUNTED ON NON-TRACK 5IDE OF BOARD KEYBOARD ASSEMBLY 40 00 4568 6.5 Parts List Display ]PCB Quantity 1 Part Number Description 4000 4564 Display PCB 4000 4563 Display Circuit Location 6 4178 0099 5082-7750 7 Seg LED 1301-1306 3 4178 0094 5082-4670 Reet LED D301-D3O3 1 4181 0043 Integrated Circuit ULN2803A 1307 1 4181 0044 Integrated Circuit UDN2981A 1308 1 4162 0068 Capacitor 1OOnF MKS 2 C301 8 4160 0299 Resistor 150R R301-R308 Keyboard PCB 4000 4567 Keyboard PCB A2 4000 4566 Circuit Diagram A4 4 4000 3607 Keytop A2 4 4184 0046 Disc Switch S1-S4 4 4178 4148 Diode I N 4 H 8 D1-D4 1 6.6 IC Pin Outs ULN-2803A DARLINGTON TRANSISTOR ARRAYS UDN-2981A CURRENT SOURCE DRIVERS 7. MAINTENANCE 7.1 Introduction 7.2 Safety Notes 7.3 Special Note At>out The Monochromator 7.3.1 7.4 Fault Finding 7.4.1 7.5 7.1 Cleaning of the Optical System Trouble Shooting Table Mechanical Servicing 7.5.1 Removal of Top Cover 7.5.2 Removal of Main Chassis 7.5.3 Replacement of Fan 7.5-4 Lamp Output Check 7.5.5 Tungsten Lamp Replacement 7.5.6 Drive Cord Replacement Introduction The only user maintenance is changing the lamp and the fuse. The LKB service engineer is responsible for all other servicing. 7.2 Safety Notes Servicing is carried out with the cover removed so proceed with CAUTION AS KAÏNS VOLTAGES ARE PRESENT. 7«3 Monochromator The monochromator housing contains the grating and the stray light filters. The filters are fixed to the arm of the grating, and by design are in the light path when necessary. 7.3.1 Cleaning of the Optical System The grating cannot be cleaned as this would destroy the diffraction lines (1200/mm). The other opties should be cleaned with a lens cloth and cleaning fluid suitable for camera and precision optical use only. 7.4 Fault Finding 7.4.1 Trouble Shooting Table It is too early to compile a suitable table. See SILs for details. 7.5 Mechanical Servicing 7.5.1 • Removal of Top Cover The top cover is attached to the base by four screws. Undo these screws and carefully lift the lid as the cable for the boards mounted in the lid is attached to main chassis. 7.5.2 Removal of Main Chassis The main chassis can be removed completely as follows: 1) Remove lid as in section 7.5.1. 2) Undo the four mounting screws. 3) Unplug the connector to lid unit. 4) Disconnect the wires from the recorder at the terminal block. 5) Disconnect earth wire from the spade terminal on the chassis. 7.5.3 Replacement of Fan The fan can be replaced by first removing the lid as in section 7-5.1. Then undo the two screws and replace with Part Number 4000 4945. 7.5«4 Lamp Output Check Switch on the instrument and allow to calibrate but do not press the SET REF key. Set the wavelength to 692nm and, without pressing the SET REF key, read the absorbance value. This gives a measure of the light output from the tungsten lamp. The absorbance value obtained should be approximately O.O35A, however, variations in output of individual lamps may result in a range of * O.O65A of the above figure, without affecting the performance of the instrument. Reduced light output from the tungsten lamp will show an increased absorbance value indicating that the lamp requires replacement. 7.5.5 Tungsten Lamp Replacement WARMING: THE LAMP BBCOMES VERY HOT IN USE. COOL BEFORE CHANGING. ENSURE IT IS To replace the lamp proceed as follows: a) Switch off the instrument and disconnect the mains input. b) Remove the spring cover from the lamp compartment at the rear of the instrument as shown in Fig. 7.1. c) Remove the faulty lamp by sliding it upwards out of the lamp holder. Slide the replacement lamp into the holder. CAUTION: IF THE LAMP IS TOUCHED BY FINGERS THEN CLEAN THE GLASS USING METHANOL. d) Refit the lamp compartment cover. If, after a lamp has been replaced, the display flashes all zeros (000) at 692nm, then proceed as follows: a) Remove the replacement lamp. b) Rotate the lamp through 180 . c) Replace lamp. If after this procedure the lamp does not function correctly then adjust photosensor PCB as in section 3« 7.5.6 Drive Cord Replacement Remove lid as in section 7-5.1, remove chassis as in section 7.5.2. Remove the plastic cover from the underside of the chassis. The drive cord is then simply replaced by hooking the new cord over the peg on the drive pulley and attaching the other loop to the hook on the grating arm. The Part Number for the ready-assembled drive cord is 4000 4593. Fig. 7.1: Lamp Compartment 8. OPERATION 8.1 8.2 8.3 8.1 Introduction 8.1.1 Key Pad 8.1.2 Display Panel 8.1.3 Sample Compartment Instrument Operation 8.2.1 Initial Switch-On 8.2.2 Performing a Measurement Further Operator Information 8.3-1 Introduction 8.3»2 Instrument Indications Introduction The three operator areas of the instrument are the key pad, display panel and sample compartment. 8.1.1 Key Pad The key pad comprises four individual keys, hinged along the upper edge and ergonomically positioned such that, during normal operation, the operator inputs progress from left to right along the key pad. Fig. 8.1 shows the key pad layout. The individual key functions are described below: a) WAVELENGTH +/WAVELENGTH-. These keys select the wavelength of light used for the measurement. Press and hold either WAVELENGTH + or WAVELENGTH - to increment or decrement the selected wavelength as shown on the display. An automatic ramp function increases the rate of change of wavelength with the length of time the key is pressed until a predetermined maximum rate is reached. b) MODE. Used to select the mode of instrument operation as indicated on the display panel. This key has a sequential operation, the order being 0-1A, 0-2A, %T, 0-1A, etc. c) SET REF. When pressed, this key sets the absorbance readout to zero or the transmission readout to 100$T. 8.1.2 Display Panel The display panel comprises two digital display units and three indicator LEDs. Figure 8.2 shows the layout of the display panel, the display functions are as follows: a) WAVELENGTH. Three digit display indicating the selected wavelength in nanometers. b) MODE. Three LEDs indicating which of the three instrument modes is selected. Only one of these LEDs is illuminated at any one time. 0-1A. When this LED is illuminated, the measurement display indicates the sample absorbance in the range -.30 to .999A. 0-2A. When this LED is illuminated, the measurement display indicates the sample absorbance in the range -.30 to 1.99A. $T. When this LED is illuminated, the measurement display indicates the sample transmission, in the range of 0.1 to 200$T. c) 8.1.3 MEASUREMENT. Three digit display, the information displayed being dependent on the selected mode. Sample Compartment The sample compartment is enclosed by a light tight cover which is hinged along the rear edge. To gain access to the sample compartment, lift the front of the lid. If it is necessary to remove the lid completely, it can be sprung off the hinge pins. The instrument sample compartment will accommodate samples in standard 24mm (1 ") test tubes as shown in Fig. 8.3. For tubes greater than 100mm in length the extended sample compartment cover should be placed over the test tube to exclude light. A removable small test tube/cuvette holder is supplied with the instrument to allow samples in 12mm (1/2") test tubes or 10mm cuvettes to be accommodated as shown in Fig 8.4. The spring clip in the lower section of the holder, firmly clamps the cuvette in position. A tall 10mm cuvette may also be used with the holder. When handling cells, only hold the cell using the ground faces. rn ^ ^ ^ ^ W ^ • 1 WAVELENGTH ; MODE - • ; . ; ; > -••'!'..•.•• SET • - ' * ' • F i g . 8 . 1 : Key Pad C D 0-1A CID 0 2A 1 1 «/„f SPECTROPHOTOMETER WAVELENGTH MODE MEASUREMENT Fig. 8.2: Display Panel Sample Compartment Cover -Test Tube Cover Small Test Tube/ Cuvette Holder 12mm Test Tube 24mm Test Tube Fig. 8.3: Sample Compartment Fig. 8.4: Small Test Tube/Cuvette Holder 8.2 Instrument Operation 8.2.1 Initial Switch-On Before switching on the instrument ensure that the sample compartment is empty with the cover closed and that the voltage selector is set to the appropriate voltage. To switch on the instrument, set the main ON/OFF rocker switch located at the rear of the instrument to ON. Vhen switched on the instrument automatically performs a series of 3 calibration checks, for a period of approximately 90 seconds, during which the sample compartment cover must be closed. While these calibration checks are being performed the digital displays on the display panel are as shown in Fig. 8.5If the calibration check fails on CAL 2 then the instrument automatically returns to CAL 1 and recommences the calibration process. To indicate that the calibration has failed once, the CAL and number displays flash throughout the subsequent recalibration. If the calibration procedure fails totally, then the displays flash and the measurement display holds the value of the failed calibration number. Attempt recalibration by switching off and on again. When the instrument has completed these checks the operation may commence. The satisfactory conclusions of the checks is indicated on the display panel as follows: a) Wavelength - changes from CAL to 36Onm. b) Mode - 0-1A indicated. c) Measurement - changes from 3 to an absorbance value below 1A. When this condition is achieved then the instrument is ready for operation. If the instrument does not attain this condition then a fault may exist. The identification mark on the removable small test tube/cuvette holder should be used to ensure reproducibile location of the marked test-tube. When inserted the mark should be nearest the front left-hand corner of the sample compartment. CR Wavelength C 3 OlA i—i 0-2A C=l %T 1 1 Mode Measurement i No. of calibration check, progressing from 1 to 3. Fig. 8.5: Calibration Display Fig. 8.6: Select Wavelength MODE Fig. 8.7: Select Mode 8.2.2 Performlng a Measurement To perform a measurement in any of the three modes of operation, proceed as follows: 8.3 a) Select the required wavelength using the WAVELENGTH +/- keys (Fig. 8.6). b) Press the MOBE key until the LED indicating the desired operating mode is selected (Fig. 8.7). c) Load the reference cell or test tube into the sample compartment and close the lid. d) Press the SET REF key to zero the display (Fig. 8.8). This is either zero absorbance or 100$ transmission. e) Remove the reference tube and insert the sample cell or test tube into the sample compartment then read the absorbance or transmission value from the measurement display. f) To measure further samples, repeat step e) above. g) If the wavelength is adjusted then return to step c) above. Further Operation Information 8.3.1 Introduction The instrument provides the operator with information in the event of action being required due to an operator error or instrument malfunction. n n n u u u MODE MEASUREMENT Fig. 8.8: Set Reference f 8.3.2 c f Instrument Indications The following table describes the possible indications, lists the probable reasons and then describes the relevant operator action. INDICATION POSSIBLE REASON OPERATOR ACTION Wavelength shows only CAL 1 Grating motor failed or backstop opto malfunction, broken drive cord. Check motor drive/opto electronics. Replace drive cord. Wavelength display flashes CAL. Automatic calibration has failed - the instrument re-attempts calibration from CAL 1 . a) Measurement display flashes .999» Mode 0 to 1A selected, sample absorbance greater than 1A. a) b) Measurement display flashes 1.99• Mode 0 to 2A selected, sample absorbance greater than 2A. Dilute sample Measurement display flashes 200. Mode %T selected, sample transmittance greater than reference. Range available 1.0 to 200$T. Measurement display flashes -.30. Mode 0 to 1A or 0 to 2A, sample absorbance less than reference. Range available -.30 to 1.99A. Measurement display indicates Wavelength value being changed. Display returns to normal after wavelength reaches set value. Instrument performing Set Reference Display returns to normal after Set Ref sequence completed. NOTE: b) c) Ensure that the sample compartment is empty. Check the lamp. Check that the sample compartment lid is closed. Select mode 0 to 2A. Dilute sample. When the wavelength is altered in single steps the measurement display continues to indicate value, thus allowing maximum determinations. C202 100PF J201.1 SIGNAL DECOUPLING CAPACITORS C203 - C20G TO BE LAYED NEAR TO OPERATIONAL AMPLIFIERS _ÏO1.3 +5V(A) _201.4 SIGLOW '01.2 TV(A) R203 4M7 C203 1201 TLC271CP GND D201 PHOTO DIODE -vcc R214 I1R213 n 1.21K J147K 0.1% Tl.O'A T 12 14 R216 hR2Q7 MlOK C205 0.1UF 0.1% R215 90.9K M Ul.0% U 15 11 1 13 1203 MC4052 5 5 R217 100R 0. 1% R202 4M7 sD 4 GND PHOTOMETER PCB 4000 4574 DISPLAY P.C.B. 40 00 4563 c: I I J I— n O m ~ i s "1 n C o m LJ I _J I r. _ J -^ LJ CO o m LJ m a o o n CD m nu nu rn r r r I I •U o m n LUI/) OUJ 1 o m cl. 1— n • 1 1 * *—« lic rn ti. | I l 1 CD . s| oz: a. LJ ) O m »—i " 1 1 J DISPLAY P.C.B. ASSEMBLY 40 00 4565 T 3QIS f ssi ai > . Rl CD O \- 05Td 3STd • U cc cc • STTd al 1• CC m • IC120 OOIP RH4 • to CD en u U. • • 51 • u 9TTd u. u. 61 Td • \' . in 01 o .S0T3 . CD ui CD M so H cc or • ai • ^* > en « • ai o (U ZTTd • CD f3 o • m u Q_ E3 13 u u 0 1!• TOTd • • in «H . u — * ^H i r n rETT3n • t * ai VTT3 CC • • to •1 .> TTTd o Z2T3 I92T3 10 • # M • • • * / rl"! • ID o n u G CO o o o xcc. J100.1E \ MOTOR POSITION DETECTOR Gfiu « . 11047BL0S 11 nn " -SVIA) MOTOR CONNECTIONS air n T32 •1101 ULNSB03A d * RELAY FOR DARK FLAP —' H nn q ^. Mfin 7 1 M^rnmm l i C f i . S 5 4 G 7 I r;« mm nnn p e G?iir DISPLAY PCB KEYBOARD PCB DECOUPLING CAPACITORS C123 - C13S ARE ALL 0.1LF AND TD BE MOUNTED BY IC 1111 SN74LS138 GND' CONTROL PCB 4000 4560